Method for generating inner surface polishing path of spatial bend pipe by c reconstruction

A technology of inner surface polishing and space bending, applied in instruments, digital control, control/regulation systems, etc., can solve the problems of reducing processing efficiency, reducing service life, generating turbulence, etc., so as to improve work efficiency and reduce preparation work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The specific embodiments of the present invention will be further described below in conjunction with the drawings.

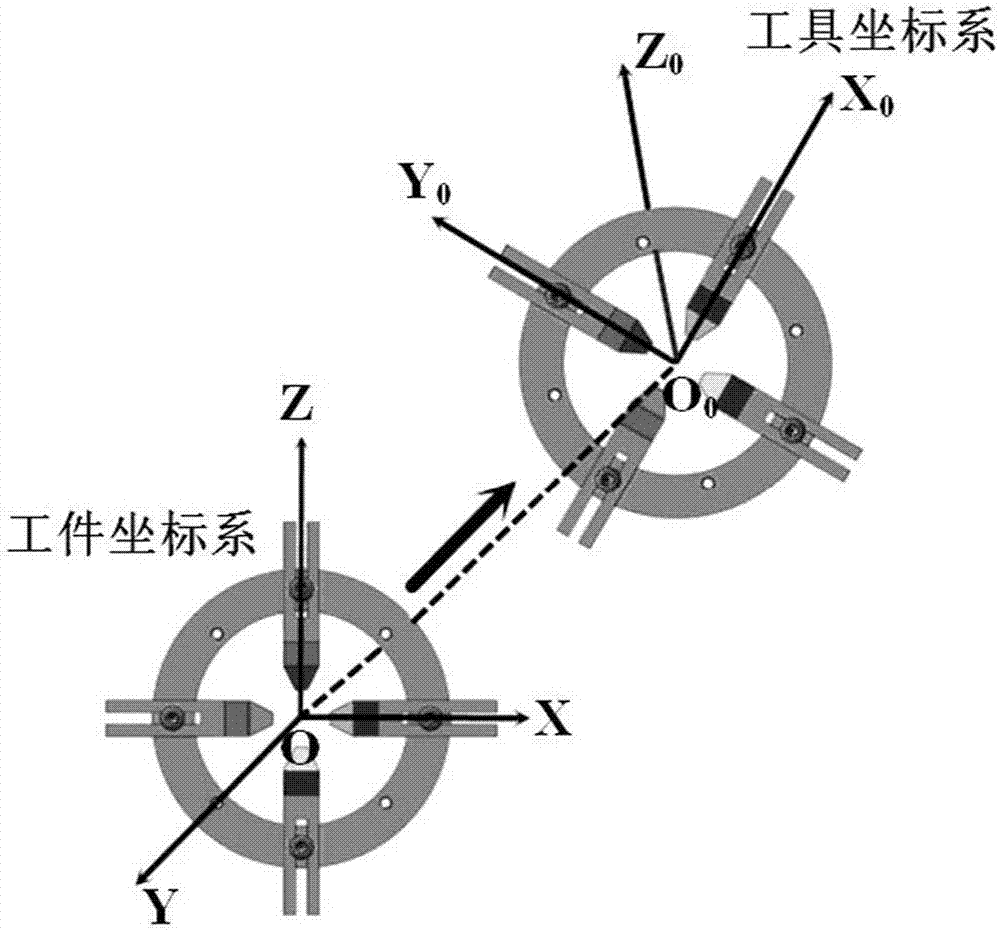

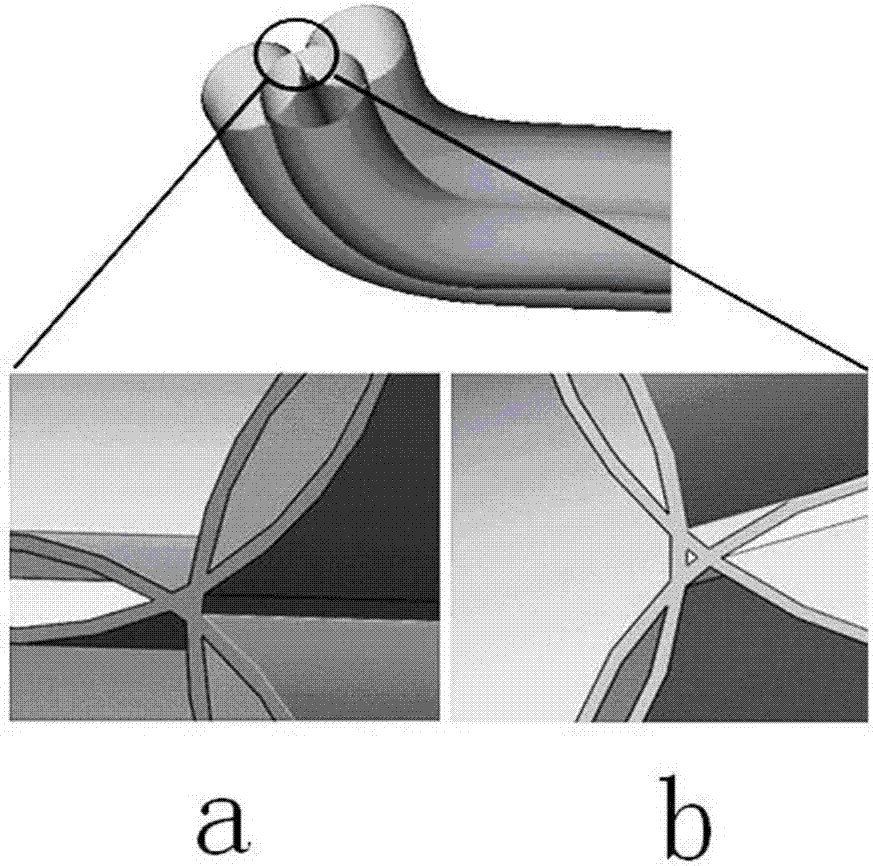

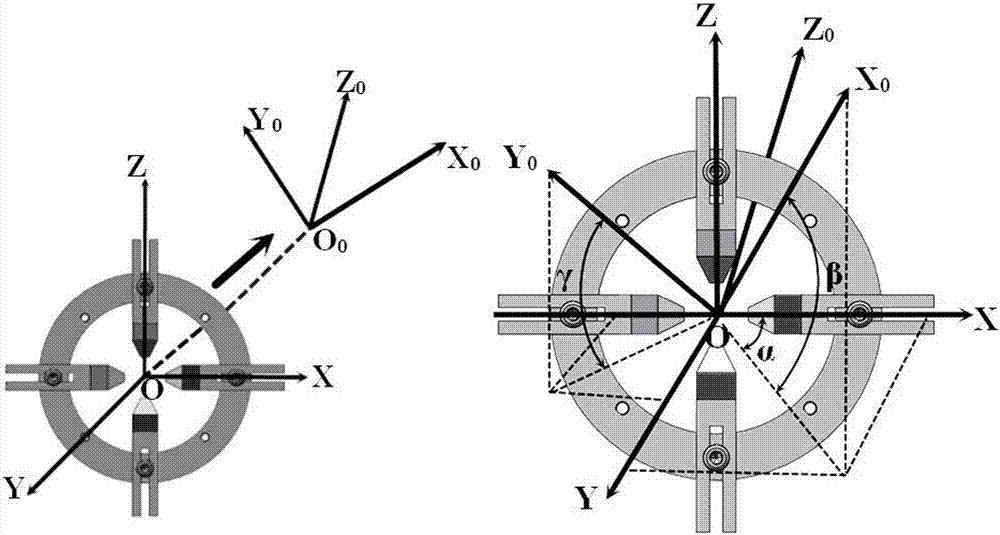

[0063] Such as figure 1 , 2 As shown in, 3, 4, 5 and 6, the method for generating the polished trajectory of the inner surface of the spatial elbow by the centerline reconstruction of the present invention is characterized by the following steps:

[0064] Step 1: Obtain the point cloud of the outer contour of the space elbow; scan the outer contour of the space elbow with a three-coordinate measuring instrument to obtain the point cloud of the three outer contours of the space elbow;

[0065] Step 2: Perform data processing on the point cloud, and obtain three contour lines through curve fitting;

[0066] Step 3: The centerline of the elbow is generated by the method of intersecting the cross section by using the fitted outer contour line;

[0067] Step 4: Discretize the point of the generated centerline of the elbow and the outer contour line generated by the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com