Stretch film dispenser with lifting device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]Embodiments of the present invention will now be described, by way of example only, with reference to the accompanying drawings.

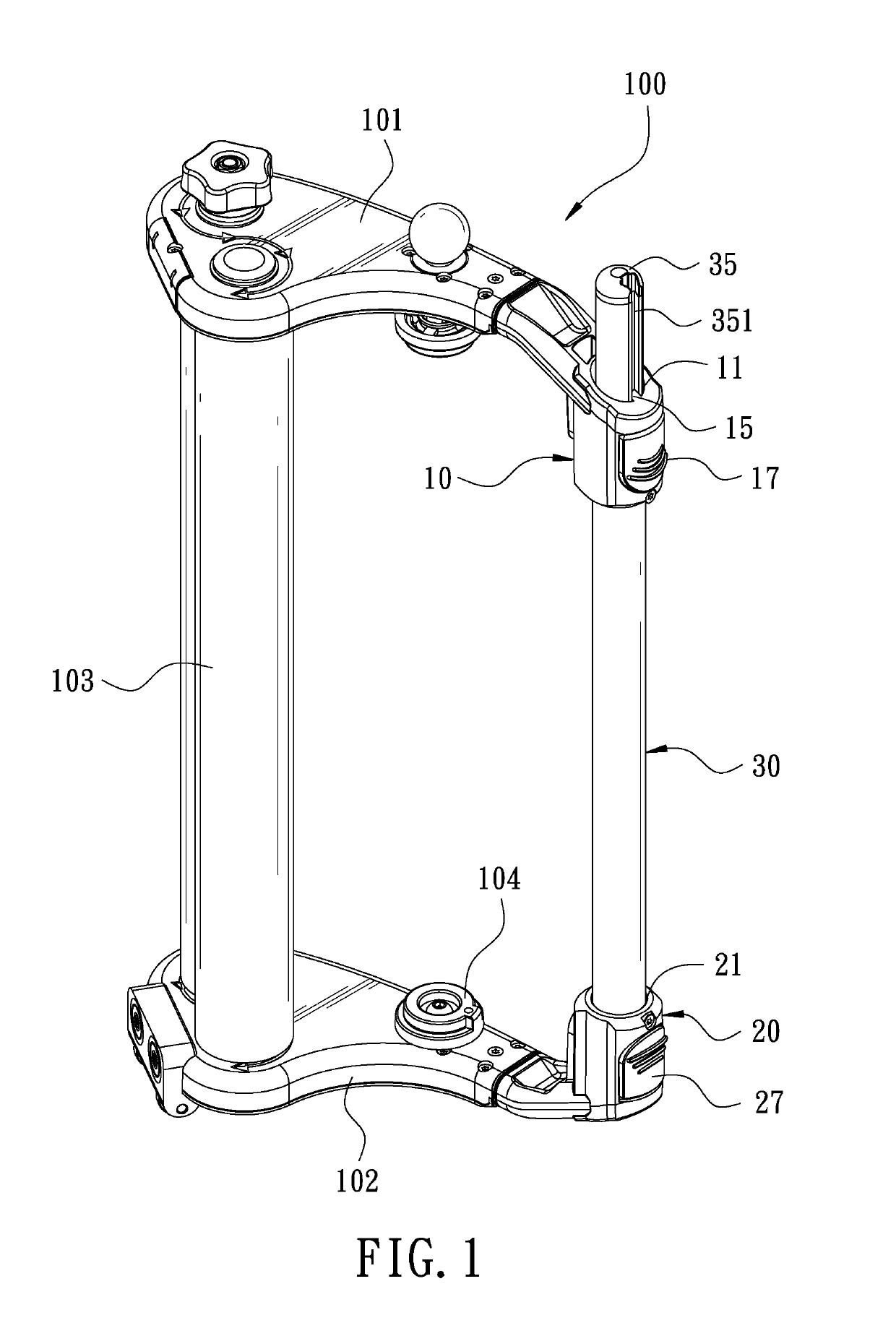

[0021]FIG. 1 is a perspective view in accordance with a preferred embodiment of the present invention. The present invention discloses a stretch film dispenser with a lifting device. The lifting device is mounted to a stretch film dispenser 100. The stretch film dispenser 100 comprises a first seat 101 and a second seat 102. The lifting device is disposed between the first seat 101 and the second seat 102. The stretch film dispenser 100 further comprises a roller assembly 103 and a film mounting unit 104.

