Patents

Literature

157results about How to "Increase tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

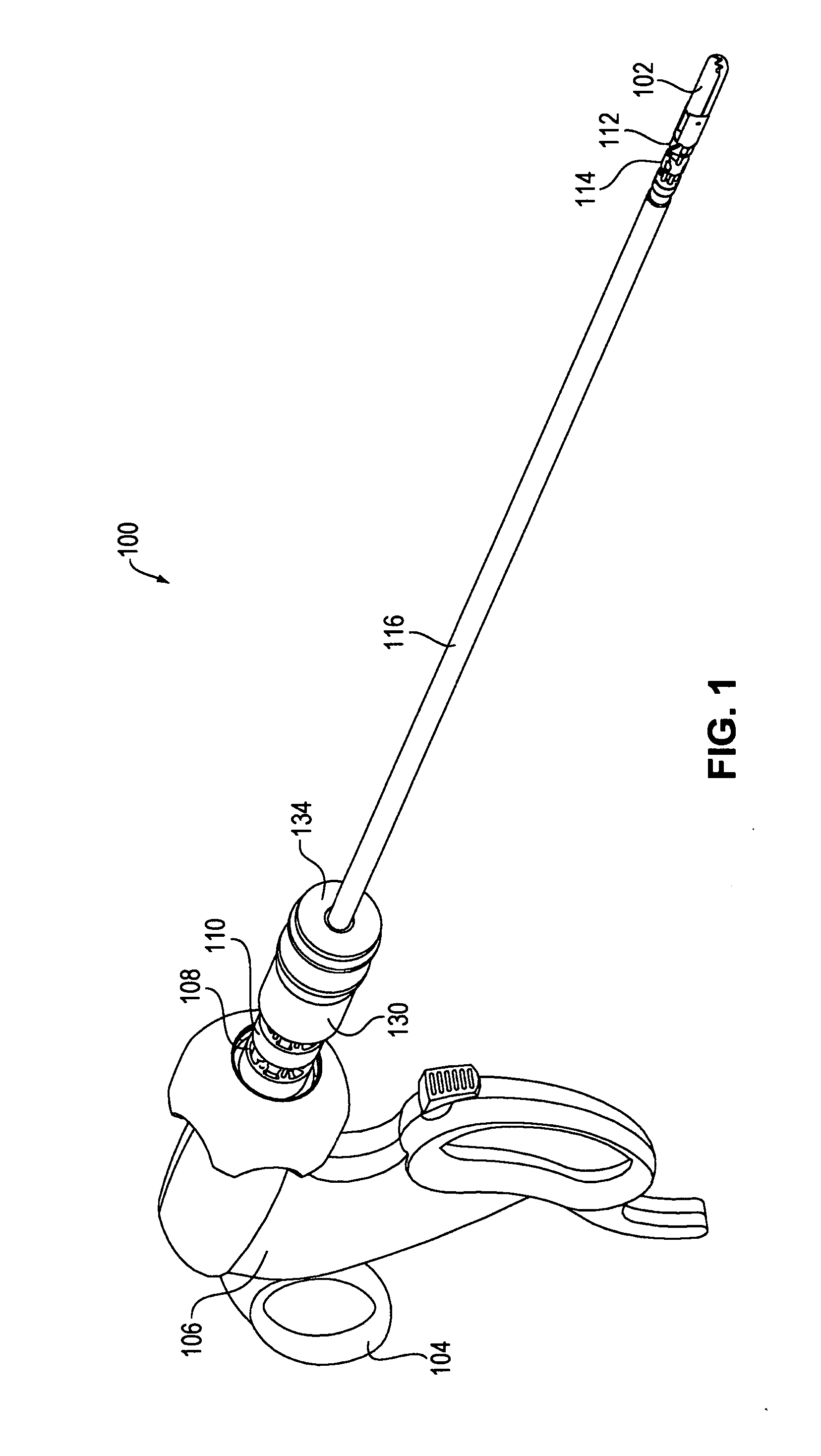

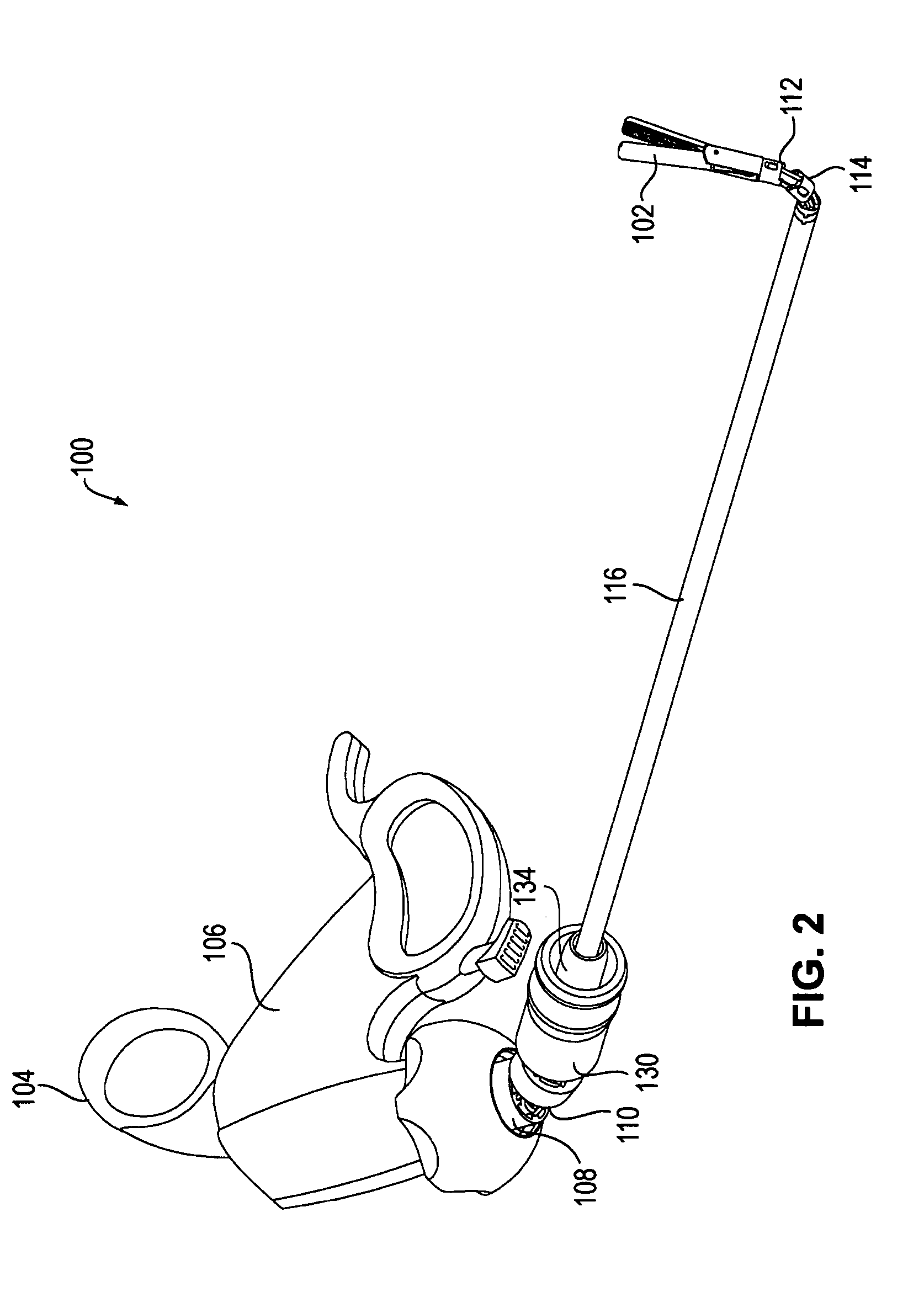

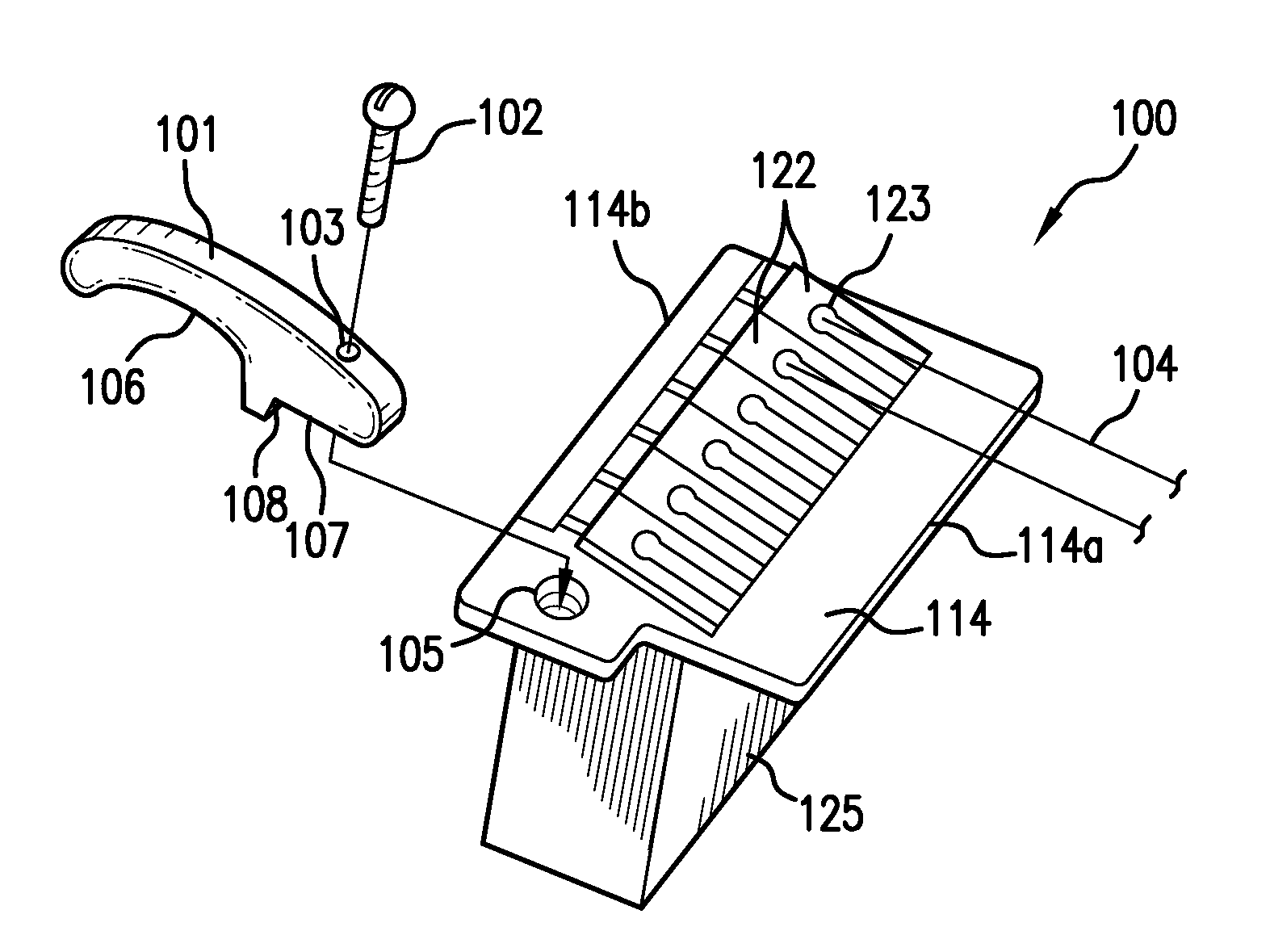

Tool with articulation lock

ActiveUS20070250113A1Increase tensionIncrease frictionEndoscopesSubstation equipmentSurgical departmentDiagnostic tools

The invention provides surgical or diagnostic tools and associated methods that offer improved user control for operating remotely within regions of the body. These tools include a proximally-located actuator for the operation of a distal end effector, as well as proximally-located actuators for articulational and rotational movements of the end effector. Control mechanisms and methods refine operator control of end effector actuation and of these articulational and rotational movements. An articulation lock allows the fixing and releasing of both neutral and articulated configurations of the tool and of consequent placement of the end effector. The tool may also include other features. A multi-state ratchet for end effector actuation provides enablement-disablement options with tactile feedback. A force limiter mechanism protects the end effector and manipulated objects from the harm of potentially excessive force applied by the operator. A rotation lock provides for enablement and disablement of rotatability of the end effector.

Owner:INTUITIVE SURGICAL OPERATIONS INC

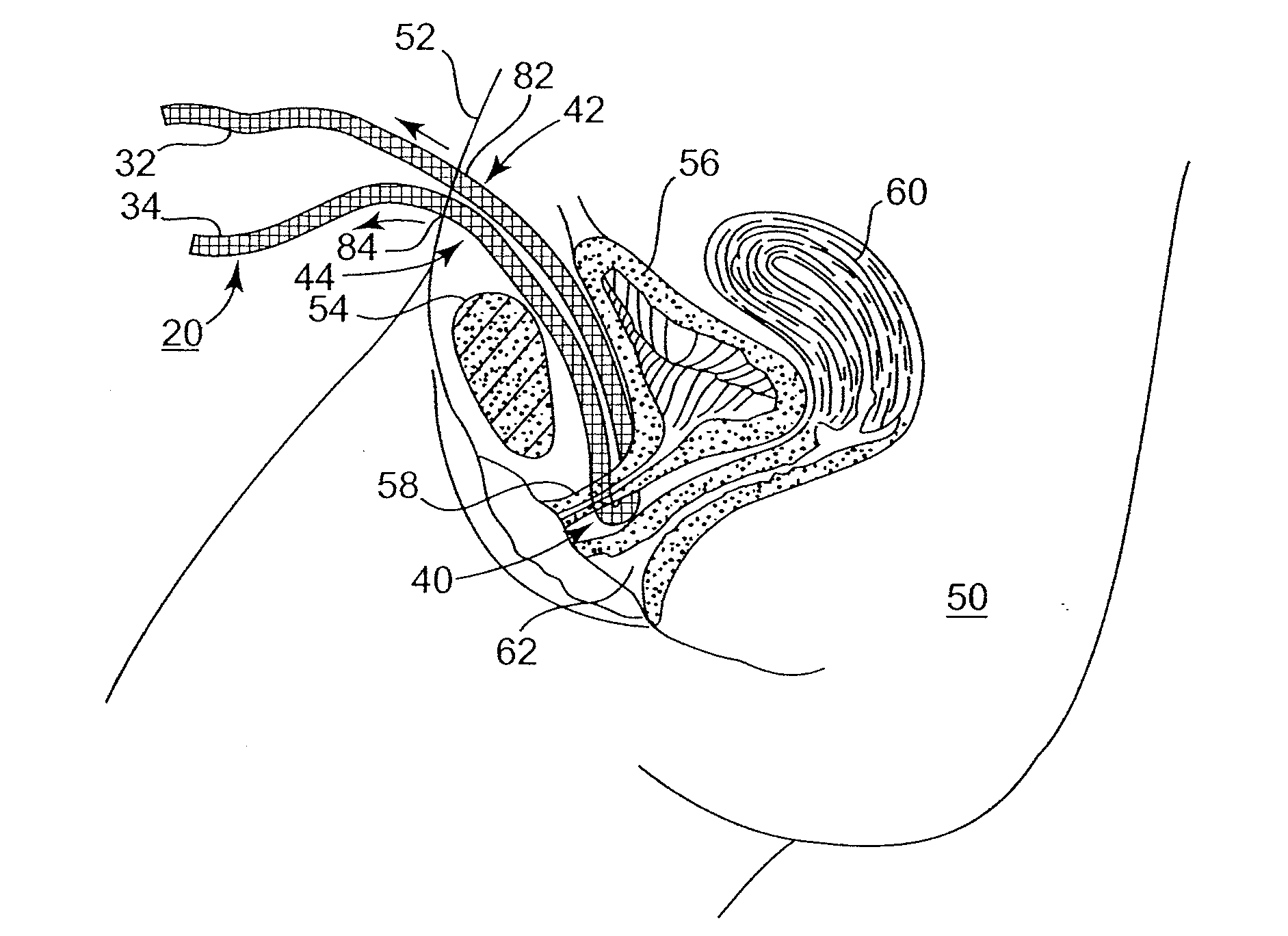

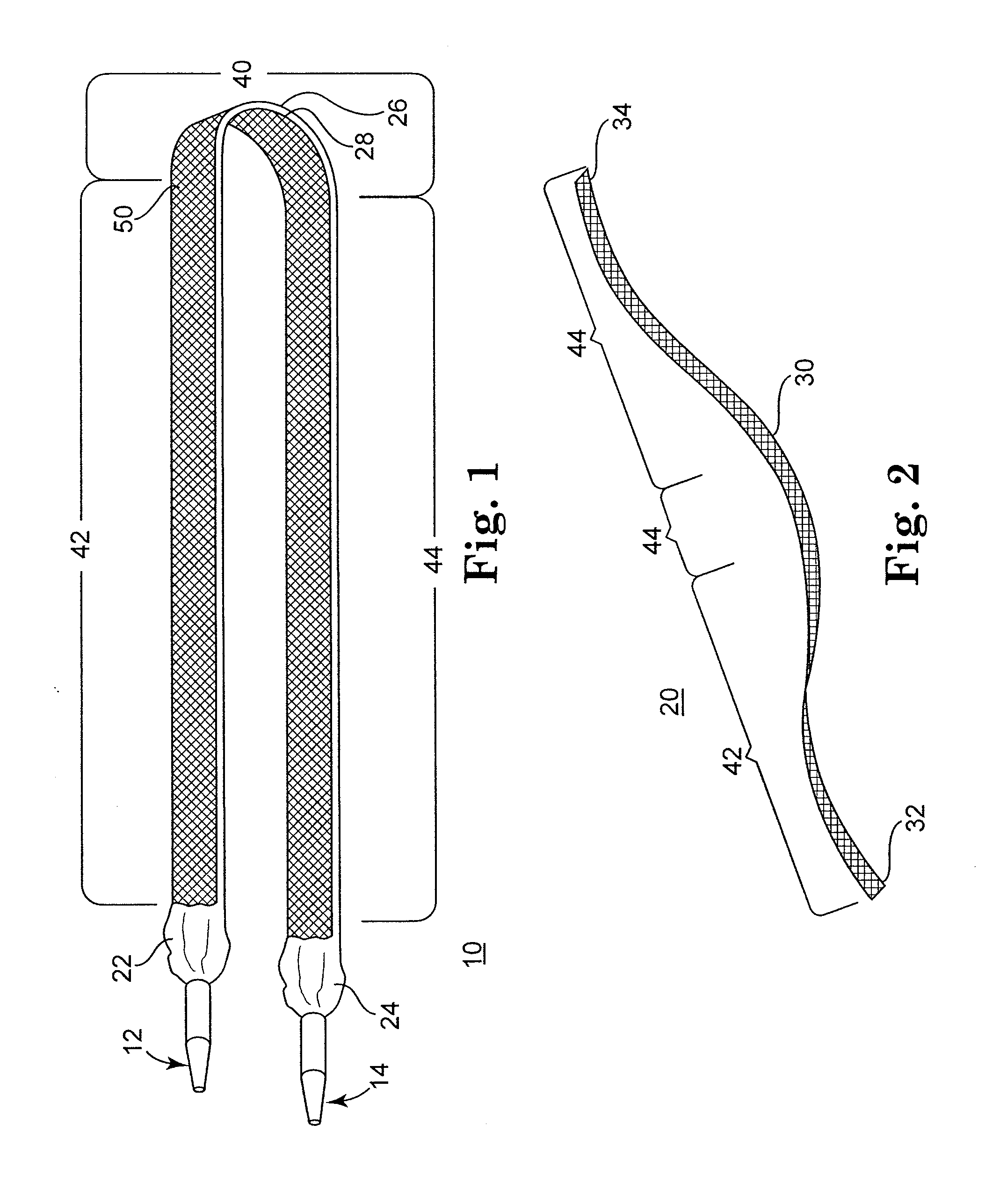

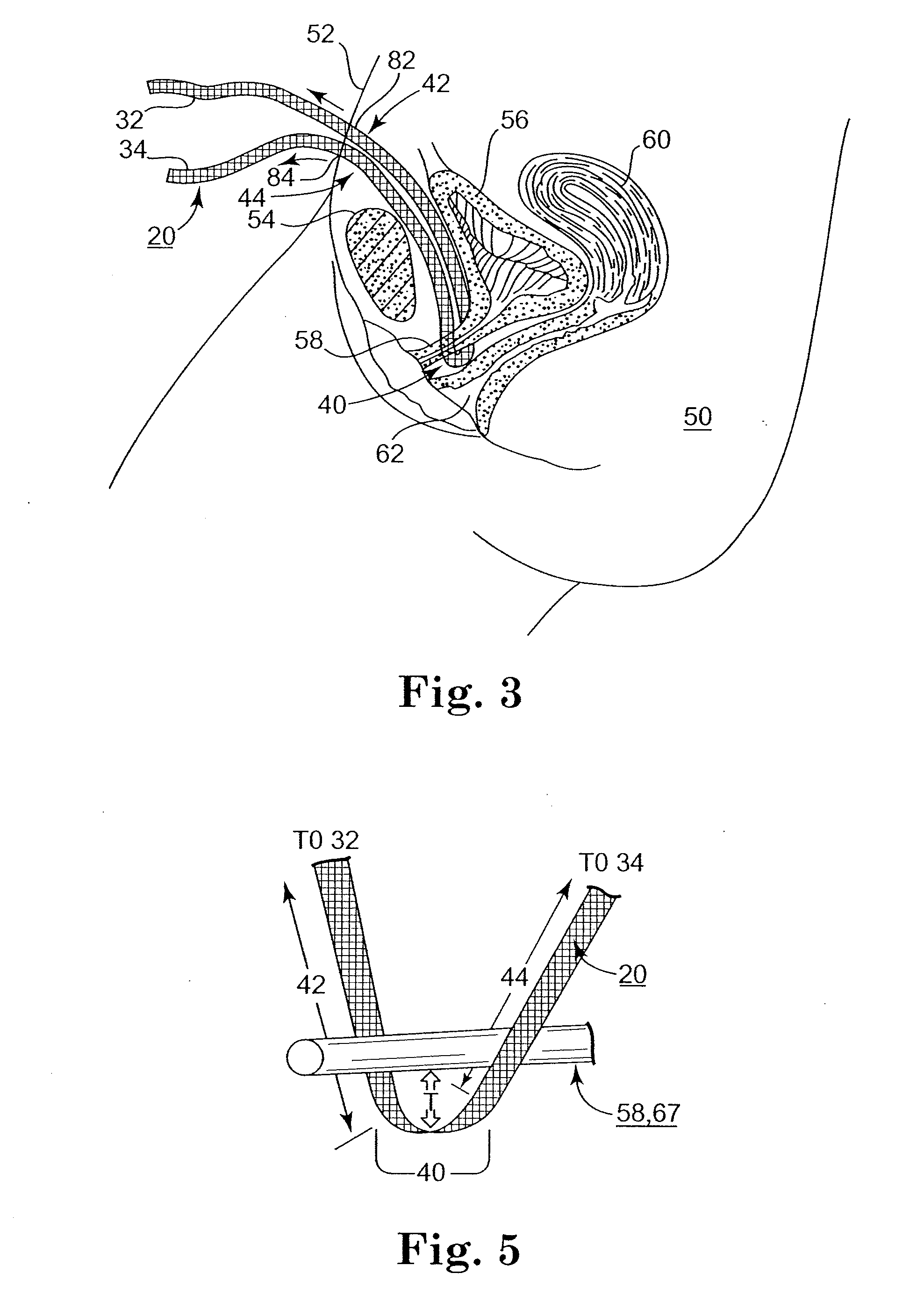

Adjustable Sling and Method of Treating Pelvic Conditions

InactiveUS20090259092A1Increase and decrease adjustment spacingIncrease tensionAnti-incontinence devicesBandagesAnusUrethra

Systems for providing support within the pelvic region of a patient. The systems can include an elongated incontinence sling having a central support portion adapted to be positioned to support any one of the urethra or anus, and a sling tension adjustment mechanism operatively attached to the elongated sling. The sling tension adjustment mechanism can include a plunger device adapted for traversal within an interior of the housing, and an inflatable bladder provided within the housing to selectively control traversal of the plunger. Alternatively, the adjustment mechanism can include a bobbin device within the housing and one or more retention devices to selectively restrict unwinding of a suture from the bobbin device.

Owner:AMS RES CORP

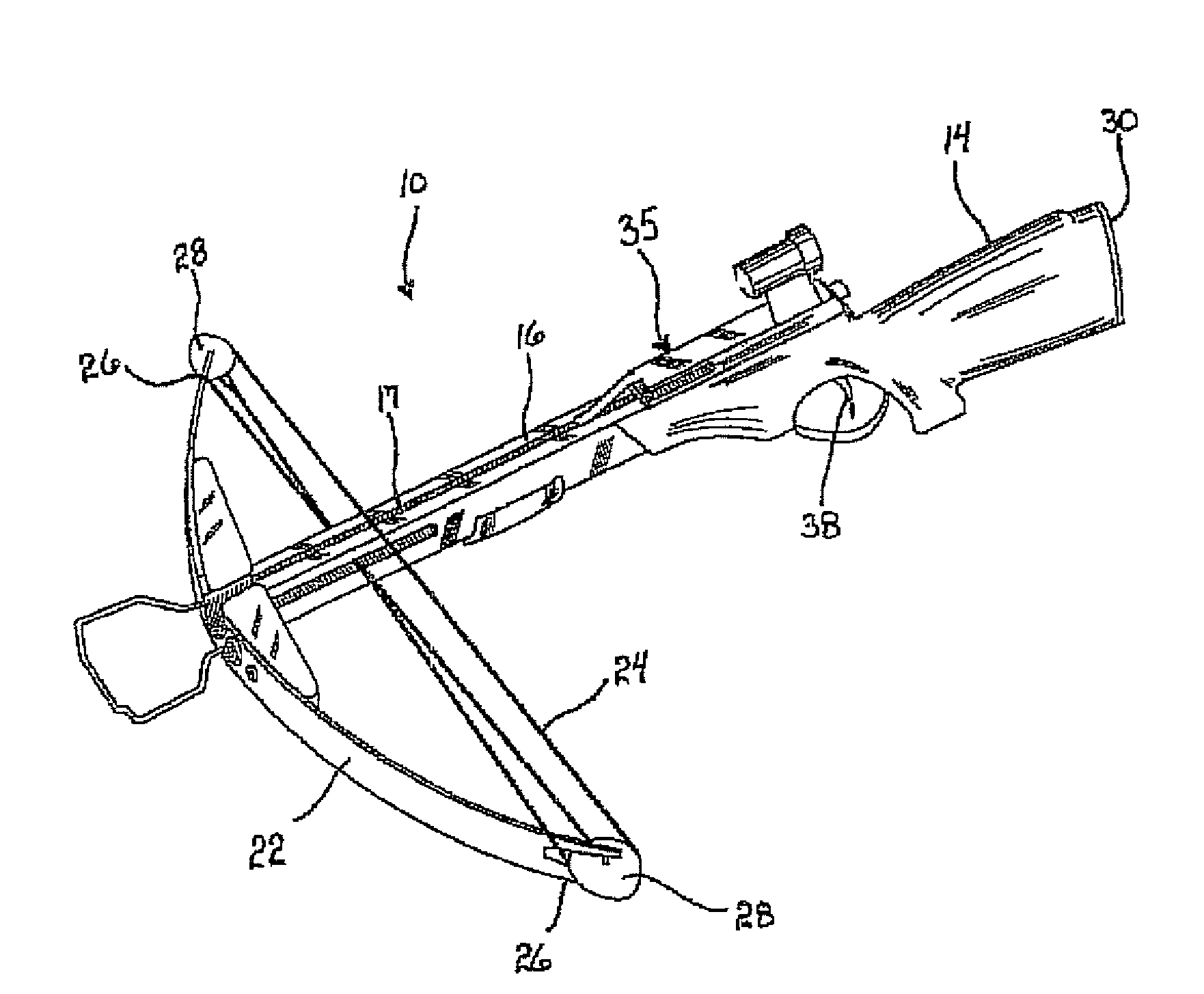

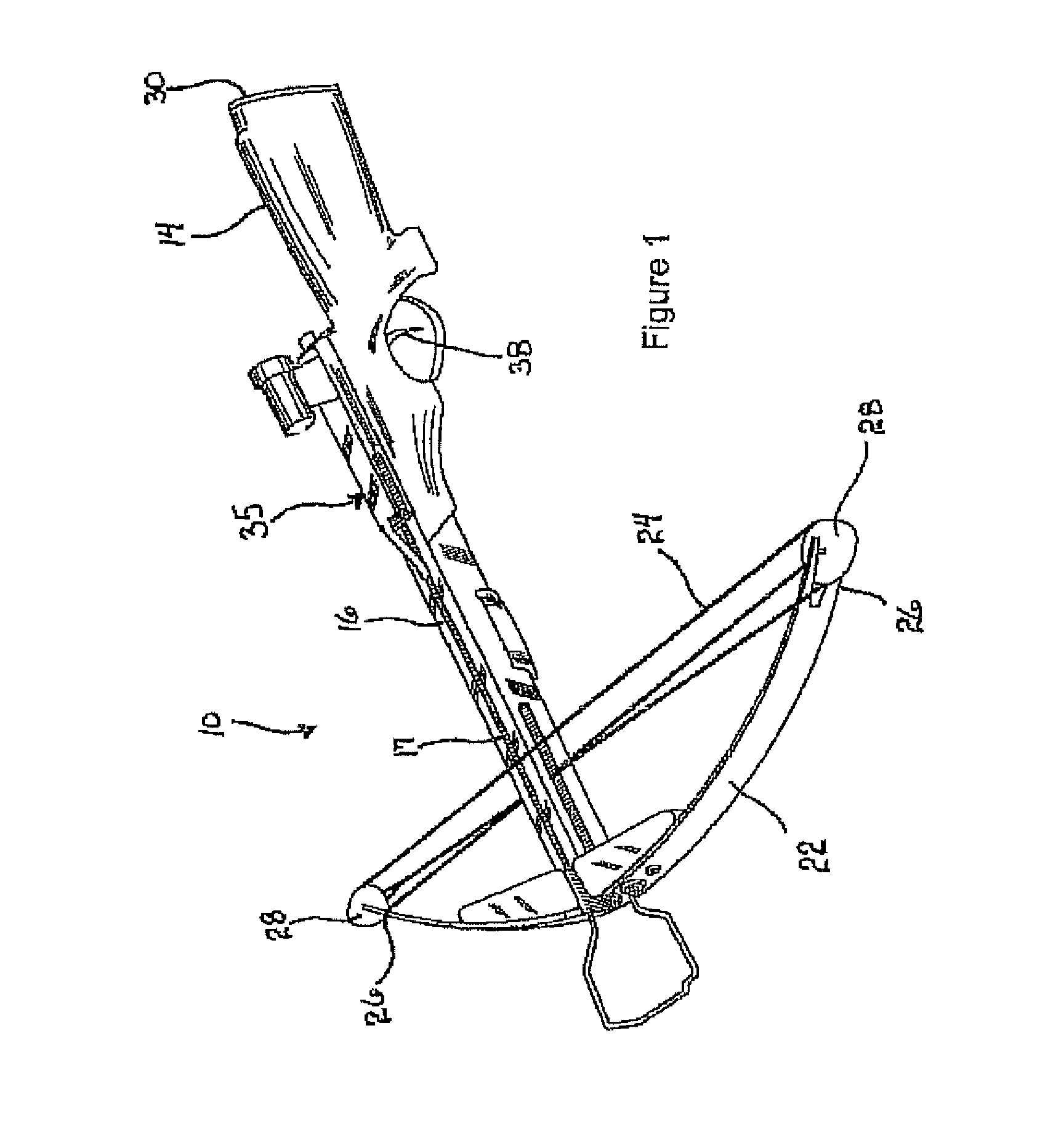

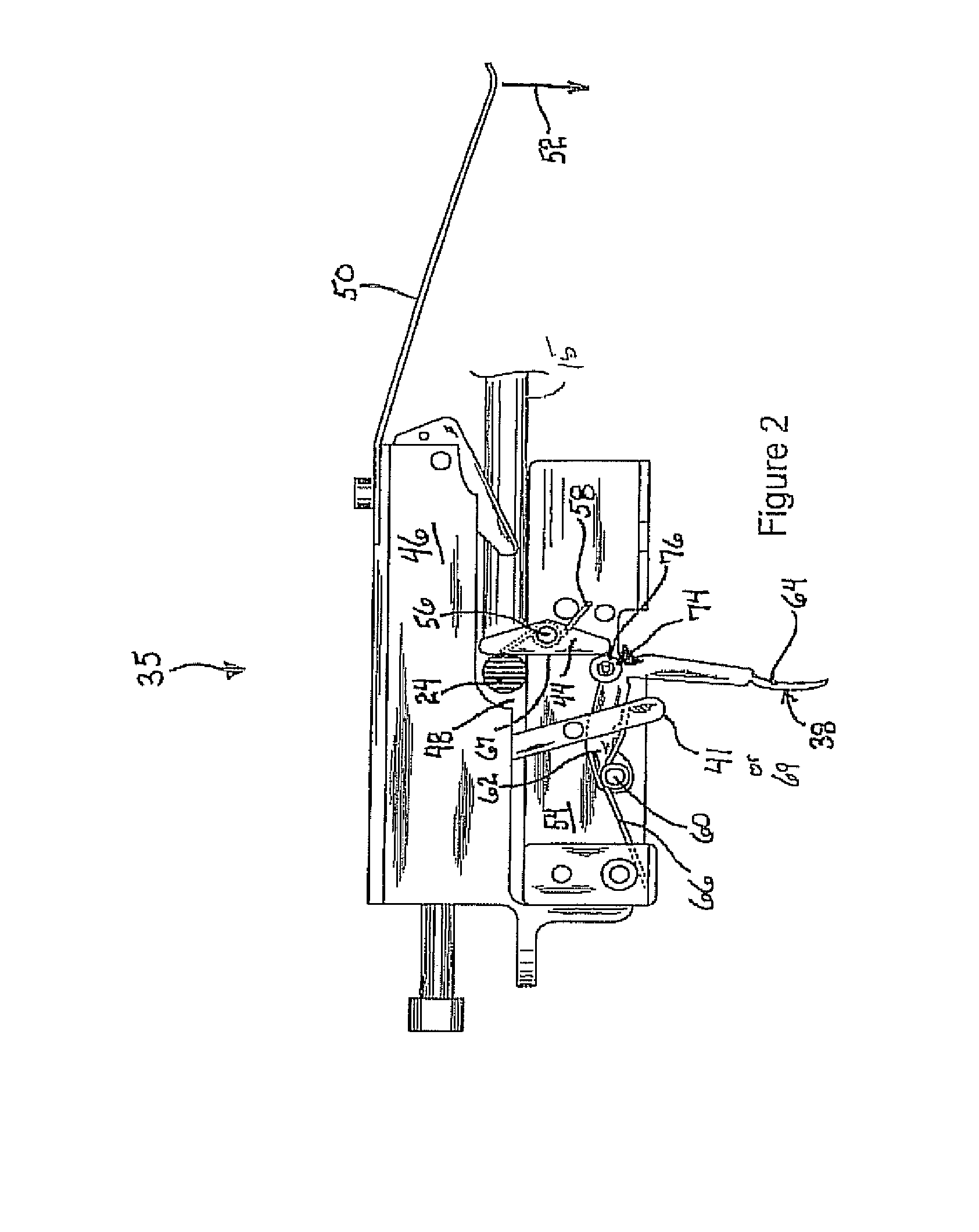

Trigger assembly for an archery device

InactiveUS20090078243A1Increase tensionFiring/trigger mechanismsBows/crossbowsMechanical engineeringBowstring

A trigger assembly is disclosed for releasing a bowstring of an archery device from a drawn position to propel an arrow from the archery device toward a target. The trigger assembly includes a guide along which the bowstring is retracted and held in the drawn position; and a pivotal string latch that can be adjusted between a first orientation in which the string latch contacts the bowstring in the drawn position to interfere with the release of the bowstring from the guide, and a second orientation in which the string latch allows the bowstring to be released from the guide. A trigger lever that can be manually actuated by an archer is provided to cause adjustment of the string latch between the first and second orientations, and a roller assembly rolls over a surface of the string latch when the trigger lever is actuated to adjust the orientation of the string latch.

