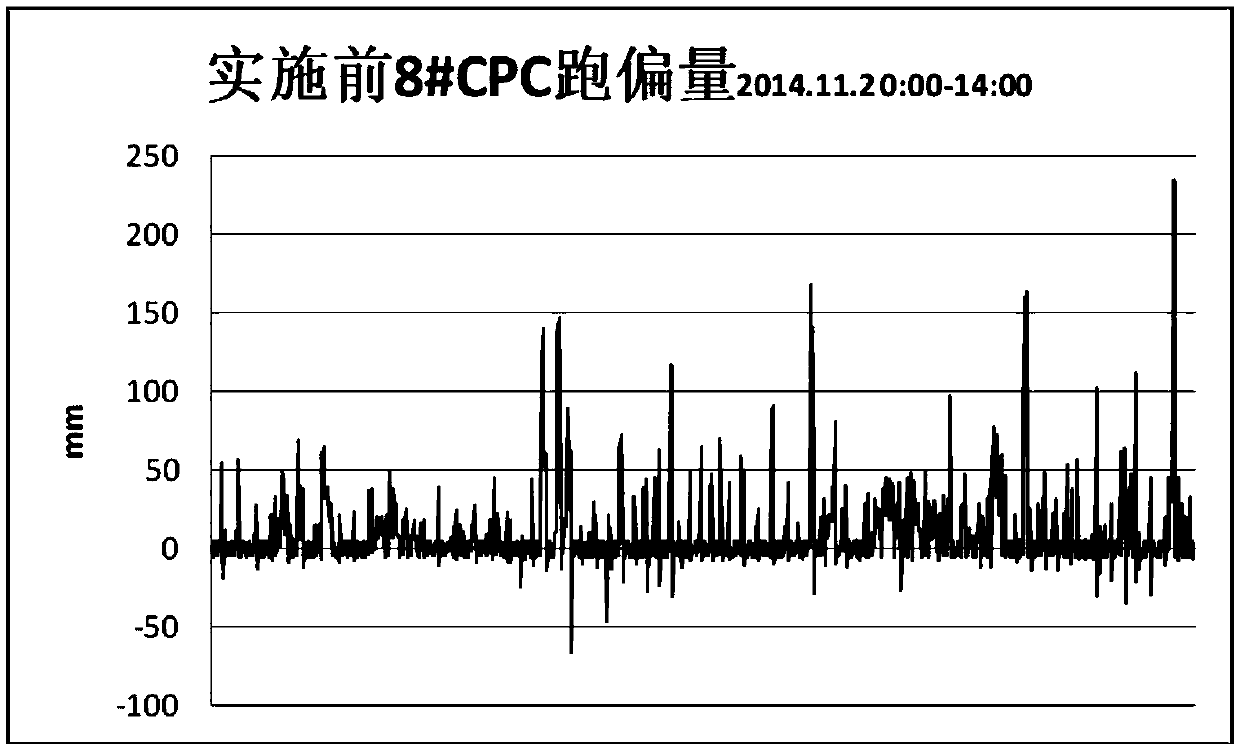

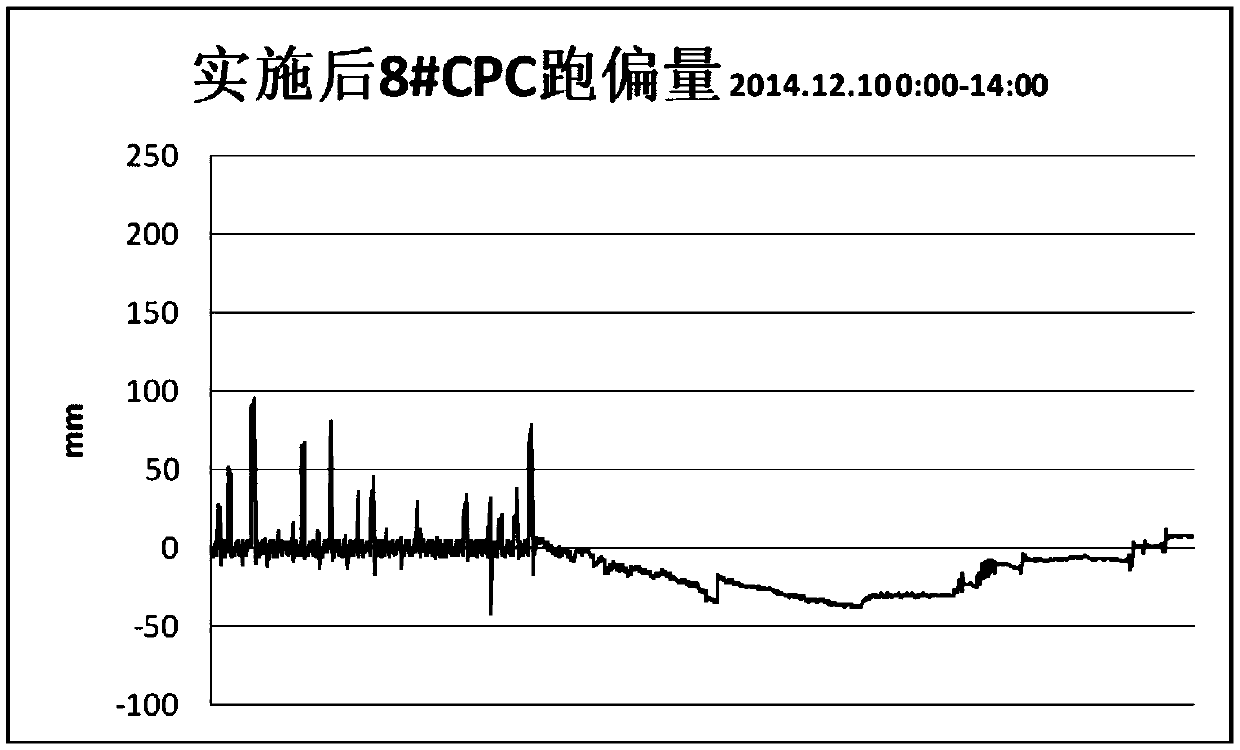

Continuous annealing unit phosphorus-containing high-strength steel anti-deviation method

A technology for continuous retreating units and anti-tracking, which is applied to heat treatment equipment, furnaces, heat treatment furnaces, etc., can solve problems such as no obvious improvement in track deviation, and achieves prevention of track deviation, increased friction coefficient, and improved production quality and production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

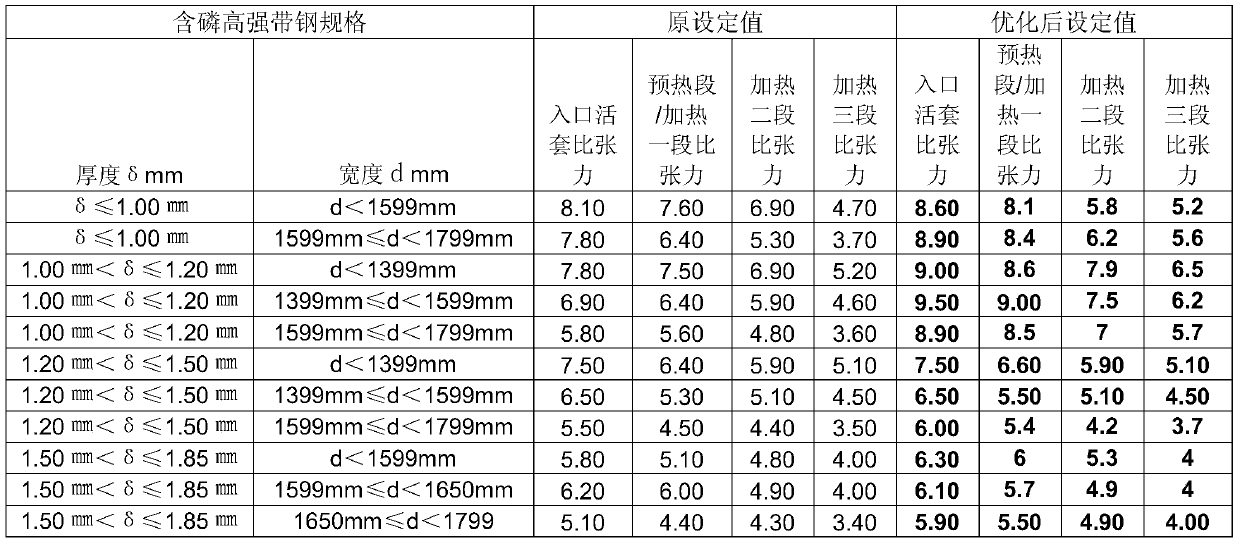

[0034] The high tension in the continuous annealing furnace zone is good for deviation correction, but too high tension will cause the phosphorus-containing high-strength strip steel in the furnace to be narrowed. At the same time, the maximum tension limit set in the original design must be maintained to avoid the overload of the furnace roller motor and cause tripping.

[0035] The solution is: increase the tension of the heating section, and make corresponding adjustments in other sections of the furnace area on this basis. Since there is no tension roller from the preheating section to the soak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com