Pneumatic winding shaft

A technology of rewinding and air inflation, applied in the field of air inflation reel, can solve the problems of inability to unload strip copper foil, inability to meet the requirements of convenient coiling and unloading of strip coiling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

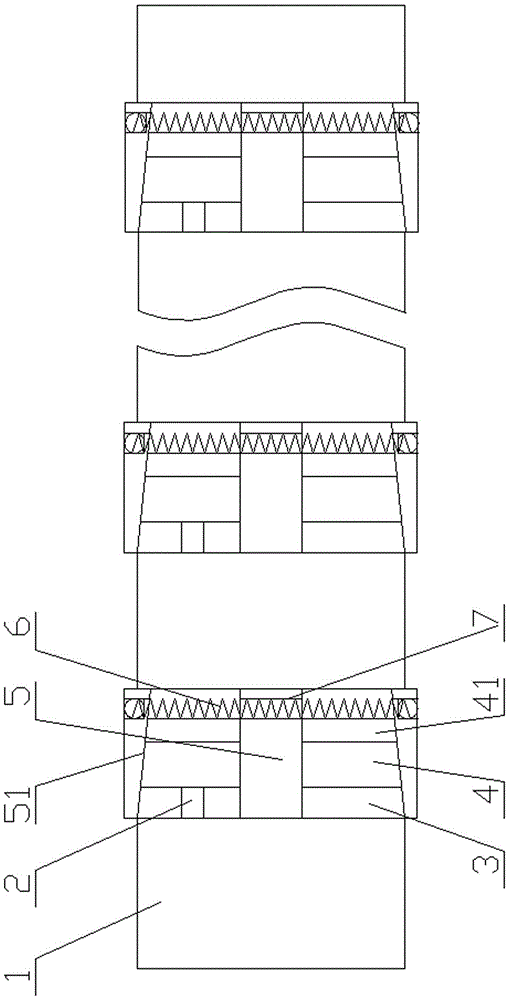

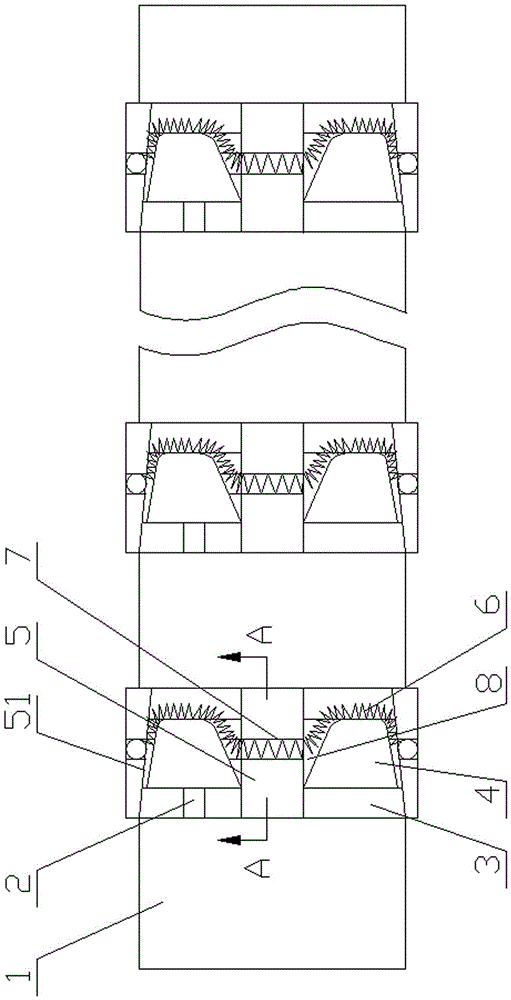

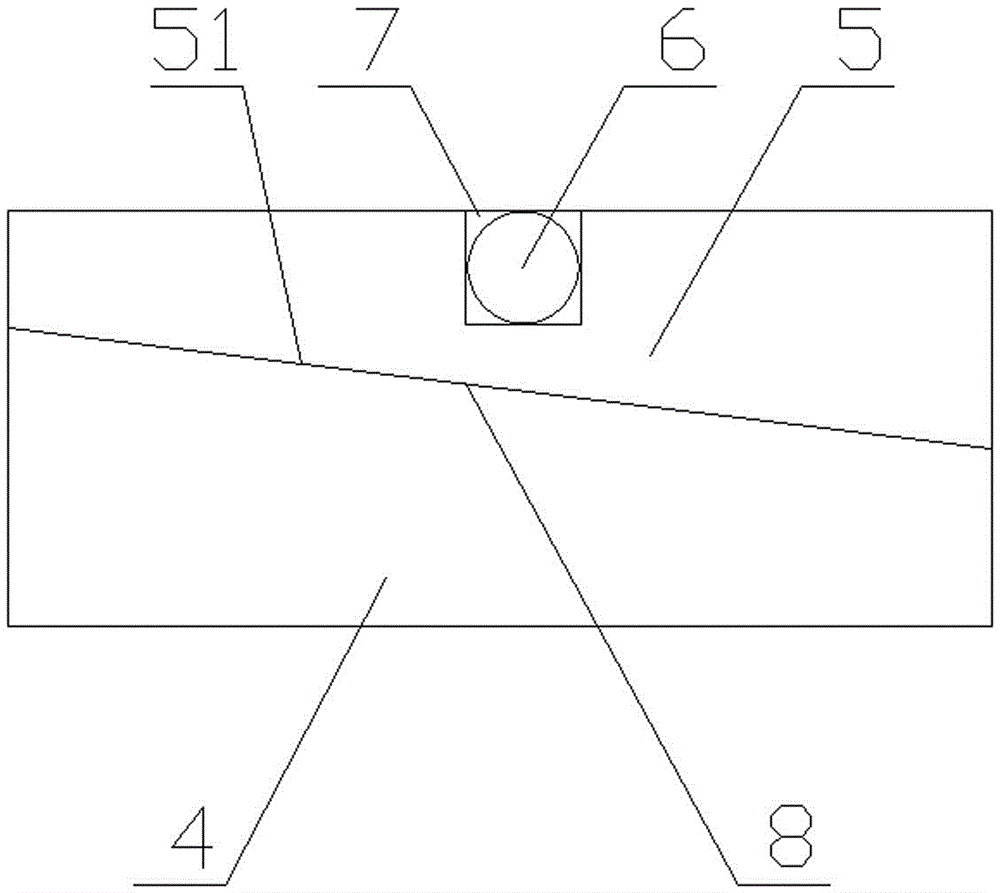

[0016] figure 1 Embodiment 1 shown: an inflatable reel includes a shaft body 1, a plurality of inflatable ring grooves 3 are evenly spaced on the outer peripheral wall of the shaft body 1, and an inflatable device is arranged in the inflatable ring groove 3, and the inflatable device Including an air-expanding push ring 4, a return spring 6 and a plurality of push-out blocks 5, the air-expanding push ring 4 is coaxially installed in the air-expanding ring groove 3 with the shaft body 1 and connected to the air pipe 2 connected in the shaft body to form an air supply The axial displacement state occurs in the air-expanding ring groove under the force, and the outer peripheral wall of one end of the air-expanding push ring 4 is an outer cone 41 structure, and a plurality of push-out blocks 5 are evenly arranged and tightened on the air-expanding push ring 4 through the return spring 6 Above, the inner wall of the ejection block 5 is a structure of the inner tapered surface 51 ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com