Owner:HUNTERS MFG CO INC

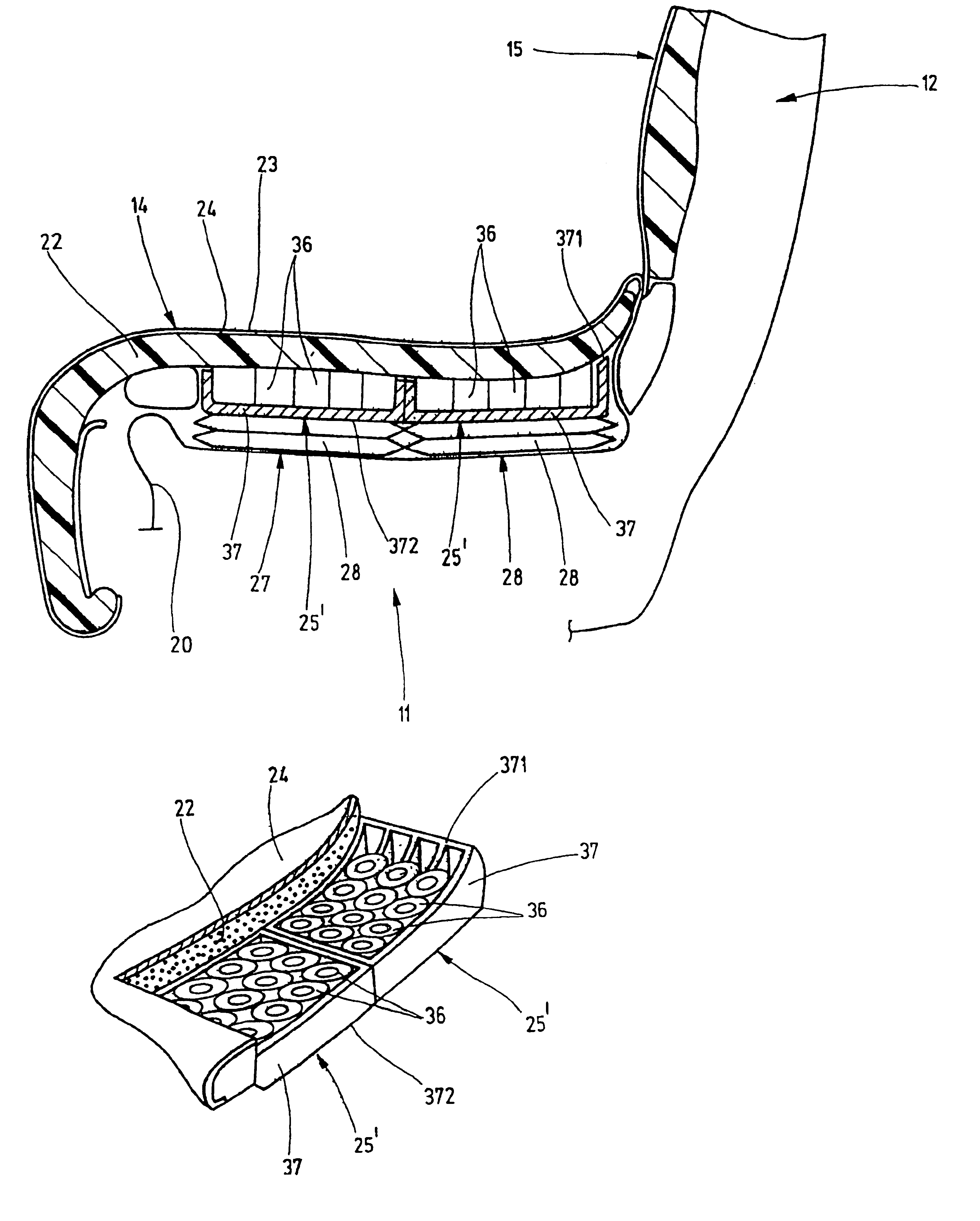

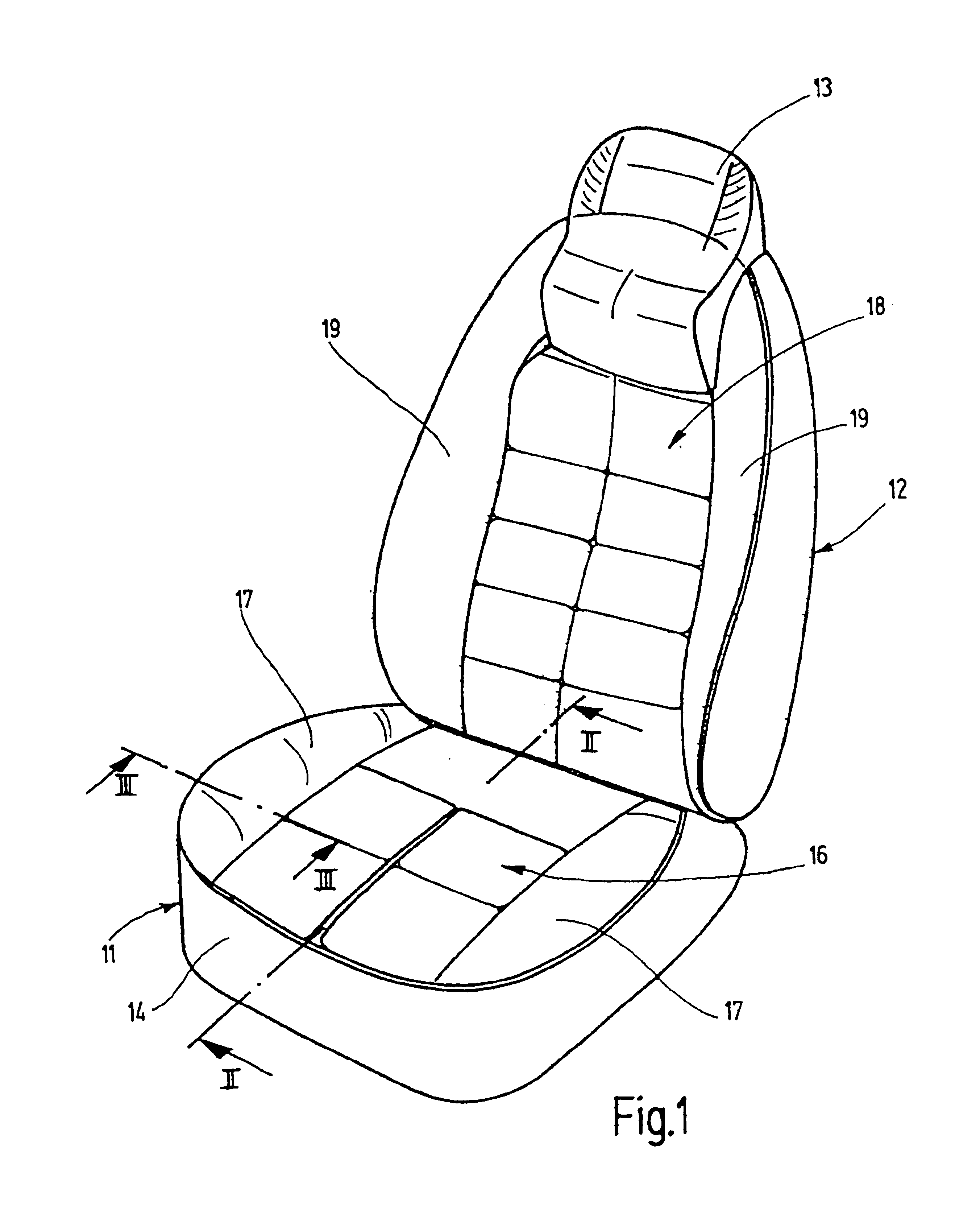

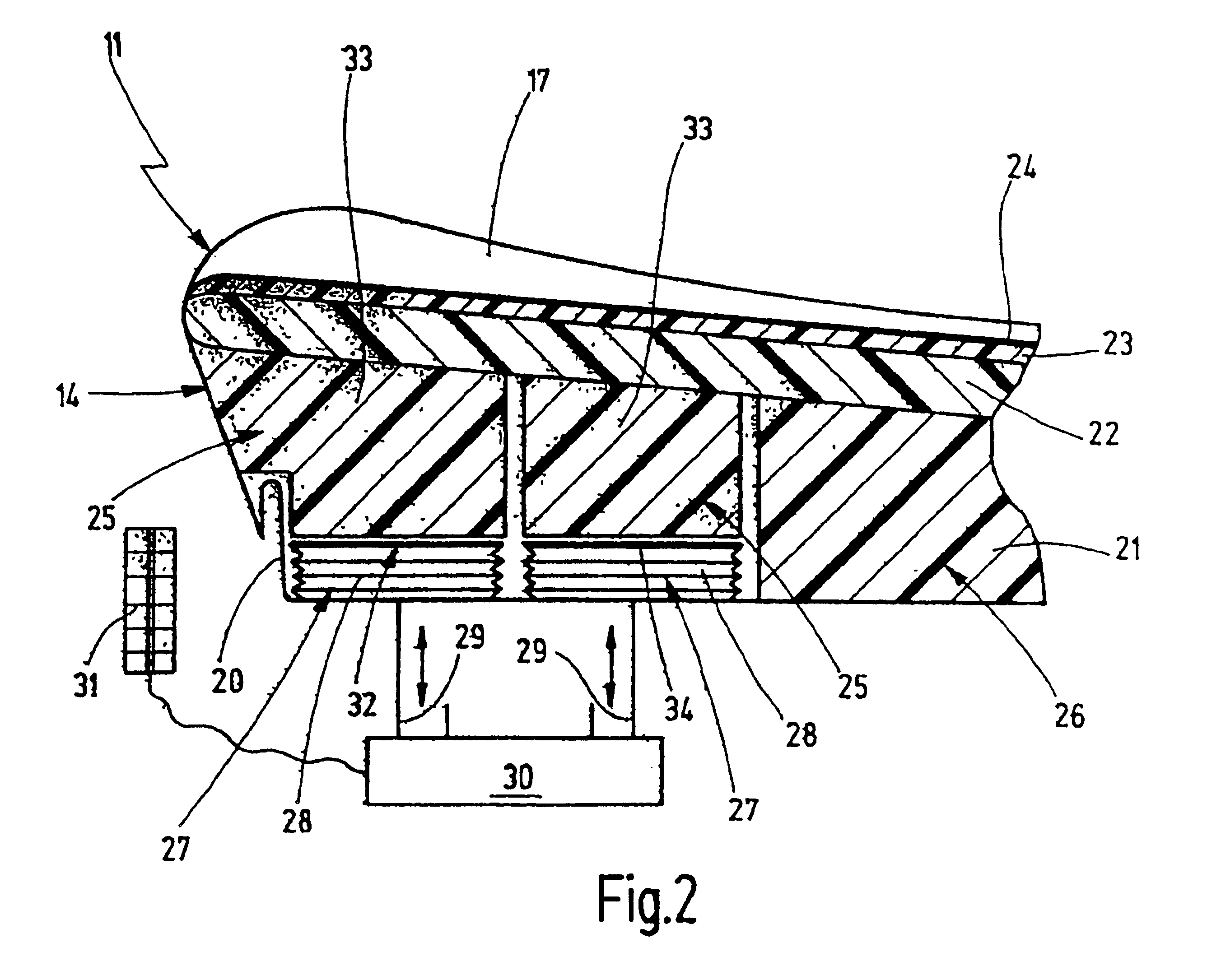

Padding for seats, in particular vehicle seats

InactiveUS6851755B2Uniform distributionIncrease tensionVehicle seatsStuffed mattressesAdverse effectBiomedical engineering

Padding for seats, in particular vehicle seats, has a padded body predetermining the contour of the padded surface, which can be changed. In order to adjust the padded surface contour to support the body of a seated person in an individual and orthopaedically correct manner, avoiding hardening of the padded surface which has an adverse effect on the seat comfort, the padded body is composed, at least in subregions, of a plurality of individual padded segments which are arranged next to one another and can be displaced relative to one another in the direction of the normal of the padded surface. Adjusting elements can displace the padded elements individually.

Owner:BAYERISCHE MOTOREN WERKE AG

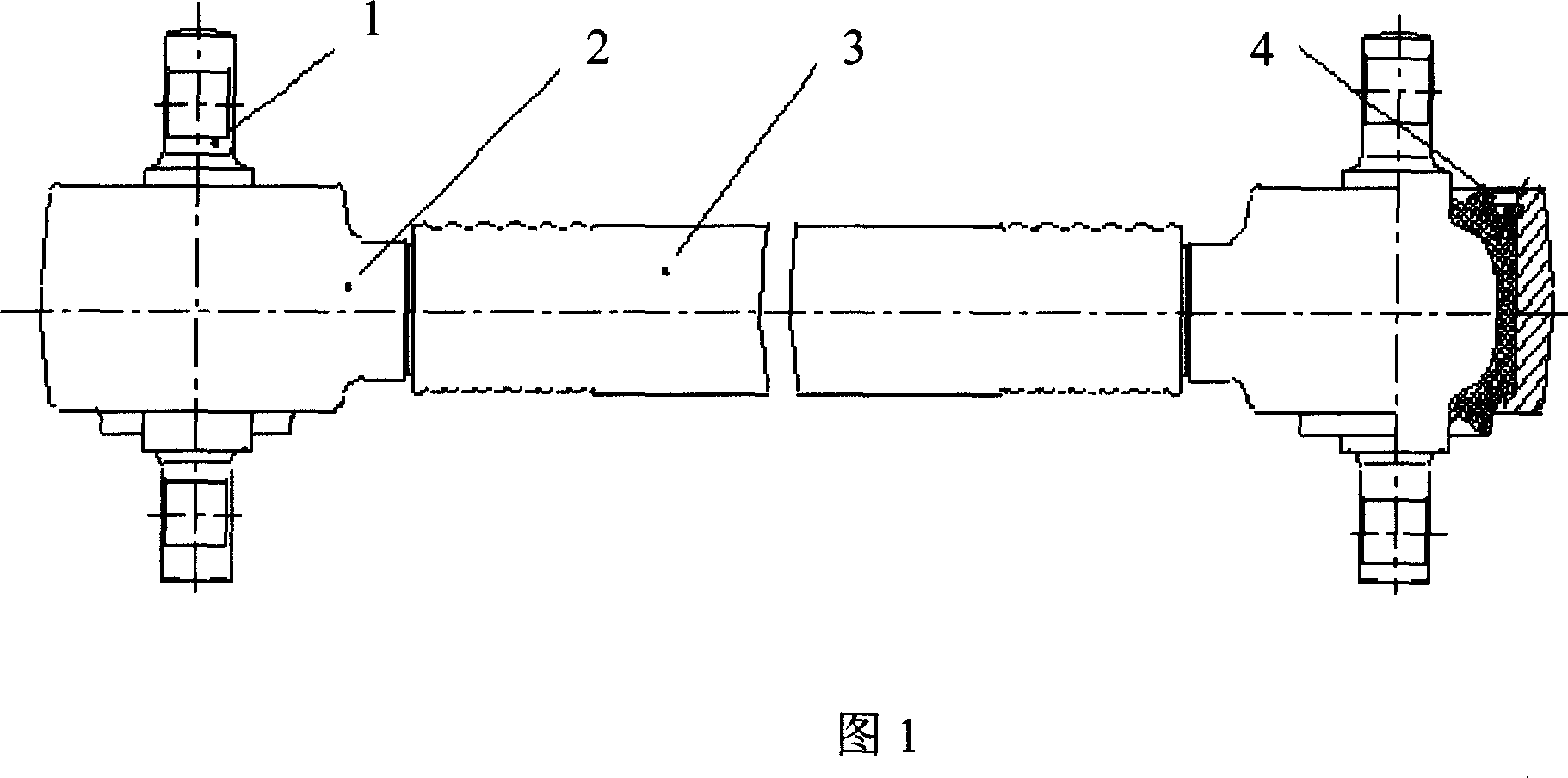

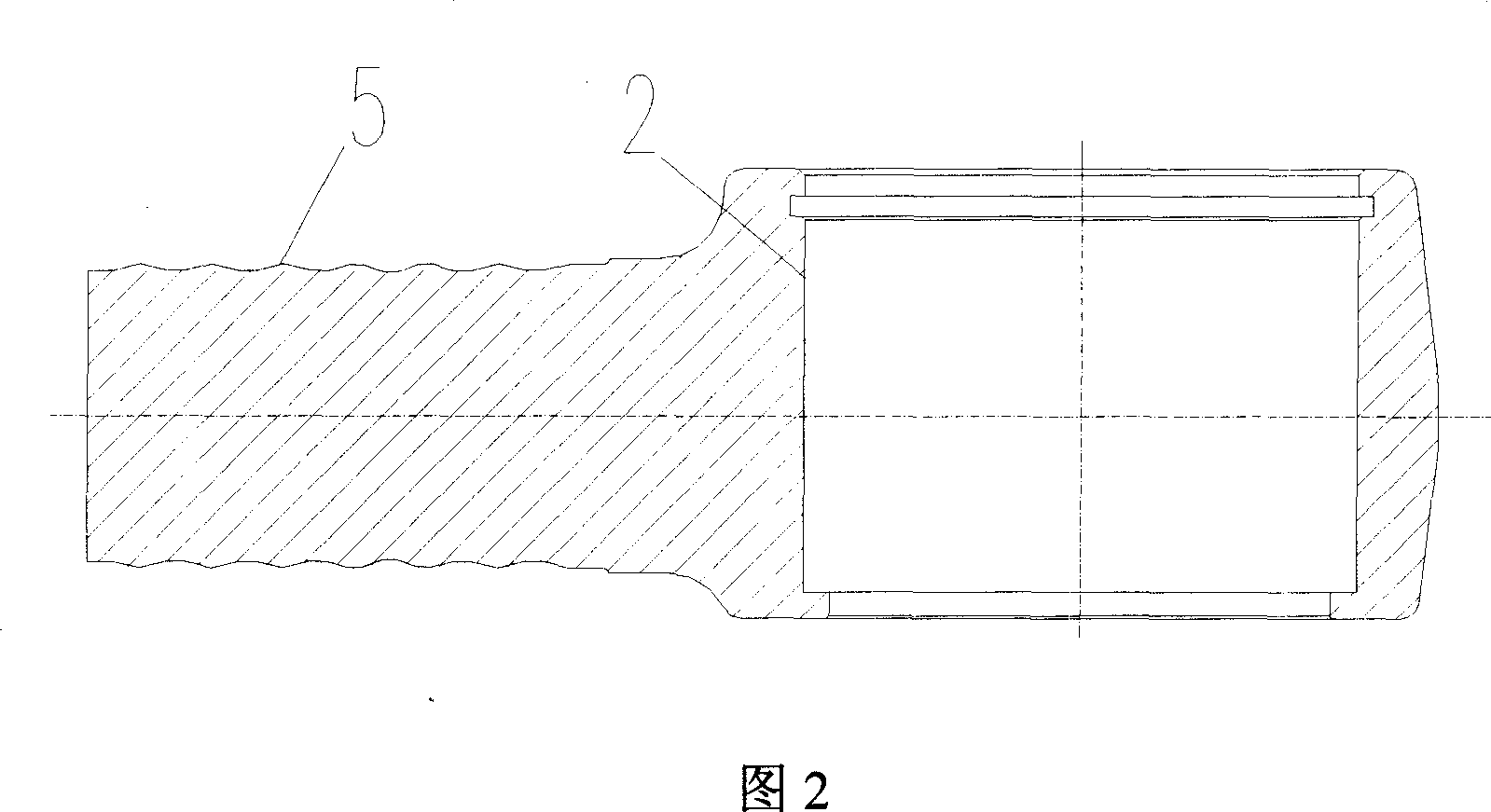

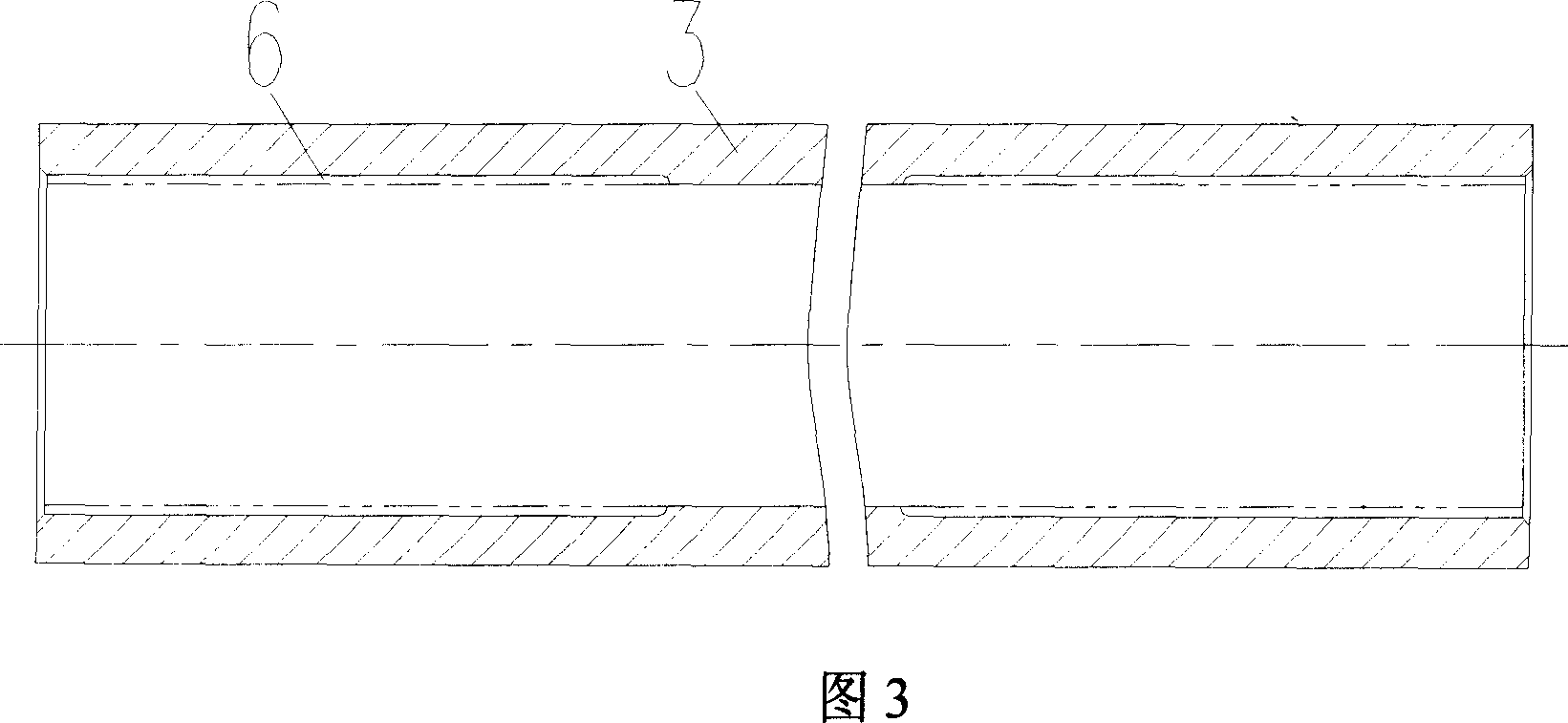

Subassembly of buttonhead of car distance rod and sheath, and assembling technique

ActiveCN1958319AMeet the connection strengthImprove torsion resistancePivoted suspension armsMetal working apparatusHeating furnaceHeating power

A thrust ball head-sleeve pipe assemblage for car is composed of a ball head of thrust rod and a sleeve pipe, which are coupled in corrugated mode. Its assembling technology includes such steps as corrugating the coupled part of said ball head of thrust rod, machining the coupled part of sleeve pipe to become thin wall, setting up the pressing parameters of hydraulic press, setting up the heating power and time of MF heater, heating the thin-wall part of sleeve pipe, inserting it in a dedicated riveting apparatus, turning on hydraulic press to rivet the sleeve pipe with the ball head of thrust rod, and cooling.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

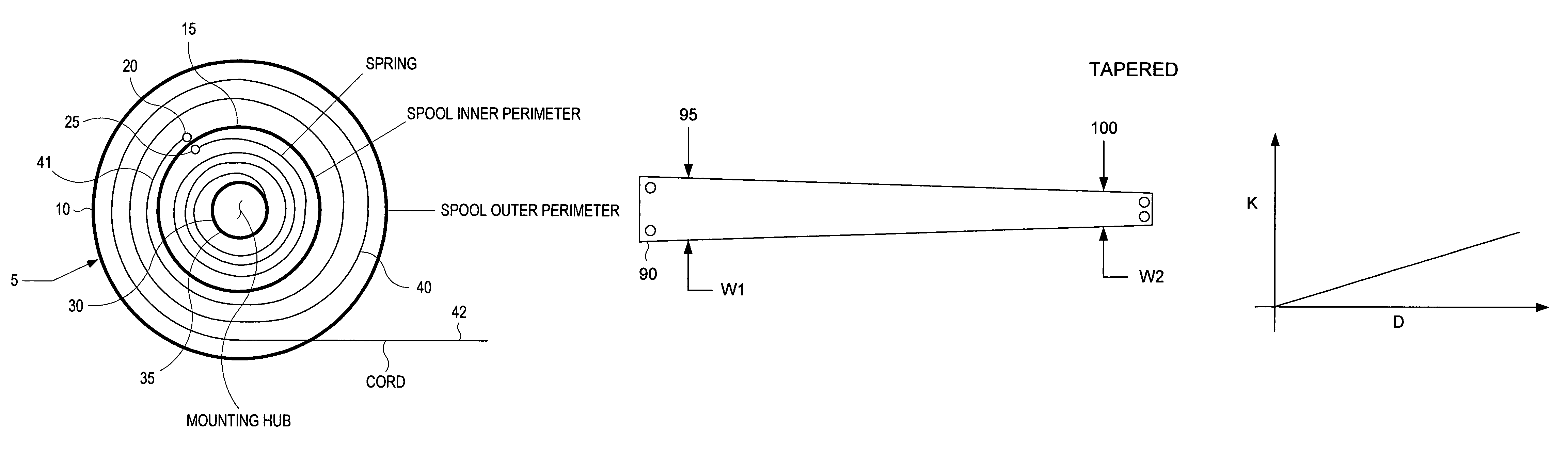

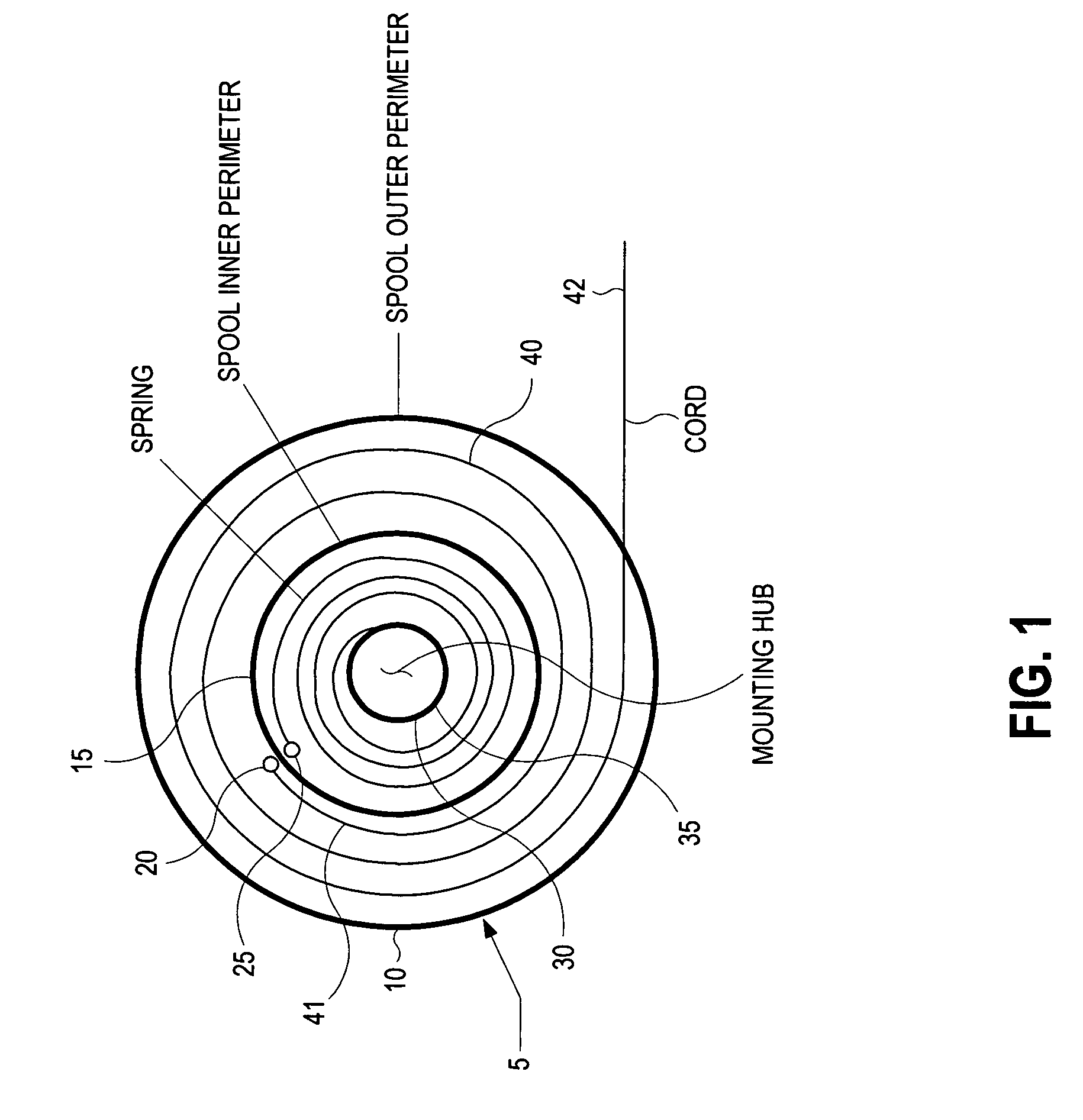

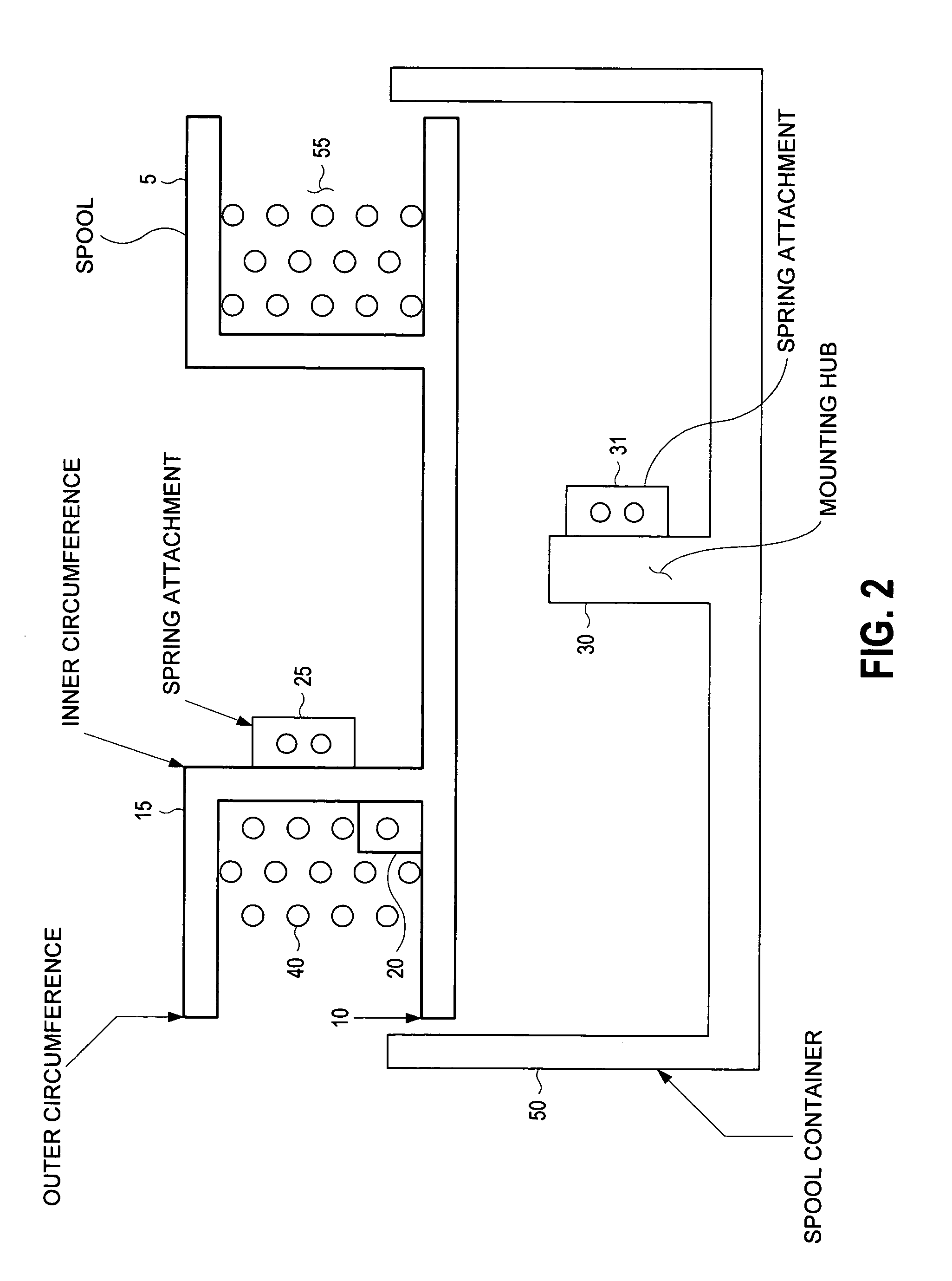

Method and apparatus for variable tension cord recoil and tethered user interface

ActiveUS7344102B1Weak in tensionIncrease tensionTorsion springsResilient suspensionsEngineeringUser interface

Variable tension is applied to a cord as it is drawn from a spool. More tension is applied to the cord as more cord is drawn preventing impulse stress. Cord used to attach user interface device for receiving input and presenting information.

