A high-pressure hydraulic radial drilling guide device and method under the condition of drilling

A technology of guiding device and high-pressure water pump, which is applied in the direction of drilling with liquid/gas jet, which can solve the problems of increasing the working intensity of workers and increasing the working time of radial drilling, so as to improve the coal seam drainage effect and increase the forward power and destructive power, the effect of increasing the output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

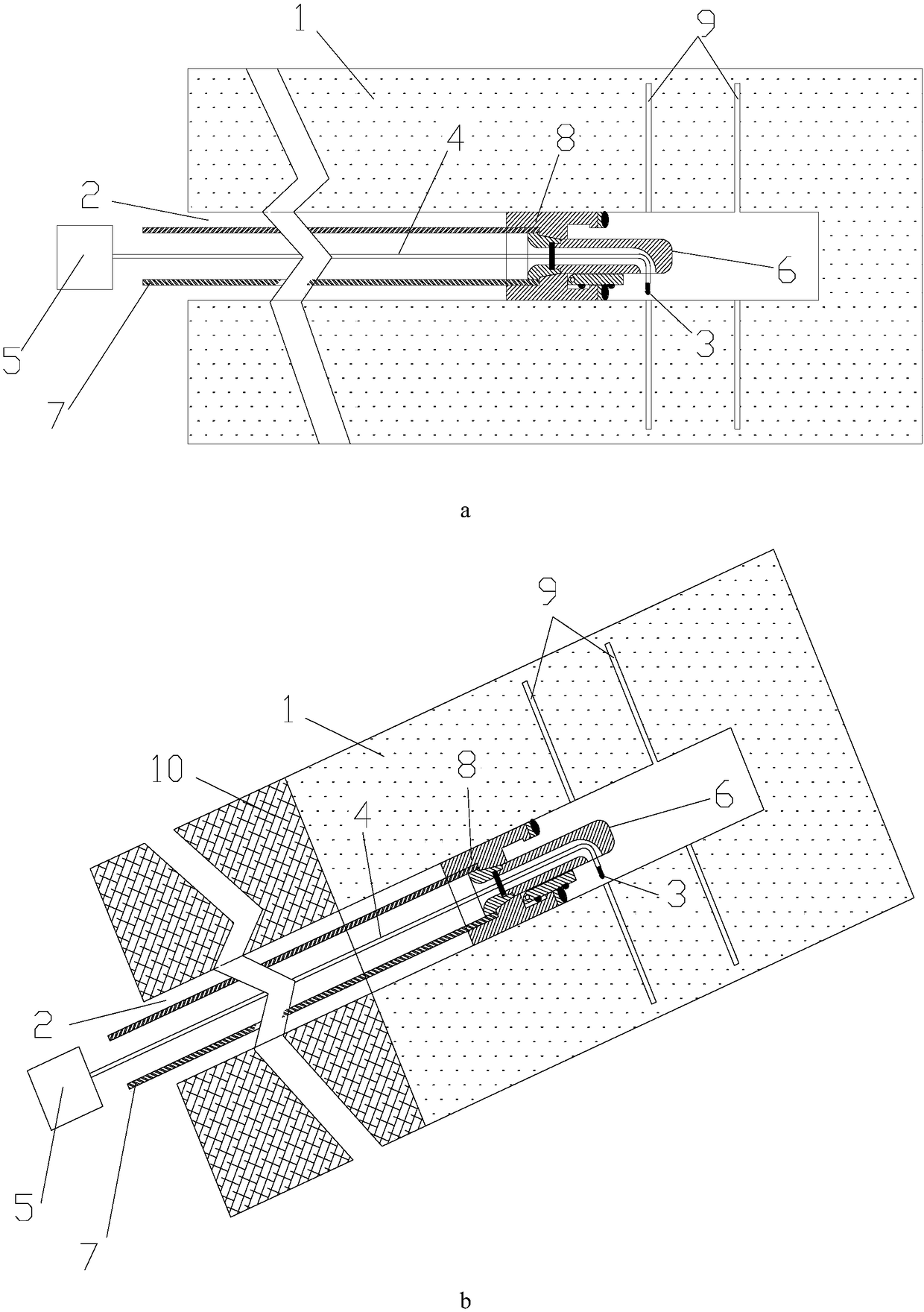

[0029] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

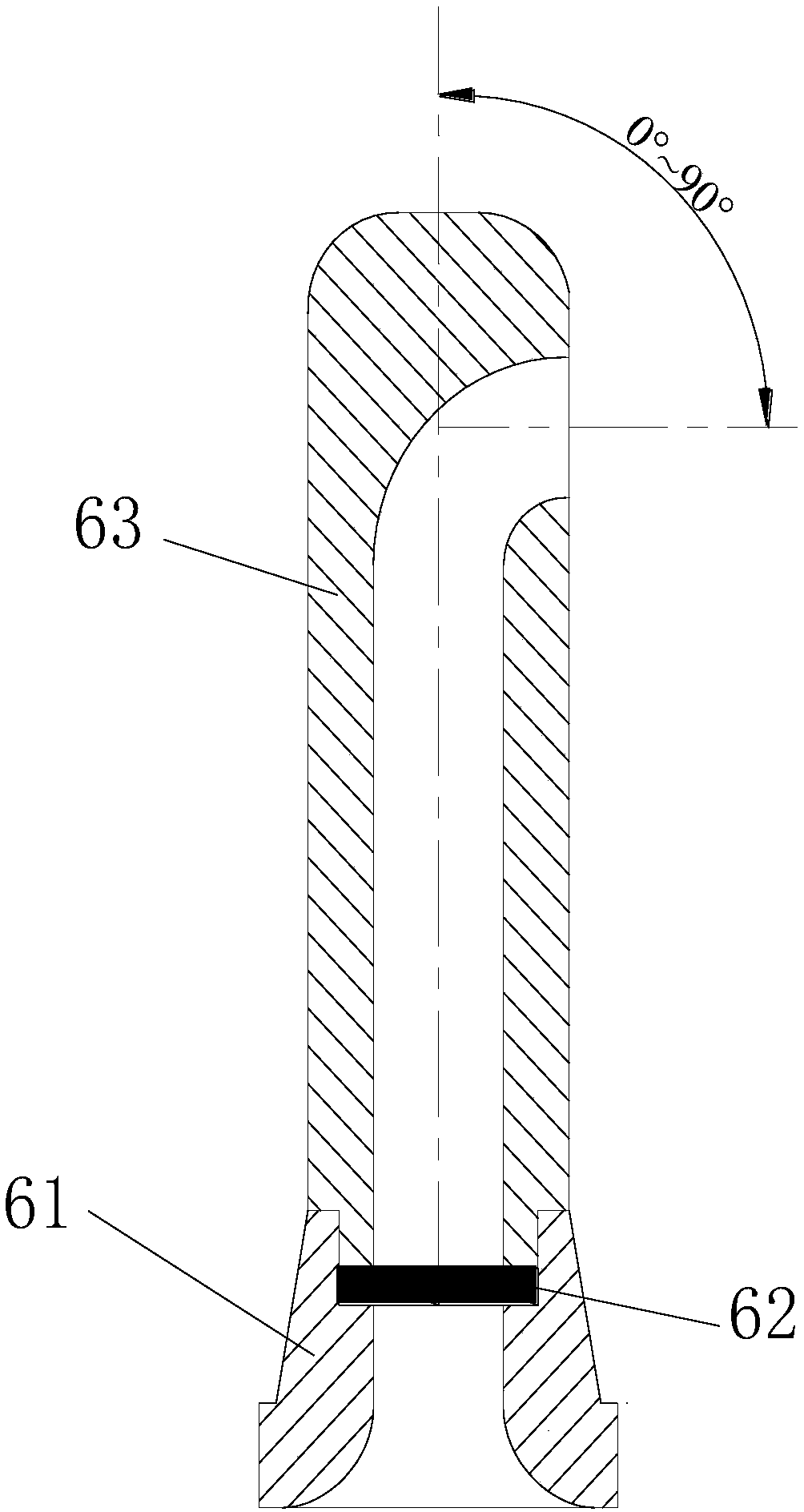

[0030] Such as image 3 As shown, the present invention provides a high-pressure hydraulic radial drilling guide device under drilling conditions. The guide device 6 is mainly used to control the azimuth angle of the self-propelled nozzle 3 during radial drilling. The bottom of guide device 6 is provided with a tapered bottom baffle 61, and guide tube 63 is arranged on the bottom baffle 61, and bottom baffle 61 is connected with guide tube 63 by screw thread, and the diameter of both straight holes is the same; the axis of guide tube 63 There is an angle of 0 to 90° between the axis of the guide transition tube, and guide tubes with different angles can be selected for installation according to the specific project; the bottom baffle 61 and the guide tube 63 are connected by a stopper 62, and the stopper 62 The outer diameter is the same a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com