Subassembly of buttonhead of car distance rod and sheath, and assembling technique

An assembly process and thrust rod technology, which is applied in vehicle parts, manufacturing tools, metal processing, etc., can solve problems such as low torsion resistance and tensile resistance, thread slippage, and thread looseness, so as to increase tensile pressure and improve Effect of Torsional Moment Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

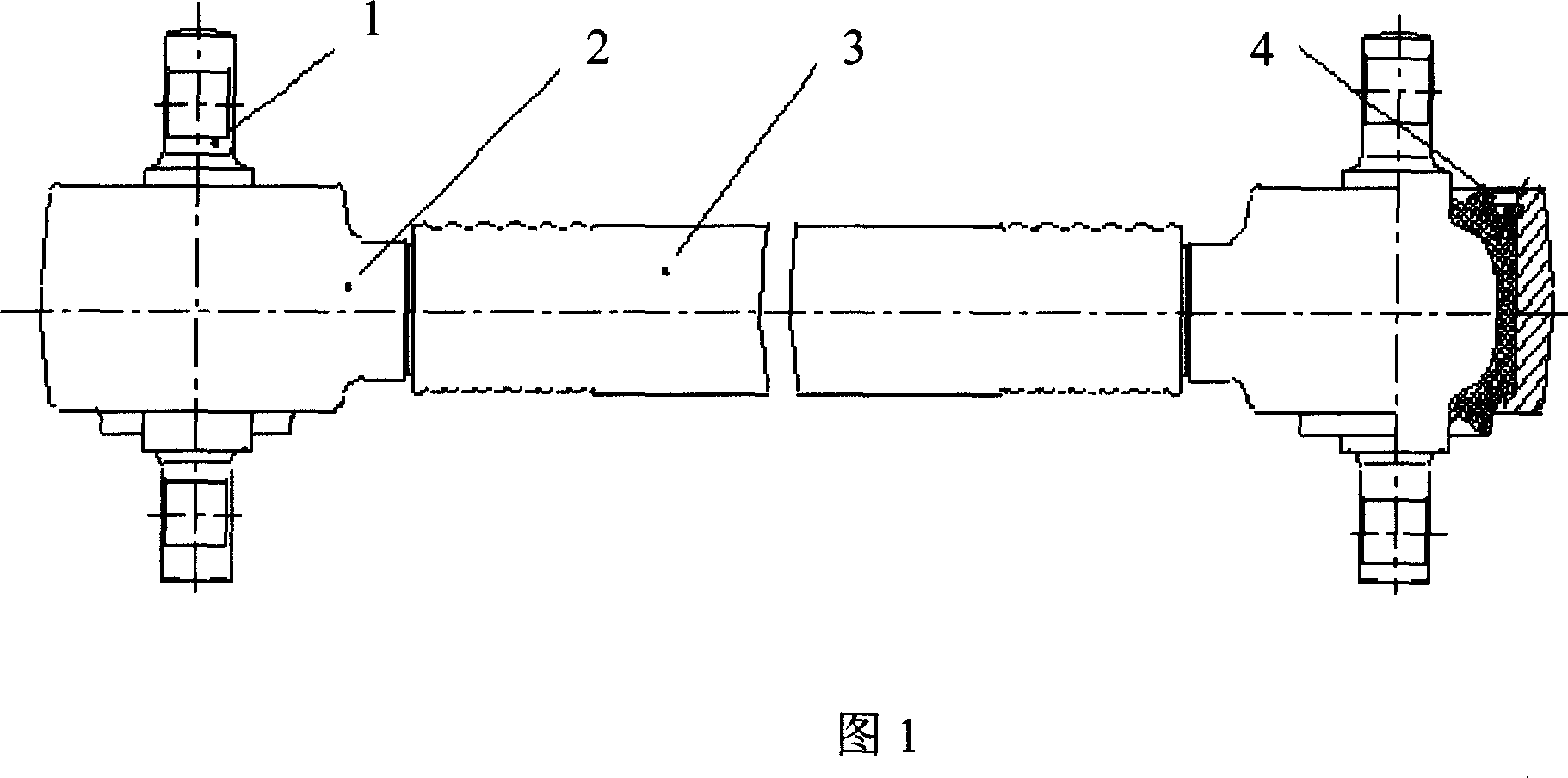

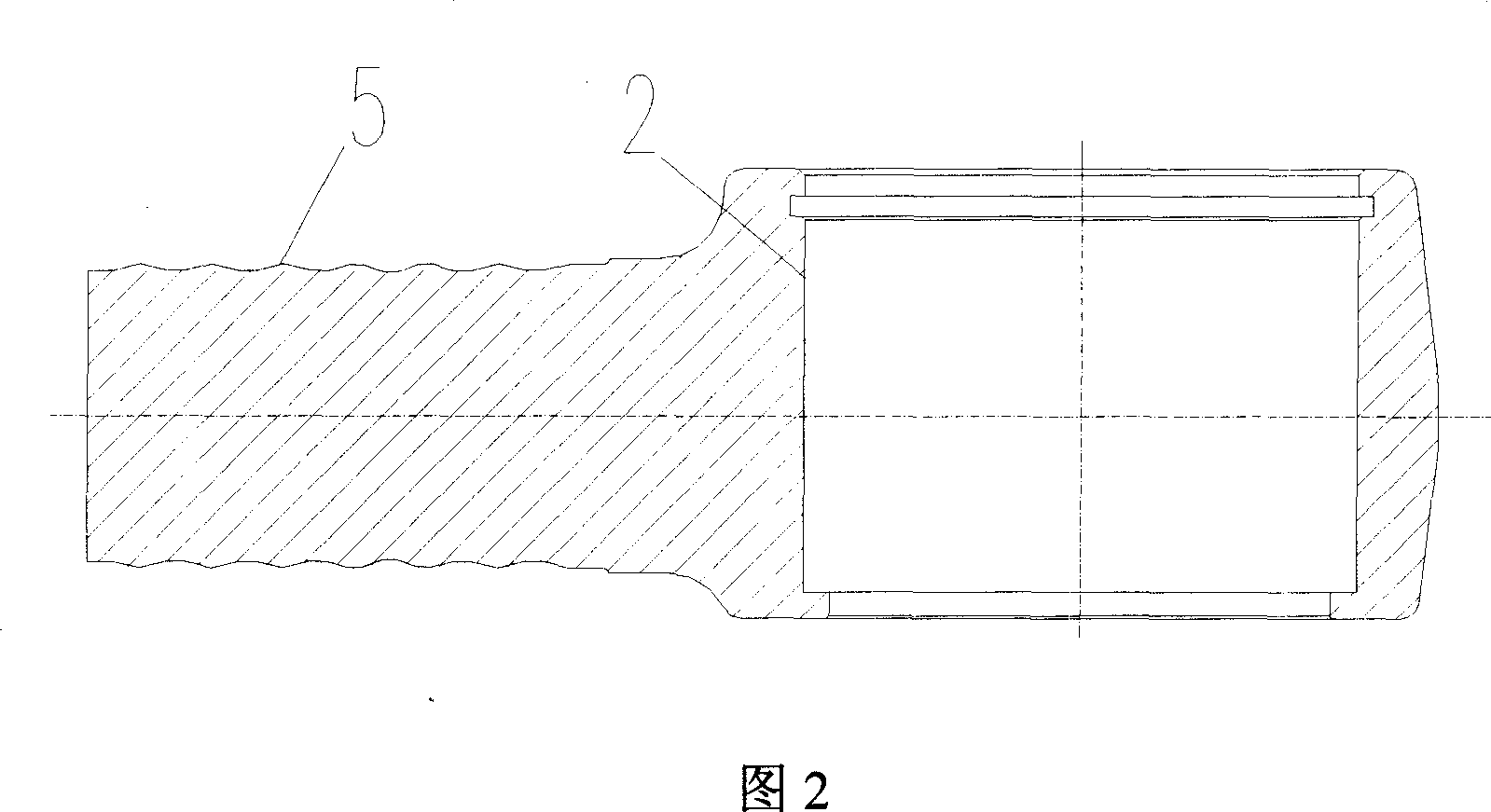

