A method of manufacturing an inducer provided with a shaft sleeve

A manufacturing method and induction wheel technology, applied in the direction of manufacturing tools, welding equipment, auxiliary welding equipment, etc., can solve the problems of stress concentration, difficult mold, poor dynamic balance performance of induction wheel, etc., to meet the connection strength and reduce processing effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

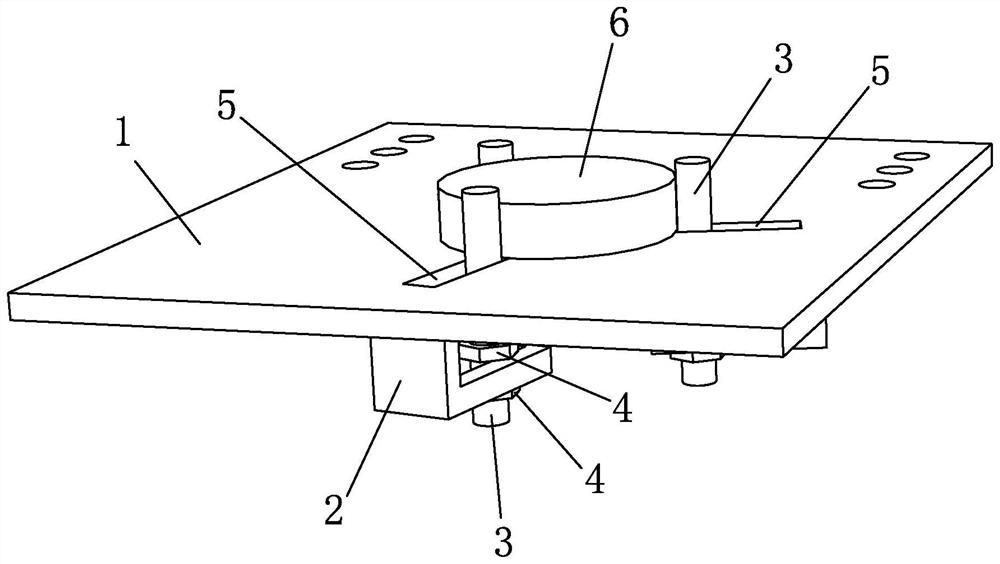

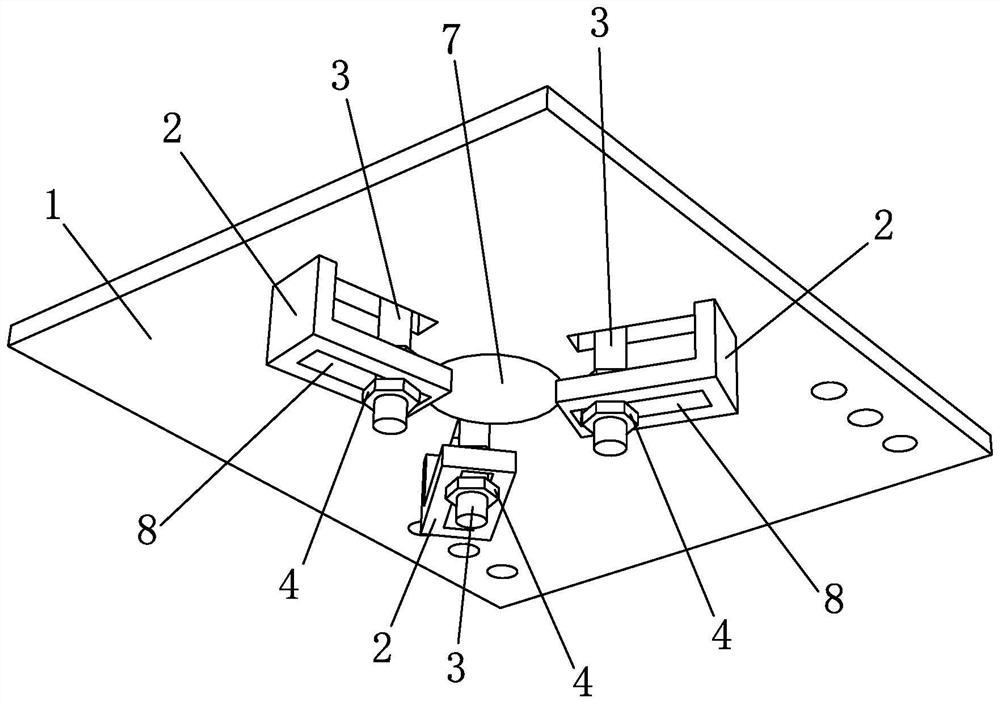

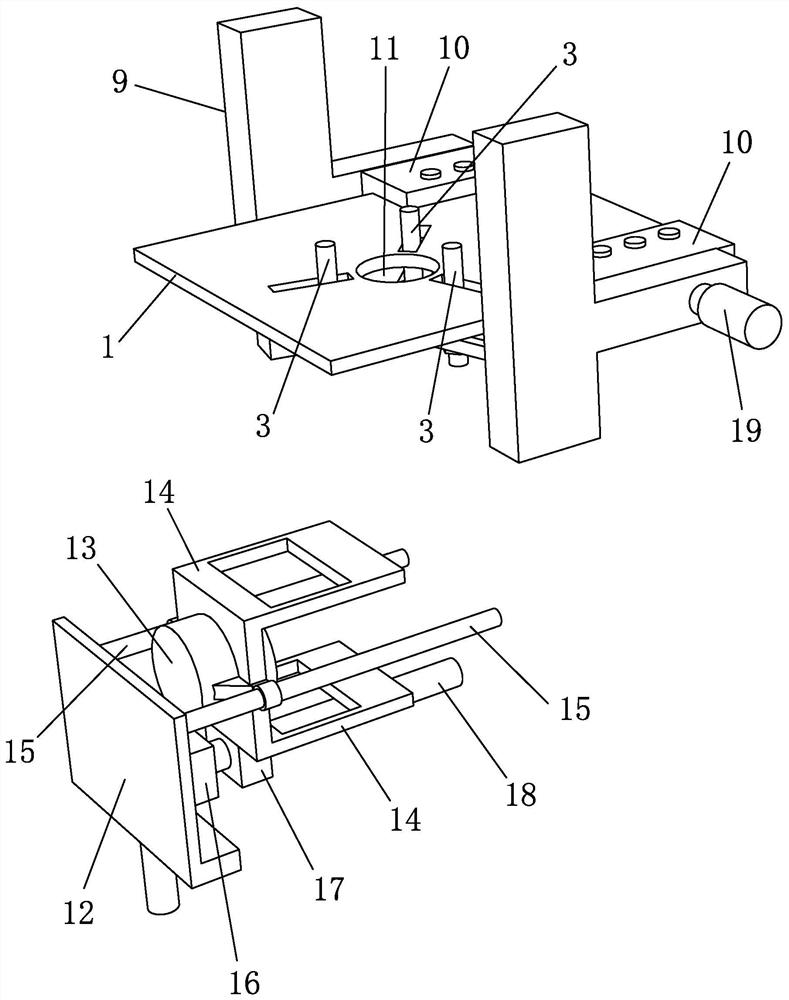

[0050] Such as Figure 1 to Figure 8 Shown, for the present invention a kind of inducer manufacturing method that is provided with axle sleeve, comprises the following steps:

[0051] a. Determine the positioning welding position of the shaft sleeve 20 of the inducer on the workbench 1:

[0052] (1) Place the sample 6 on the workbench 1, and insert the central shaft 7 at the bottom of the sample 6 into the through hole 11 of the workbench 1. The diameter of the sample 6 is the same as that of the shaft sleeve 20.

[0053] (2) Three L-shaped adjustment blocks 2 are welded on the bottom of the workbench 1, and the three L-shaped adjustment blocks 2 are arranged rotationally symmetrically with respect to the through hole 11 of the workbench 1. The single L-shaped adjustment block 2 is provided with a threaded rod 3, The threaded rod 3 passes through the sliding hole 5 of the workbench 1, and the threaded rod 3 of each L-shaped adjustment block 2 is adjusted. First, loosen the nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com