Owner:ROCKWELL COLLINS INC

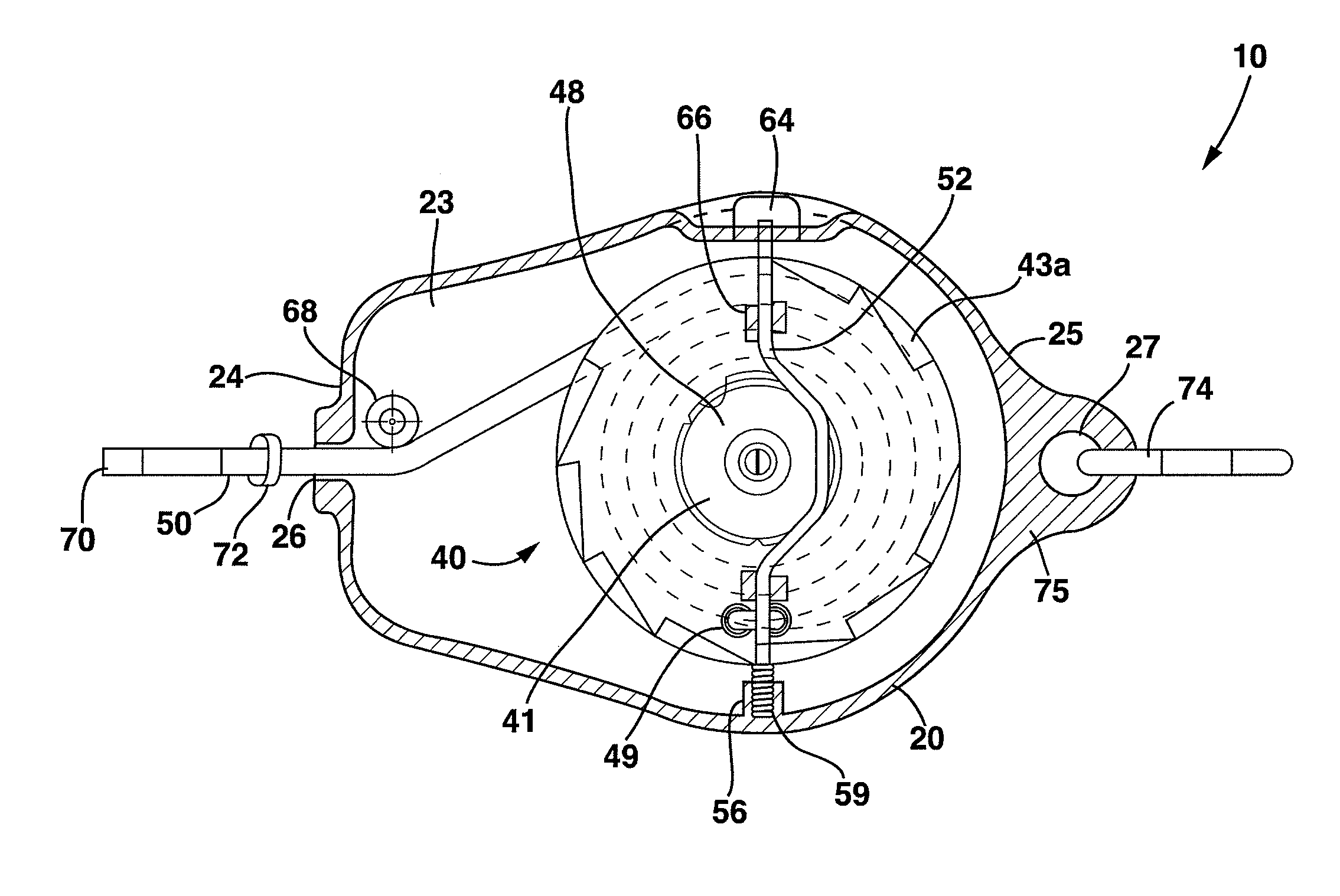

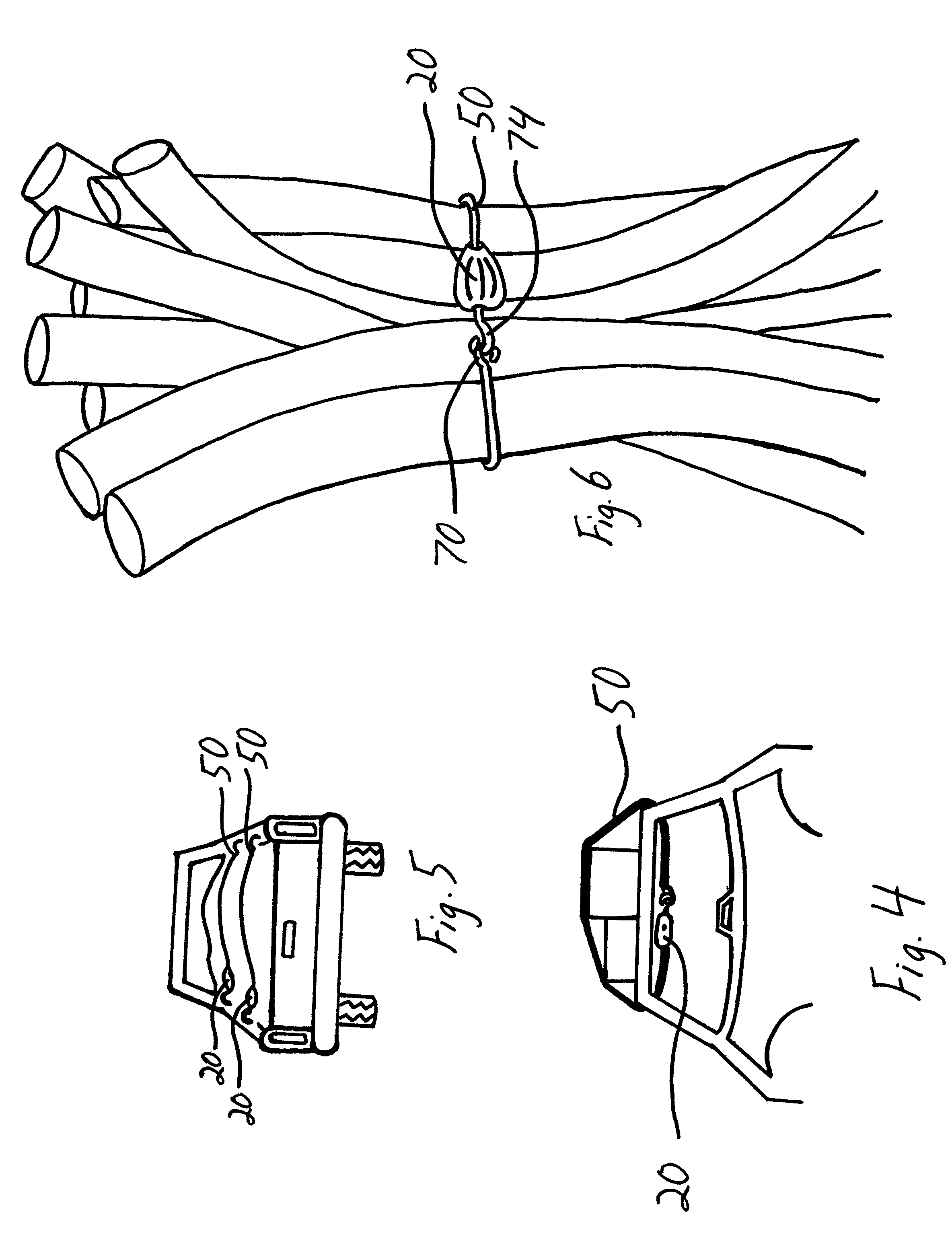

Retractable bungee cord tie down

InactiveUS7575224B1Prevent movementIncrease tensionSnap fastenersPortable liftingFrenulumEngineering

A retractable bungee cord tie down having a housing enclosing a ratcheting mechanism and a bungee cord. The bungee cord is wrapped around a spool having a biasing member operatively coupled thereto to permit automatic retraction of the bungee cord into the housing. Operatively coupled to the spool is a control arm that is used to engage and disengage spool movement and thus movement of the bungee cord into or out of the housing. A button connected to the control arm permits a user to secure items by securing the bungee cord first and then operating or moving the housing to another secure location.

Owner:MADLAND ERIK

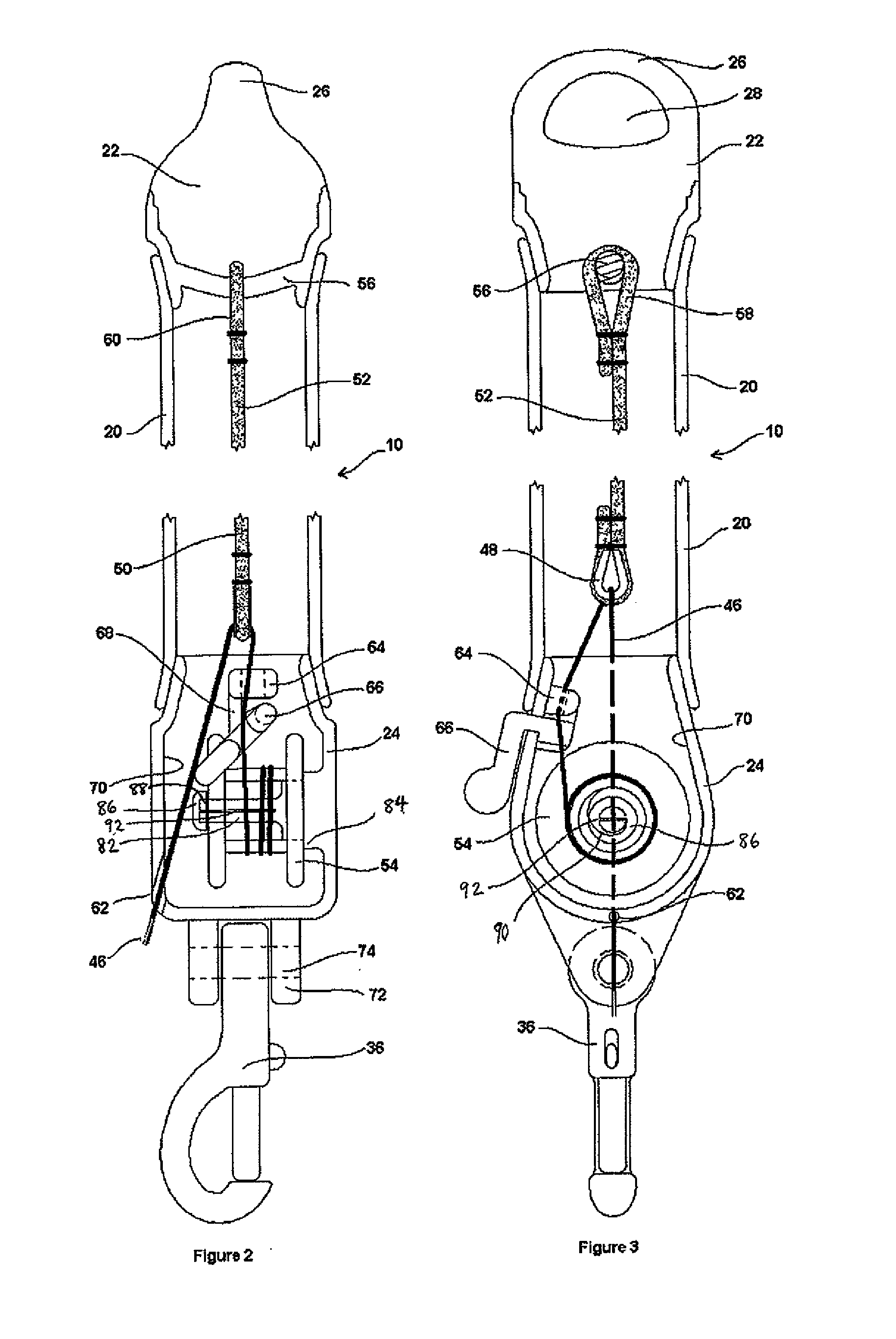

Leash slack control system

InactiveUS20130074783A1Increase tensionReduce in sizeTaming and training devicesEngineeringMechanical engineering

A leash system for controlling the slack in the leash to prevent the animal from becoming entangled in the leash. The leash system has a spool mounted wire controlling the effective length in the leash by forming a loop in the leash to absorb any slack. If the animal pulls away from the person and additional leash length is required, wire can be automatically played out from the spool so that the loop can be opened to provide the required slack. Similarly, the wire will automatically retract to reform the loop and absorb the slack the leash once the animal moves back toward the person such that the effective length of the leash remains relatively taut.

Owner:CHAPIN PAUL W

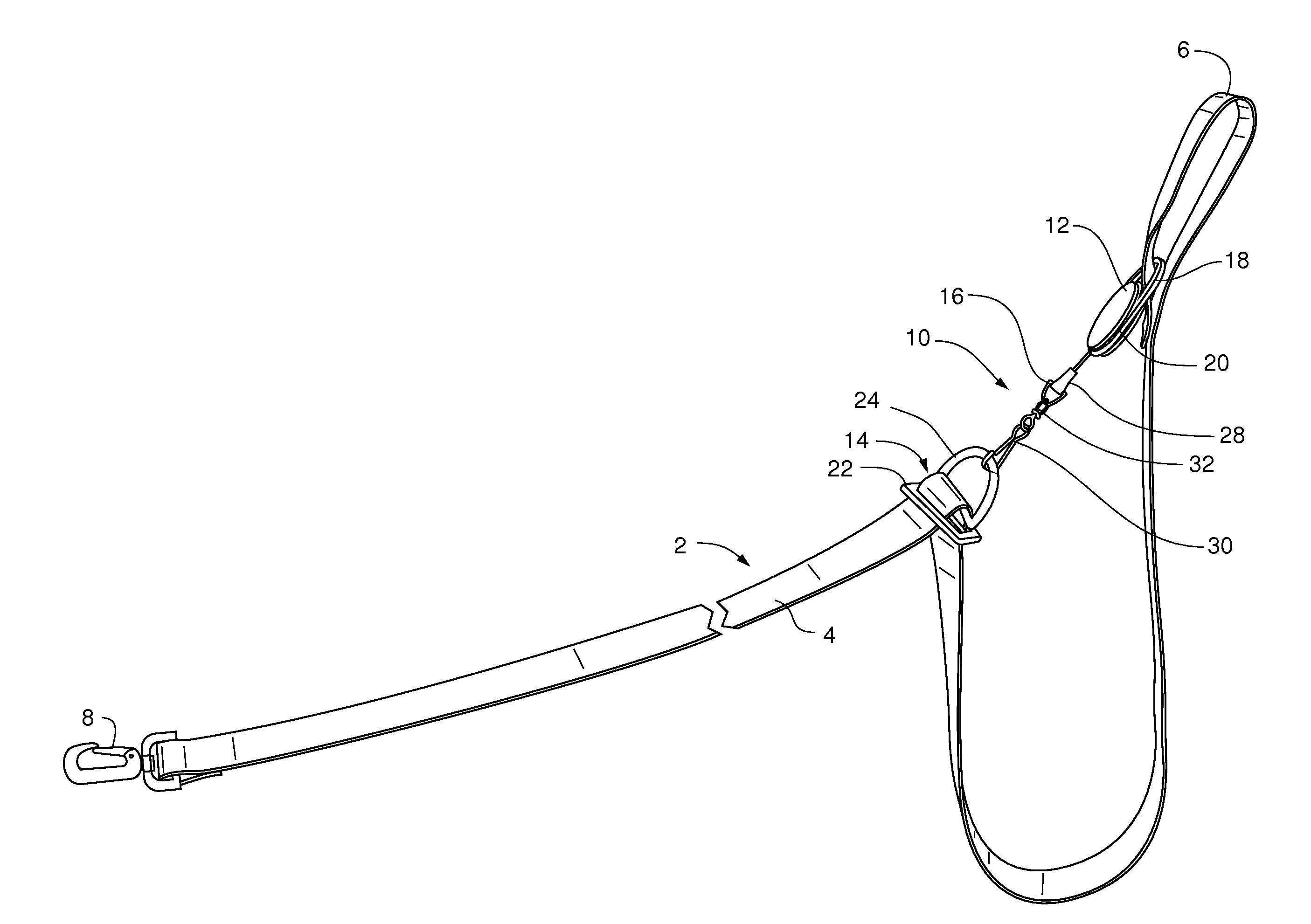

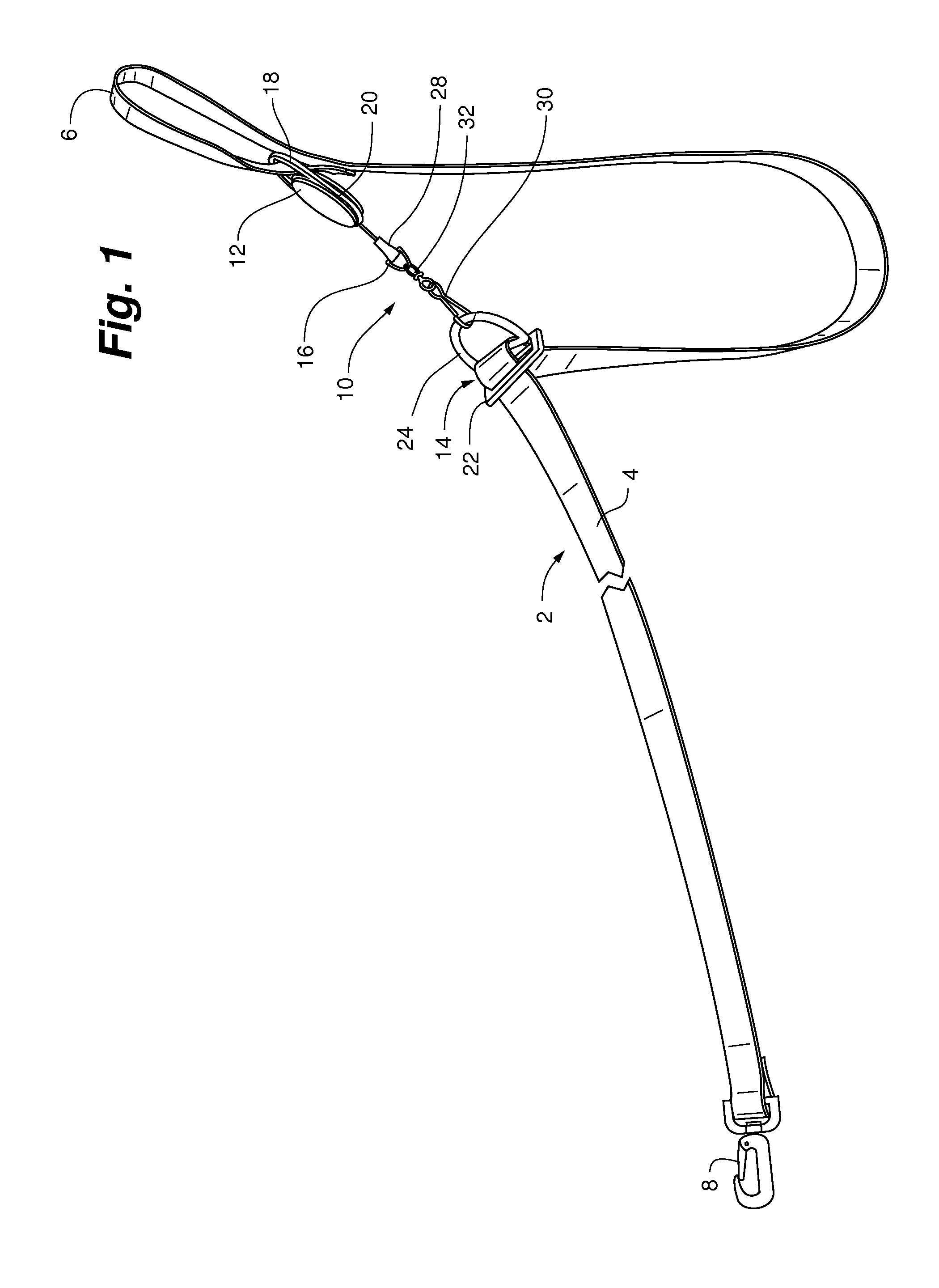

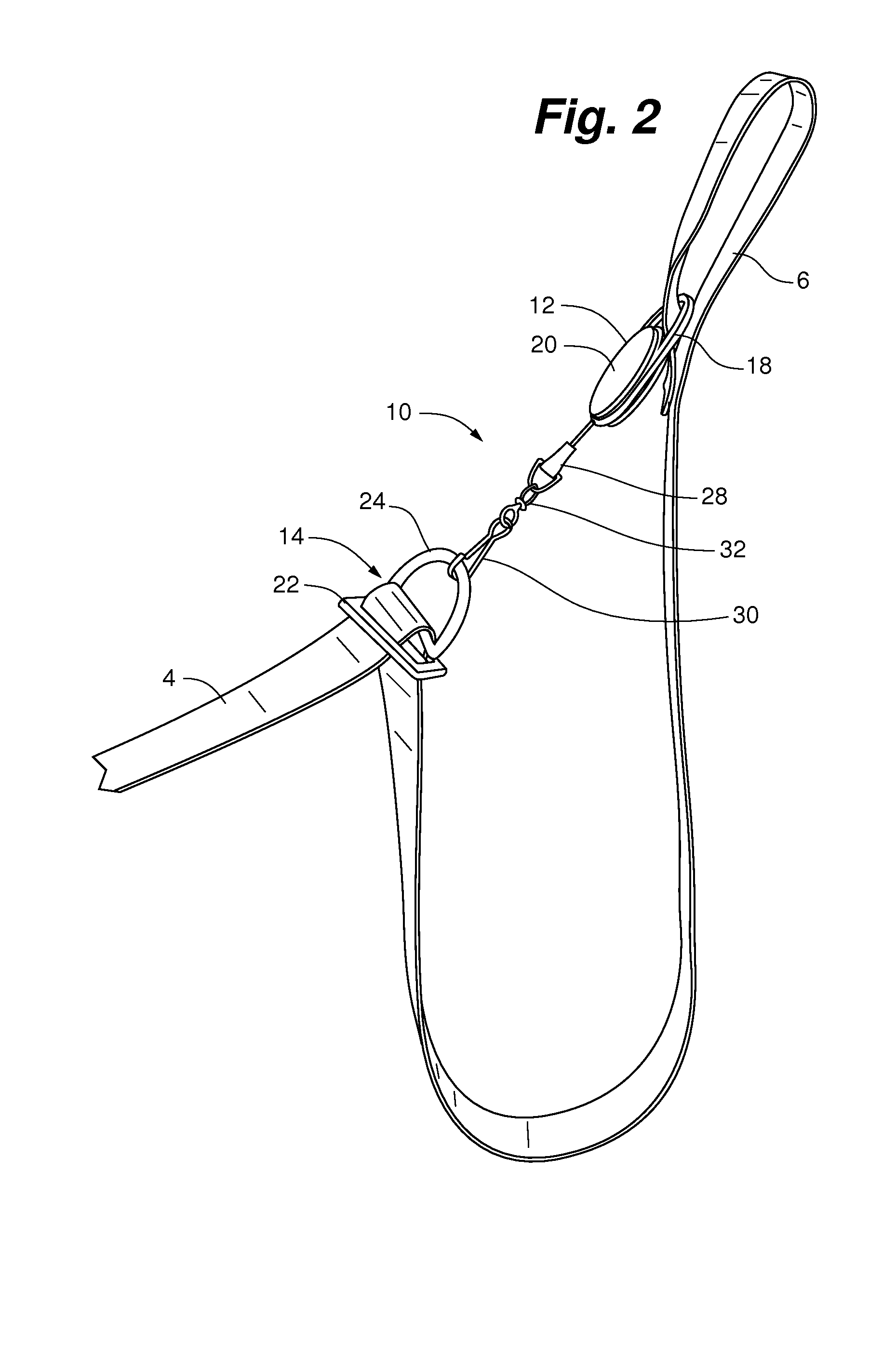

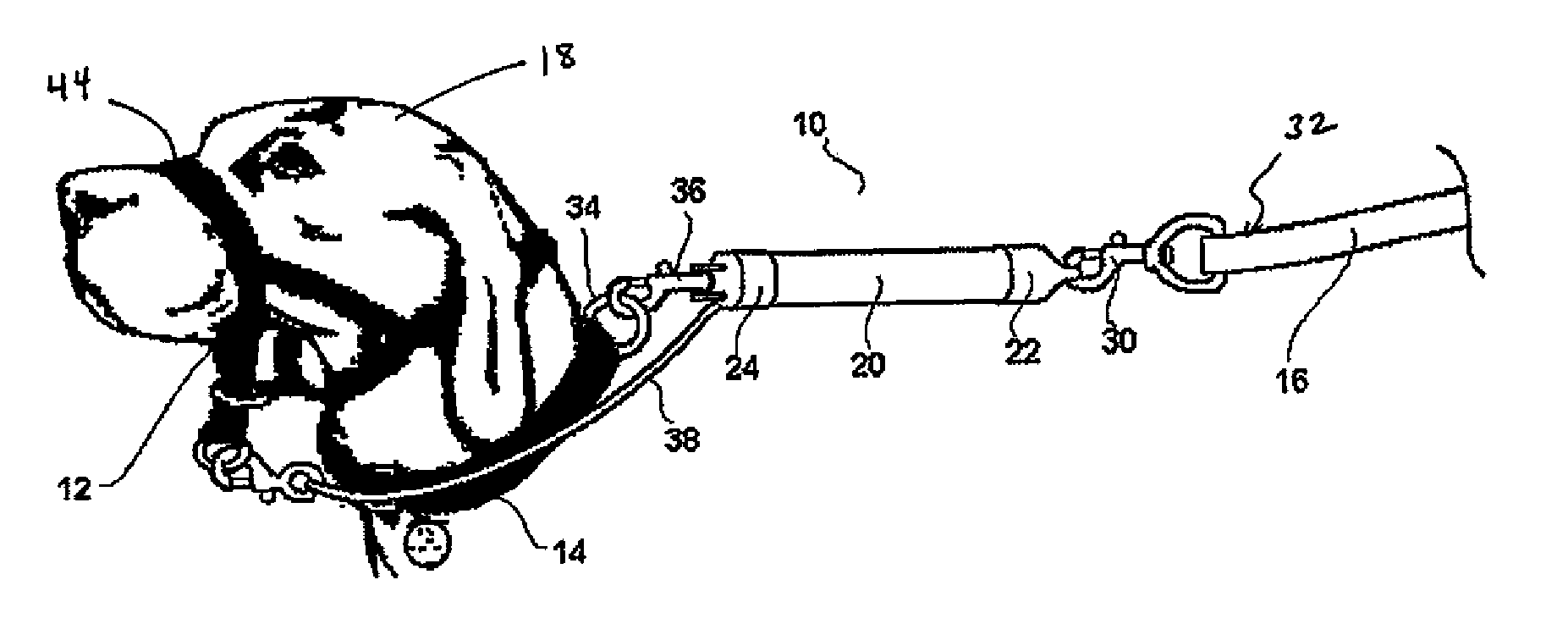

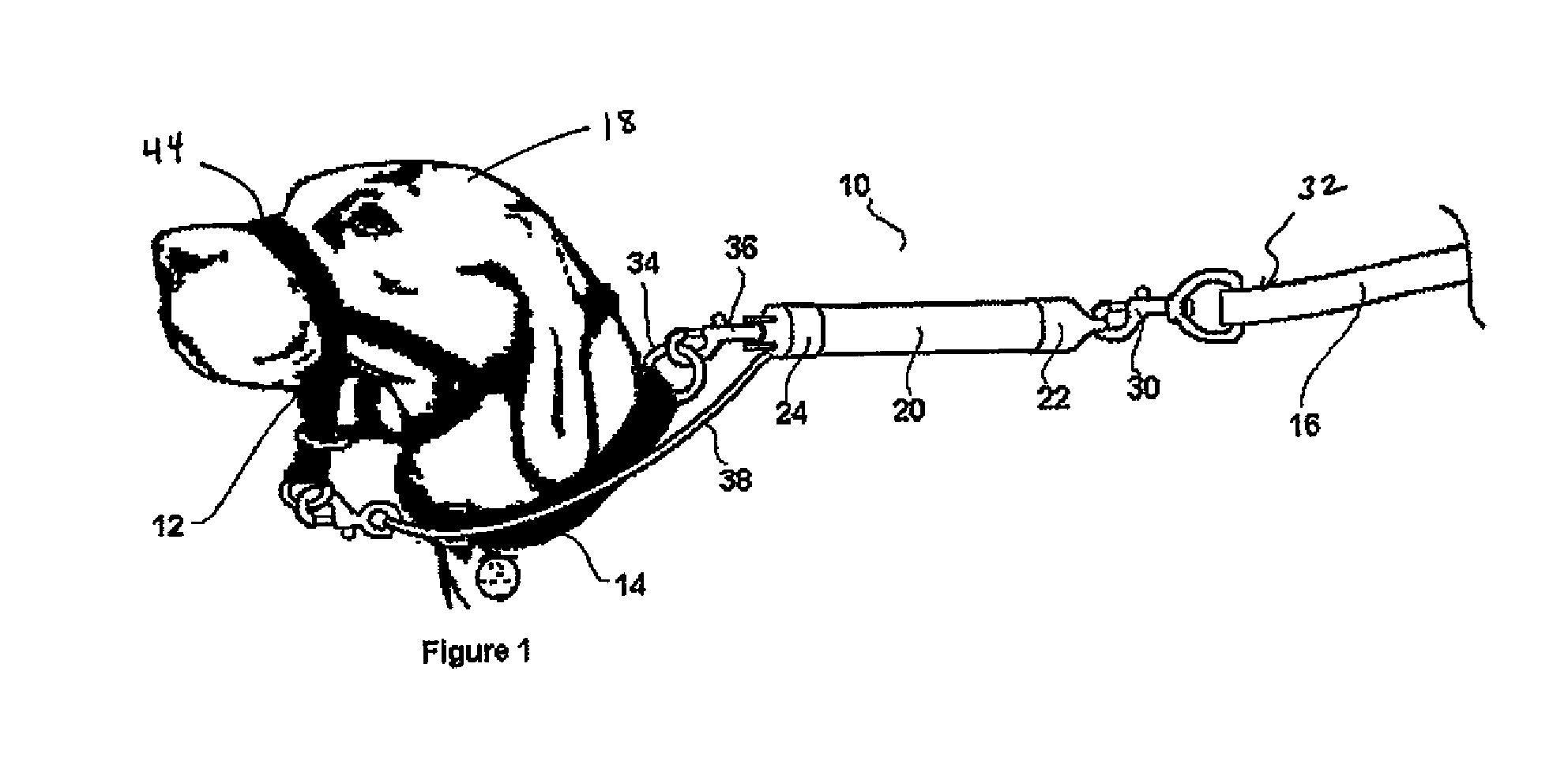

Animal training device

An animal training device for use with a head collar, a neck collar and a leash simultaneously includes: an elastic body removably coupled between the neck collar and the leash, the elastic body lengthening in response a separating force between the neck collar and the leash and an inelastic line removably coupled between a snout portion of the head collar and the leash, the inelastic line having a fixed length. When the animal pulls against the leash, the inelastic line exerts a force on the snout portion of the head collar.

