High-elasticity thermal insulation cotton and method for producing same

A production method and technology of thermal insulation cotton are applied in the field of chemical fiber thermal insulation cotton, which can solve the problems of difficulty in realization and lack of elasticity, and achieve the effects of high elasticity, increased tension and good air permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

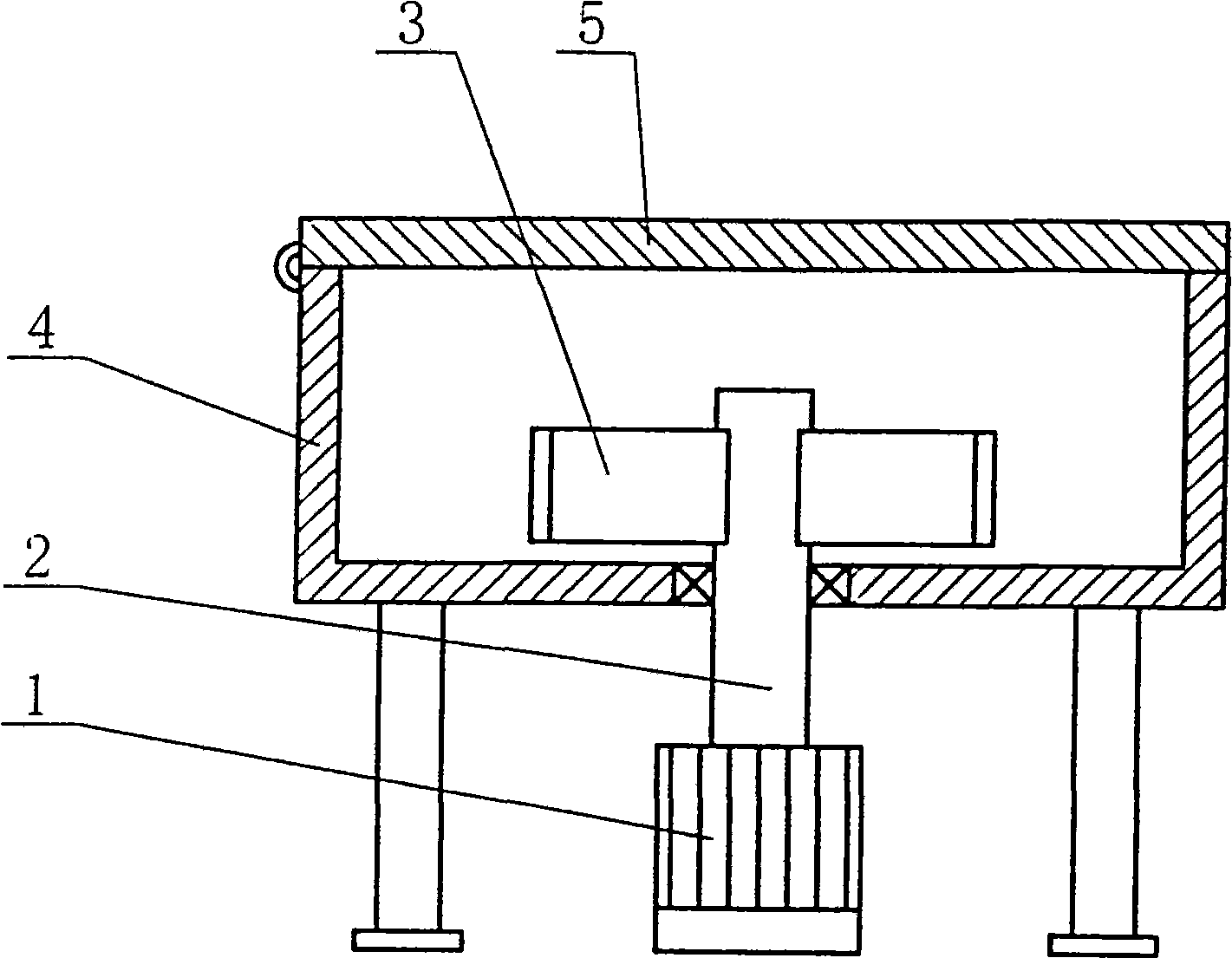

Image

Examples

Embodiment Construction

[0018] The high-elastic thermal cotton of the present invention is composed of two kinds of raw materials, namely: by weight percentage, it is composed of 75%-85% polyester fiber and 15%-25% low-melting point composite fiber, wherein the polyester fiber The fineness is 0.6-2.75 Dan. Its preferred scheme is: the denier of the polyester fiber is 0.6-1.4 weight, and the preferred combination of the two raw materials is 80% polyester fiber and 20% low-melting point composite fiber, which is a combination of better strength and elasticity. The test results show that the strength of this optimal combination is increased by 8.5-9 times, and the elasticity can be extended by 33.2 cm after a 20 cm long sample is subjected to tension, and quickly returns to its original state after the tension is removed. Of course, combinations of 75% polyester fibers and 25% low-melting point composite fibers, 85% polyester fibers and 15% low-melting point composite fibers can all achieve the purpose ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com