Long spiral drilling machine for efficient soil clearing

A long-spiral drilling and soil-clearing technology, applied in earth-moving drilling, drilling tools, drill pipes, etc., can solve problems such as increasing manufacturing difficulty and production cost, limited drilling force, and idling of power heads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

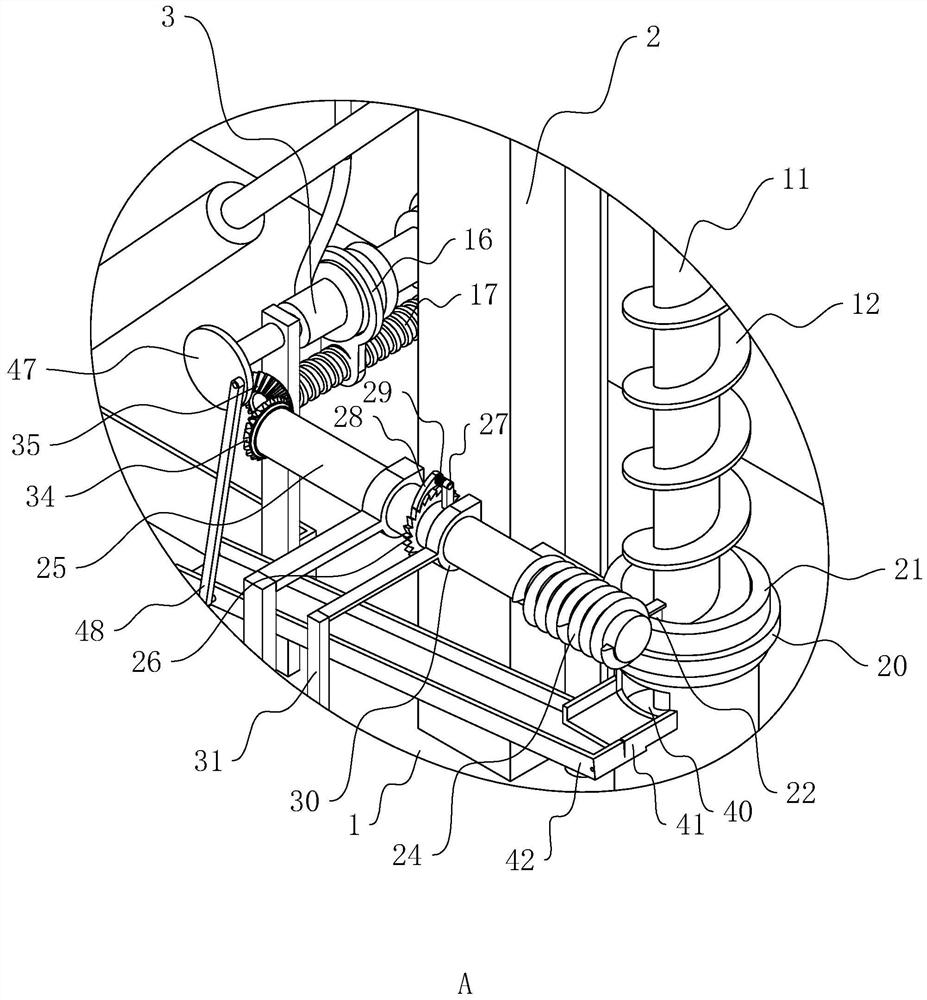

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

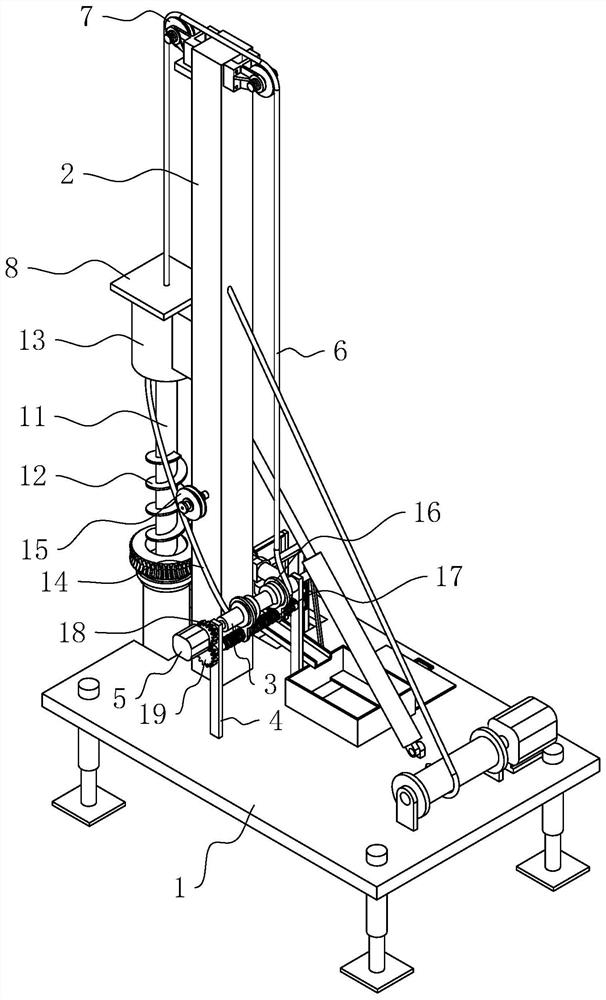

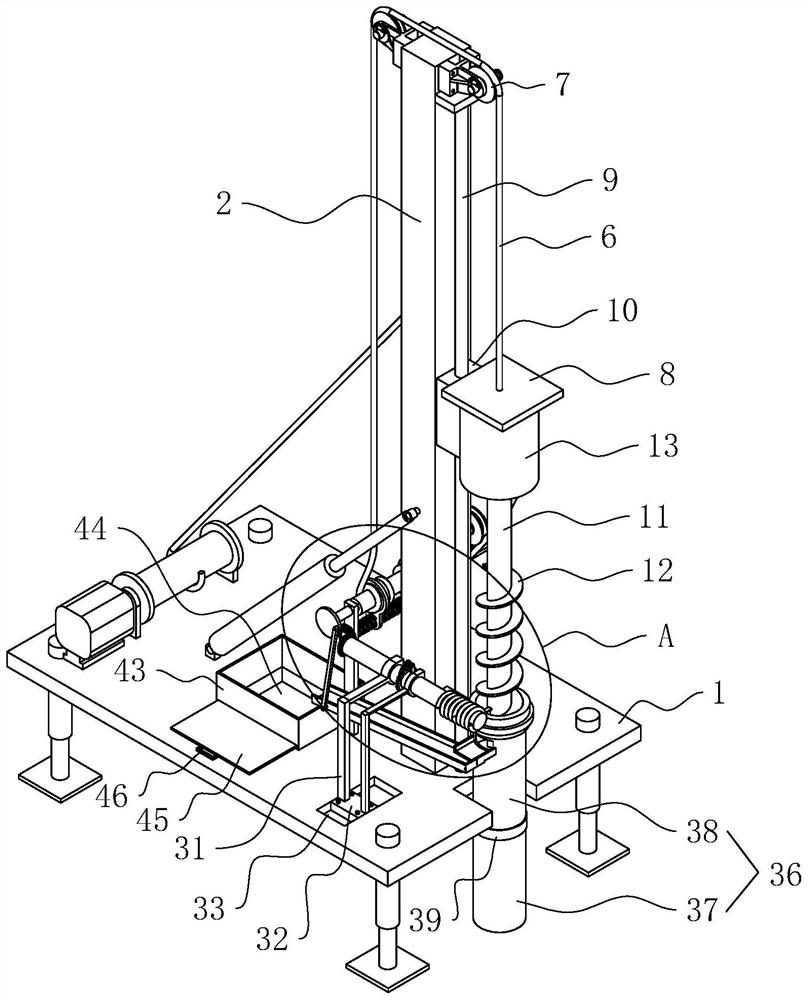

[0032] refer to figure 1 with figure 2 , is a long auger drilling machine for efficient soil removal disclosed by the present invention, comprising a body 1, a column 2 is installed on the body 1, a support 4 is vertically fixedly connected to the body 1, and a winding roller 3 is rotatably connected to the support 4 , the axis of rotation of the winding roller 3 is arranged along the width direction of the body 1, a motor one 5 is fixedly connected to the bracket 4, and the output shaft of the motor one 5 is coaxially fixedly connected to one end of the winding roller 3.

[0033] One end of the take-up roller 3 is wound and fixedly connected with a steel cable 6, and the upper end of the column 2 is rotatably connected with a pulley 7, and the end of the steel cable 6 away from the take-up roller 3 bypasses the pulley 7 and is fixedly connected with a power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com