Owner:HENDERSON STEVEN

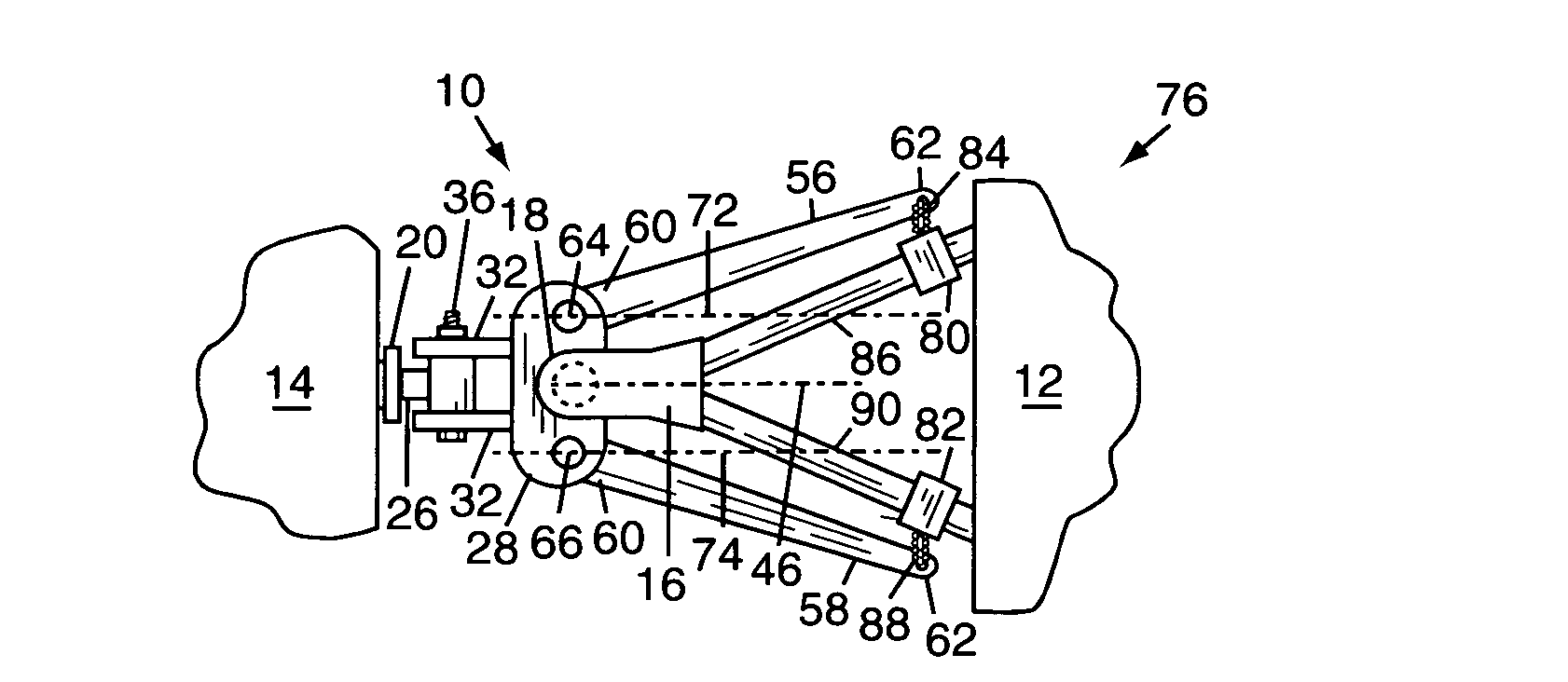

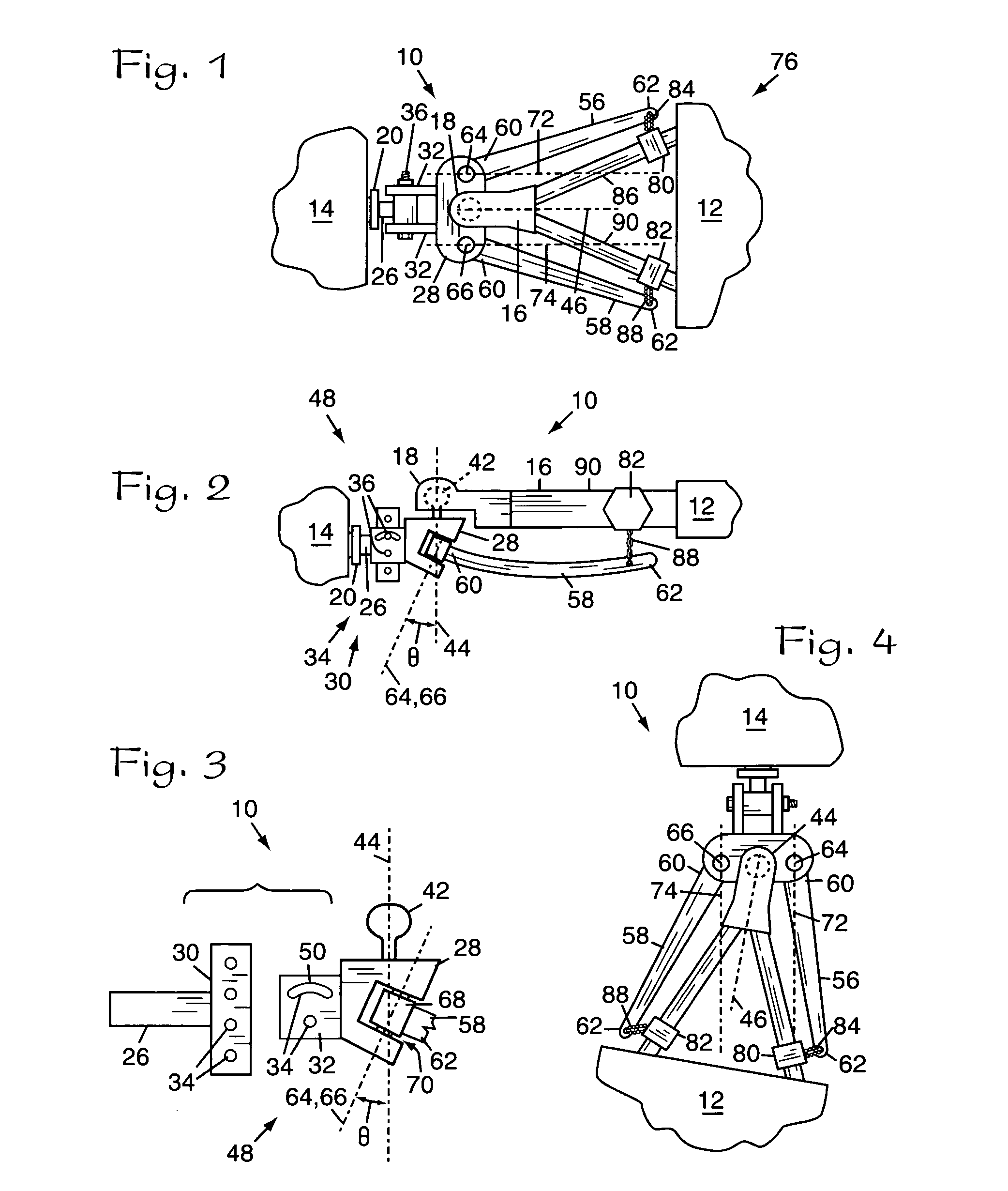

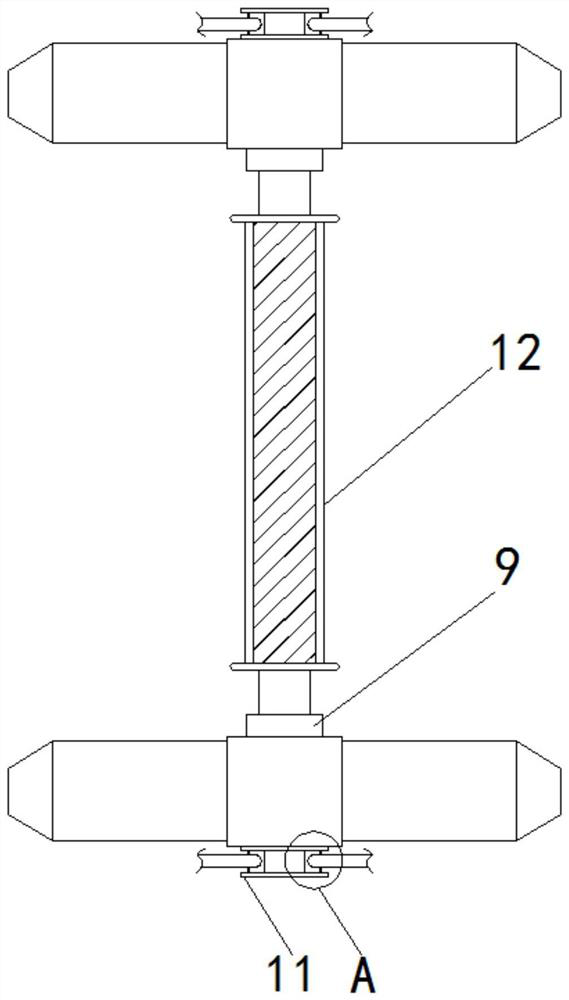

Dynamic anti-sway, tongue weight-equalizing trailer hitch

ActiveUS8328222B1Reliable performanceIncrease tensionTractor-trailer combinationsTowing devicesEngineeringMechanical engineering

An anti-sway, tongue-weight equalizing hitch for a trailer having a hitch ball socket; a shank structured for releasably connecting to a towing vehicle; a hitch head secured to the shank and having a longitudinal axis, a hitch ball with a tow axis on the longitudinal axis; an elevating mechanism for adjusting the relative elevations of the hitch head and the trailer tongue; a leveling mechanism for vertically-orienting the tow axis; right and left spring bars mounted to the hitch head to pivot about opposing right and left rearwardly-tilted stabilizing axes disposed in opposing vertically-oriented pivot axis planes spaced laterally and equidistantly outwardly from the longitudinal axis; and right and left suspension mechanisms tensionally suspending distal ends of the spring bars wherein distal ends thereof are normally spaced laterally and equidistantly outwardly from the respective vertical-oriented pivot axis planes in an equilibrium configuration.

Owner:AUTOMATIC EQUIP MFG

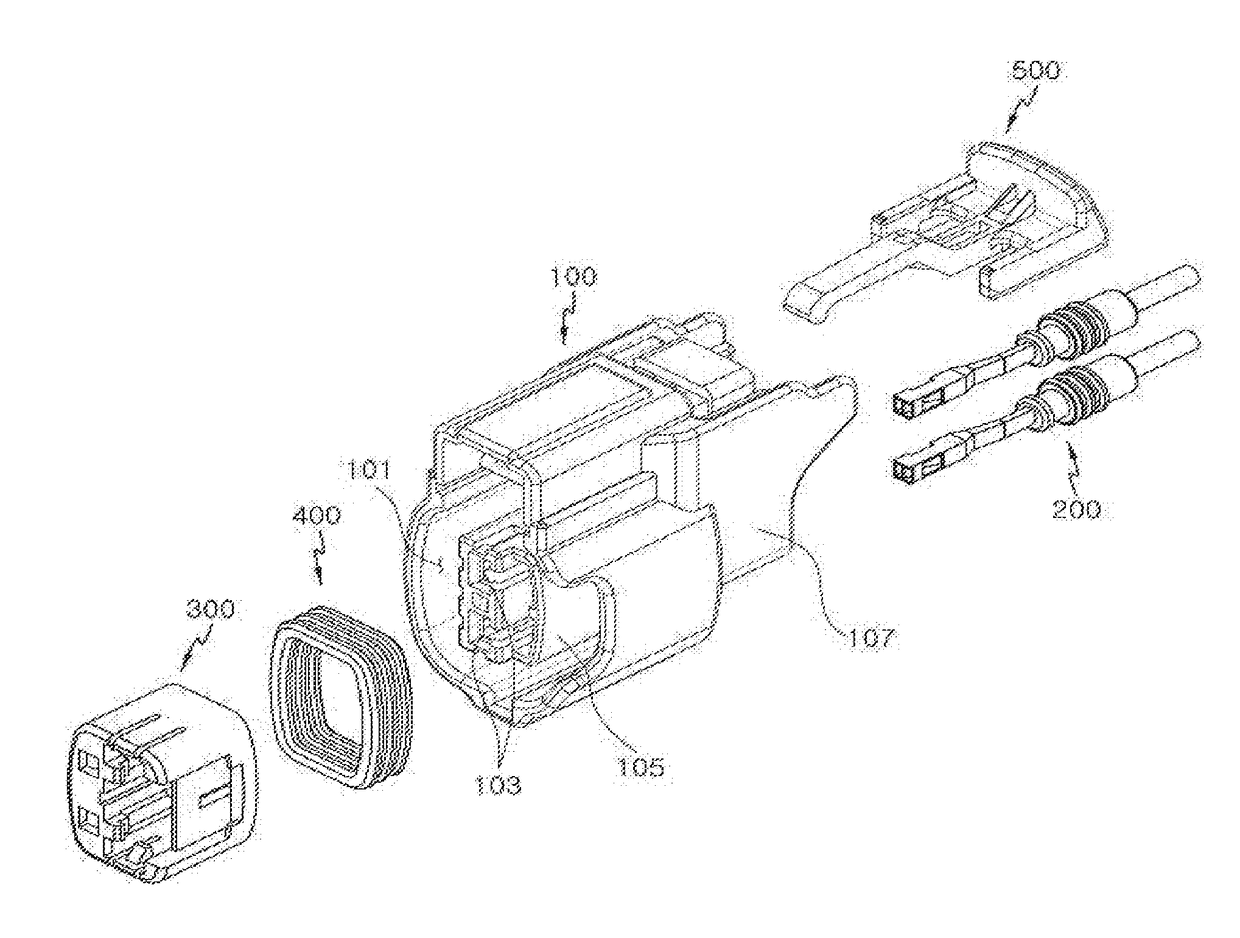

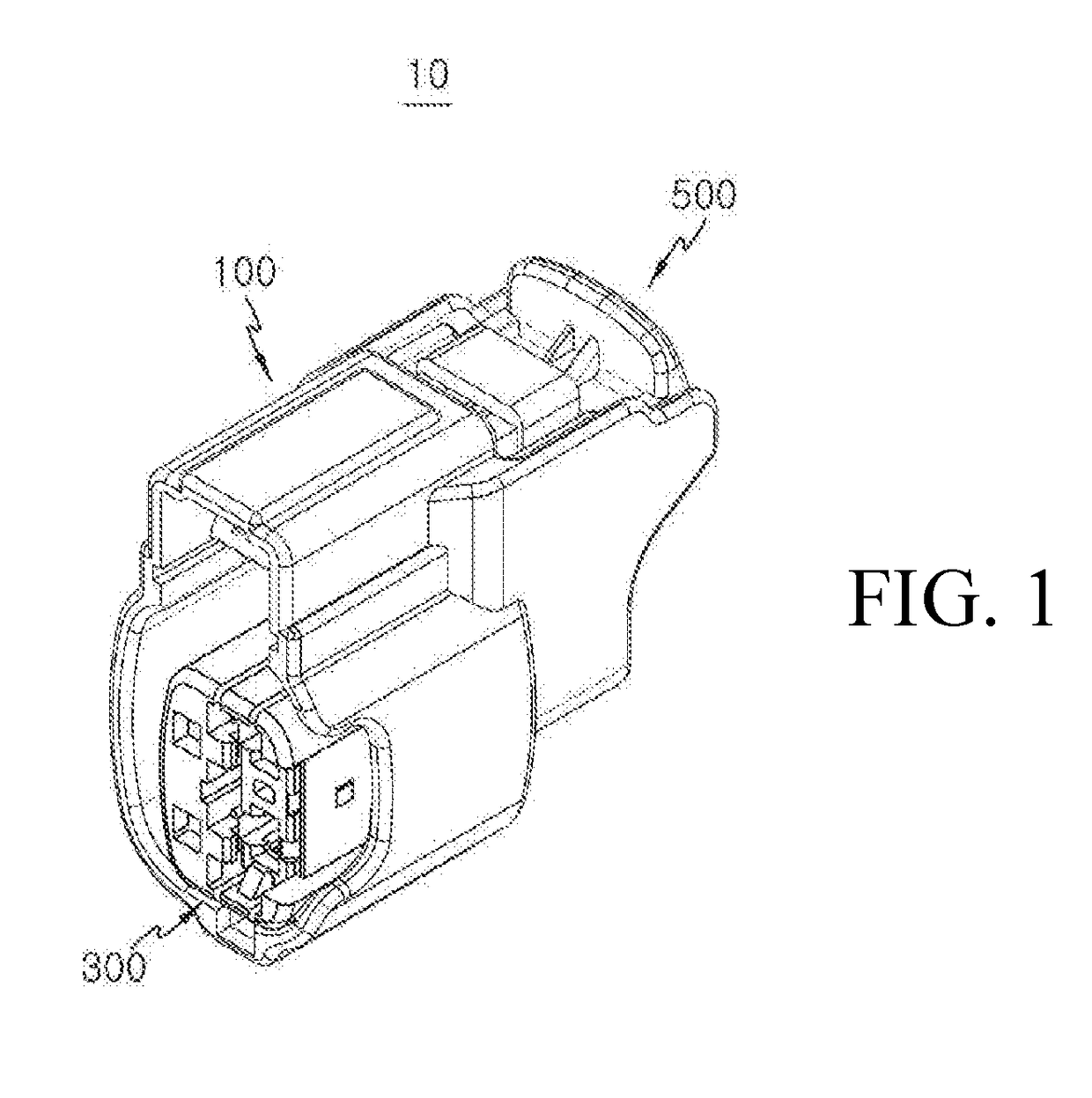

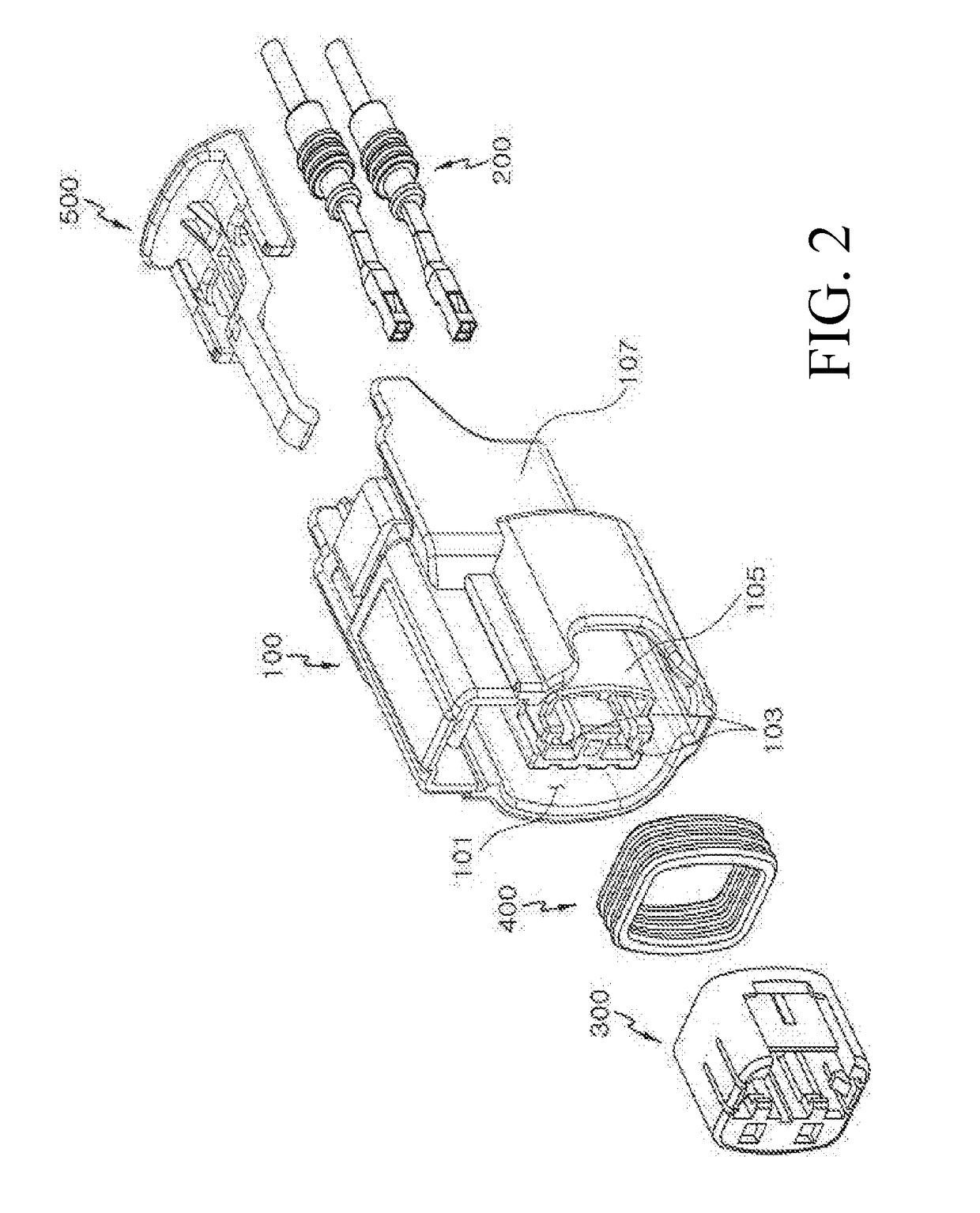

Connector assembly having cpa

InactiveUS20170077646A1Increase fasten force and removal forceIncrease tensionCoupling device detailsMechanical engineeringEngineering

Owner:MOLEX INC

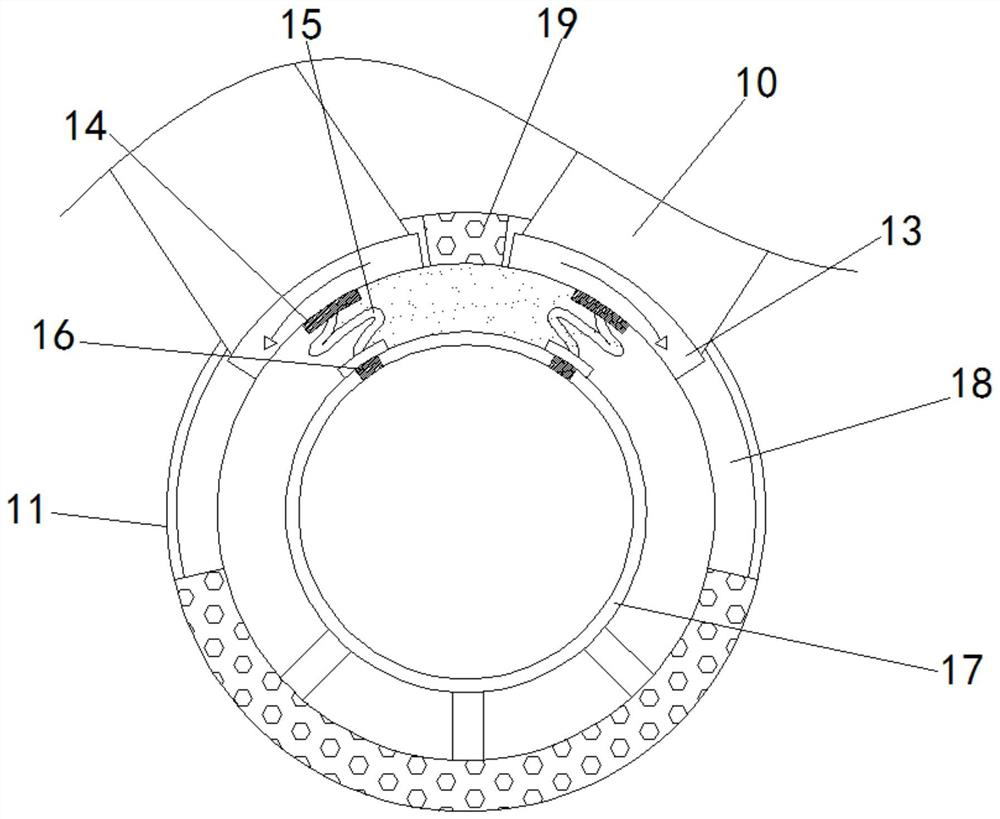

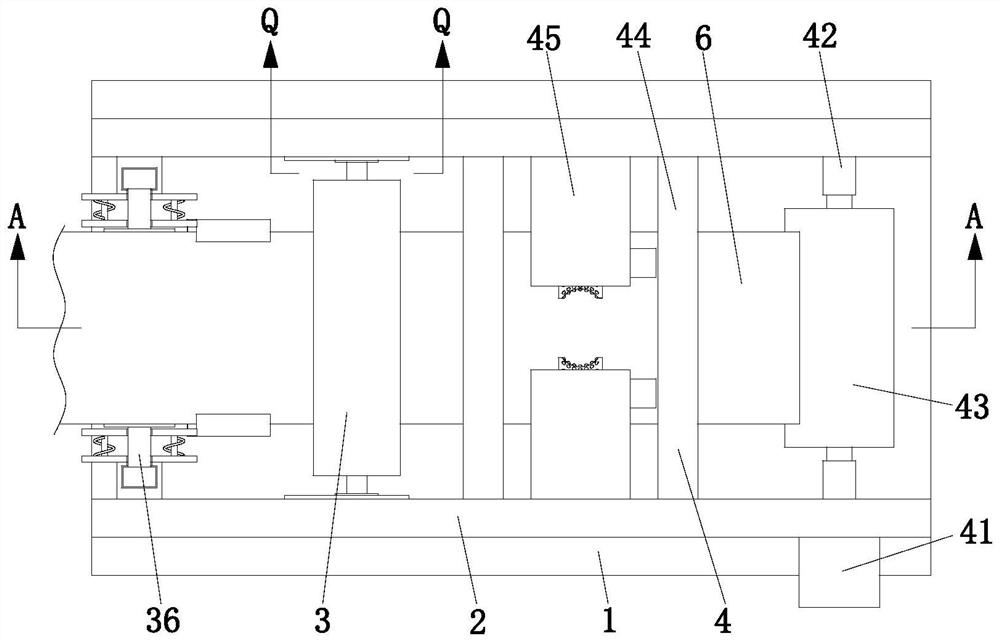

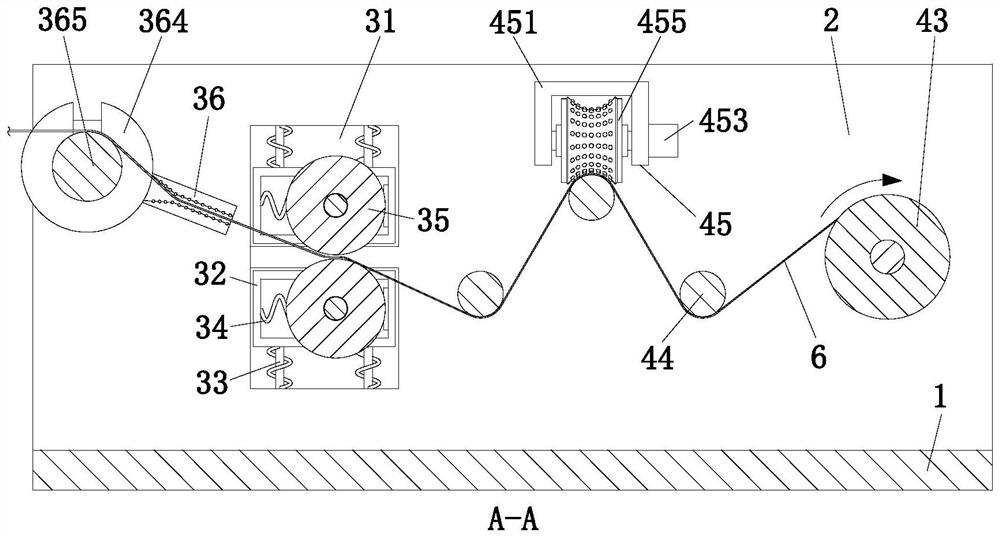

Tension adjusting device in non-woven fabric bundling process

The invention relates to the technical field of textiles, and discloses a tension adjusting device in a non-woven fabric bundling process. The tension adjusting device comprises a supporting frame, wherein the back surface of the supporting frame is movably connected with a bundling roller; a stabilizing rod is fixedly mounted at the top end of the supporting frame; the bottom end of the stabilizing rod is movably connected with a roller; the outer wall of the roller is wound with fabric; the fabric is wound with a fixed roller; and the front surface of the fixed roller is movably connected with a roller frame. According to the tension adjusting device in the non-woven fabric bundling process, a top block is matched with cushion gas blocks for use, so that when tension of the fabric is toogreat, the top block in a stressed roller is stressed to move upwards; in a process that the top block moves upwards; four bent rods are in contact, and a coil spring rotates, so that a moving spaceof a movable rod is increased, and the bent rods rotate and stretch; and when the bent rods rotate and stretch, the four cushion gas blocks extrude each other, and gas in the cushion gas blocks is extruded out through gas leaking holes, so that the effects of extruding the gas into a gas pressure rod and triggering constant gas pressure unbalance in the gas pressure rod are achieved.

Owner:仪征金海洋无纺制品有限公司

Antifouling fishing net

The invention relates to the field of fishing gear and particularly relates to an antifouling fishing net. The production raw materials of the antifouling fishing net include acrylic acid epoxy resin, chlorosulfonated polyethylene, cuprous oxide, rosin, methyl ethyl ketone, zinc oxide, dimethylbenzene, a benzimidazole-based antimicrobial agent, a crosslinking agent and a plasticizer. According to the antifouling fishing net provided by the invention, by adopting the chemical raw materials with an antifouling property such as cuprous oxide and methyl ethyl ketone, the antifouling property of the fishing net can be improved in use; meanwhile, by adding the plasticizer and a wetting agent, the tension and quality of the fishing net can be enhanced; and by adding the antimicrobial agent, pollution of the fishing net caused by seawater can be avoided.

