Energy absorption device for multi-section vehicles

A technology for energy dissipation and vehicles, which is applied in the direction of buffer vehicles, transportation and packaging, railway car body parts, etc., can solve problems such as not being designed, and achieve the effect of increasing tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

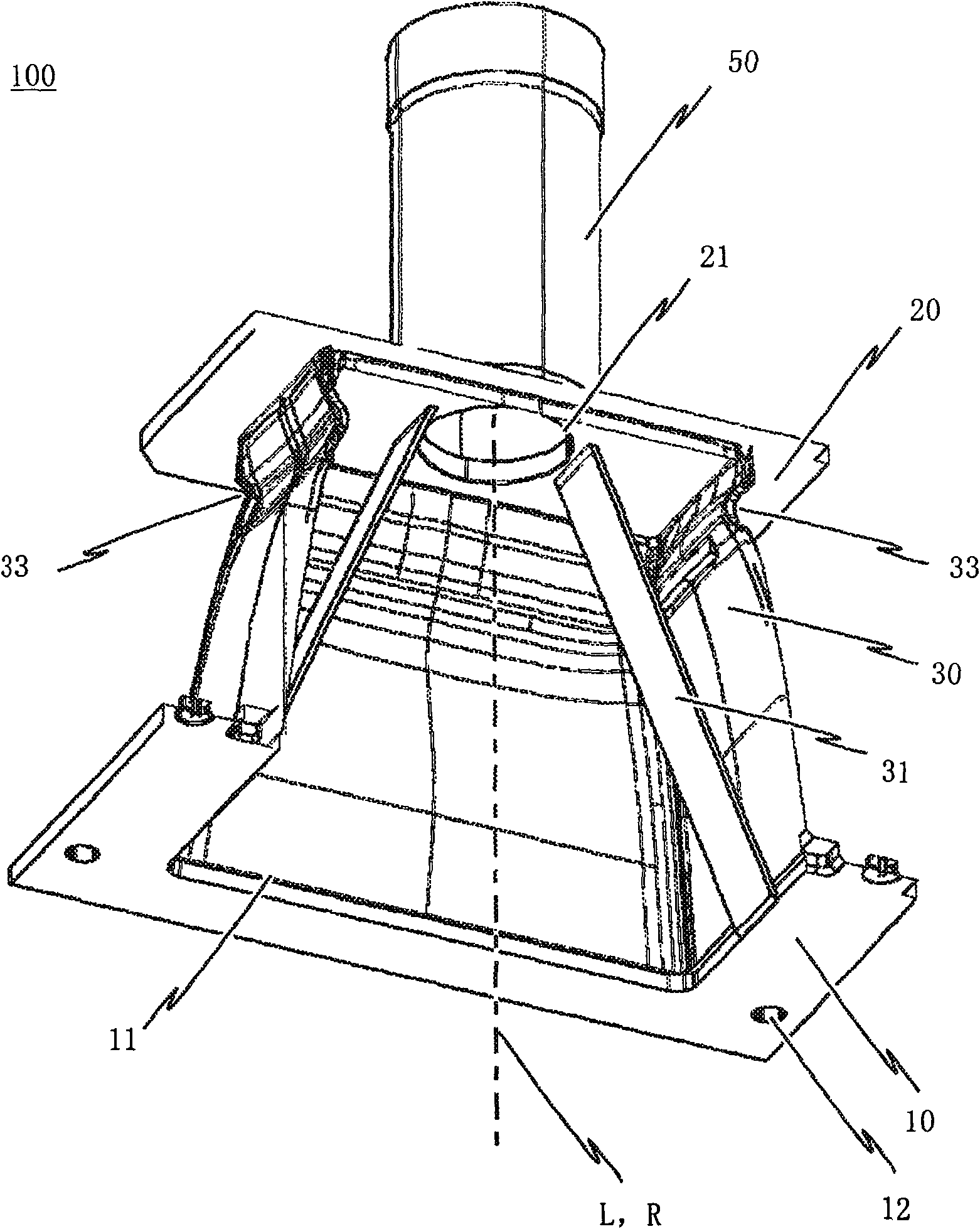

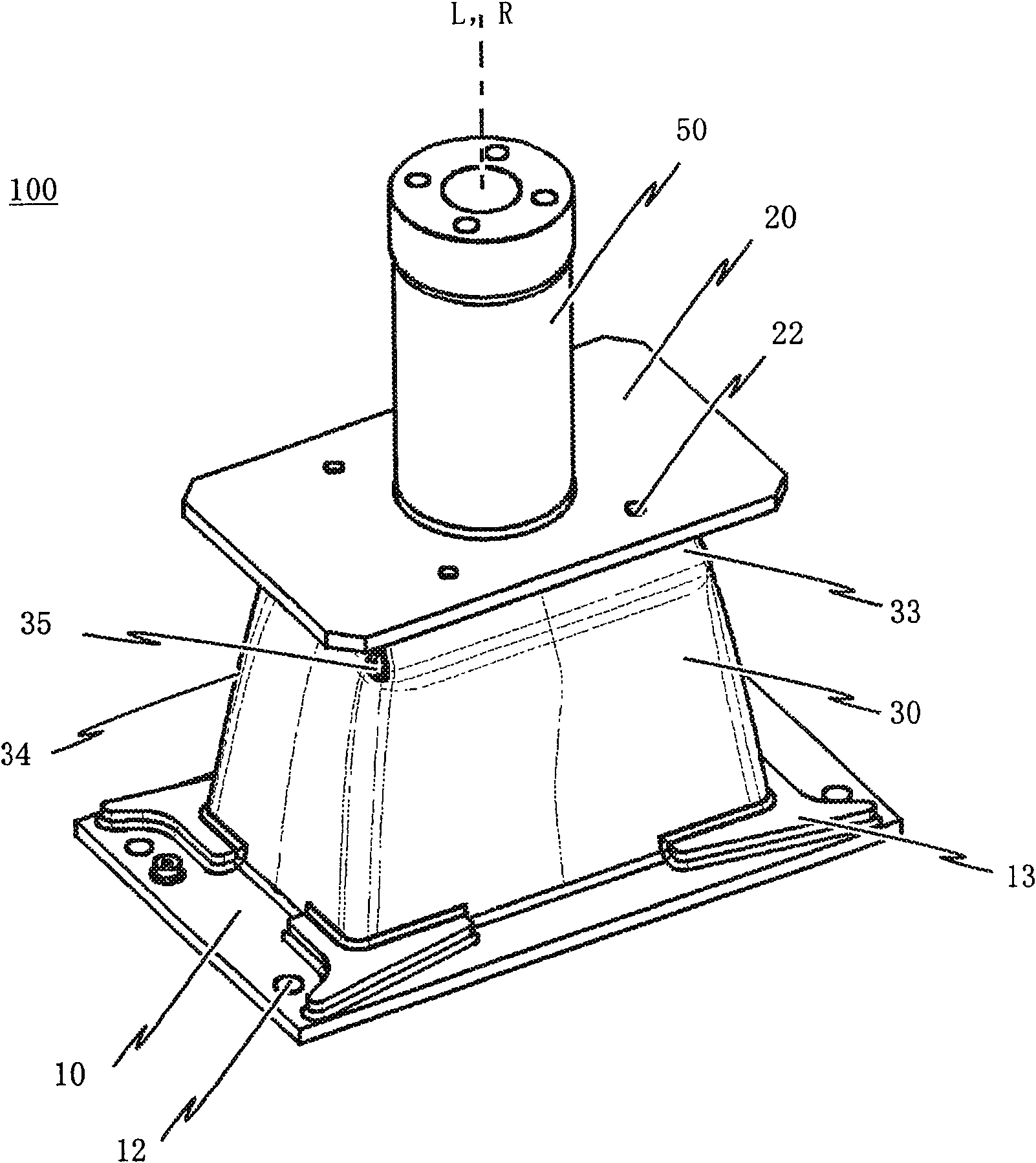

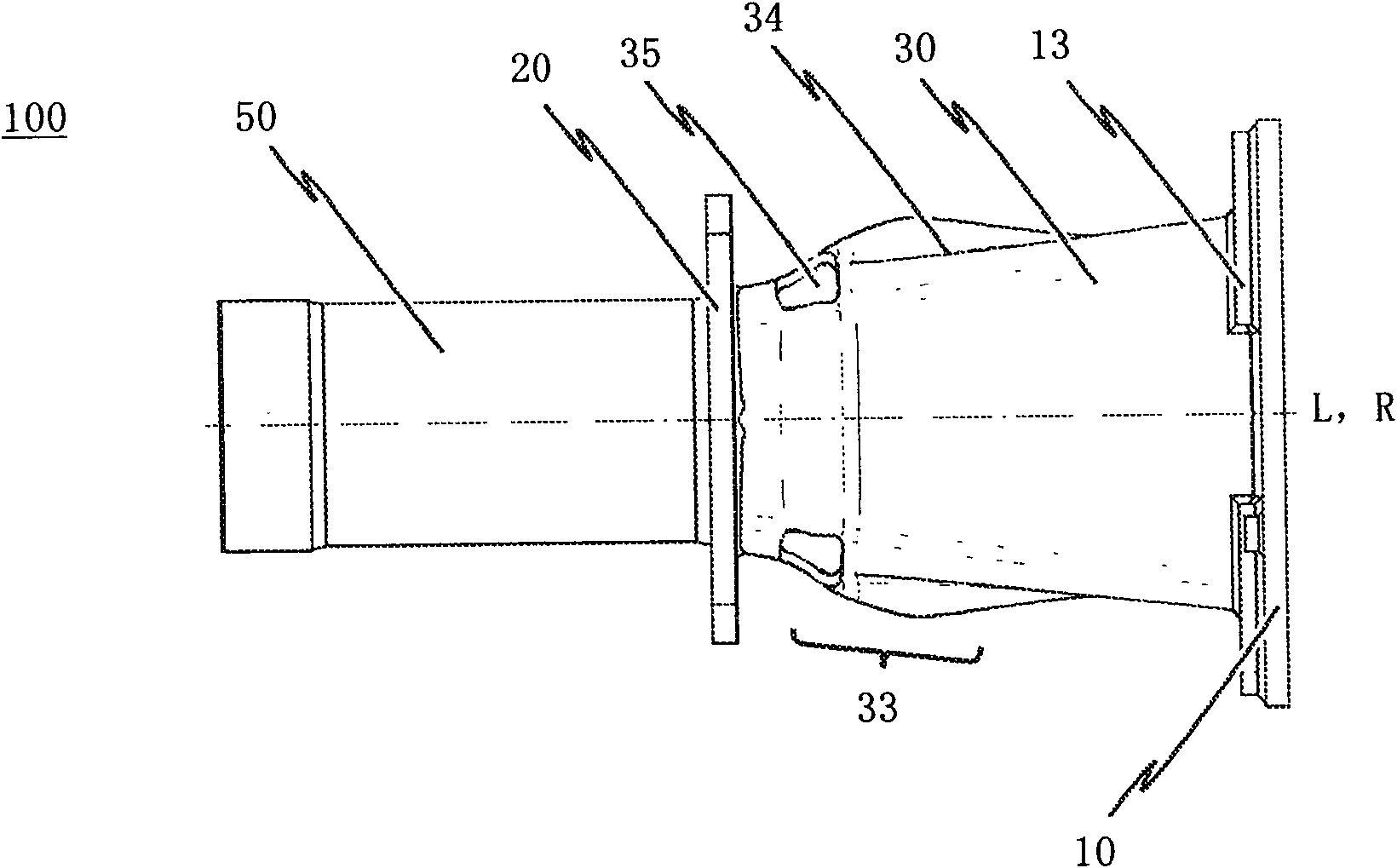

[0066] 【0048】 Figure 1-6 Different views of a preferred embodiment of the energy dissipating device 100 of the present invention are shown. The energy dissipation device 100 is particularly suitable for use as a shock absorber, preferably in combination with a traction device (not shown in detail) to protect the vehicle chassis of a multi-component rail vehicle.

[0067] [0049] As shown, the energy dissipating device 100 comprises a first end plate 10 and a second end plate 20, each end plate respectively having the function of a force transmission element. In a preferred embodiment of the energy dissipation device 100 according to the invention, each of the two end plates 10 , 20 is respectively configured as a rectangular joint plate. Of course, the invention is obviously not limited to end plates 10, 20 having this design or form.

[0068] [0050] The first end plate 10 is designed to attach the energy dissipating device 100 to the main frame of the vehicle body (not show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com