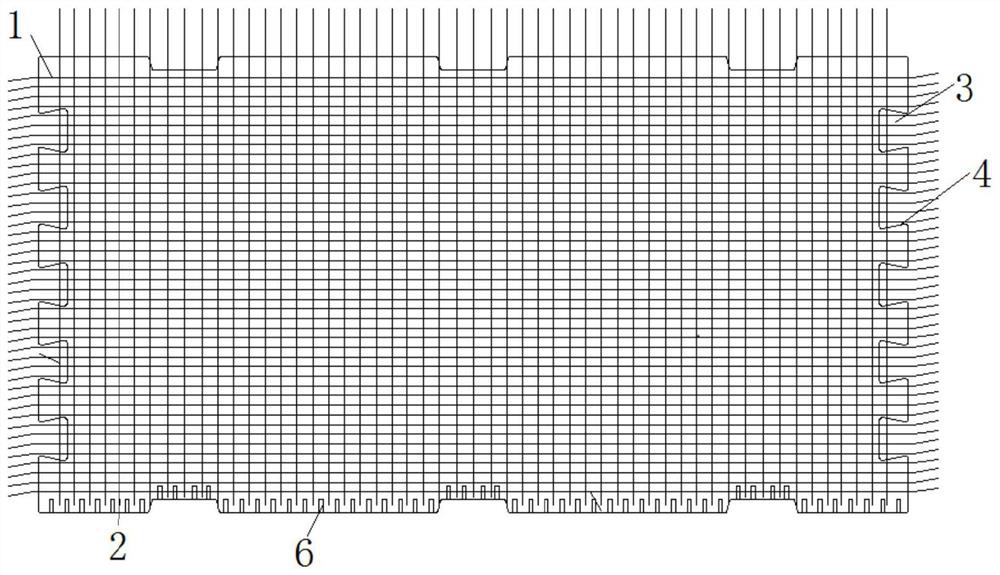

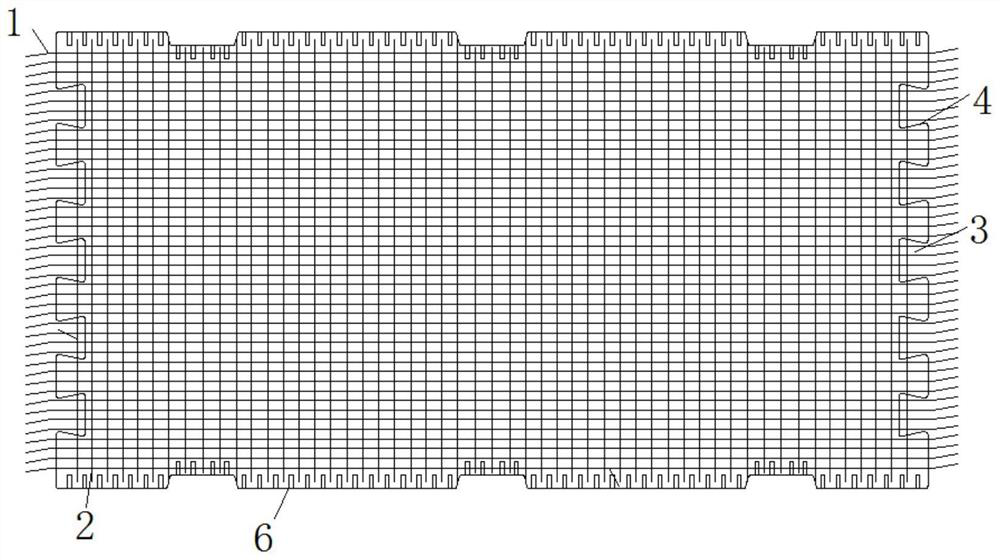

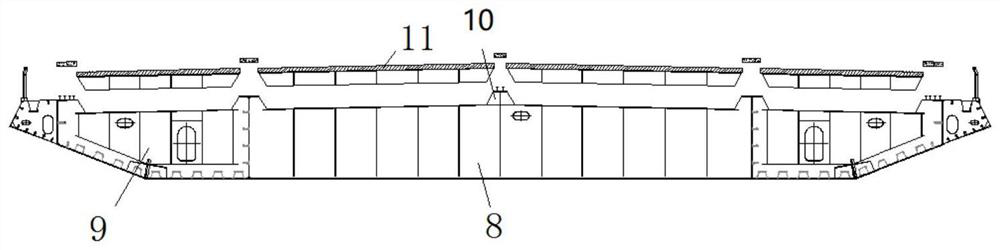

Prefabricated bridge deck slab, cable-stayed bridge and construction method thereof

A bridge deck and prefabricated bridge technology, applied to cable-stayed bridges, bridges, bridge parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0060] The embodiment of the present invention provides a construction sequence of a cable-stayed bridge, see Figure 9(a)-9(d) As shown, the construction sequence includes the following processes:

[0061] Step 1: Erection of temporary pier 16, auxiliary pier 17 and bridge tower 21 substructure synchronous construction, and then erect push platform 19 on the common pier at one end of the bridge;

[0062] Step 2: Complete the superposition of the steel structure main body and the prefabricated slab on the pushing platform 19, pour the wet joints on site, then install the guide beam 20, and push into the entire section of the cable-stayed bridge;

[0063] Step 3: Complete the steel structure main body and the prefabricated slab push-up on the upper part according to the placement in step 2, and the construction of bridge tower 21 is completed;

[0064] Step 4: Install and tension stay cables, dismantle temporary facilities, carry out bridge deck pavement and guardrail installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com