Coiling control method for producing hot-formed steel by continuous casting and continuous rolling of thin slab

A thin slab continuous casting and hot-forming steel technology, which is applied in metal rolling, metal rolling, tool manufacturing, etc., can solve the problems of flat coils in hot-formed steel, so as to improve the total tension of the inner ring and increase the coil tightness degree, the effect of improving the winding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

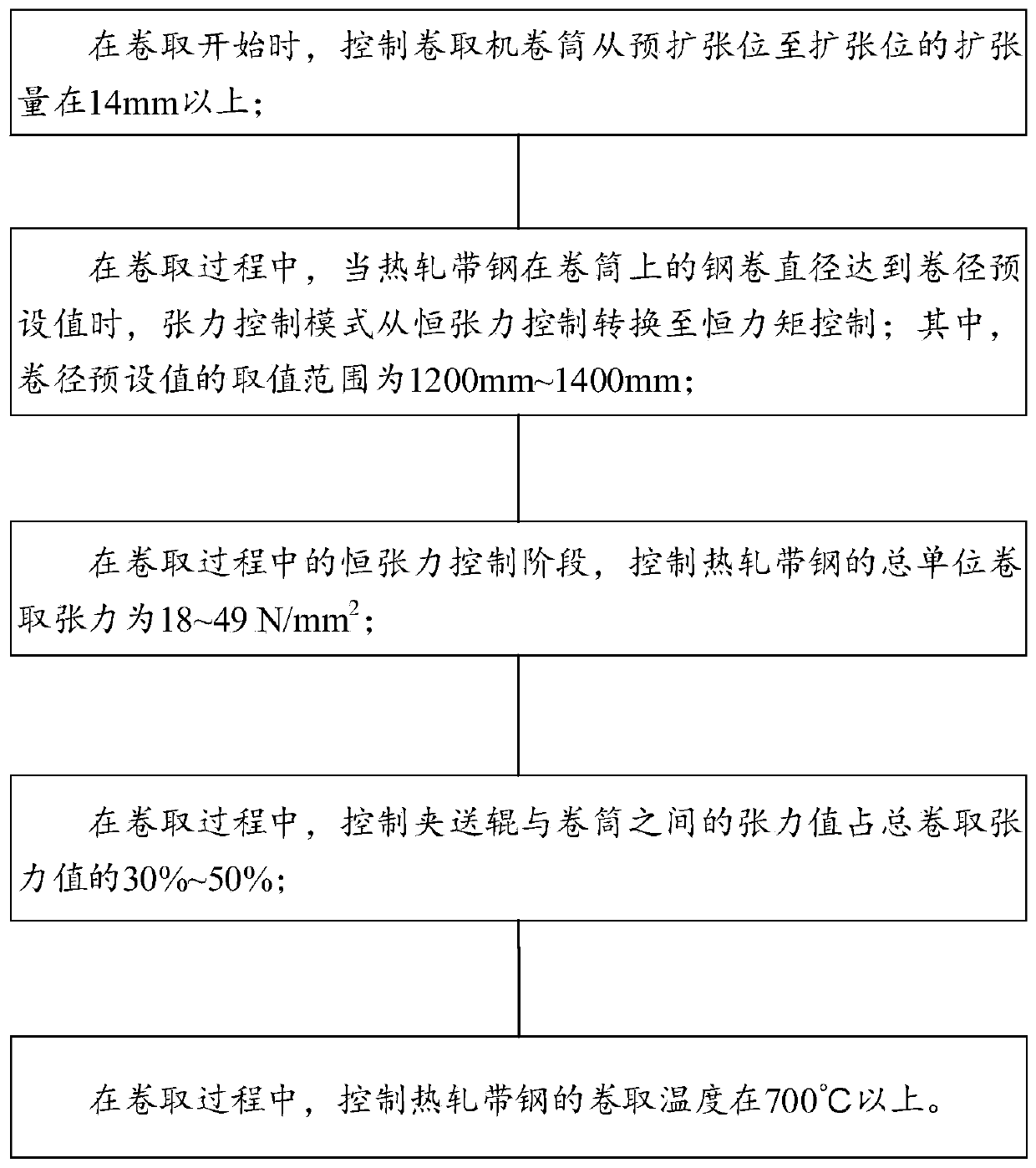

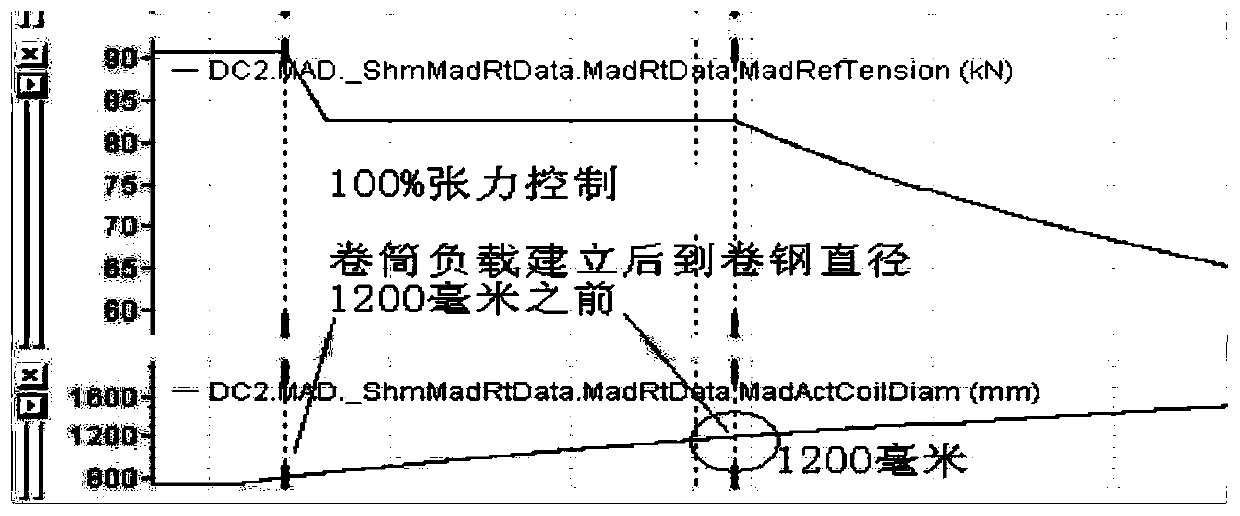

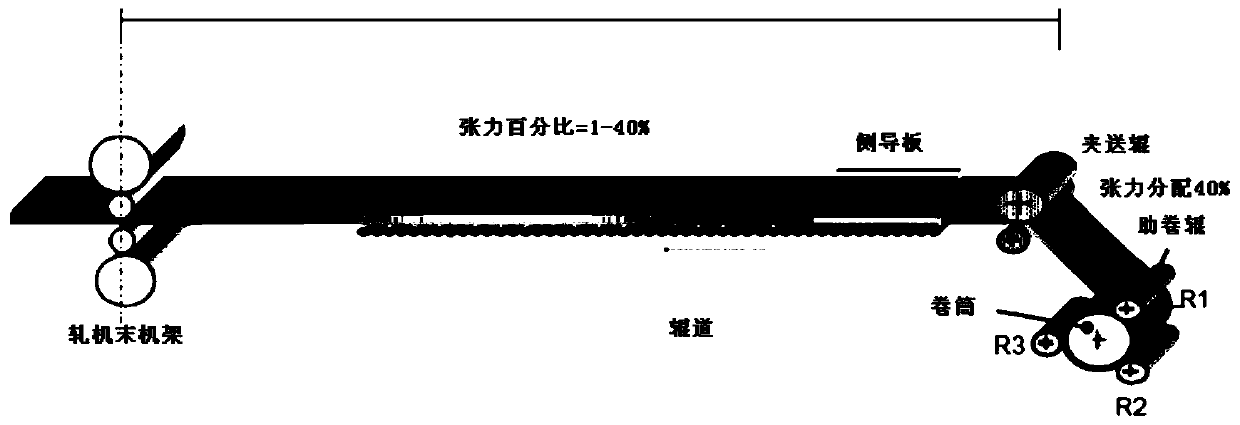

Method used

Image

Examples

Embodiment 1

[0082] Production of hot-formed steel BR1500HS with a thickness of 1.2mm, the actual control target values are shown in Table 2:

[0083] Table 2: 1.2mm BR1500HS control target value

[0084] control process method unit Specific parameters Strip steel unit tension N / mm 2

[0085] Control effect: There is no coiling and flat coiling problem throughout the year.

Embodiment 2

[0087] Production of hot-formed steel BR1500HS with a thickness of 1.4mm, the actual control target values are shown in Table 3:

[0088] Table 3: 1.4mm BR1500HS control target value

[0089]

[0090]

[0091] Control effect: There is no coiling and flat coiling problem throughout the year.

Embodiment 3

[0093] To produce hot-formed steel BR1500HS with a thickness of 1.5mm, the actual control target values are shown in Table 4:

[0094] Table 4: 1.5mm BR1500HS control target value

[0095] control process method unit Specific parameters Strip steel unit tension N / mm 2

[0096] Control effect: There is no coiling and flat coiling problem throughout the year.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com