Method for mounting head sprocket wheel of belt sintering machine

An installation method and sintering machine technology, applied in the direction of furnace types, furnaces, lighting and heating equipment, etc., can solve the problems of safety hazards in production safety, restrictions on civil construction, and increased risk factors, so as to reduce installation costs and reduce preparation work , fast installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A method for installing the star wheel at the head of a belt-type sintering machine. The method uses indoor lifting equipment to complete the installation of the star wheel at the head of the sintering machine. The method is carried out according to the following steps:

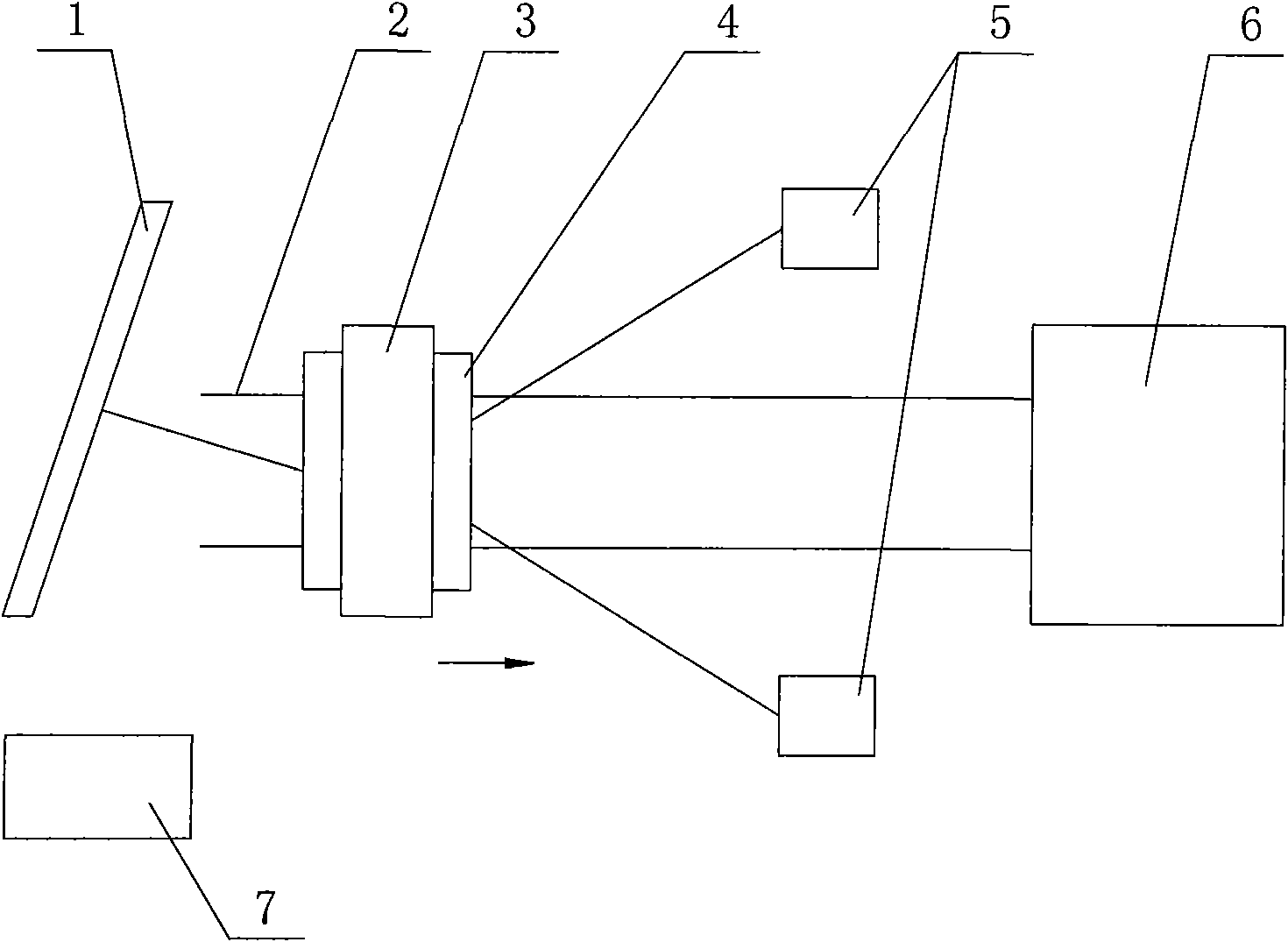

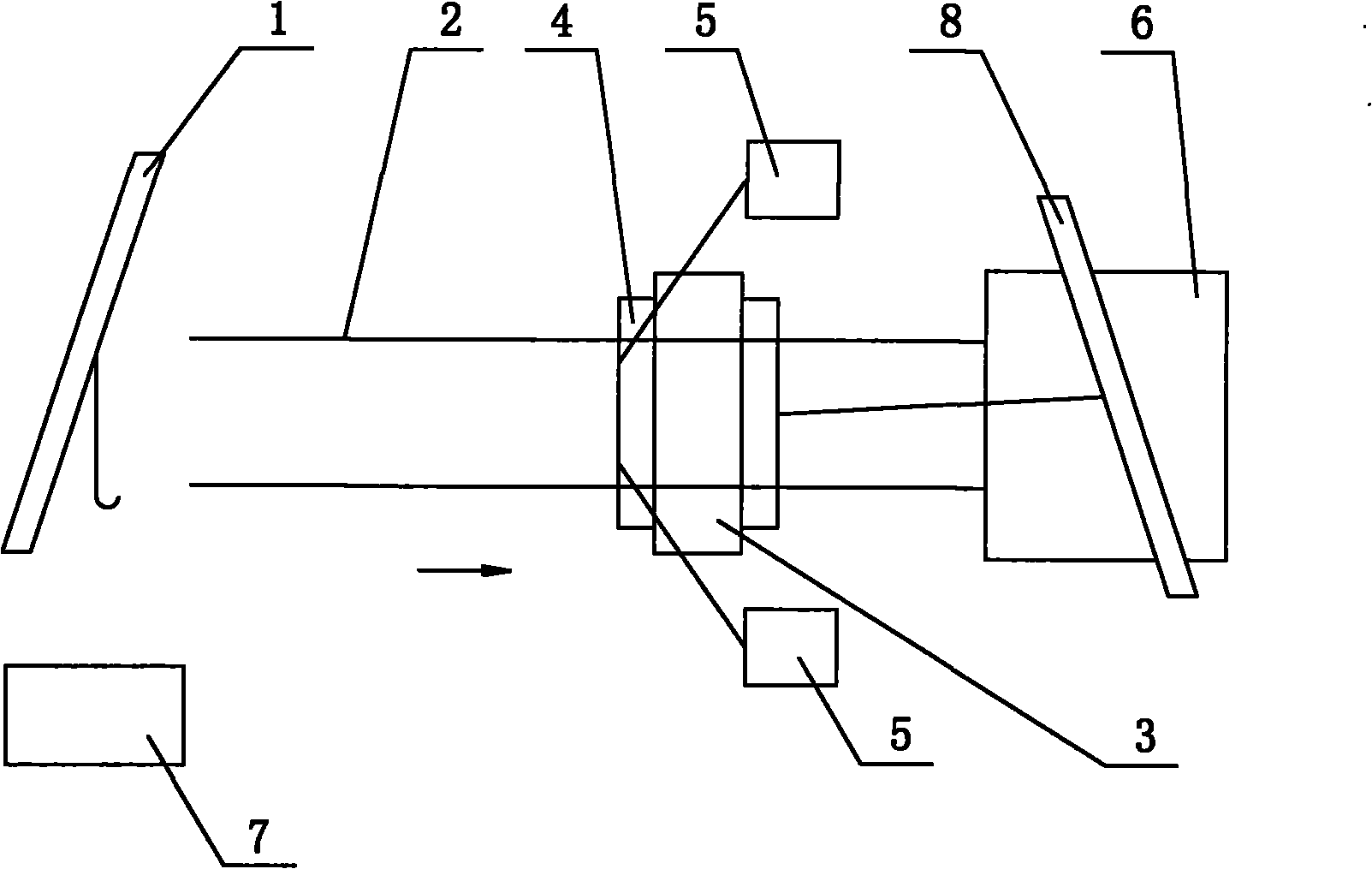

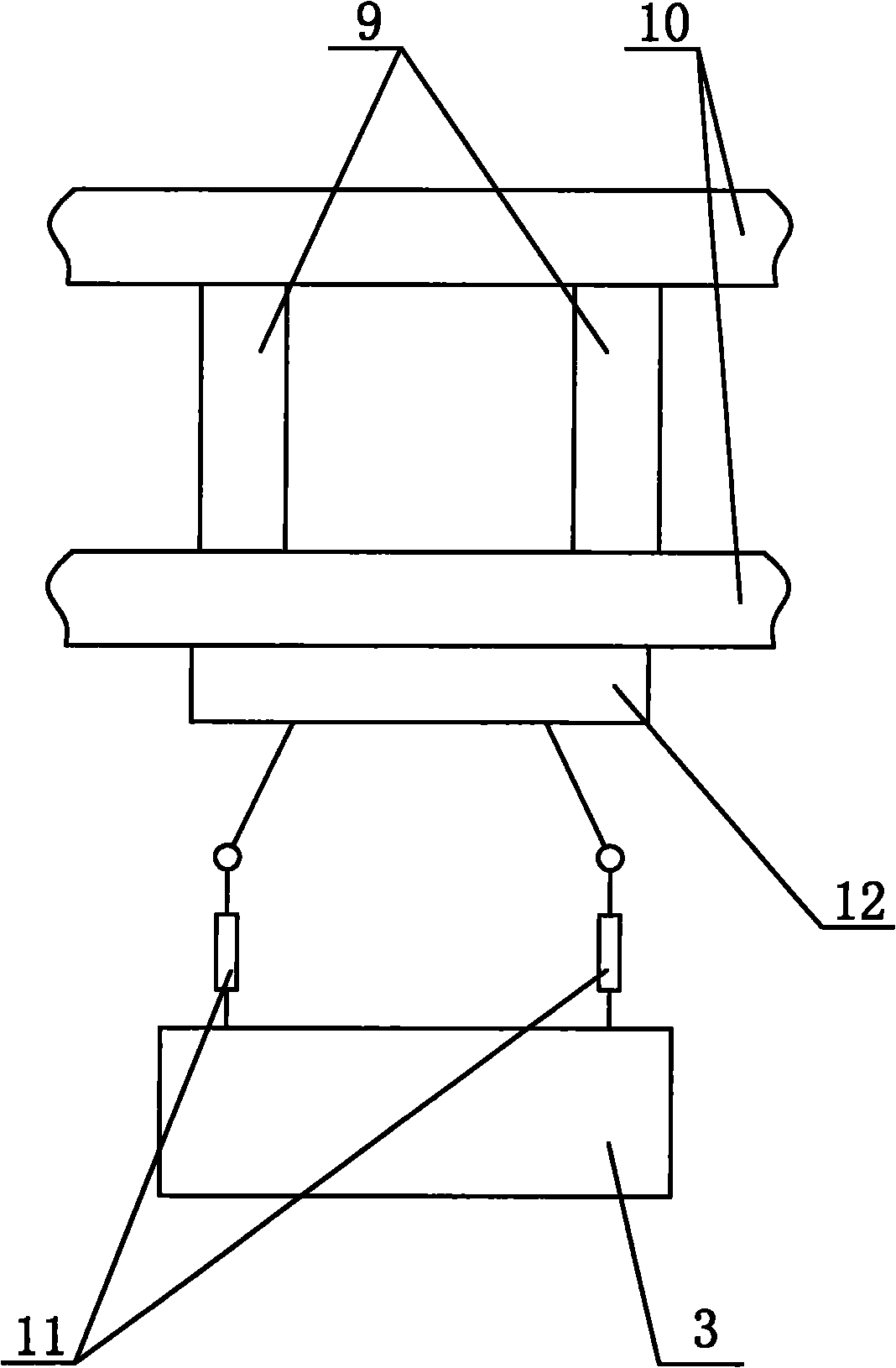

[0020] 1) see figure 1 , figure 2 , image 3 First, install the sintering machine head framework on the platform 10 and the height does not exceed the elevation of the track 2 on the trolley 4, and the sintering machine head frame above the elevation of the track 2 will not be installed temporarily.

[0021] 2) see figure 1 , figure 2 , place two sintering machine trolleys 4 on the track 2, pay attention not to install grates and side plates, otherwise the star wheel 3 cannot be placed flat on the trolley 4, and temporarily tie the two trolleys 4 together with a 4-point steel wire rope , fix it with a small bayonet so that it can keep synchronous during operation, fix a crescent seat on the troll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com