Intelligent long-distance negative pressure traction positive pressure propulsion cable system and method

A long-distance, negative pressure technology, applied in the direction of optical fiber/cable installation, etc., can solve the problems of insufficient thrust, potential safety hazards, major construction accidents and losses, saving time and manpower, reducing friction, and speeding up the progress of the project. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further illustrate the technical solutions of the present invention, the present invention will be further described below with reference to the examples.

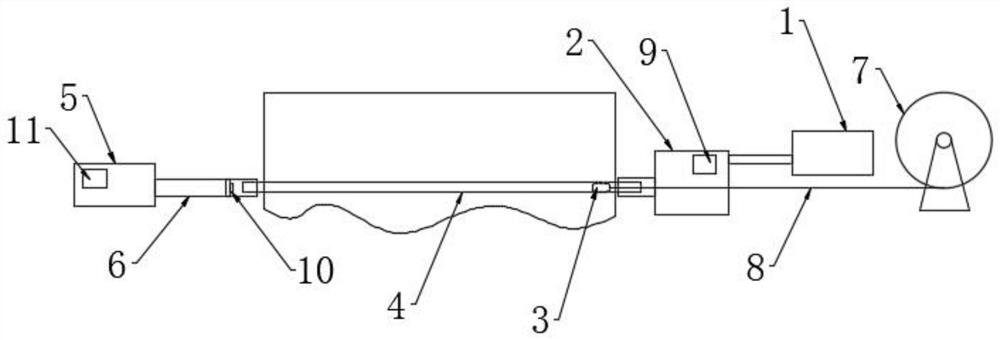

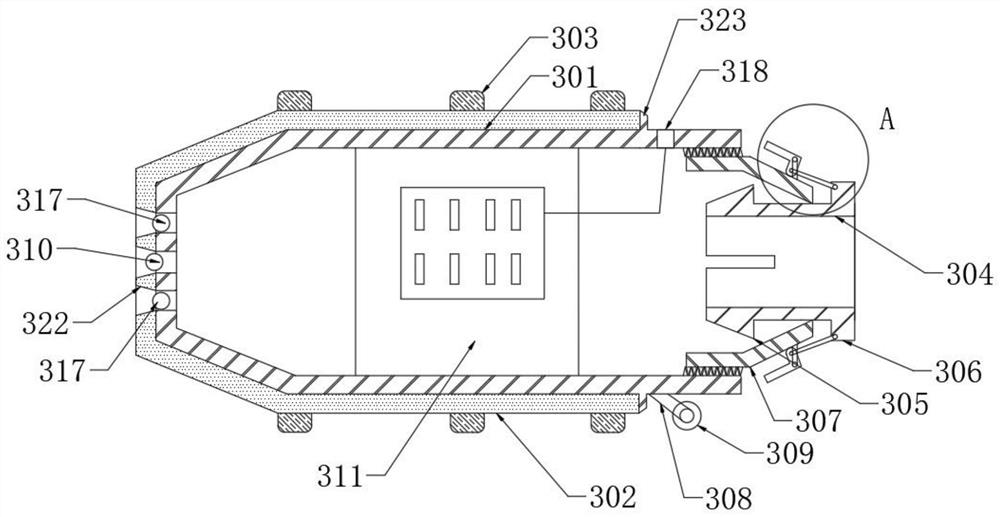

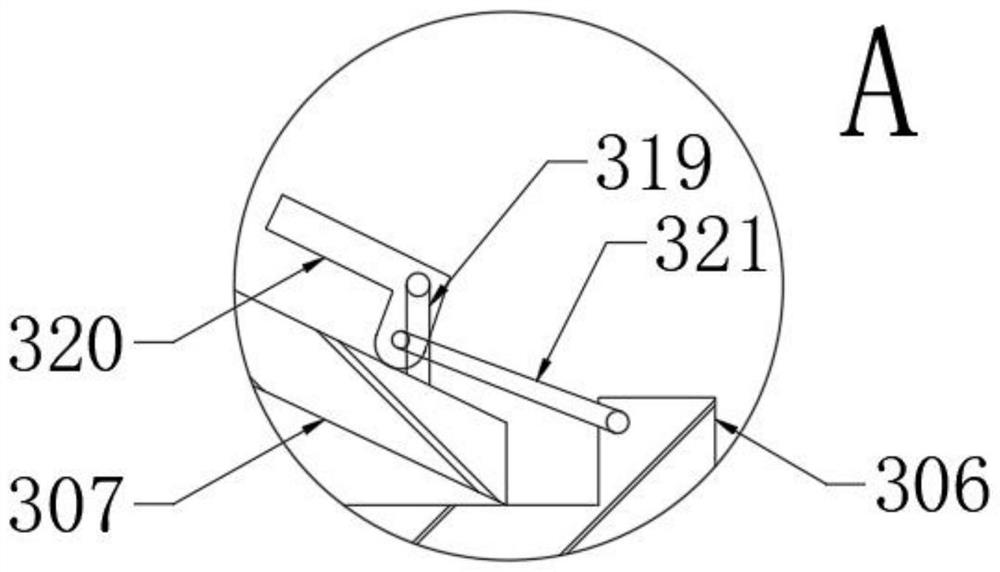

[0032] like Figure 1 to Figure 4As shown in the figure, the intelligent long-distance negative pressure traction and positive pressure propulsion cable-through system includes the No. 1 air pump 1, the cable blowing machine 2, the air sealing piston 3, the silicon core tube 4, the No. 2 air pump 5 and the optical cable reel 7. The No. 1 air pump The air outlet end of the air pump 1 is connected to the air inlet end of the cable blowing machine 2 for providing compressed air for the cable blowing machine 2. The other end of the core tube 4 is sealedly connected to the buffer tube 6, and the buffer tube 6 is sealed to the intake end of the No. 2 air pump 5. The buffer tube 6 is composed of a hollow tube and a blocking net arranged in the hollow tube. Continue to move forward after the blocking gas seal p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com