Owner:CHAOHU LOTUS FISHING NET

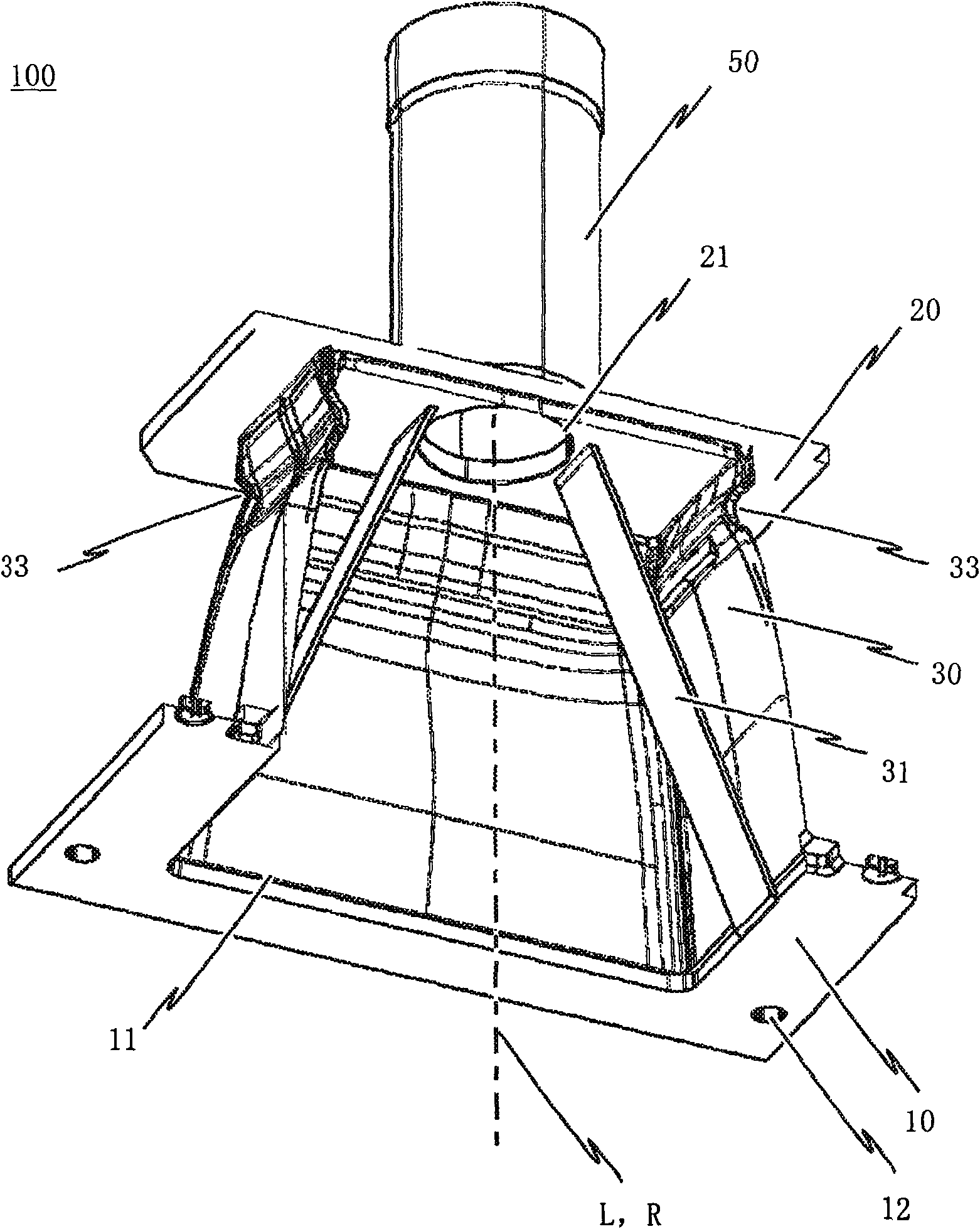

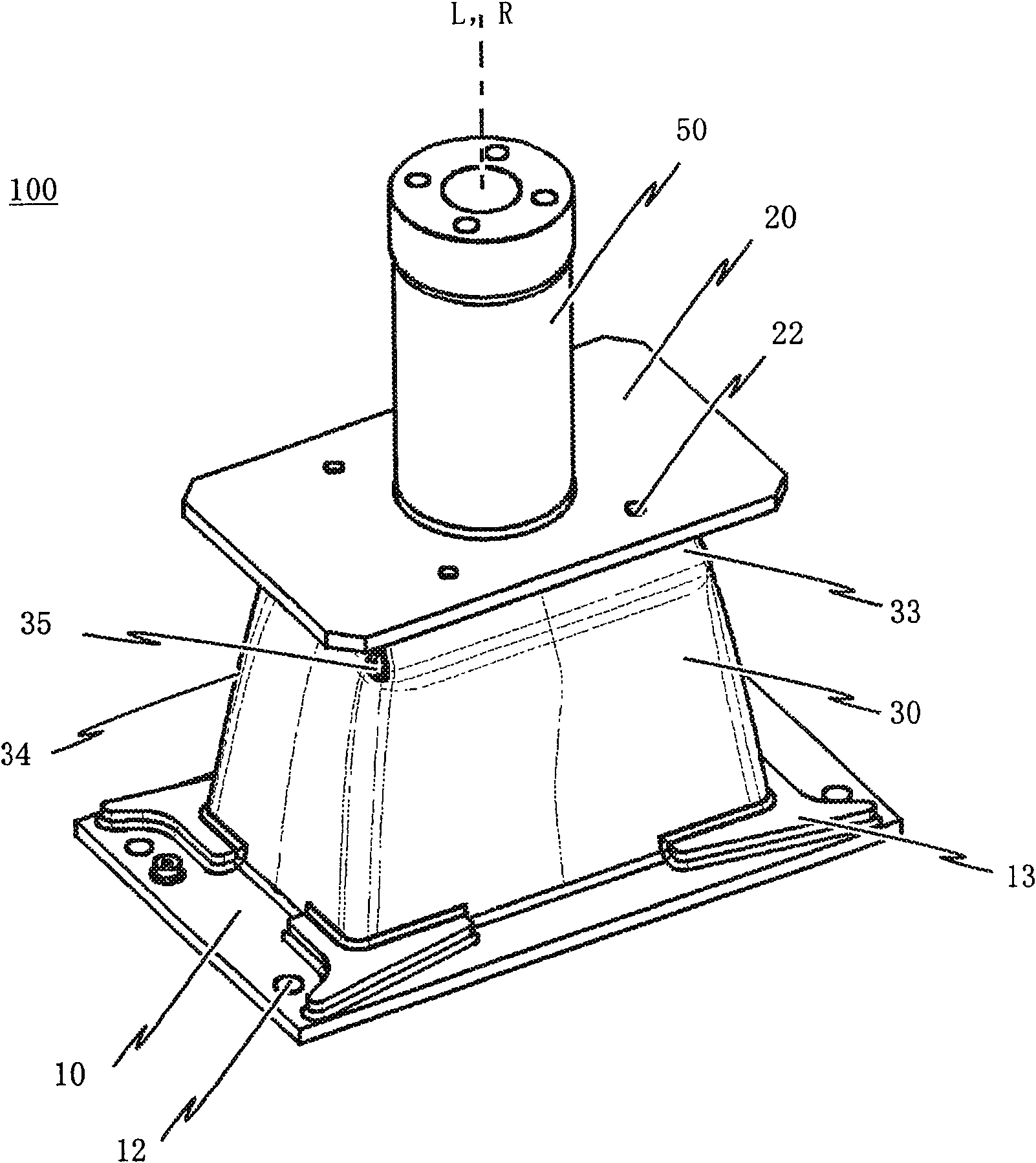

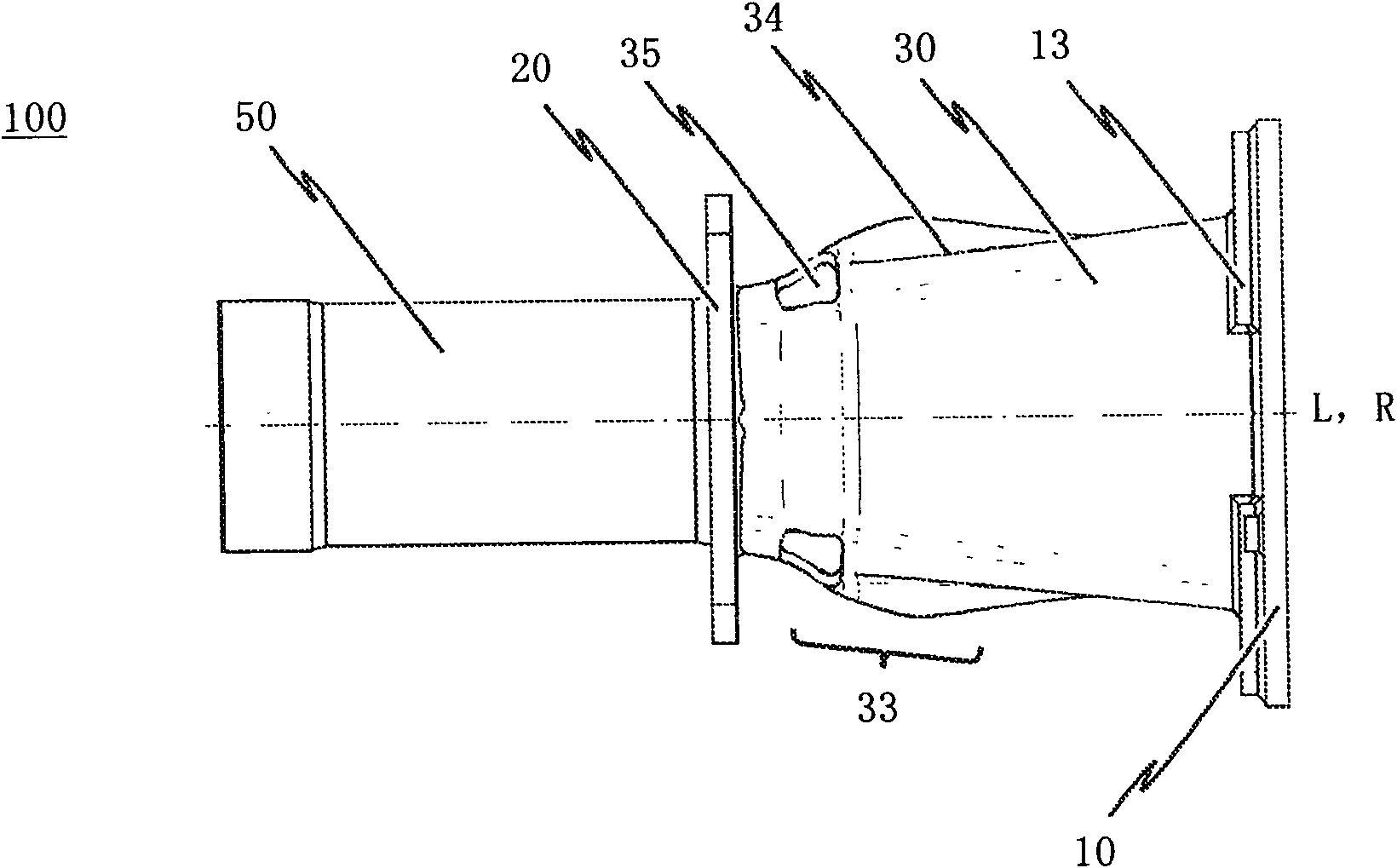

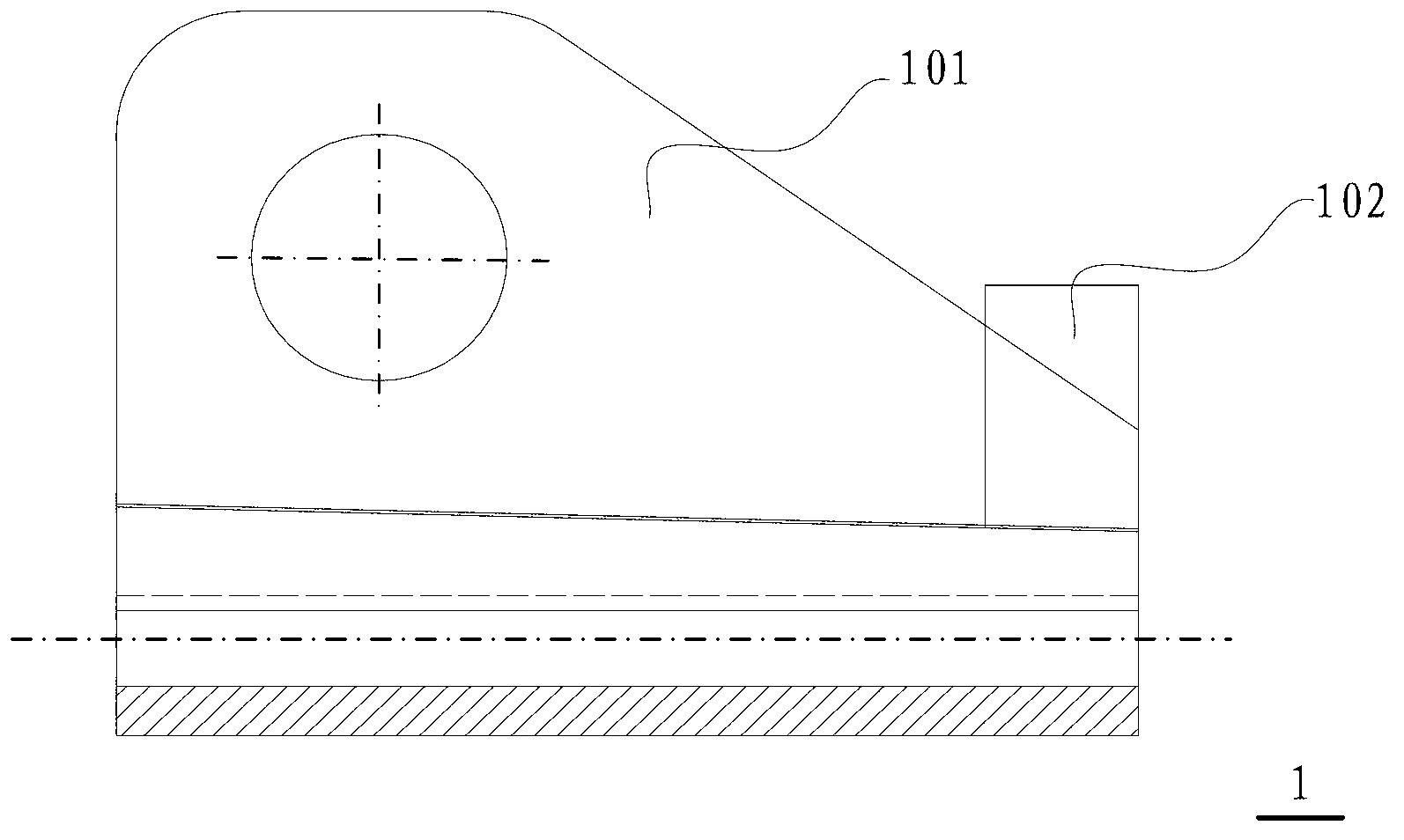

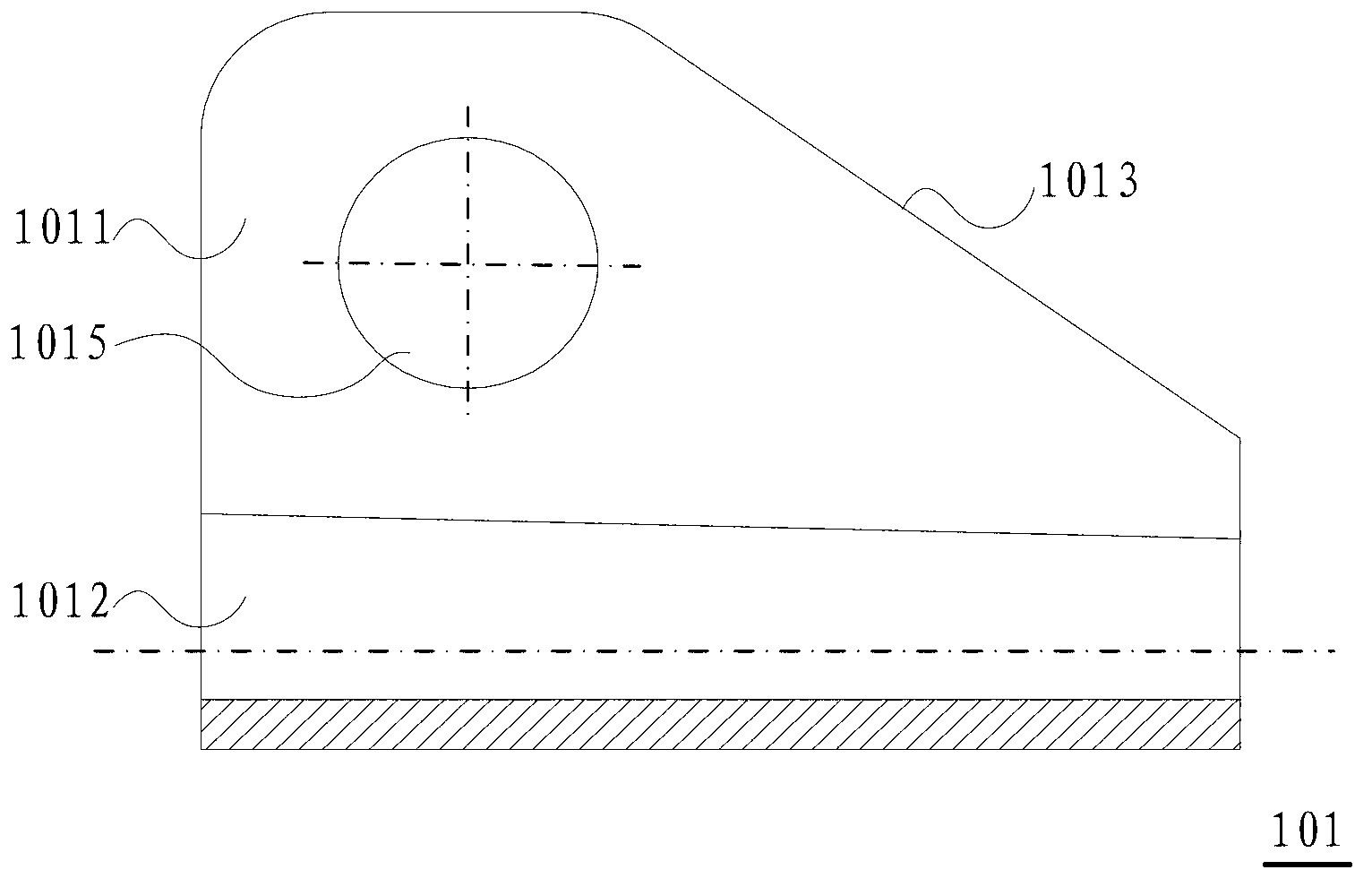

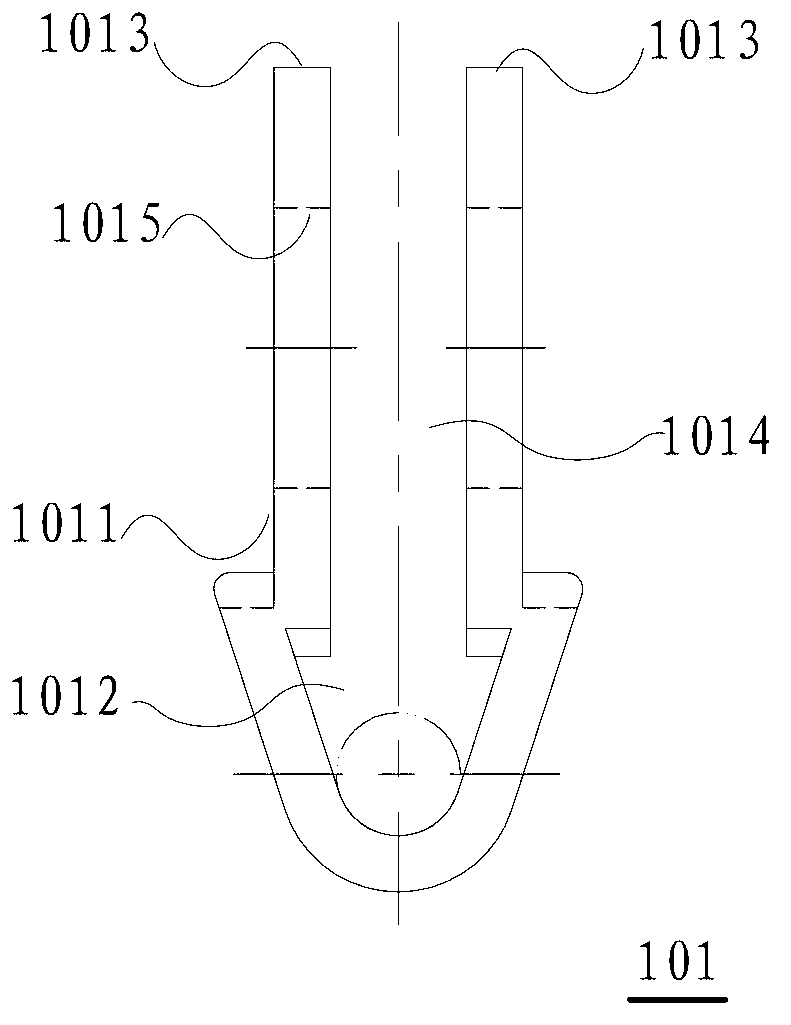

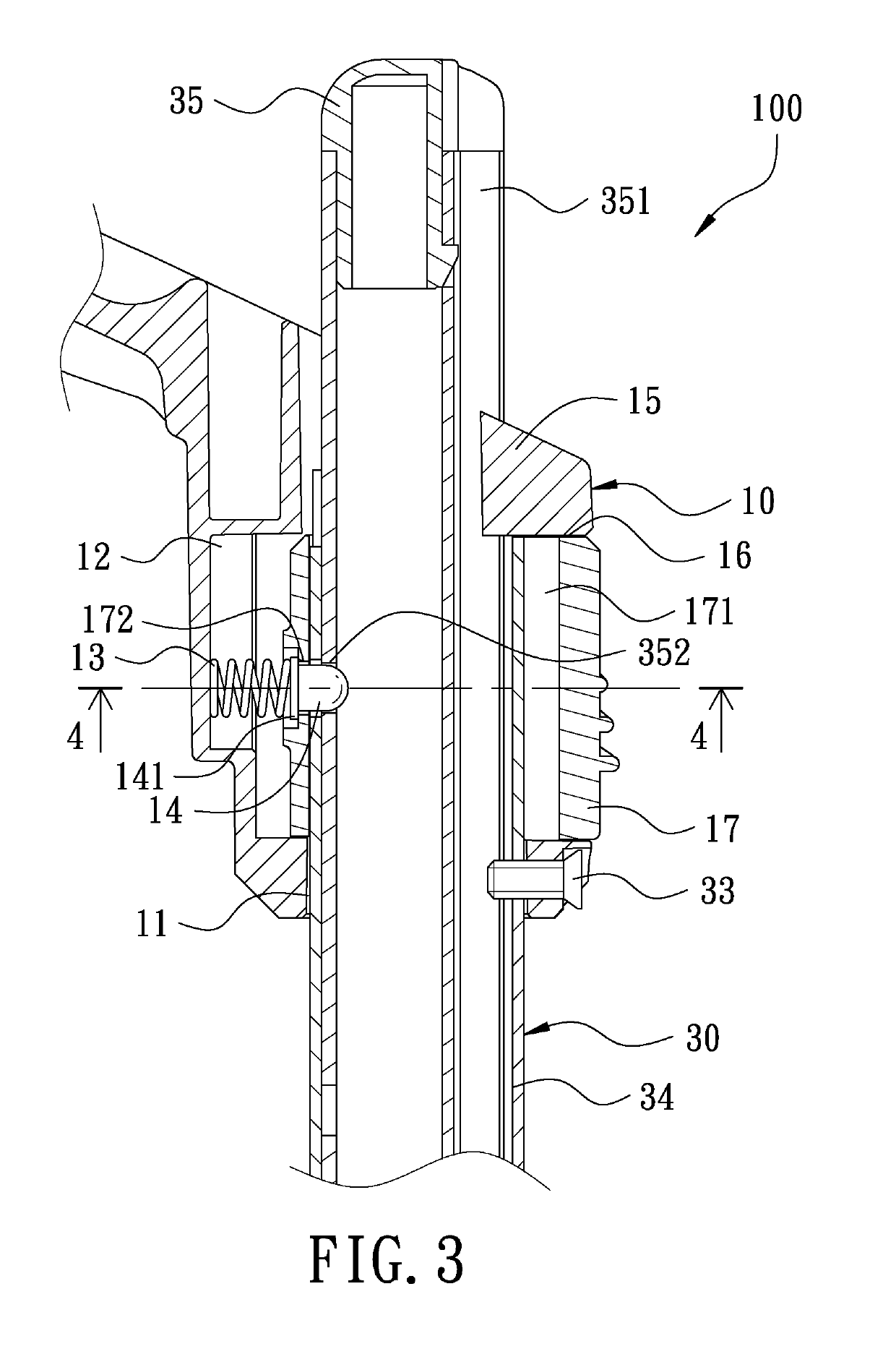

Energy absorption device for multi-section vehicles

ActiveCN101553390AIncrease tensionReduce irregularitiesBuffer carsBufferEnergy absorptionEngineering

The invention relates to an energy absorption device (100) for multi-section vehicles, in particular rail vehicles, with a first front plate (10), a second front plate (20), and an energy absorption element (30) which is in the form of a hollow body extending in the longitudinal direction (L) of the energy absorption device (100) and which is arranged between the first and the second front plates(10, 20). For the predetermination of the fold-formation of the energy absorption element (30) when the energy absorption device (100) responds, the energy absorption element (30) has a response trigger in the shape of a folding or buckling area (33, 33') which extends in the direction of rotation at least partly around the circumference of the hollow body. In order for the energy absorption device (100) to be used not only for the transfer of compression forces but also for the transfer of tensile forces, the invention provides for the energy absorption device (100) to have at least one tensile force-transferring element (31) which connects the first front plate (10) to the second front plate (20) and which is designed to transfer tensile forces in the longitudinal direction (L) of the energy absorption device.

Owner:VOITH PATENT GMBH

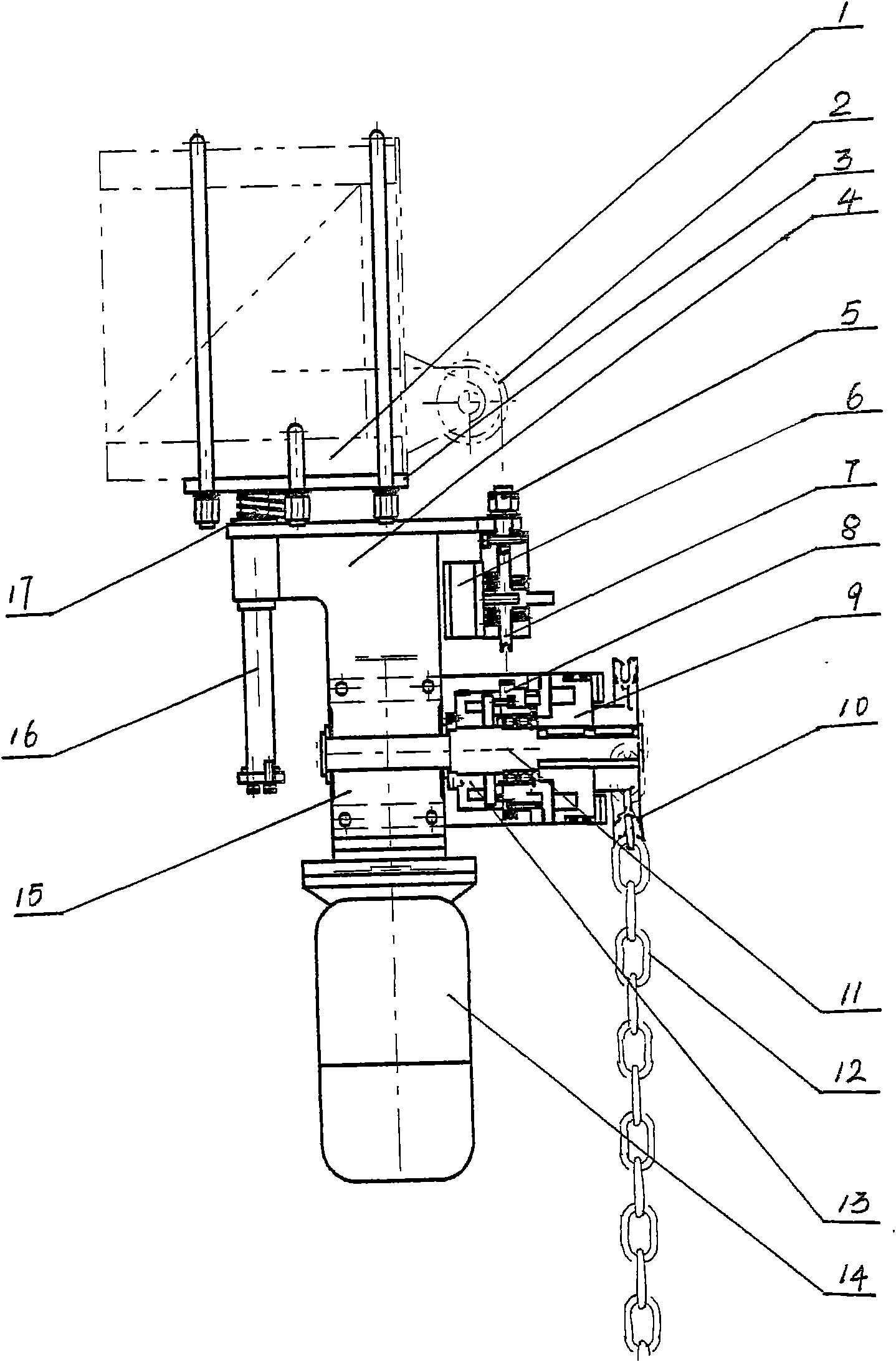

Rope clamping device and rope tightening device for vehicle connection

ActiveCN102797792AIncrease tensionReduce wearRopes and cables for vehicles/pulleyWinding mechanismsSafety coefficientEngineering

The invention provides a rope clamping device and a rope tightening device for vehicle connection. The rope clamping device comprises a rope locking assembly and a wedge-shaped block, wherein the upper part of the rope locking assembly is a connection part for connecting a tightening rope, and the lower part of the rope locking assembly is provided with a wedge-shaped rope hole through which a main rope passes; the wedge-shaped block is of a wedge-shaped strip structure, can penetrate into the wedge-shaped rope hole from a large-section end of the wedge-shaped block, and the wedge-shaped block can be pressed on the main rope penetrating through the wedge-shaped rope hole. In the practical application, the rope locking assembly and the wedge-shaped block of the rope clamping device can tightly fix the main rope on the rope clamping device by utilizing a wedge-shaped clamping principle, and the contact area of the rope clamping device and the main rope is larger so that the tension degree of the main rope can be improved; in addition, the abrasion of the main rope can be reduced, the strength of the rope clamping device is high and the rope clamping device is not easy to break, thereby further improving the safety coefficient.

