Carbon fiber three-dimensional flow centrifugal fan impeller and molding method thereof

A centrifugal fan and carbon fiber material technology, which is applied to household components, other household appliances, household appliances, etc., to avoid welding deformation, reduce weight, and shorten the cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0020] Referring to the accompanying drawings, the specific implementation is as follows:

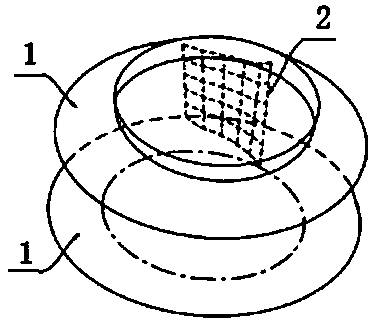

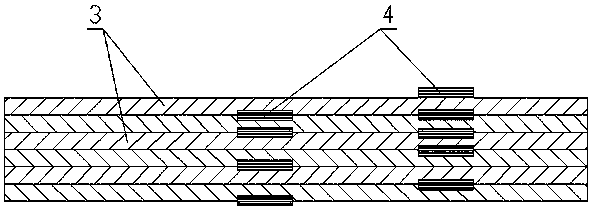

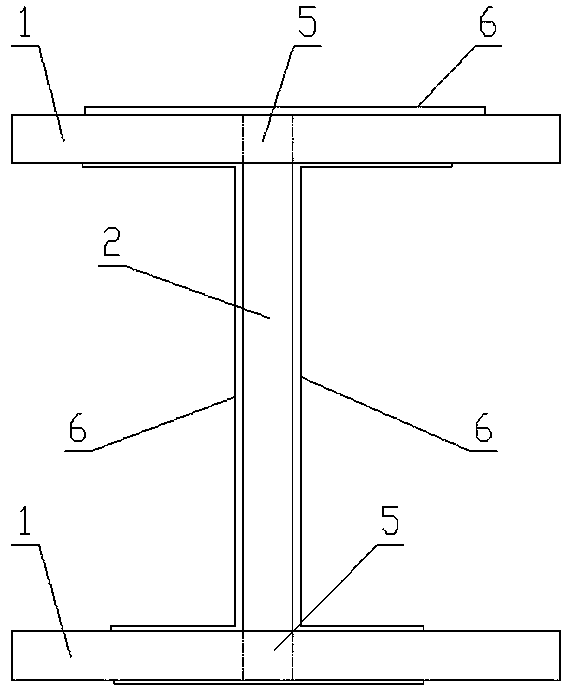

[0021] Such as figure 1 As shown, a three-dimensional flow centrifugal fan impeller made of carbon fiber includes two discs 1 and a plurality of three-dimensional twisted blades 2, the two discs 1 are arranged oppositely, and the three-dimensional twisted blade 2 is located between the two discs 1 and connect with two roulettes 1 at the same time; figure 2 As shown, the wheel disc 1 and the three-dimensional twisted blade 2 are composed of multiple layers of carbon fiber material 3 sequentially laminated along the thickness direction, and the carbon fiber material 3 is made of carbon fiber prepreg, carbon fiber dry cloth, carbon fiber powder, and carbon fiber unidirectional yarn. One, the interior of the three-dimensional twisted blade 2 is sandwiched with a plurality of carbon fiber reinforcement strips 4 along its length direction, thereby forming a plurality of reinforcing ribs ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com