Energy-saving and environment-friendly building roof structure and using method thereof

A roof structure, energy-saving and environment-friendly technology, applied to building components, building structures, roofs, etc., can solve the problems of poor production environment, excessive dust, and poor dust effect in factories, and achieve low cost, maintain air permeability, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

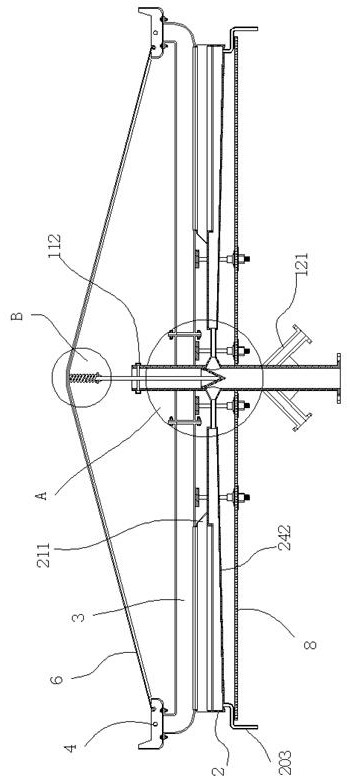

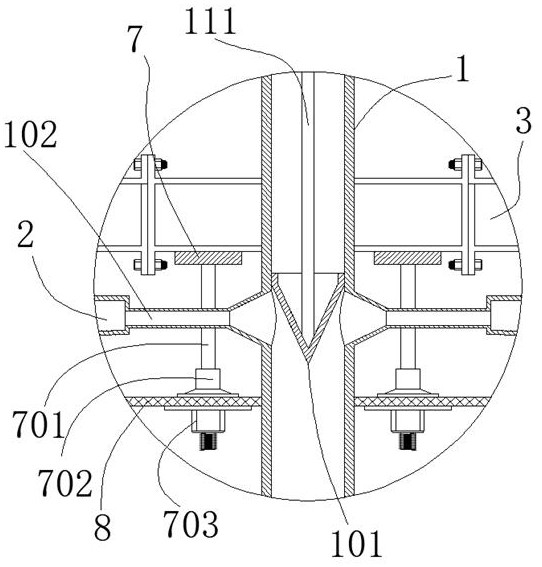

[0040] An energy-saving and environment-friendly building roof structure, comprising a plurality of uprights 1 arranged at equal distances in the longitudinal direction, and connecting rods assembled between two vertically adjacent uprights 1; the uprights 1 are hollow pipes, and There is a baffle 101, on the outer wall of the column 1, two left and right air outlet pipes 102 are arranged below the baffle 101; The air outlet box 2, the air outlet pipe 102 communicates with the air outlet box 2, and the air mixed with particulate matter that enters upward from the column 1 enters the air outlet box 2 through the air outlet pipe 102; The top of the air outlet box 2 is provided with a through groove 201, and the inside of the through groove 201 is sunken to be provided with a screen cloth 202 for filtering particulate matter; the particulate matter in the air entering from the outlet pipe 102 is removed The screen 202 intercepts and captures; the bottom of the air outlet box 2 is...

Embodiment 2

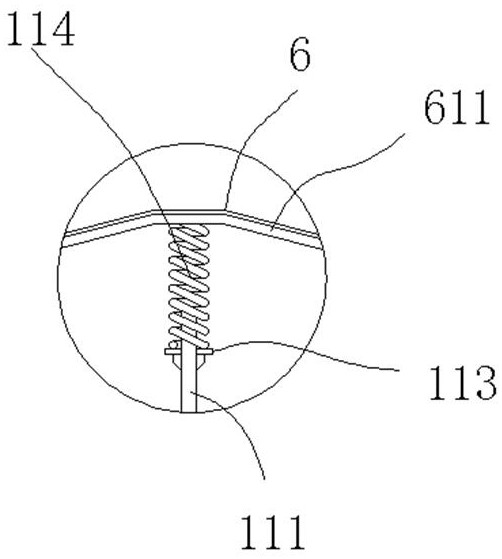

[0042] The height of the end of the water tank 4 away from the cover plate 6 is higher than the height of the other three sides of the water tank 4. When the rainwater is heavy, the rainwater that slides down the cover plate 6 passes through the side wall of the water tank 4 After being blocked, it falls into the water tank 4; when the amount of rainwater is large, the water flow sliding down the cover plate 6 has a certain flow rate, so the height of the side of the water tank 4 corresponding to the cover plate 6 is relatively high, which can block the water flow .

Embodiment 3

[0044] A cover 211 is provided above the air outlet box 2, and an opening 232 is formed at the end of the cover 211 away from the column 1, and an assembly groove for assembling the water distribution plate 5 is provided at the upper end of the cover 211 212; the above-mentioned structure is mainly to guide the discharged air. After adopting the above-mentioned structure, the air pumped to the outside can only be discharged from the opening 232. When the water keeps dripping from the water distribution plate 5, the water and The air contact efficiency achieves the purpose of further dust reduction, and the above structure can also prevent the discharged particles from accumulating under the cover plate 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com