Owner:HUAINAN MINING IND GRP

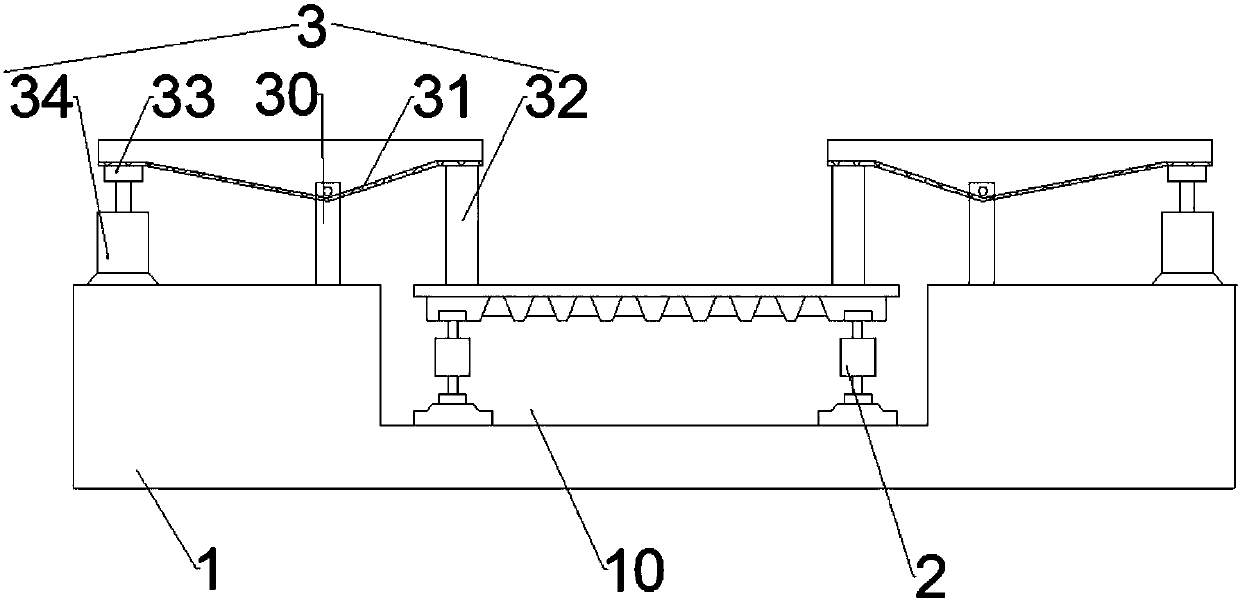

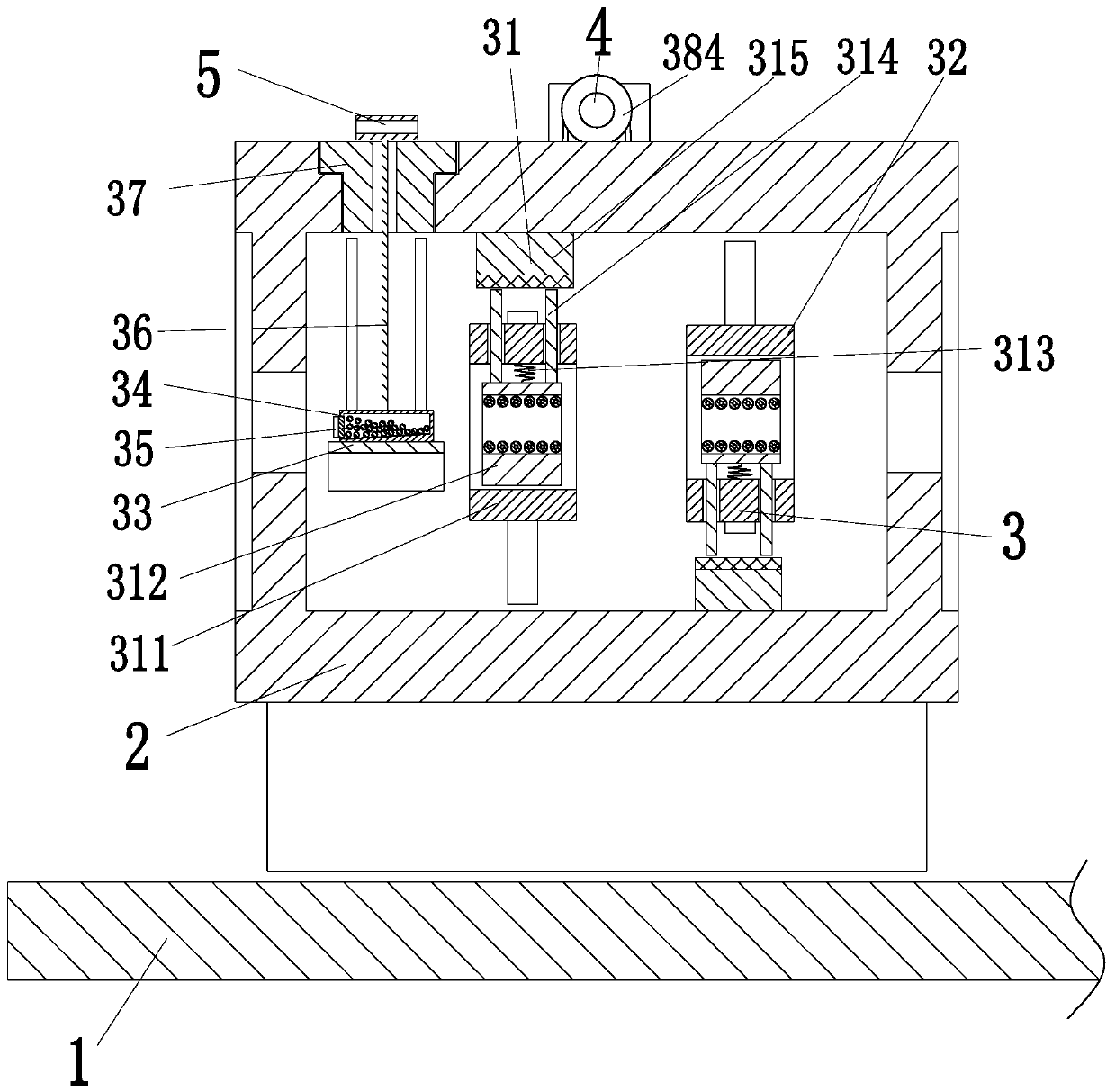

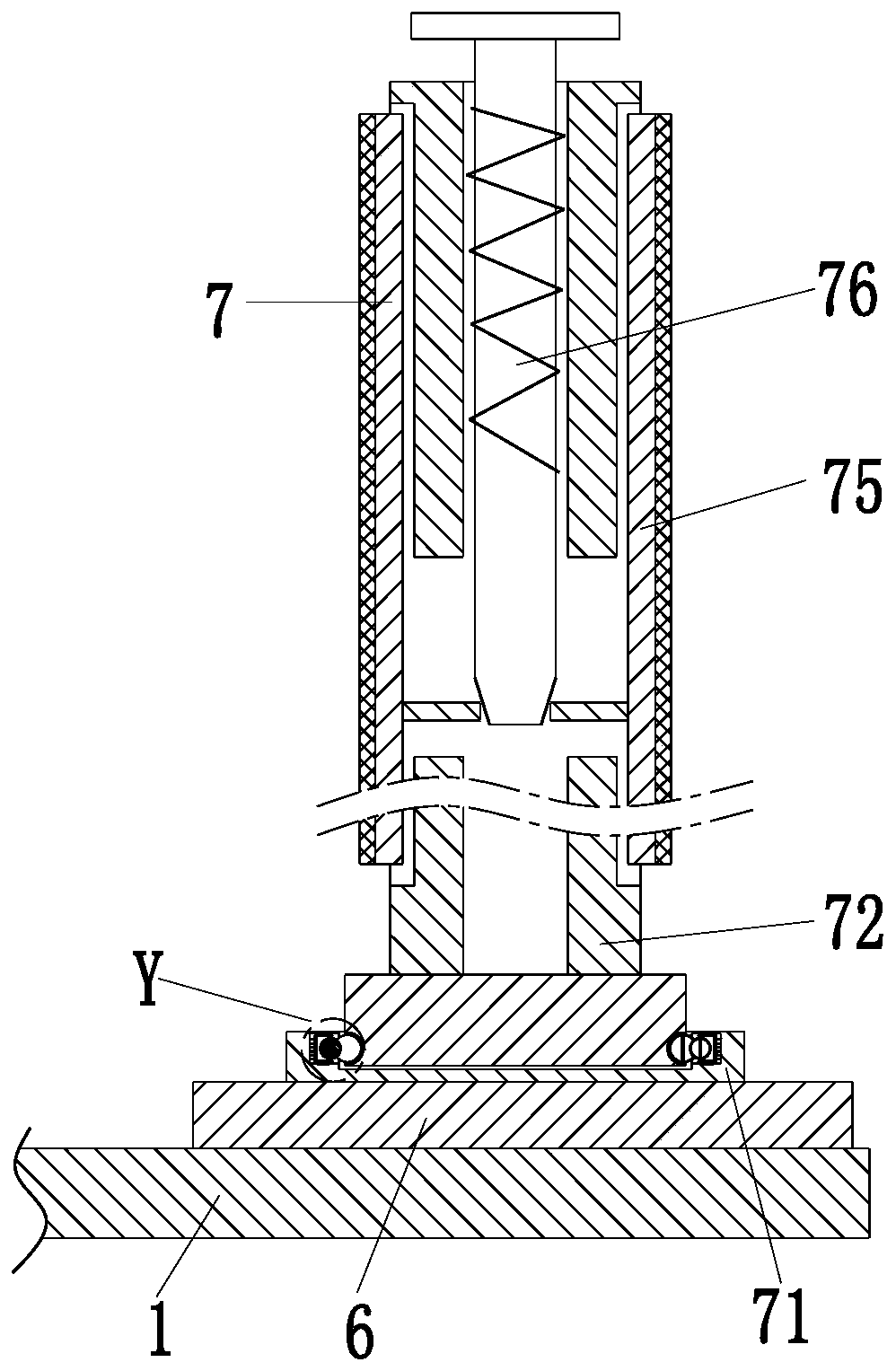

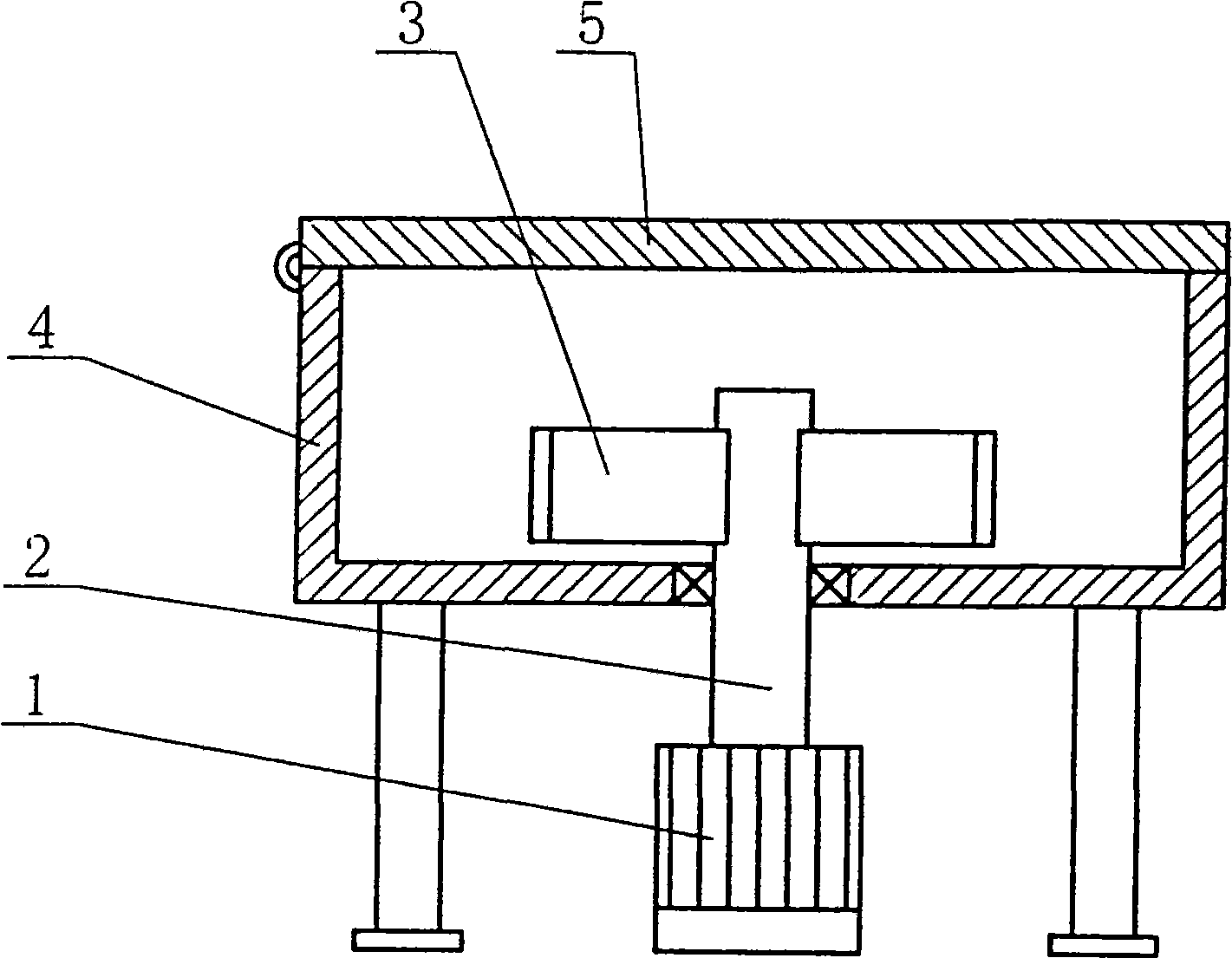

Weighing apparatus intelligent calibrator

InactiveCN107941317AImprove accuracyExtended service lifeWeighing apparatus testing/calibrationHydraulic cylinderCalibration result

The invention discloses a weighing apparatus intelligent calibrator which includes a base, a pit on the base for holding a weighing apparatus, and a calibration unit on the top of the base. The calibration unit includes a support column vertical to the top of the base, a lever hinged to the top of the support column, a vertically downward force-transferring column fixedly connected to the end of the lever close to the weighing apparatus, and a pressure sensor fixedly and horizontally disposed at the bottom of the other end of the lever. A hydraulic cylinder is disposed right under the other end of the lever when the lever is arranged horizontally. The distance from the hinge joint of the support column and the lever to the pressure sensor is greater than the distance from the hinge joint of the support column and the lever to the force-transferring column. The weighing apparatus intelligent calibrator applies force to the weighing apparatus from the outside, solves a problem that a traditional calibrator is directly pressed on the weighing apparatus and affects the accuracy of a calibration result, achieves a purpose of accomplishing a great task with little effort by using the unequal-arm level, reduces the bearing capacity of the pressure sensor of the calibrator, and is prolonged in the service life. Further, the bottom of the level is designed to be in a latticed shape suchthat the tension and pressure of the lever is increased.

Owner:覃世宁

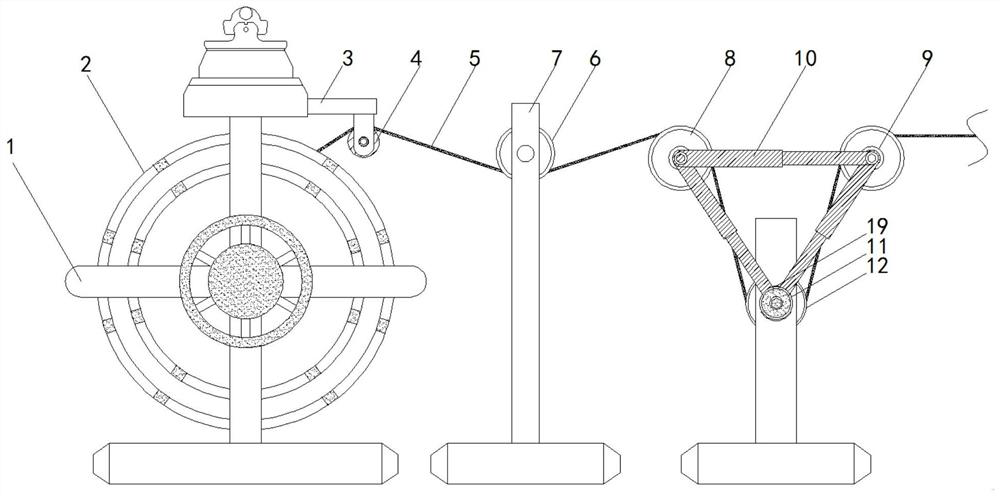

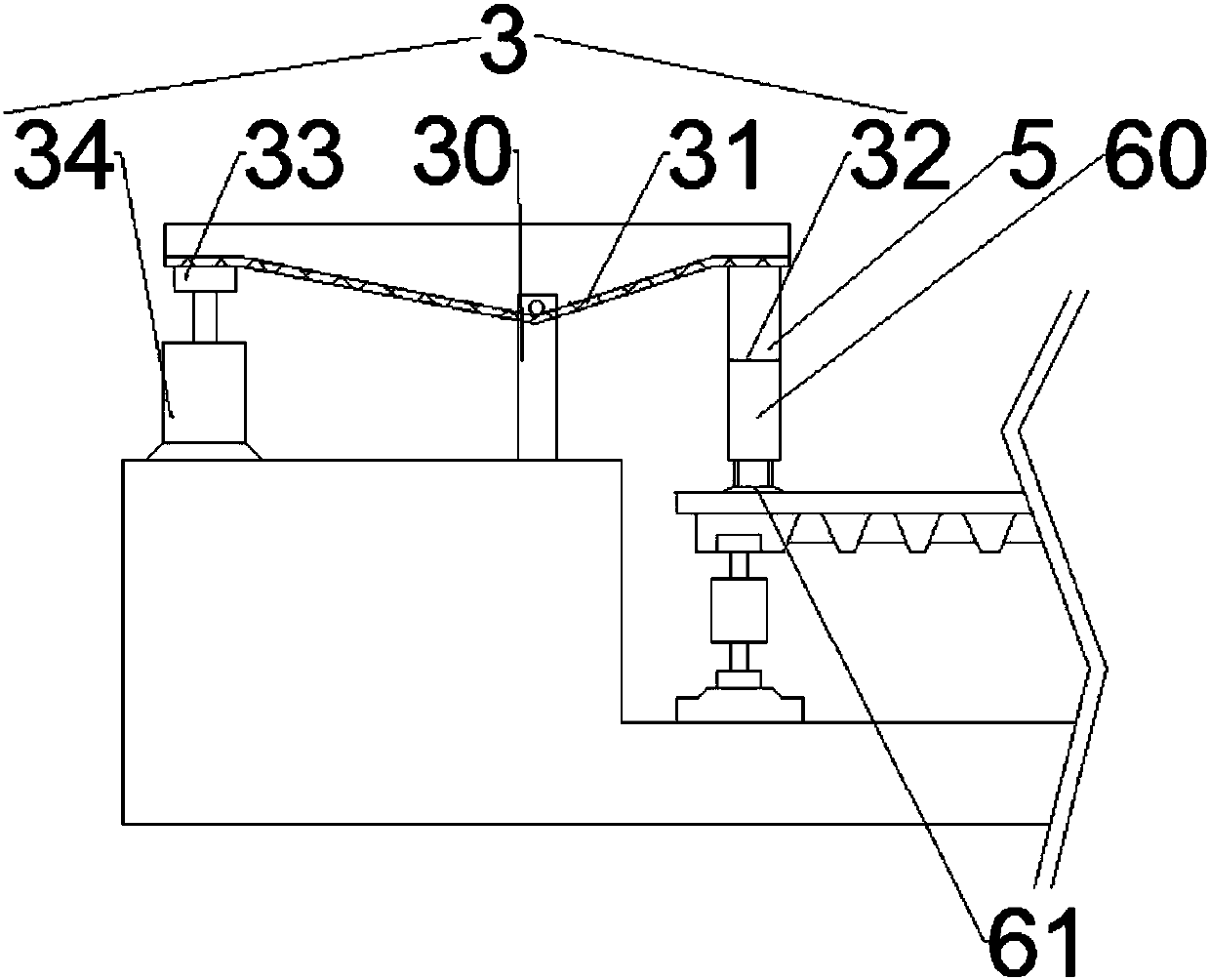

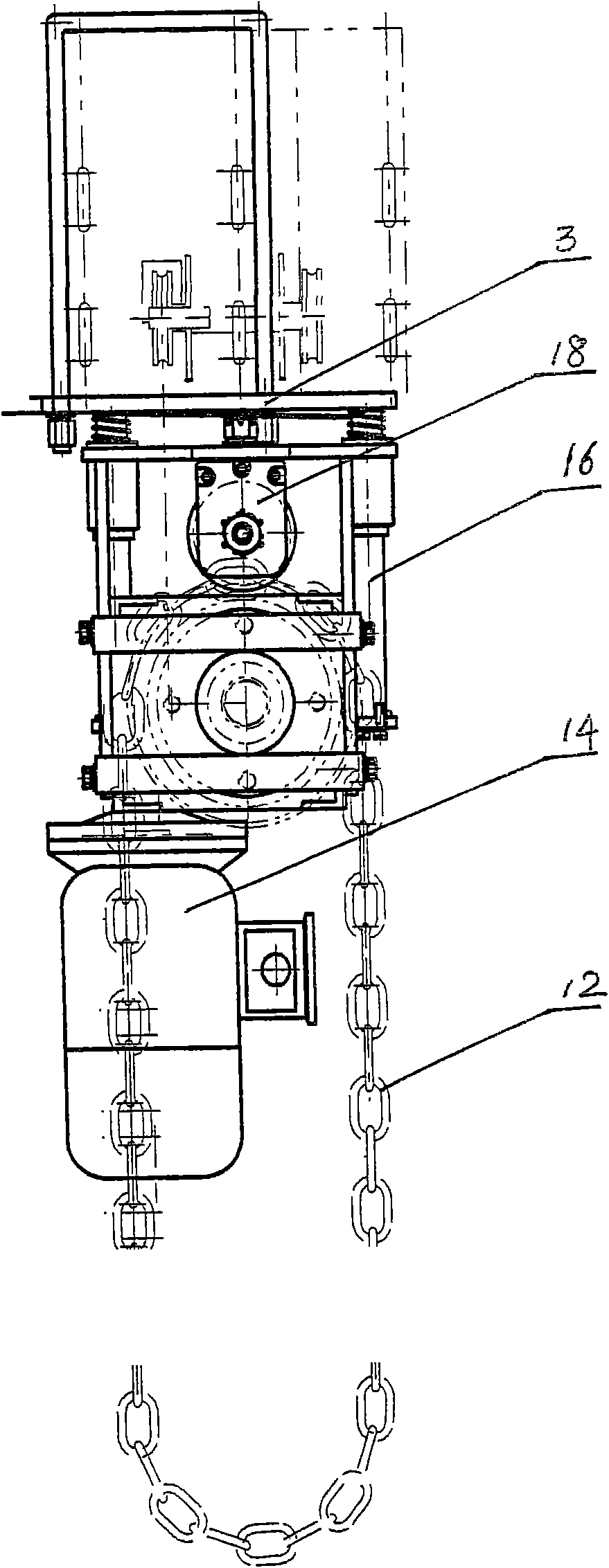

Multifunctional hoisting bisecting stage act curtain towing mechanism

The invention relates to a multifunctional hoisting bisecting stage act curtain towing mechanism comprising a support body, a motor, a speed reducer and a towing wheel. The motor and the speed reducer are fixedly mounted on the support body, and the motor drives the towing wheel to rotate by the speed reducer; an output shaft of the speed reducer is horizontally arranged, and the vertical towing wheel is rotatably mounted on the output shaft; a driven fluted disc clutched by gaining electrons and another driven fluted disc clutched by losing electrons are respectively coaxially fixedly mounted at both sides of the towing wheel, a driving fluted disc clutched by gaining electrons and the output shaft of the speed reducer are fixedly mounted, and a driving fluted disc clutched by losing electrons and a chain wheel which is rotatably mounted at the output shaft end are fixedly mounted. The invention has the advantages of compact structure and smart design, can be mounted at one end of an act curtain guide rail support, not only saves stage floor area, but also can simultaneously take effect along with a hoisting mechanism to realize the variety of the towing mechanism, can realize the automatic and manual control functions, the automatic tightening function of wire ropes and the high-precision position signal collection and control functions, thereby being the stage act curtain towing mechanism with higher novelty.

Owner:马超

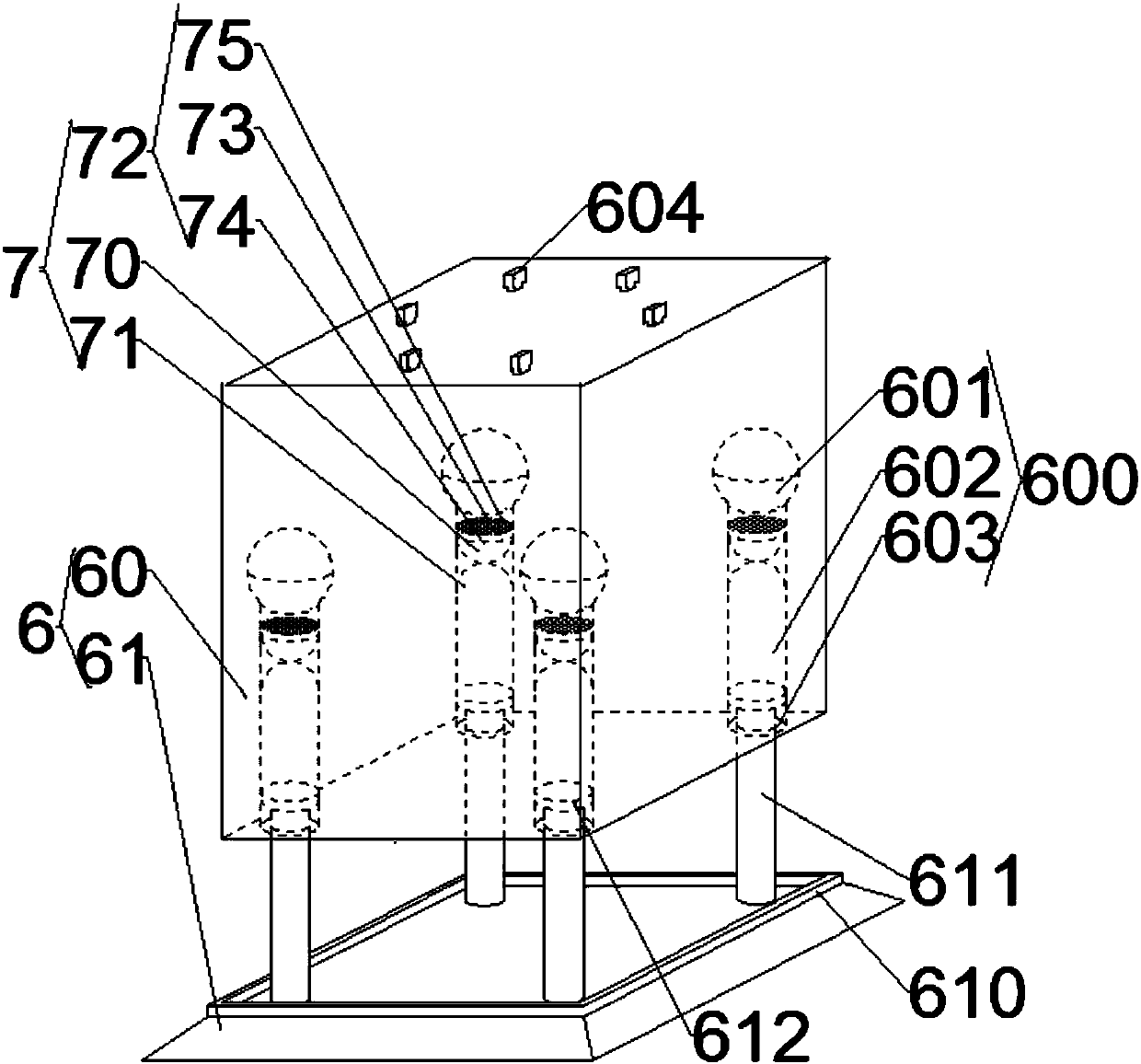

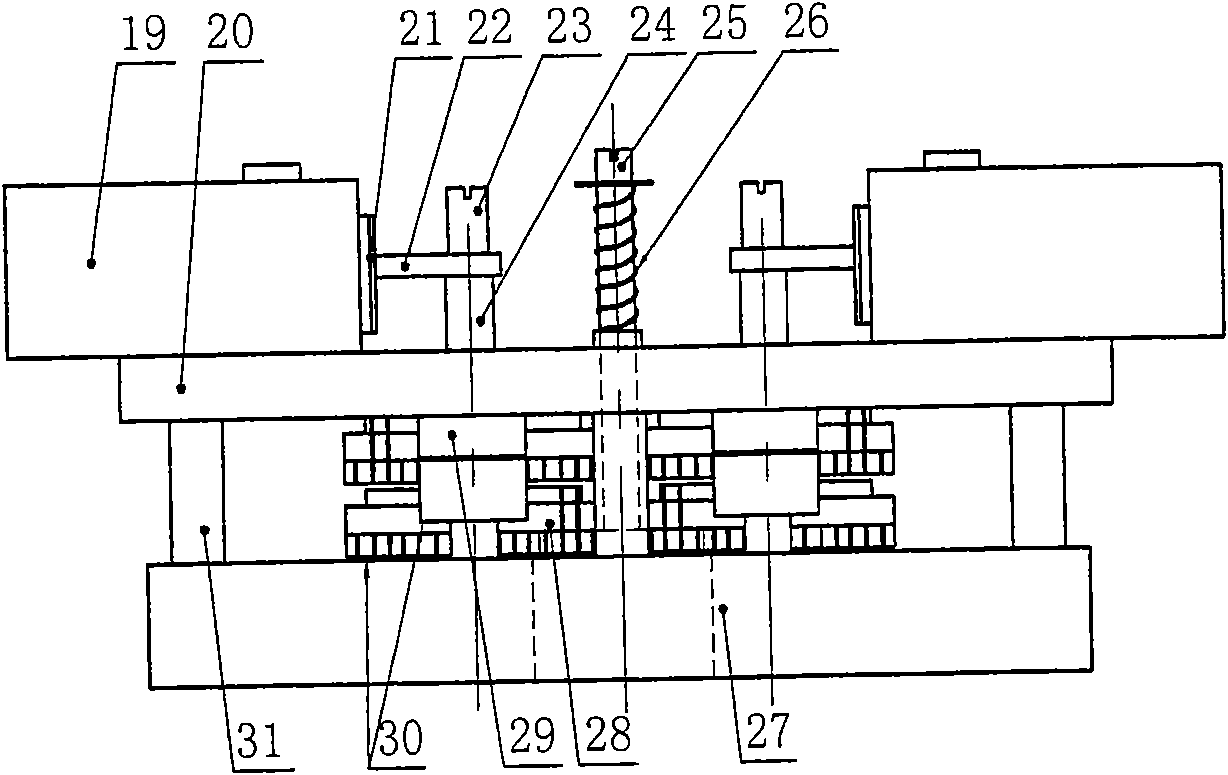

Yarn spinning tensioning device

The invention relates to a yarn spinning tensioning device. The yarn spinning tensioning device comprises a detachable bottom plate, a mounting frame, tensioning units, a positioning rotating shaft, alinkage rod, a mounting plate and sleeves, wherein the mounting frame is mounted at the front end of the detachable bottom plate, the tensioning units are evenly arranged in the mounting frame, the upper ends of the tensioning units are connected with the positioning rotating shaft, the positioning rotating shaft is mounted at the upper end of the mounting frame through a bearing, the linkage rodis arranged in front of the positioning rotating shaft, the mounting plate is mounted at the rear end of the detachable bottom plate, and the sleeves are evenly arranged on the mounting plate. The problem that yarns can drive yarn bobbins to synchronously rotate at high speed after being drawn, when the drawing force suffered by the yarns disappears, the yarn bobbins still rotate for a while under the action of inertia, then the unwound yarns are not in a tensioned state at the moment, and the untightened yarns are prone to knotting after being subjected to secondary drawing force is solved.