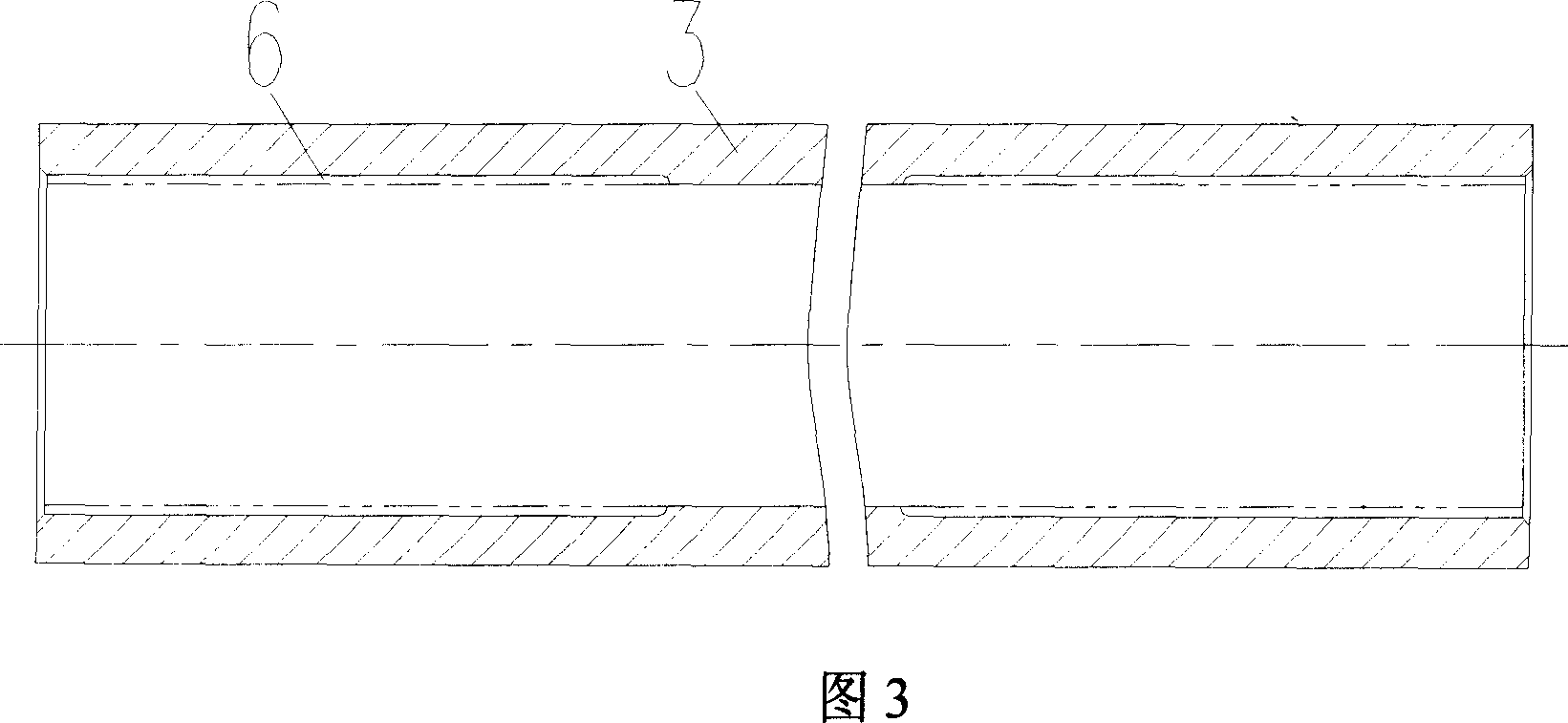

[0020] The structure and manufacturing process for implementing the present invention will be described below in conjunction with the accompanying drawings. The present invention is an automobile thrust rod ball head and bushing assembly, which includes a thrust rod ball head 2 and a bushing 3, and a ball joint 1 and a retaining ring assembly 4 are installed on the ball head 2, and is characterized in that the thrust rod ball head 2 and the bushing 3 are connected in a corrugated shape, and the main assembly process includes: 1. Process the connecting part 5 of the thrust rod ball and the bushing into a corrugated shape; 2. Process the connecting part 6 of the bushing and the thrust rod ball Form a matching thin-walled sleeve, and the connection between the sleeve and the ball head of the thrust rod is an interference fit; fix the special riveting tooling on the upper and lower plates of the hydraulic press; 3. Set the pressure parameters of the hydraulic press according to req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com