Preparation method for colloidal stannic sulfide hollow nanoparticles

A technology of hollow nanoparticles and nanoparticles, which is applied in chemical instruments and methods, nanotechnology, inorganic chemistry, etc., can solve the problems of failing to obtain hollow nanoparticles of tin sulfide, and achieve the effects of easy control, convenient operation and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

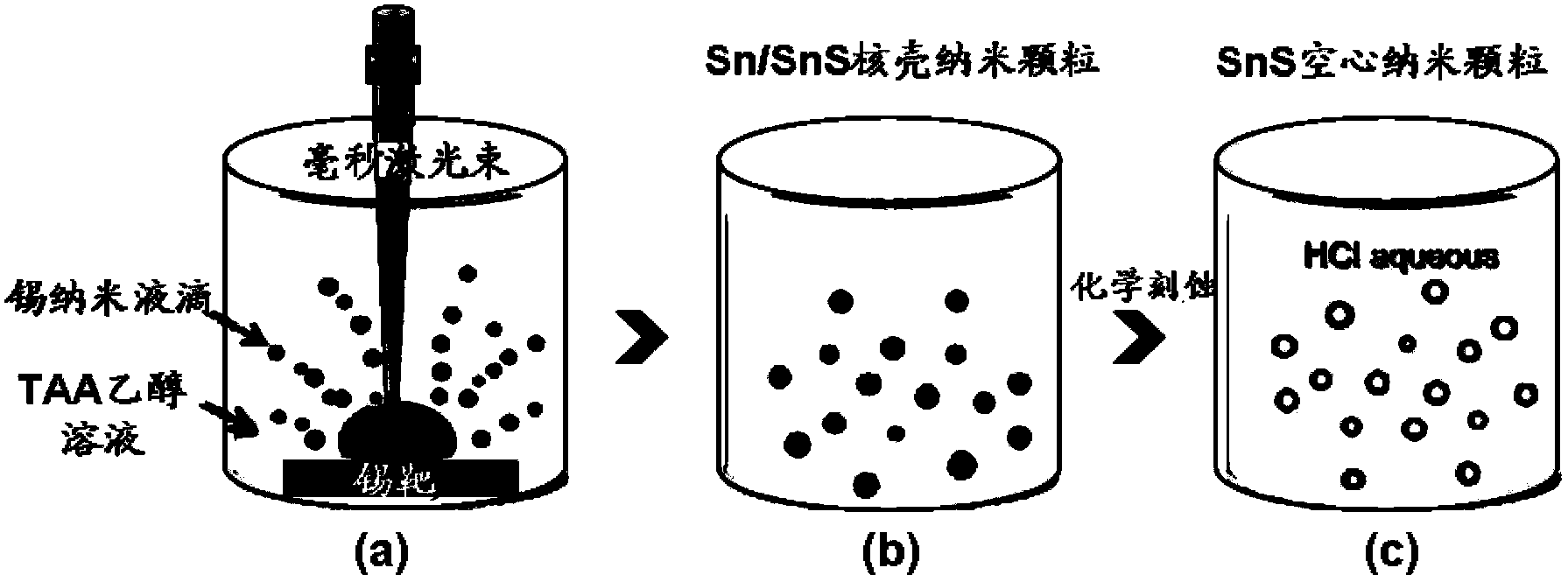

[0026] Such as figure 1 As shown in (a), put a tin target with a purity of 99.99% and a thickness of 5 mm in 12 mL of ethanol solution of thioacetamide (TAA), the distance between the liquid surface and the upper surface of the tin target is about 5 mm, and use millisecond pulse Nd:YAG The laser (fundamental frequency 1064nm) is focused to irradiate the target surface, and the laser power density is 10 6 W / cm 2 , pulse width 1.5ms, repetition frequency 5Hz. The laser irradiation process is protected by an argon flow with a flow rate of 60 sccm to prevent oxidation of tin.

[0027] When the long-pulse millisecond laser irradiates the tin target in the liquid medium, due to its power density (10 6 W / cm 2 ) than the nanosecond laser power density (10 8 -10 10 W / cm 2 ) is at least two orders of magnitude lower. Therefore, the millisecond laser can heat the irradiation area of the target surface relatively mildly and sputter out many tin nano-droplets from the target surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com