Owner:安徽金弘润新材料科技有限公司

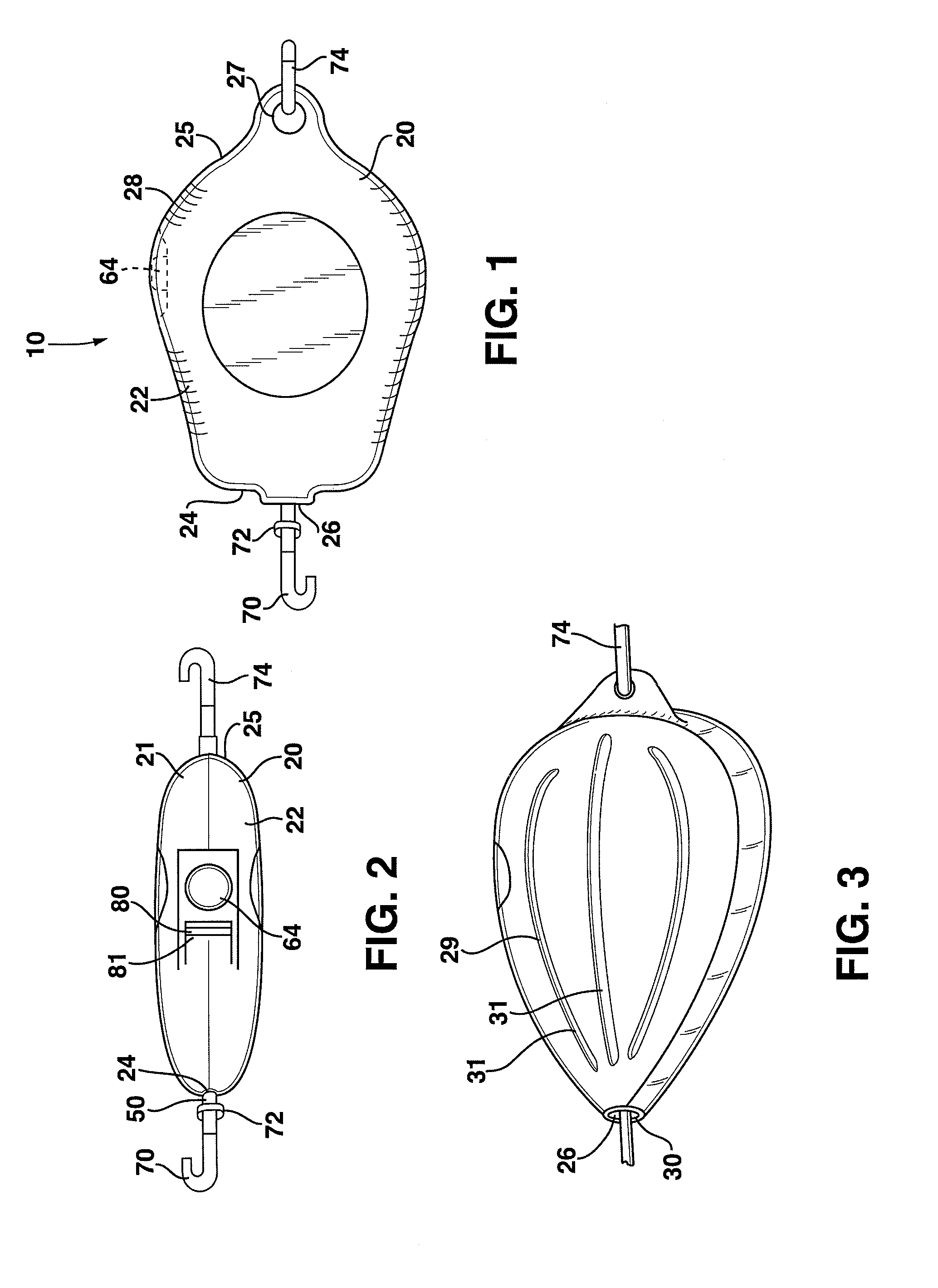

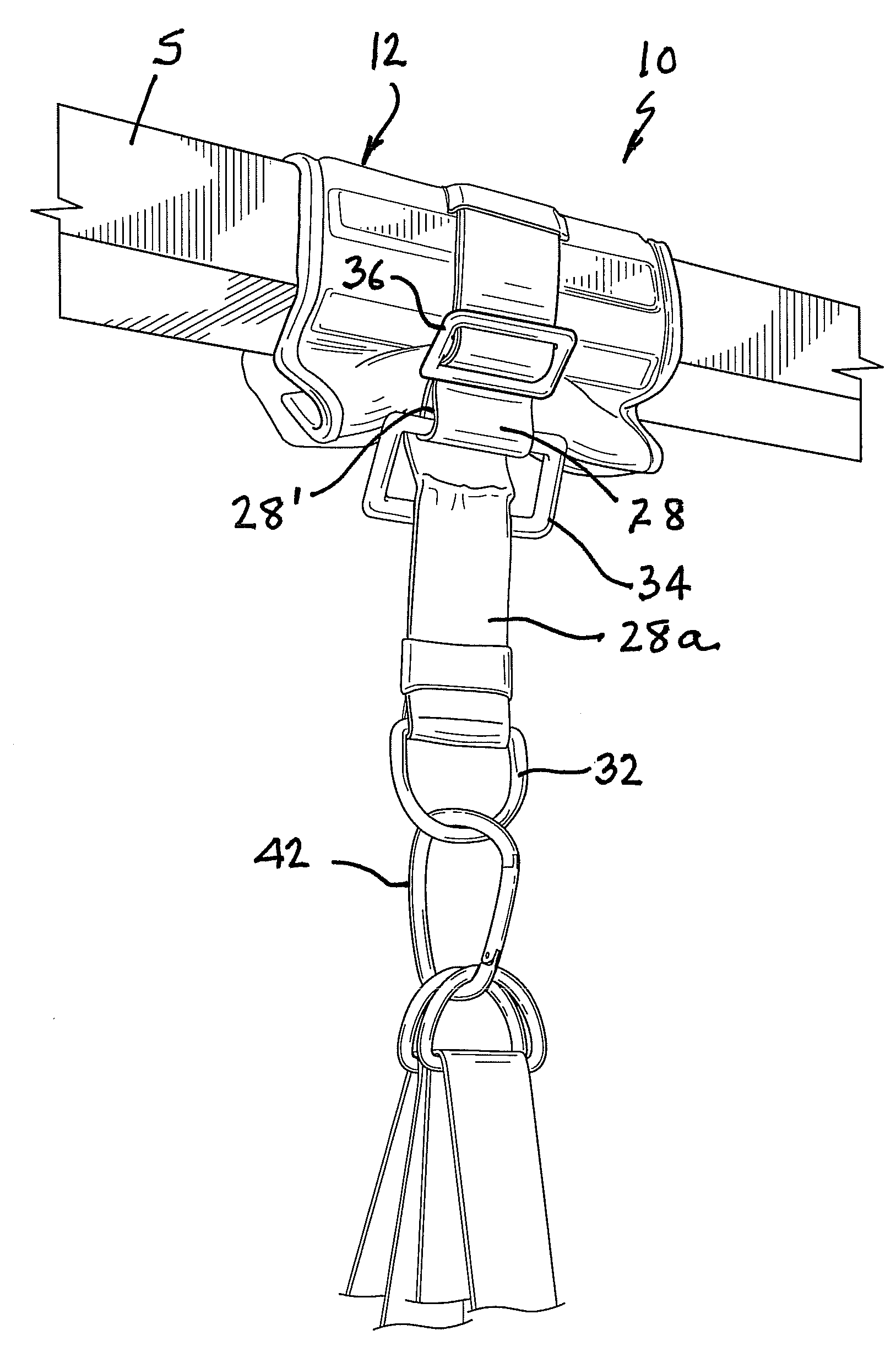

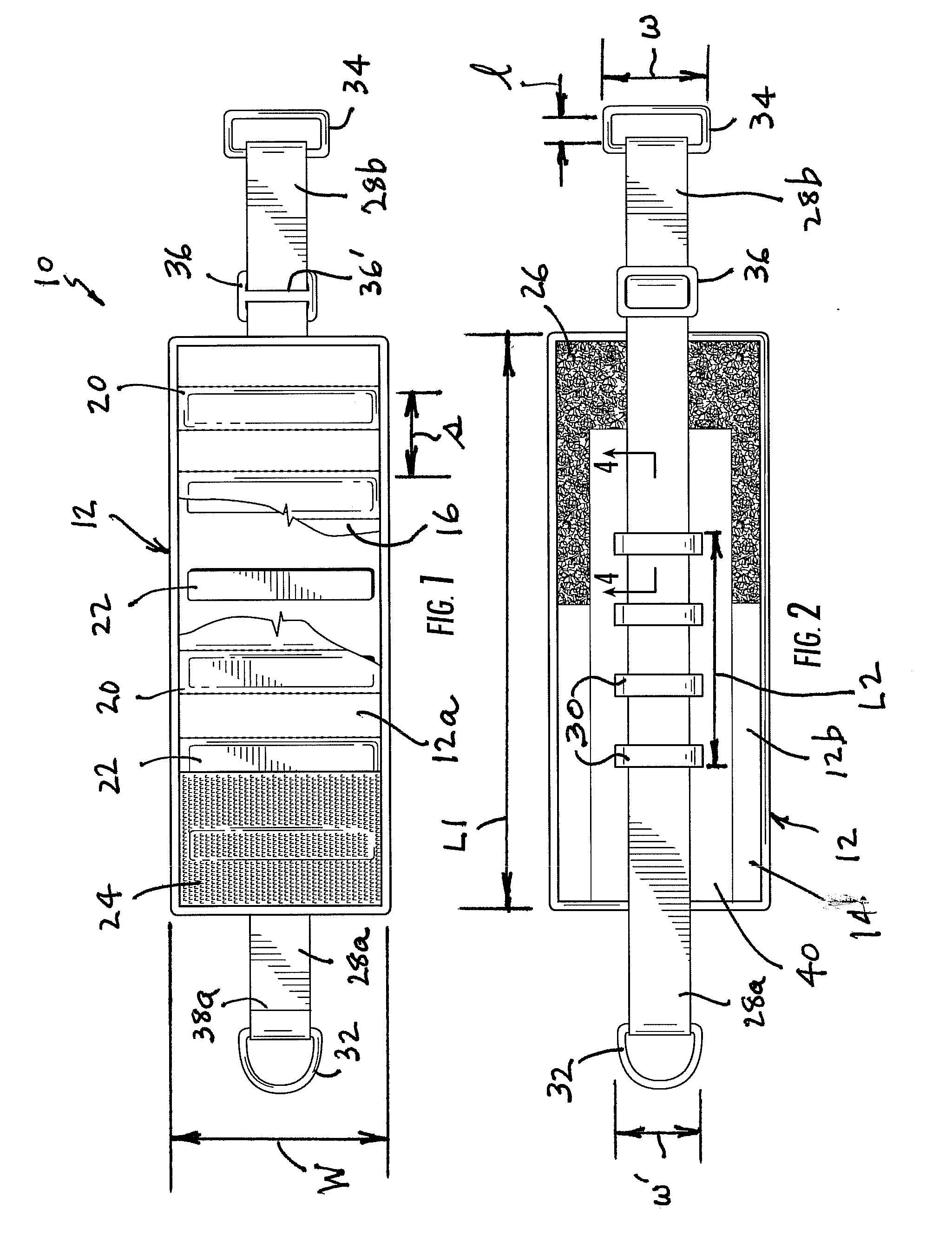

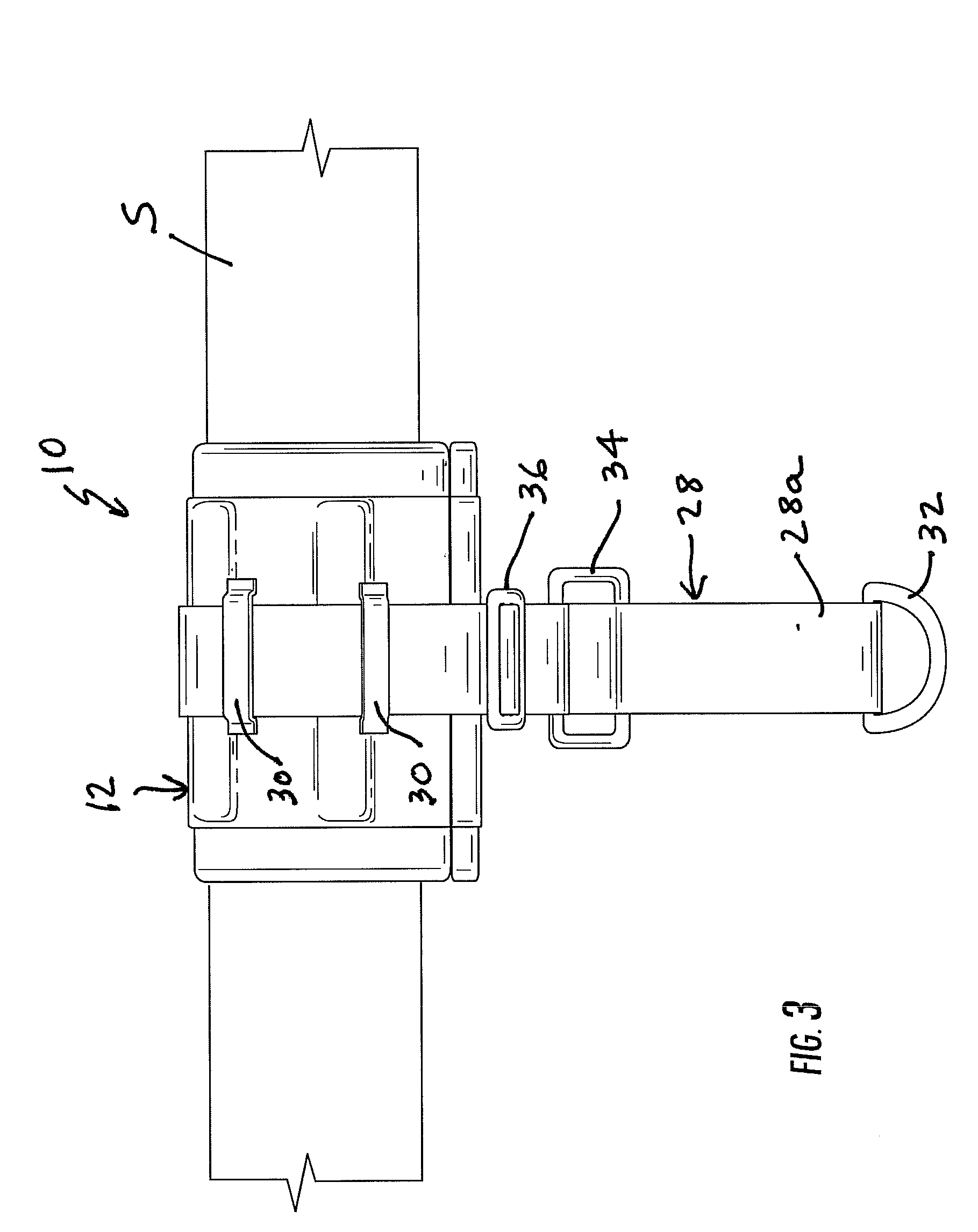

Universal heavy bag hanger

ActiveUS20120091294A1Increase tensionIncreased frictional forceTravelling sacksTravelling carriersMechanical engineeringEngineering

The universal heavy bag hanger is used to secure a heavy bag to an overhead horizontal support member. The bag hanger includes a flat pad that has a length along a length direction to wrap around a support member. The pad includes a slip resistant material that engages the support member when mounted thereon. A strap is secured to the outside surface and extends beyond the longitudinal ends of the flat pad. A D-shaped ring is attached to one free end of the strap suitable for attachment to a heavy bag or the like. The other end of the strap is provided with a rectangular closed ring dimensioned to allow the D-shaped ring to pass through it to form a slip joint for tightening the strap about the pad, when increased load is applied to prevent or inhibit relative sliding movements between the hanger and the support member.

Owner:EVERLAST WORLDS BOXING HEADQUARTERS CORP

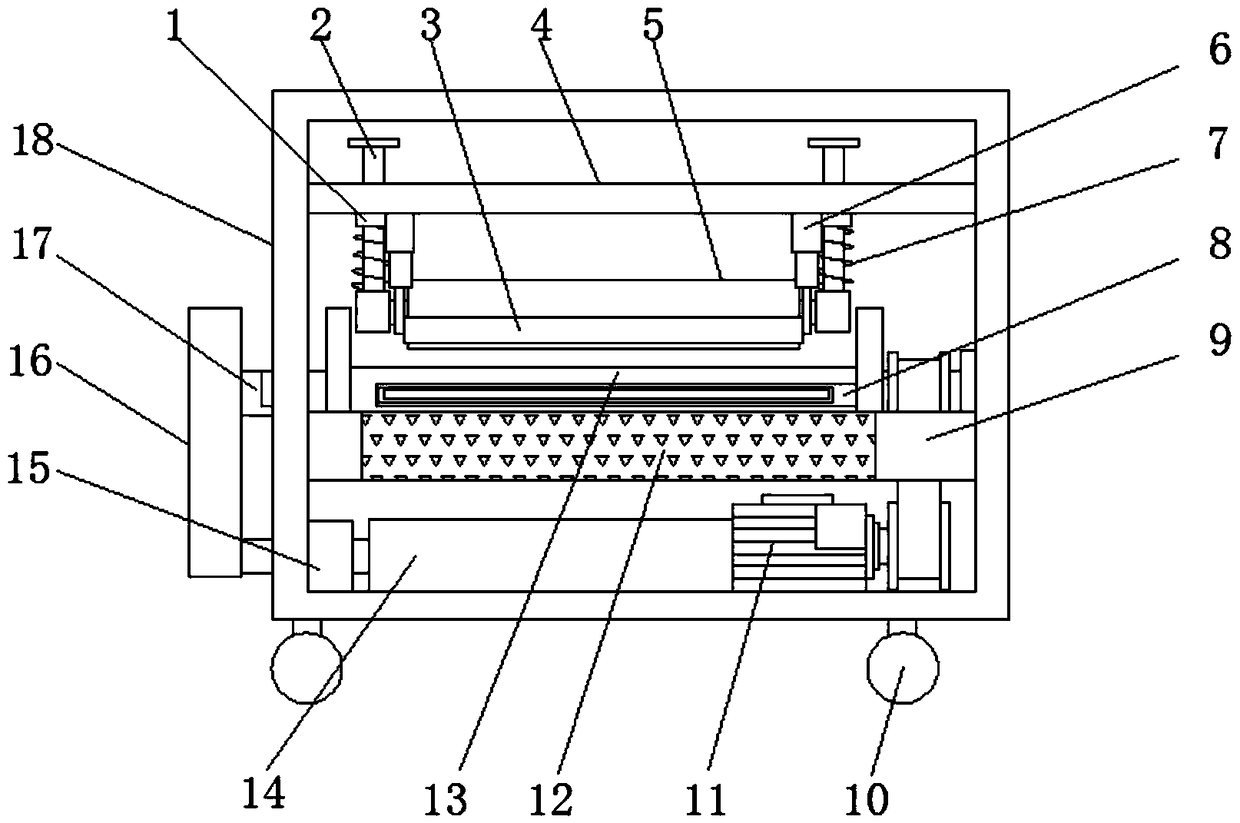

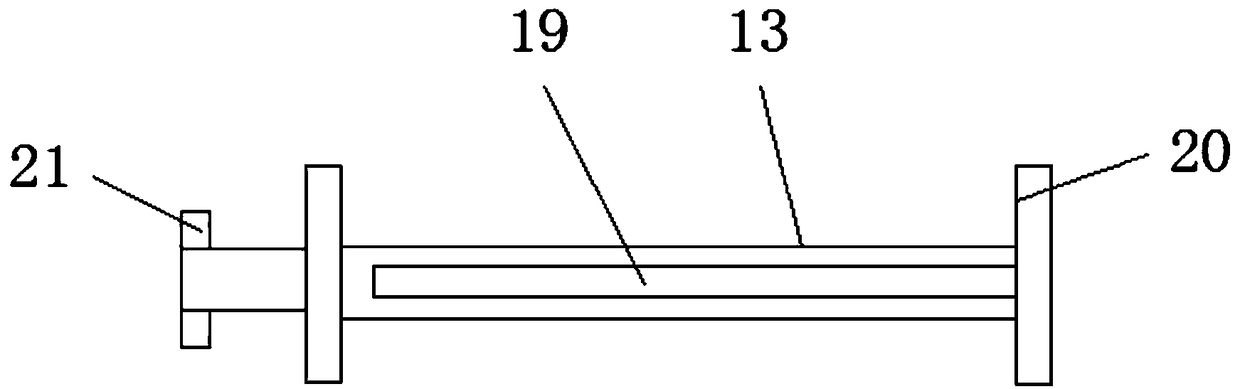

Textile fabric winding and cutting device

The invention discloses a textile fabric winding and cutting device. The device comprises a cutter, a pressing roller, a rotating shaft, a cloth rolling roller and a shell, the rotating shaft is arranged on one side of the middle position of the interior of the shell, two stop blocks are arranged on the outer side wall of the rotating shaft, the cloth rolling roller is connected to the outer sideof the rotating shaft in a sleeved mode, a fixture block is fixed arranged at one end of the cloth rolling roller, a limiting groove matched with the stop blocks is arranged on the cloth rolling roller, a first electric telescopic rod is arranged at the bottom end of the interior of the shell below the cloth rolling roller, the output end of the first electric telescopic rod is fixedly provided with a connecting plate, and a fixture seat matched with the fixture block is fixedly arranged on the inner side wall of the connecting plate. According to the device, the pressing roller is arranged above the cloth rolling roller, pressure sensors are installed at the position, connected with the fixing plate, of springs on the pressing roller, the tension can be increased when the textile fabric is wound, and the winding effect of the textile fabric can be improved, so that detection of the condition whether the textile fabric is wound completely around the cloth rolling roller can be facilitated.

Owner:JIANGSU BEILIN TEXTILE CO LTD

High-elasticity thermal insulation cotton and method for producing same

The invention discloses high-elasticity thermal insulation cotton and a method for producing the same. The cotton is prepared by mixing the following raw materials in percentage by weight: 75 to 85 percent of terylene fiber and 15 to 25 percent of low-melting point complex fiber, wherein the titer of the terylene fiber is between 0.6 and 2.75D. The method comprises the following steps that: the two raw materials are put in cotton mixing equipment for even mixing; the mixed raw materials are combed into a planar flake fiber web by a combing machine; the planar flake fiber is paved into a laminar fiber web by a web paving machine; the top surface and the bottom surface of the laminar fiber web are acupunctured by a needle loom to prepare a fiber blanket; the fiber blanket is put in an oven for thermal fusion, taken out and naturally cooled at an ambient temperature of between 10 and 30 DEG C, so that the high-elasticity thermal insulation cotton is obtained. The high-elasticity thermal insulation cotton produced by the method greatly improves the strength of the thermal insulation cotton; and under the condition of equal thickness, the strength of the high-elasticity thermal insulation cotton is 6 to 9 times higher than that of the prior thermal insulation cotton; moreover, the high-elasticity thermal insulation cotton is also excellent in elasticity, permeability and the like.

Owner:张延青

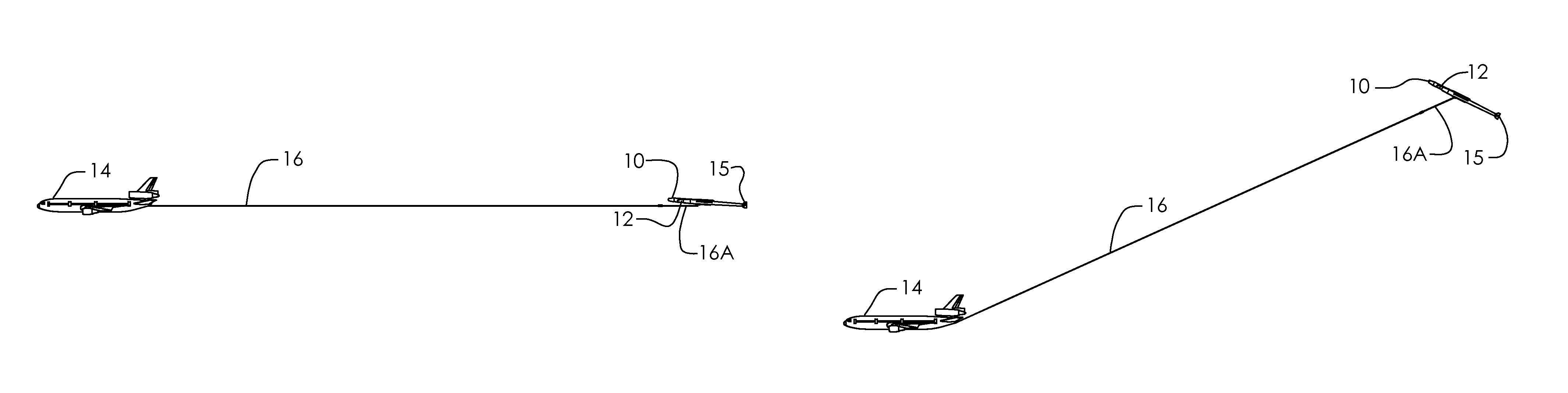

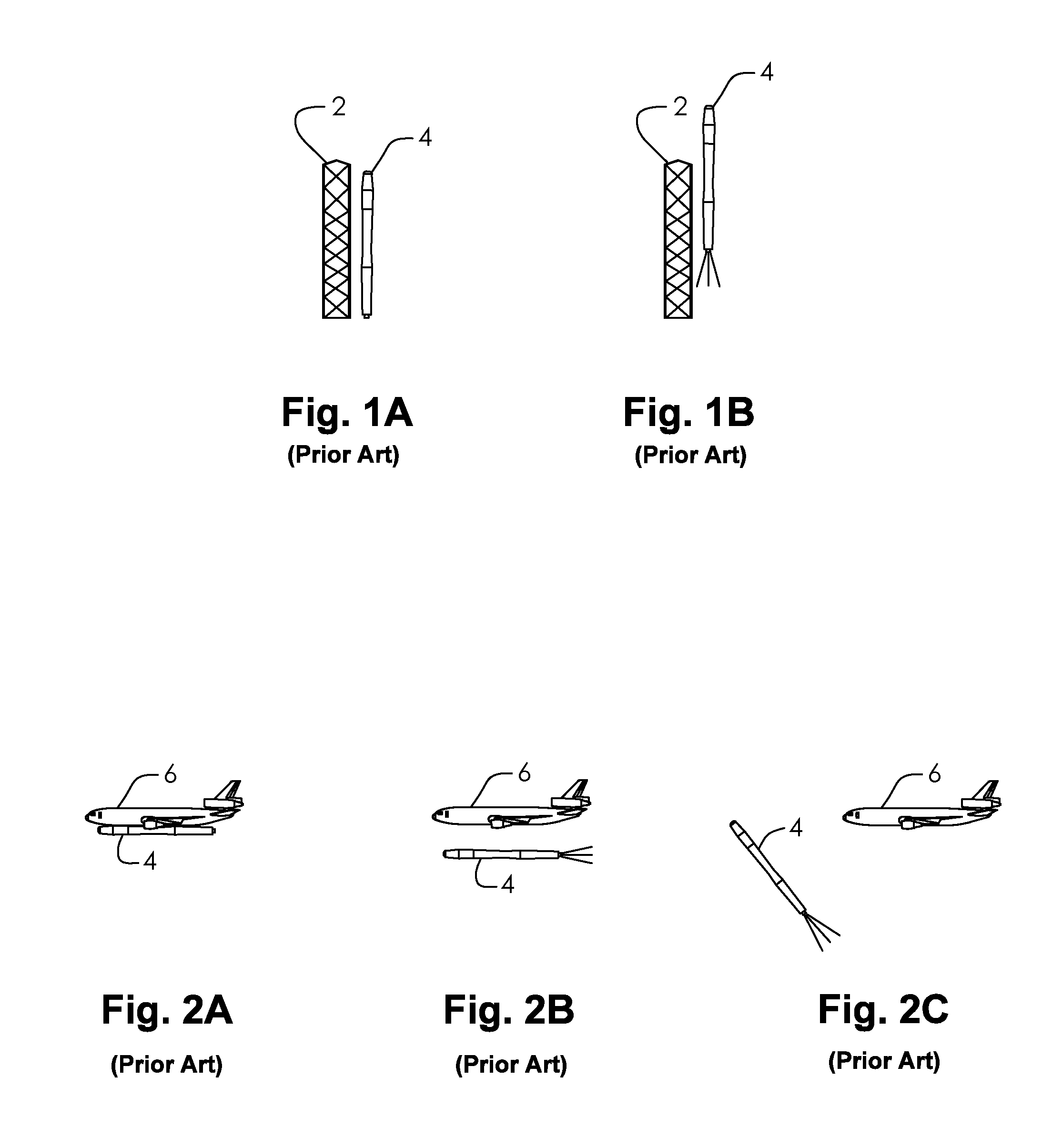

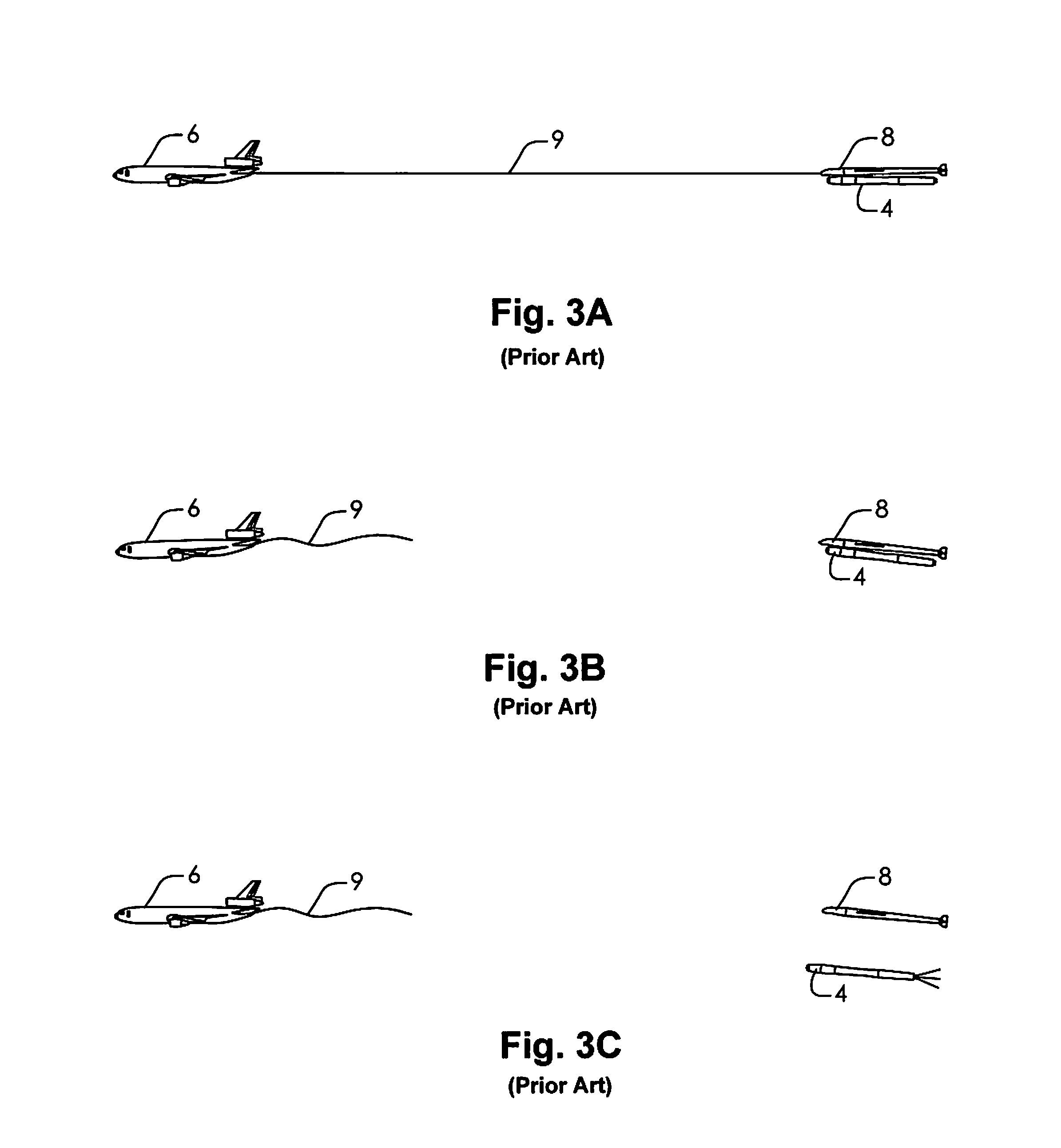

Dynamic tow maneuver orbital launch technique

InactiveUS8727264B1Increase tensionIncrease kinetic energyAircraft componentsConvertible aircraftsAirplanePotential energy

An orbital launch system and its method of operation use a maneuver to improve the launch condition of a booster rocket and payload. A towed launch aircraft, to which the booster rocket is mounted, is towed to a predetermined elevation and airspeed. The towed launch aircraft begins the maneuver by increasing its lift, thereby increasing the flight path angle, which increases the tension on the towline connecting the towed launch aircraft to a towing aircraft. The increased tension accelerates the towed launch aircraft and booster rocket, while decreasing the speed (and thus the kinetic energy) of the towing aircraft, while increasing kinetic energy of the towed launch aircraft and booster rocket by transferring energy from the towing aircraft. The potential energy of the towed launch aircraft and booster rocket is also increased, due to the increased lift. The booster rocket is released and ignited, completing the launch.

Owner:RUTAN ELBERT L

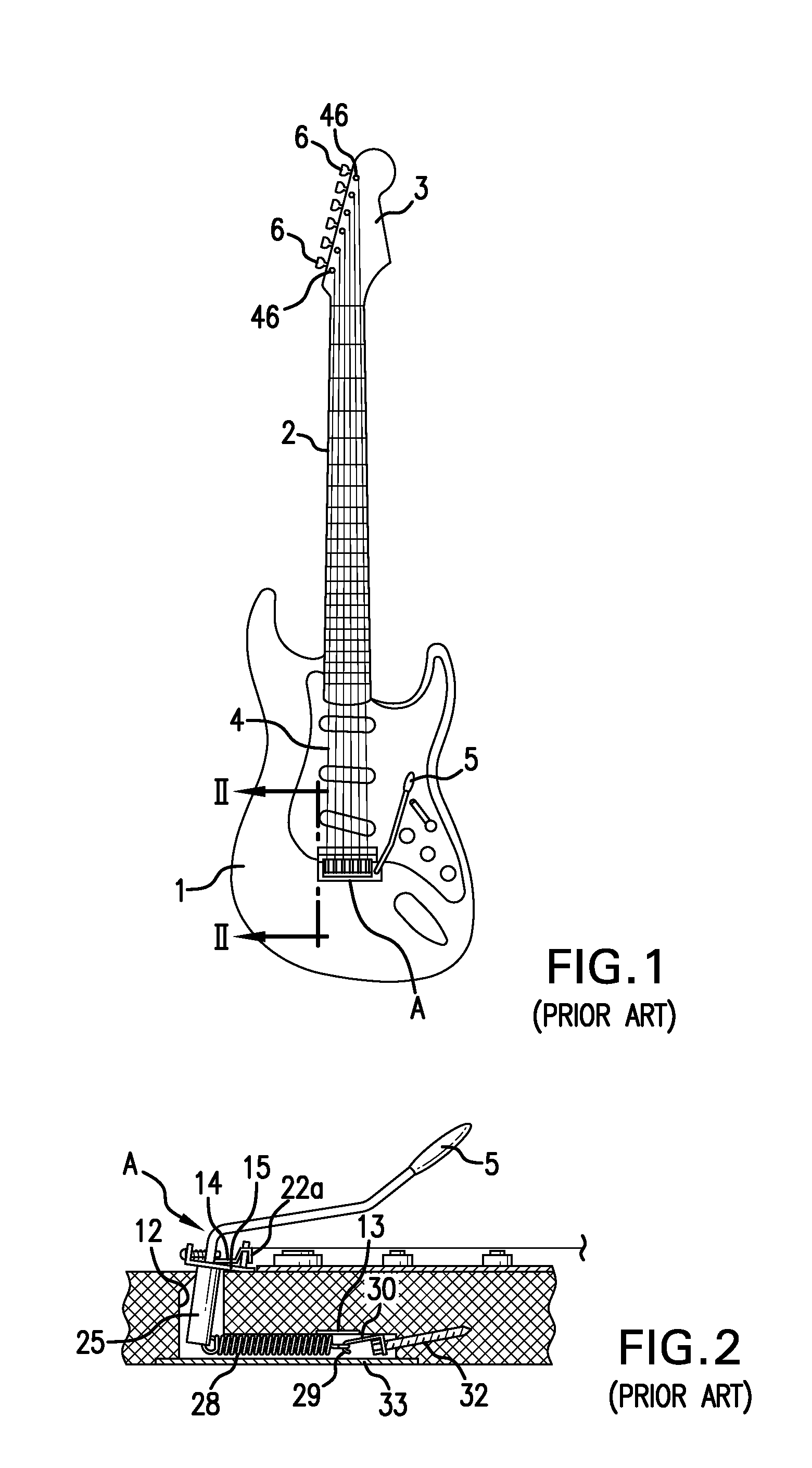

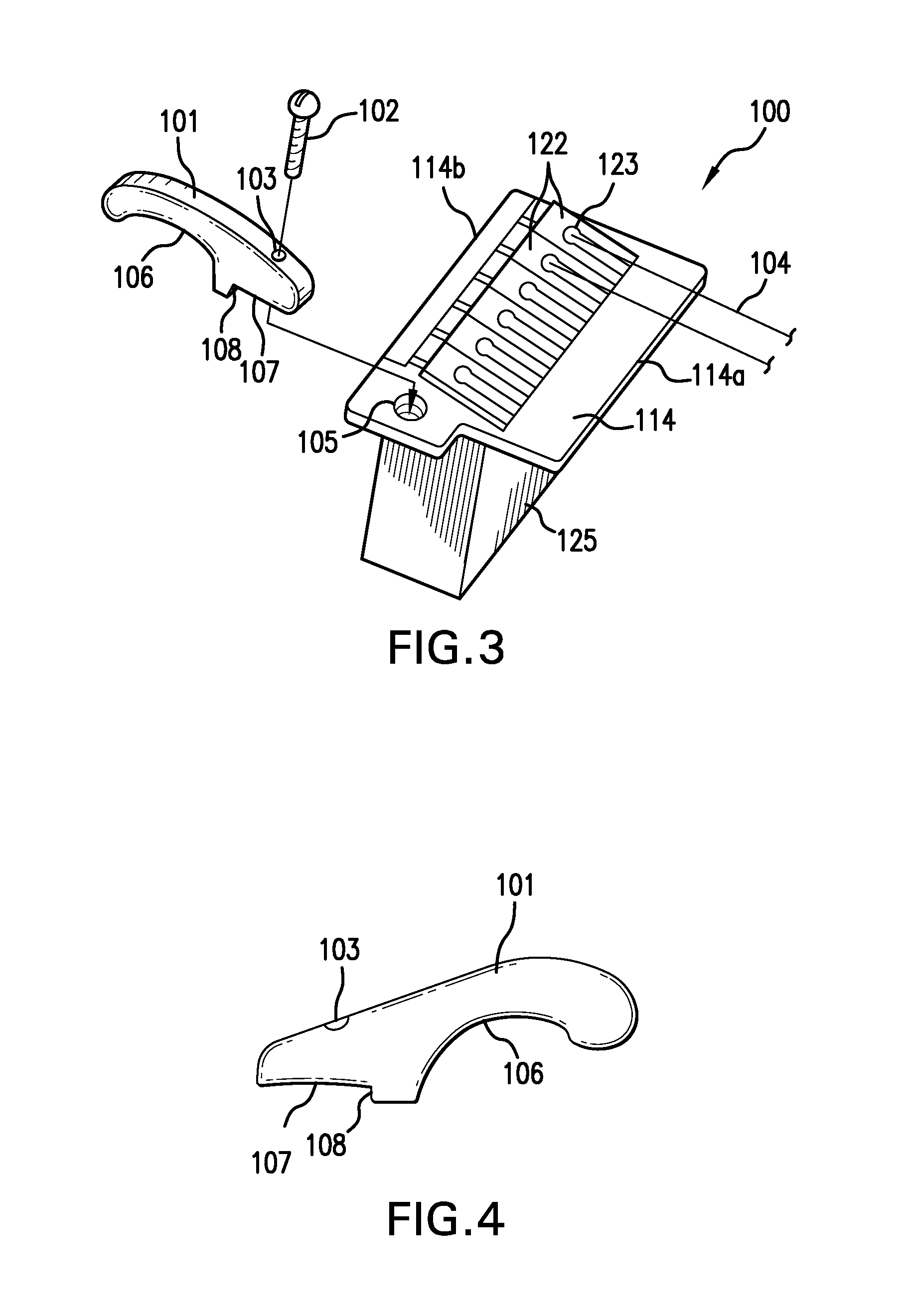

Tremolo structure for stringed instrument

InactiveUS20120152082A1Increase tensionDecrease tensionStringed musical instrumentsTremoloEngineering

A tremolo device for use on a musical instrument having a neck extending between a body and head, and a plurality of strings under tension aligned with the neck includes a bridge structure resiliently supportable relative to the body for rotation about a pivot axis transverse to the neck. String retaining elements of the bridge structure are movable therewith, each being dimensioned and arranged to engage a corresponding string. An actuating lever extends rearwardly from a point of attachment to the bridge structure to a point further from the neck and pivot axis than the point of attachment. Lifting of the actuating lever by an upward force exerted by a strumming or plucking finger reduces tension in the strings and lowers the tone of the musical element and exertion of a downward force upon the actuating lever increases tension in the strings and increases the tone of the musical instrument.

Owner:PARILLO MICHAEL A

Stretch film dispenser with lifting device

ActiveUS10479632B1Increase tensionContinuity of be extendWrapping material feeding apparatusFunction indicatorsEngineeringElectrical and Electronics engineering

A stretch film dispenser with a lifting device is disclosed. The lifting device includes a first operating unit. The first operating unit has a first through hole. The first through hole is provided with a first fixing member. The first operating unit further has a first opening. The first opening is provided with a first control member. The first operating unit is connected with an accommodating unit. The accommodating unit includes a telescopic rod therein. An outer peripheral wall of the telescopic rod is formed with a plurality of spaced first positioning holes corresponding to the first fixing member. The first fixing member is engaged in one of the plurality of first positioning holes for positioning the telescopic rod. Thereby, the telescopic adjustment of the telescopic rod is controlled by the first operating unit for articles of different heights, and the packing process is more smooth and convenient.