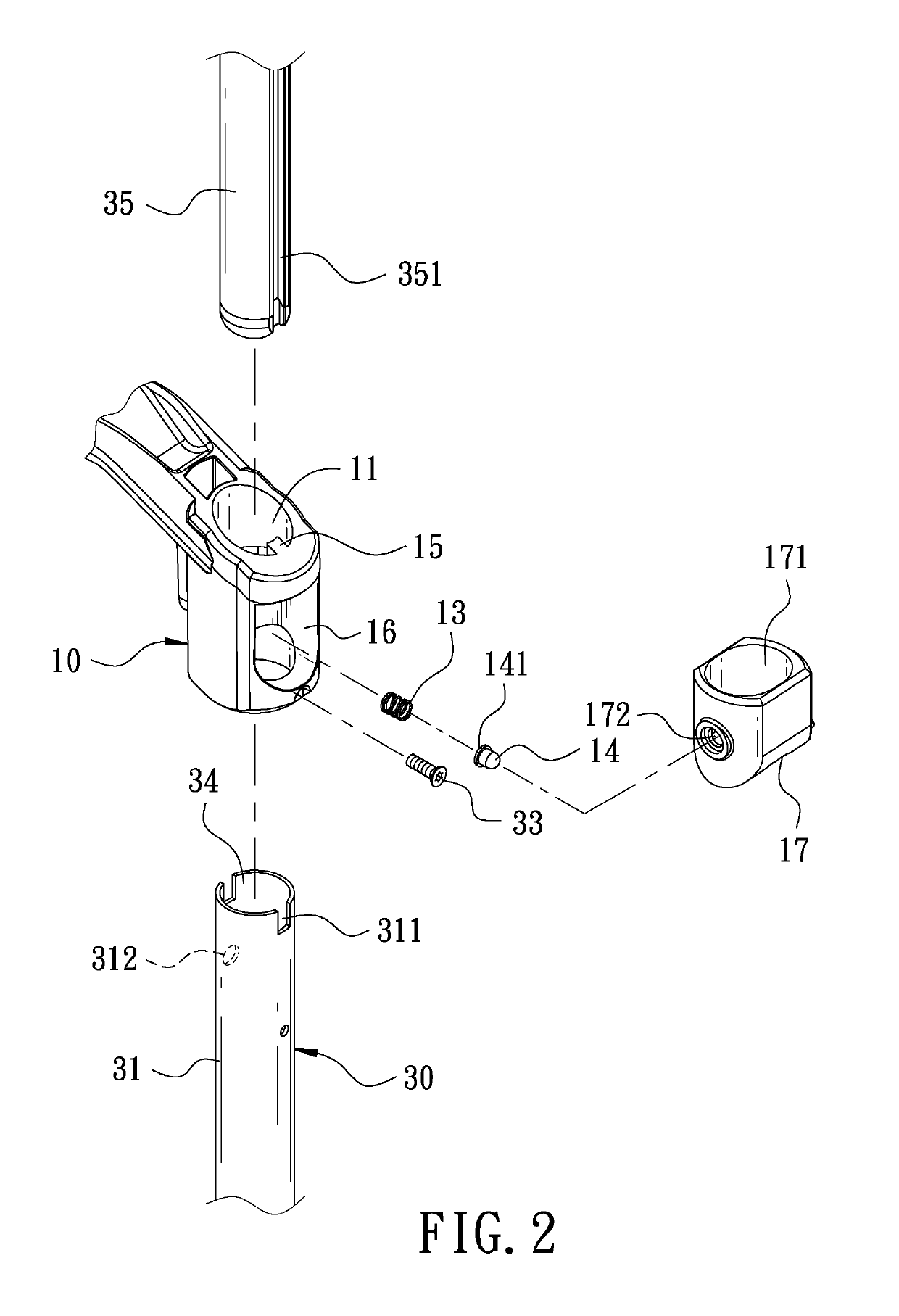

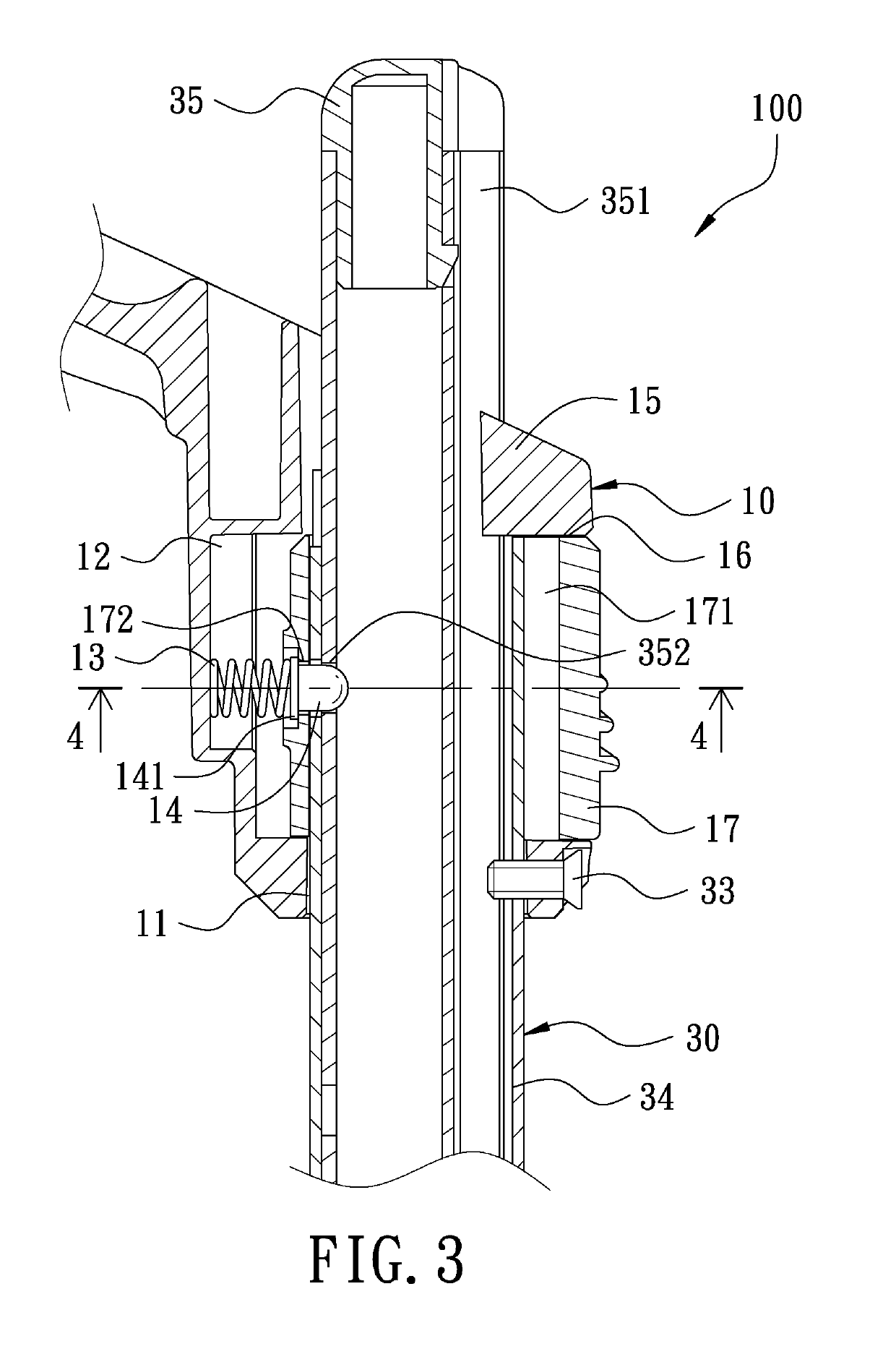

[0022]Referring to FIG. 2 and FIG. 3, a first operating unit 10 is connected to one end of the first seat 101. The first operating unit 10 is provided with a first through hole 11. A peripheral wall of the first through hole 11 is formed with a first accommodating recess 12. The first accommodating recess 12 is provided with a first elastic member 13....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com