A roof structure of a subway vehicle without side beams

A technology without edge beams and subways, which is applied in the direction of railway roofs, etc., can solve the problems of limited design space, no space to design roof side beams, and the inability to install high plug doors, etc. The effect of convenient lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

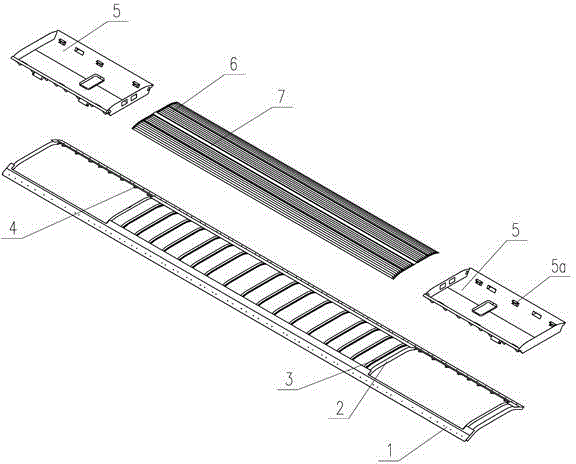

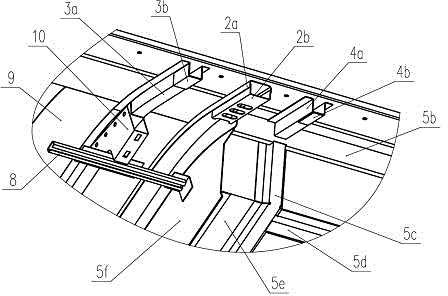

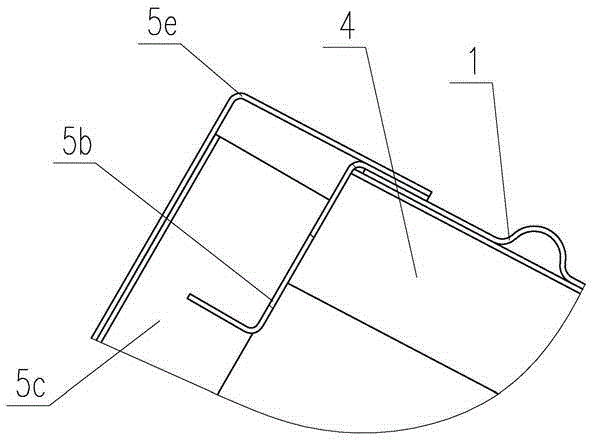

[0034] A roof structure for subway vehicles without side beams, such as figure 1 As shown, the roof frame is composed of side roof 1, middle roof 7, air-conditioning connecting curved beam 2, roof curved beam 3, and air-conditioning beam assembly 4 spot welding connections, and the air-conditioning installation platform 5 is respectively placed in the gaps at both ends of the roof frame , the two sides of the corrugated roof 6 are lapped on the middle roof 7 and the side roof 1 respectively, and spot welding with the roof frame is completed. Wherein the side top plate 1 is provided with a row of connection holes for plug welding connection with the side wall parts to enhance the connection strength and rigidity between the large parts, and the middle top plate 7 is set to compensate for the loss of stiffness caused by canceling the roof side beams. The sealing performance of the roof and the reduction of arc welding deformation, the corrugated roof 6 and the middle roof 7 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com