Catalyst compositions comprising support materials having an improved particle-size distribution

a technology of support materials and catalysts, applied in the field of supporting catalysts, can solve the problems that polymer products, especially films, produced with a high gel concentration may have limited or no commercial valu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

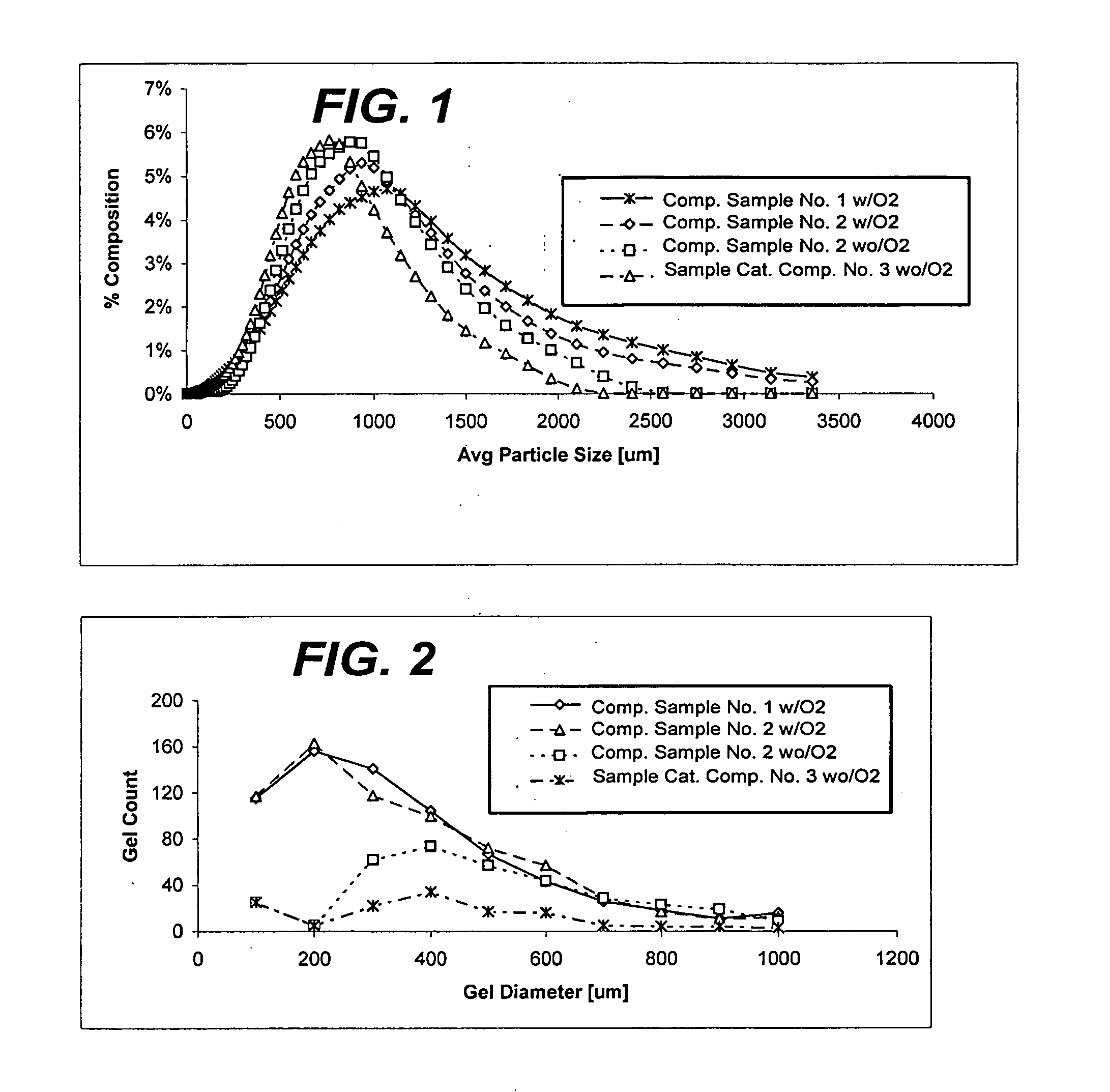

[0288] In the following example, three samples of supported, multitransition metal catalysts were prepared. Two samples are comparative samples, while one sample constitutes a supported, multitransition metal catalyst of the present invention. Specific properties of the samples are displayed in Table 1.

Preparation of Comparative Sample Catalyst 1.

[0289] A comparative sample catalyst (referred to herein as Comparative Sample Catalyst Composition No. 1) was prepared as follows. About 2,000 pounds of anhydrous iso-hexane was transferred into a nitrogen-purged, agitated and jacketed reaction vessel. The temperature of the jacket was set at 54° C.

[0290] A conventional silica was provided (Davison 955 silica), which typically has the following properties:

Average Particle Size:40micronsSurface Area:300m2 / gramPorosity:1.6cm3 / gramD10:10micronsD50:40micronsD90:90micronsD90 / D10:9.0

[0291] The conventional silica was dried under nitrogen at 875° C. About 750 pounds of the dehydrated conven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com