Flue axial rail-mounted support structure

A supporting structure and rail-type technology, applied in the direction of vertical pipes, building components, building structures, etc., can solve the problems of large horizontal friction, increased cost, and heavy weight of the flue 5, so as to achieve reasonable force and save energy. The effect of cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

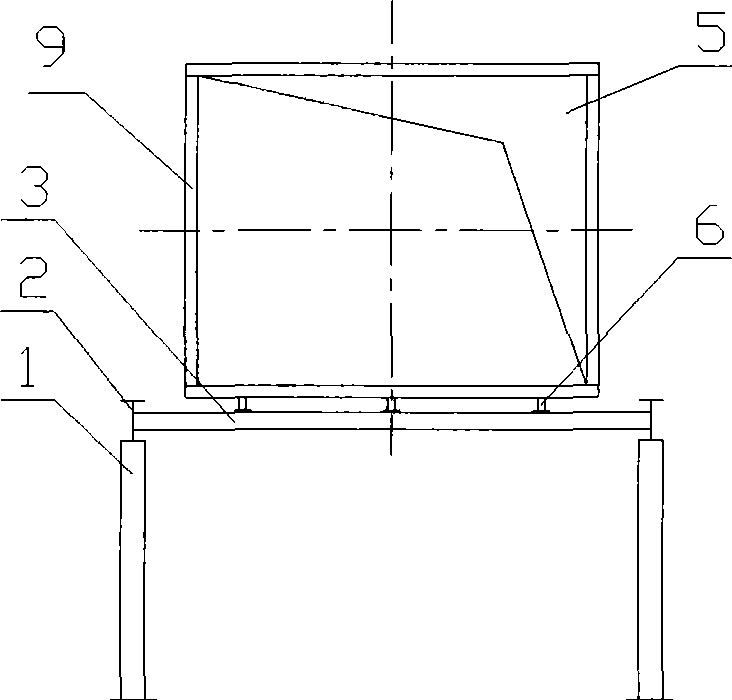

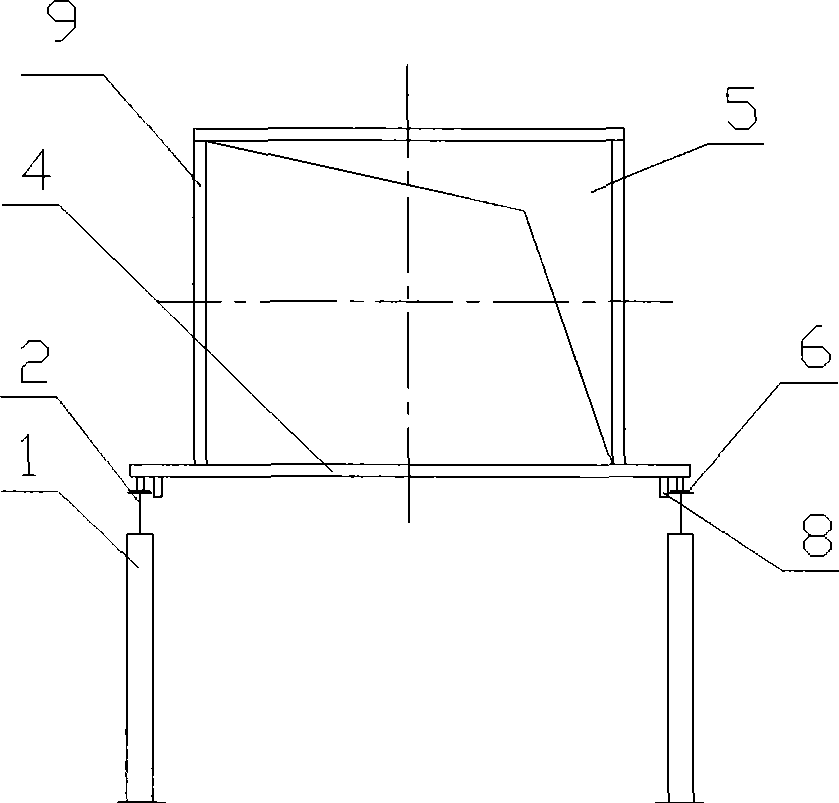

[0010] see figure 2 , the present invention includes a rectangular flue 5, a plurality of supporting columns 1 spanning the two axial sides of the rectangular flue 5, and a supporting longitudinal beam 2 fixed on the top of the supporting column 1. Reinforcing ribs 9 are arranged around the outer wall of the flue 5 , and the two ends of the bottom plane ribs 4 of the reinforcing ribs 9 extend out of the section of the flue 5 . Sliding supports 6 are respectively provided under the two ends of the ribs 4 on the bottom plane, and the sliding supports 6 are placed on the supporting longitudinal beam 2 to form a sliding surface. A limiting block 8 is arranged inside the sliding support 6 .

[0011] In the use of the present invention, the load of the rectangular flue 5 directly acts on the supporting longitudinal beam 2 through the sliding support 6 under the rib 4 of the bottom plane of the flue. The limit block 8 inside the sliding support 6 can limit the lateral displacement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com