Owner:YU CHEN HSIU MAN

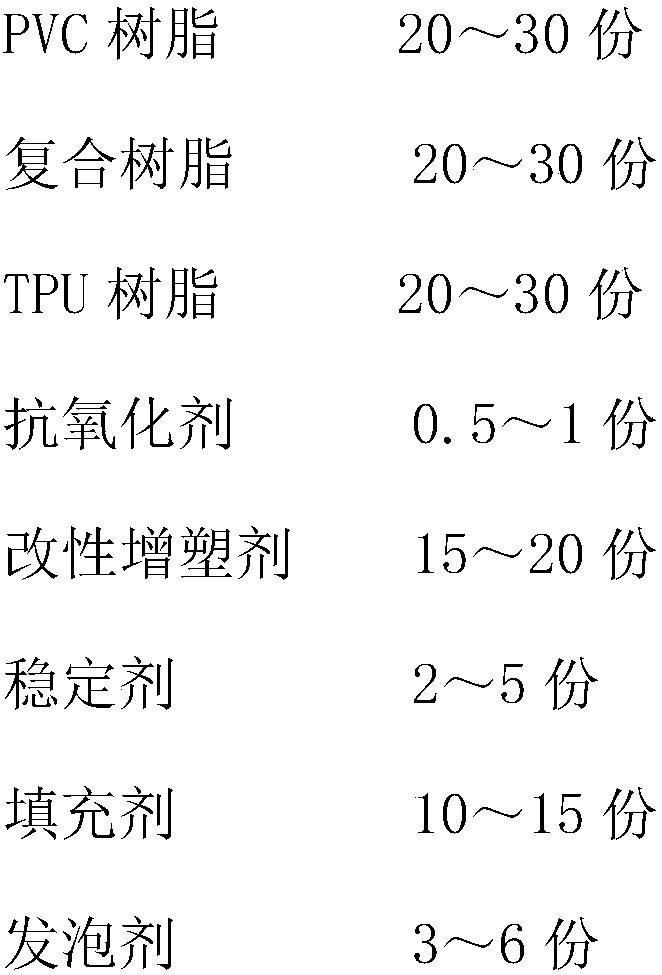

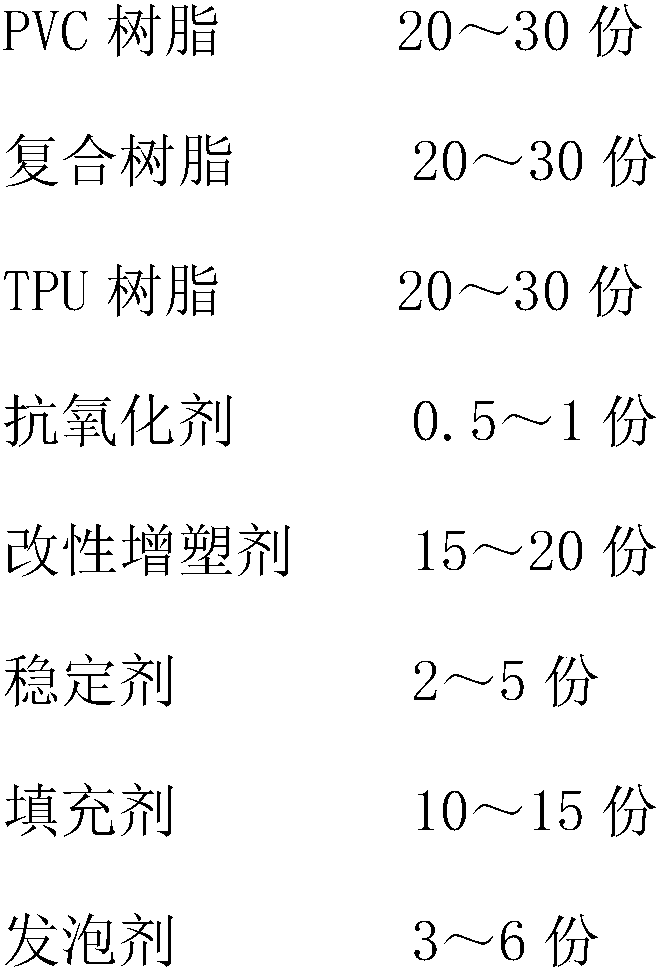

Wear-resistant PVC roll material and preparation method thereof

The invention discloses a wear-resistant PVC roll material comprising PVC resin, composite resin, TPU resin, an antioxidant, a modified plasticizer, a stabilizer, a filling agent and a foaming agent;the composite resin comprises modified ABS resin, inorganic nano-ceramic resin, vinylidene fluoride homopolymer resin, ultra-high molecular weight polyethylene resin and ethylene-vinyl acetate copolymer; and the modified plasticizer comprises the components according to the weight ratio: dioctyl phthalate, 2-ethylhexyl epoxystearate, dioctyl azelate, epoxybean oleic acid 2-ethylhexyl ester and ethylene butyl acrylate-glycidyl ester. The prepared wear-resistant PVC roll material has the effects of use convenience, high wear resistance and higher environment friendliness.

Owner:浙江金华天开电子材料有限公司

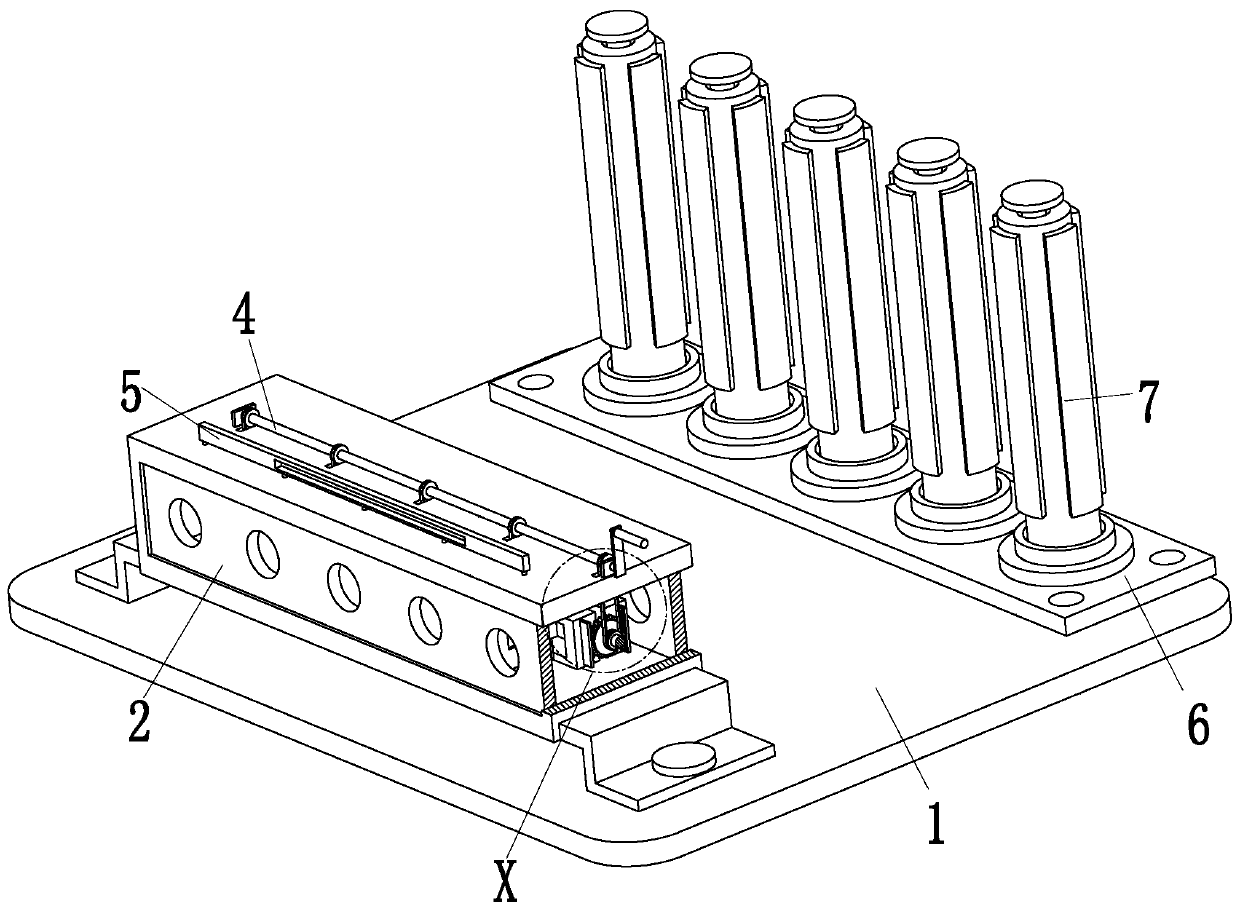

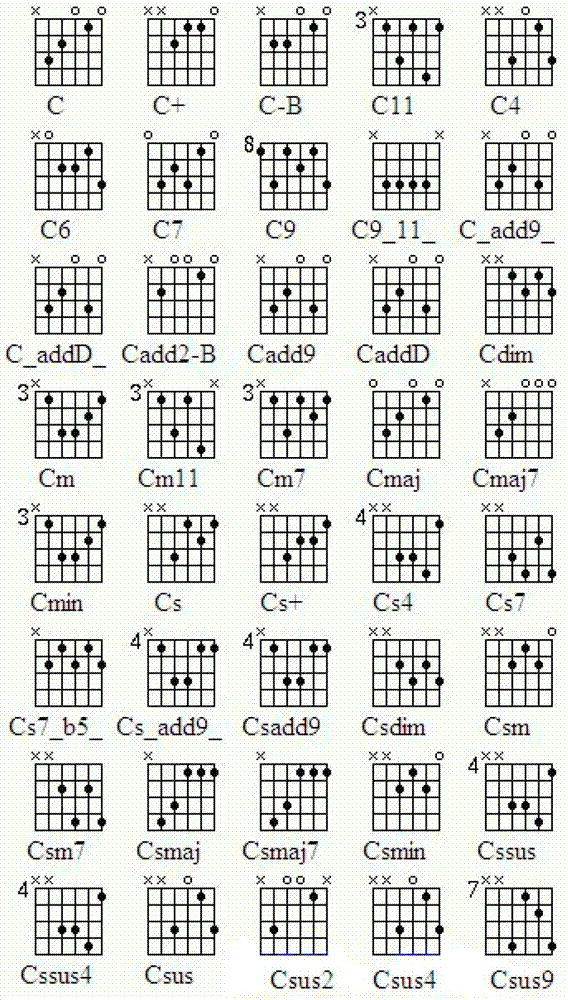

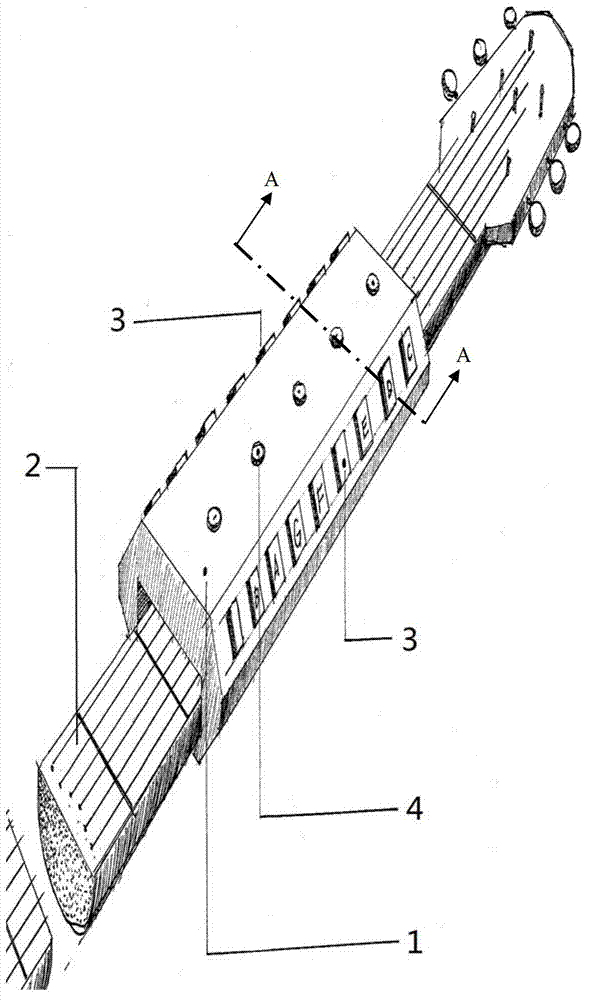

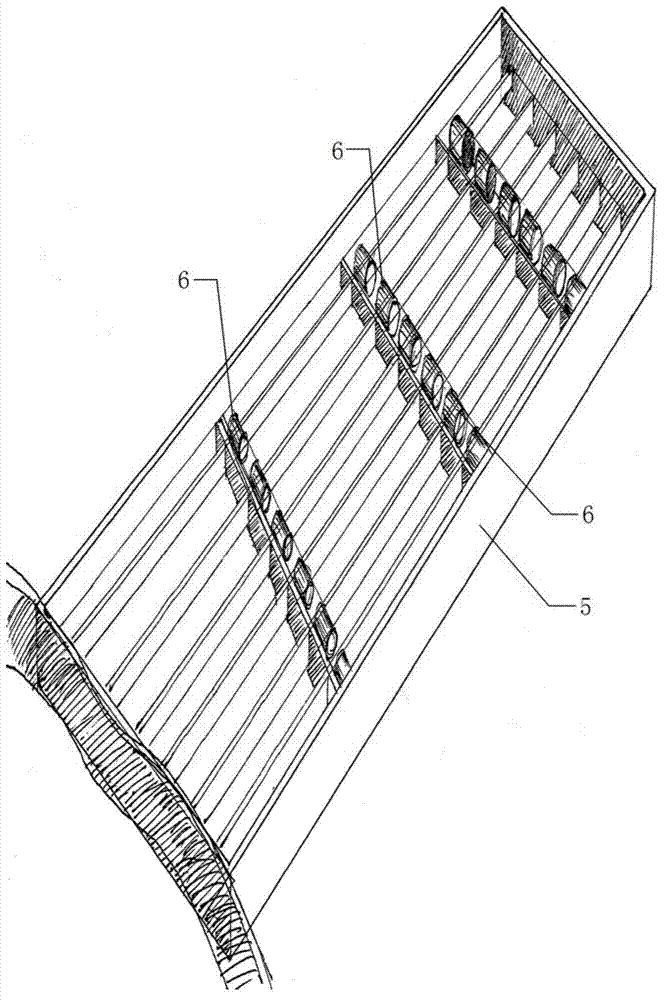

Guitar chord fingering device and guitar provided with same

ActiveCN103400571ASatisfy the requirements of the down pressure requirementNo interference problemsElectrophonic musical instrumentsElectrical controlEngineering

The invention provides a guitar chord fingering device. The guitar chord fingering device comprises a shell, a frame, a plurality of electromagnetic devices, string contact pressers and an electrical control unit, wherein the shell is provided with chord keys; the frame is fixedly arranged in the shell; the electromagnetic devices are fixedly arranged on the frame; each electromagnetic device corresponds to a different pitch of each string of a guitar; the string contact pressers are driven by the electromagnetic devices; the chord keys are electrically connected with the electrical control unit; and the electrical control unit controls the electromagnetic device at the corresponding pitch to move according to a chord fingering spectrum corresponding to the chord keys so as to drive the string contact pressers to press strings. The invention also provides the guitar provided with the guitar chord fingering device. The guitar chord fingering device and the guitar have the advantages of good universality, simple structure and capability of avoiding interference among parts in various chord processes.

Owner:周建峰

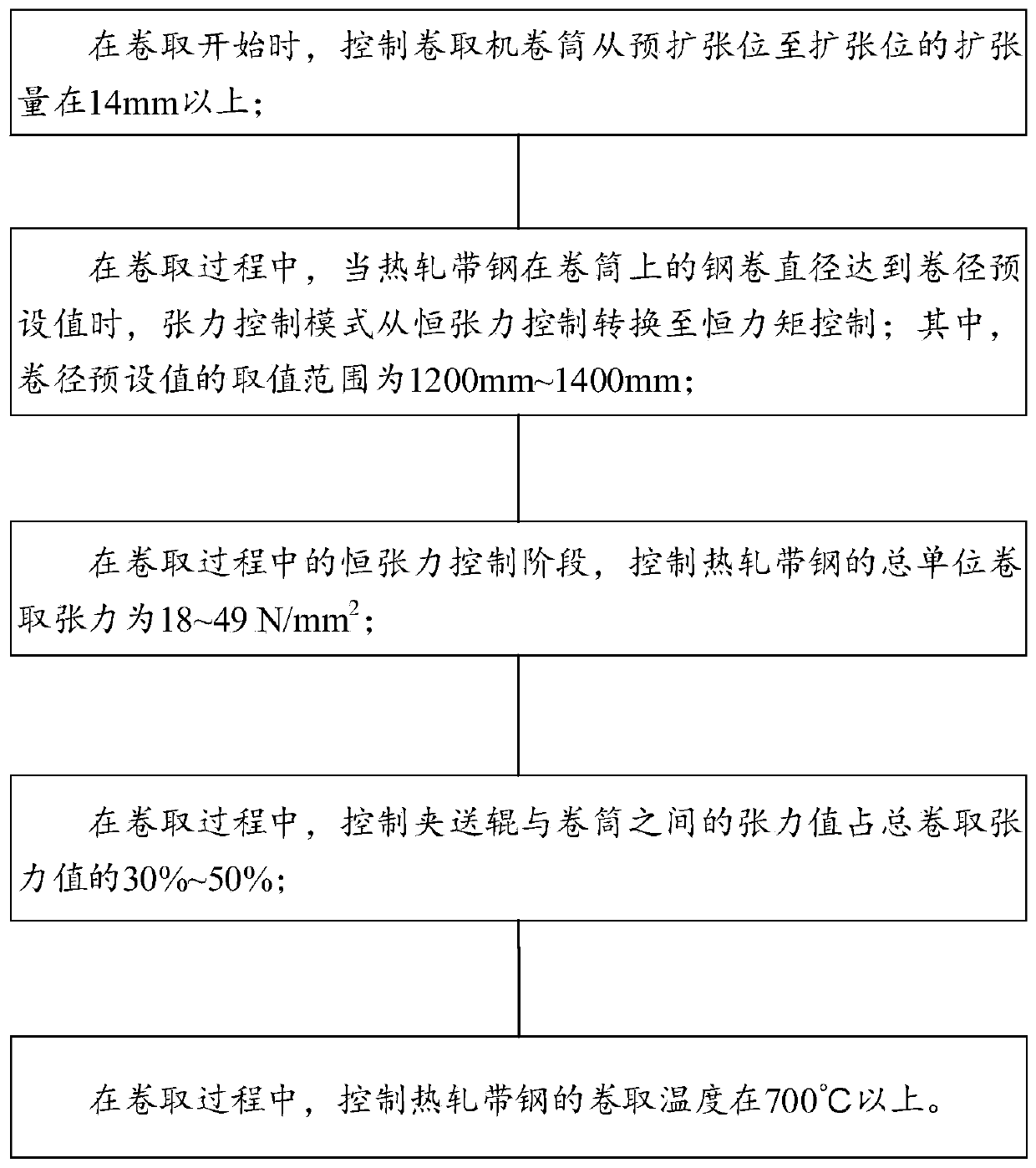

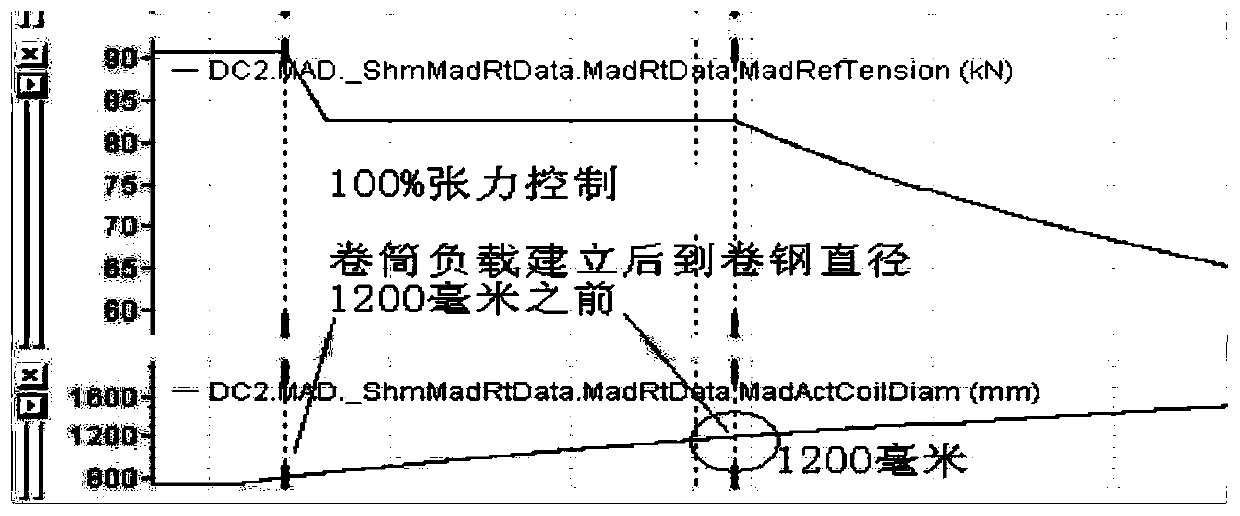

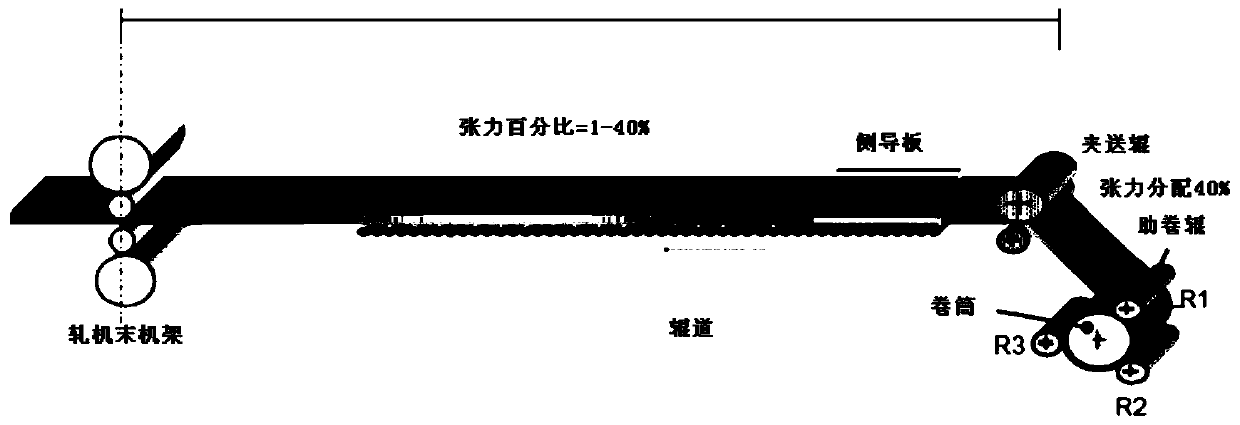

Coiling control method for producing hot-formed steel by continuous casting and continuous rolling of thin slab

ActiveCN111570517ASolve the flat roll problemReduce tensionMetal rolling arrangementsThin slabStrip steel

The invention discloses a coiling control method for producing hot-formed steel by continuous casting and continuous rolling of a thin slab. The method comprises the steps that when coiling is started, the expansion amount of a coiler from a pre-expanded position to a expansion position is controlled to be more than 14 mm; and in the coiling process, when the steel coil diameter of hot-rolled strip steel on the coiler reaches a coiling diameter preset value, a tension control mode is transformed from a constant-tension control to a constant-torque control, wherein the coiling diameter preset value ranges from 1200 mm to 1400 mm; during the constant-tension control stage in the coiling process, the total unit coiling tension of the hot-rolled strip steel is controlled to be 18 N / mm2-49 N / mm2; in the coiling process, the tension value between a pinch roller and a drum is controlled to be 30%-50% of the total coiling tension value; and in the coiling process, the coiling temperature of the hot-rolled strip steel is controlled to be above 700 DEG C. The control method can effectively solve the problem of flat coiling of the hot-formed steel.

Owner:武汉钢铁有限公司

Sunscreen fishing net and preparation method thereof

InactiveCN105385076AHigh strengthIncrease tensionConjugated synthetic polymer artificial filamentsArtifical filament manufactureChemistryPlasticizer

The invention relates to the field of a fishing gear, and particularly relates to a sunscreen fishing net and a preparation method thereof. A production raw material for the sunscreen fishing net comprises fluorocarbon resin, nitrile rubber, silicon carbide, calcium carbonate, aluminum stearate, zinc oxide, kaolin, plasticizer and deionized water. The preparation method comprises the following steps: firstly mixing and stirring the fluorocarbon resin and nitrile rubber according to a ratio at a constant speed, then adding the raw materials such as the silicon carbide, calcium carbonate, aluminum stearate, zinc oxide, kaolin, plasticizer and deionized water according to the weight percent, then placing the mixed raw materials into an extruder of a three-sectional heating way, extruding and granulating, then performing the wire drawing and forming by using a spinning machine, and finally weaving the drawn fishing wires to form the fishing net.

Owner:CHAOHU LOTUS FISHING NET

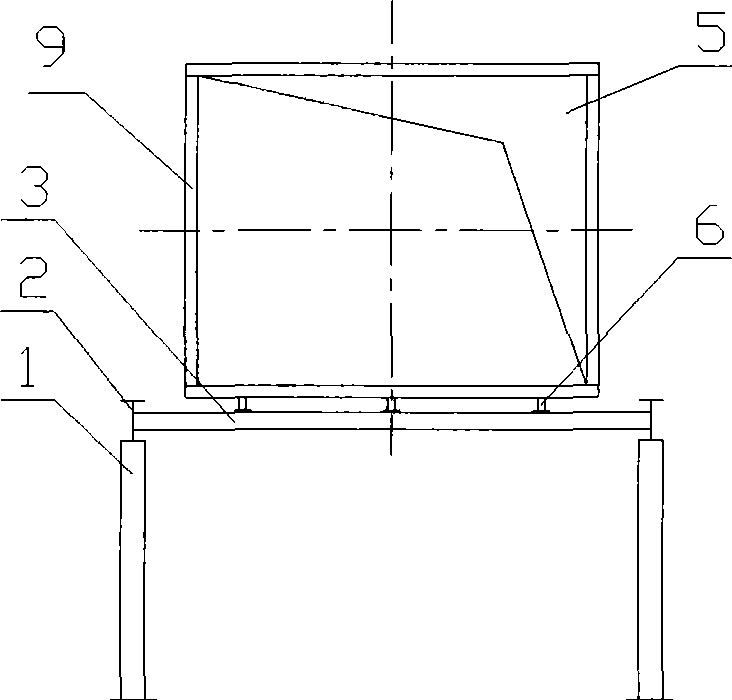

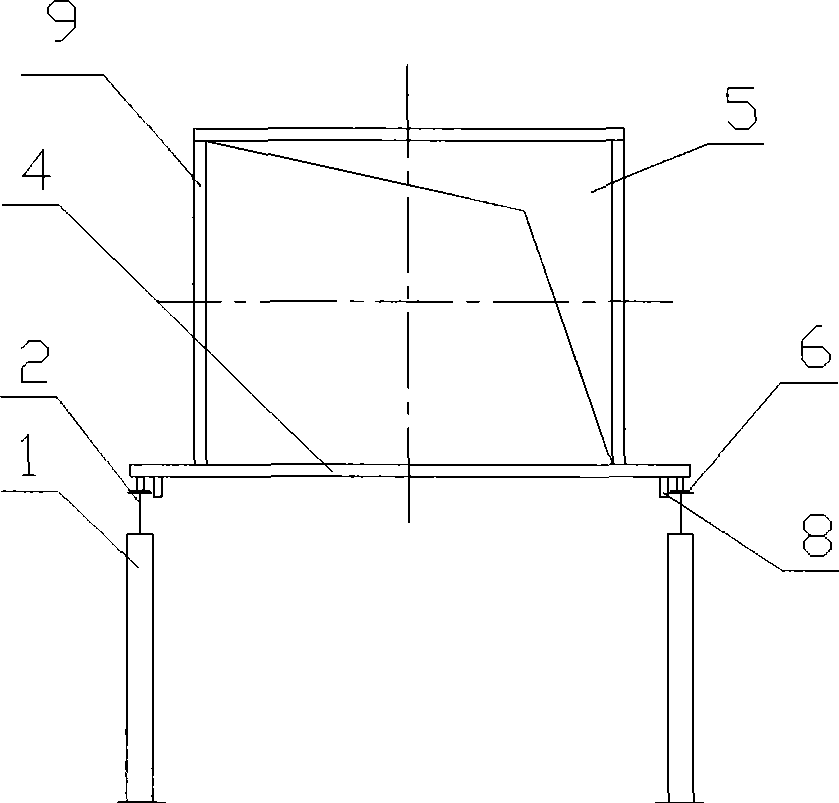

Flue axial rail-mounted support structure

The invention provides a flue axial rail-mounted support structure, which relates to the technical field of environmental protection. The flue axial rail-mounted support structure comprises a rectangular flue, a plurality of support posts arranged on two sides of the rectangular flue along an axial direction respectively, and support longitudinal beams fixed on the tops of the support posts. Reinforcing ribs are arranged around the external wall of the flue. The flue axial rail-mounted support structure has the structural characteristics that two ends of ribs at the base plane of the reinforcing ribs of the rectangular flue extend out from the cross section of the flue; and sliding supports are arranged under the two ends of the ribs at the base plane. The sliding supports are arranged on the support longitudinal beams to form a sliding plane and the internal sides of the sliding supports are provided with limiting blocks. The support structure of the invention can reduce the influence of the axial displacement of the flue on the support frame beams of the flue, and has the characteristics of simple structure, reasonable stress and construction cost reduction.

Owner:TONGFANG ENVIRONMENT

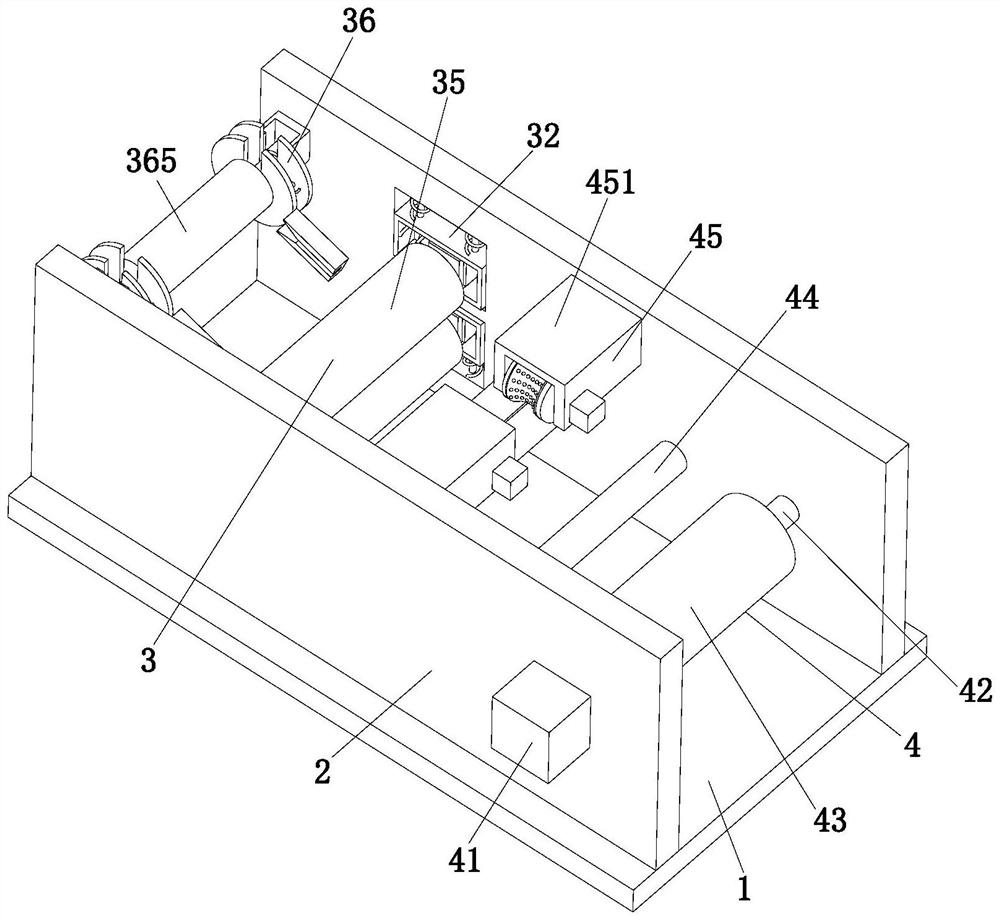

Flattening treatment device for copper foil production

ActiveCN114054544AImprove flattening effectIncrease contact areaMetal-working feeding devicesPositioning devicesMetallurgyEngineering

The invention relates to the technical field of copper foil production, in particular to a flattening treatment device for copper foil production. The device comprises a worktable, bearing plates, a rolling unit and a winding unit, wherein the two bearing plates are symmetrically arranged at the front and back of the upper end of the worktable, and the rolling unit and the winding unit are sequentially arranged on the opposite sides of the bearing plates from left to right. An existing flattening device has the following problems that: when the existing device is used for flattening copper foil with different thicknesses, the device needs to be correspondingly adjusted, and the operation is tedious; and the device cannot perform all-directional flattening treatment on the copper foil, and flattening dead angles exist, so that the flattening effect on the copper foil cannot be ensured. The flattening treatment device can be used for flattening the copper foil with different thicknesses, and does not need to be frequently adjusted, so that the workload can be reduced; and the copper foil can be subjected to all-directional flattening treatment through flattening elastic pieces, so that the flatness of the copper foil can be ensured, and the flattening effect on the copper foil is ensured.

Owner:GUANGDONG FINE YUAN SCI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com