Walking mechanism of four-wheel drive heading machine and four-wheel drive heading machine

A walking mechanism and four-wheel drive technology, which is applied in the field of excavation machinery, can solve the problems that the excavation machine cannot adapt to the working environment with large slopes and insufficient driving power, so as to improve driving stability and reliability, and improve track tension. Uniform and reduce track vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

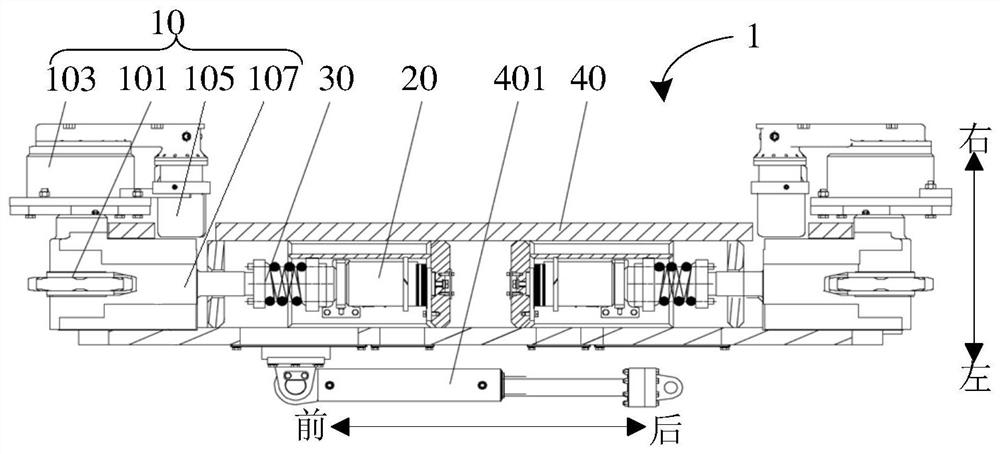

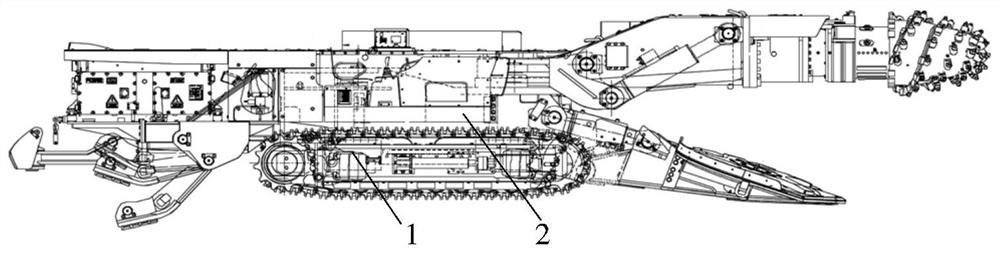

[0040] The running gear 1 includes a driving device 10 and a tensioning device 20 . figure 1 As shown, the traveling mechanism 1 arranged on one side of the four-wheel drive roadheader includes two sets of driving devices 10 and two sets of tensioning devices 20 . The driving device 10 is connected to the tensioning device 20 in one-to-one correspondence. The driving device 10 includes a driving wheel 101 and a tightening bracket 107 connected with the driving wheel 101, and the crawler belt of the boring machine is wound on the driving wheel 101; the tensioning device 20 is connected with the tightening bracket 107, and the tightening bracket 107 Driven by the tensioning device 20, it can move forward and backward to adjust the tension of the crawler belt of the roadheader.

[0041] The running gear 1 provided in this embodiment adopts a four-wheel drive mode, specifically including four driving wheels 101 , four tensioning brackets 107 and four tensioning devices 20 . In t...

Embodiment 2

[0048] On the basis of embodiment one, further, as figure 1 As shown, a buffer device 30 is provided between the tensioning bracket 107 and the tensioning device 20 , and the buffering device 30 is used to relieve the impact on the tensioning device 20 and the driving wheel 101 .

[0049] The buffer device 30 changes the connection between the tensioning bracket 107 and the tensioning device 20 from a rigid connection to a flexible connection, so as to relieve the tensioning device 20, the tensioning bracket 107, and the connection between the tensioning bracket 107 and the tensioning bracket 107. The driving wheel 101 is impacted, and by reasonably controlling the tension of the crawler belt, the wear of the crawler belt is reduced, thereby improving the service life and efficiency of the running mechanism 1 .

[0050] Optionally, the buffer device 30 includes an elastic element, and the tensioning device 20 includes a tensioning oil cylinder. Wherein the tension bracket 107...

Embodiment 3

[0053] On the basis of any of the above embodiments, further, as figure 1 As shown, the traveling mechanism 1 further includes a crawler frame 40 , and the tensioning device 20 and the buffer device 30 are arranged in the crawler frame 40 .

[0054] The crawler frame 40 can protect the tensioning device 20 and the buffer device 30 . For the situation where the buffer device 30 is provided, the crawler frame 40 can also play a certain position-limiting effect. By reasonably setting the position of the buffer device 30, the possibility of misalignment of the buffer device 30 after receiving the impact is reduced, so as to improve the position of the buffer device 30. use reliability.

[0055] Further, the crawler frame 40 is hinged with a side pull cylinder 401, which is used to connect traction equipment to assist the traveling mechanism 1 to perform uphill work.

[0056] The traveling mechanism 1 provided in this embodiment is provided with a side pulling cylinder 401, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com