Hydraulic waste drilling machine

A hydraulic and drilling machine technology, used in rotary drilling rigs, impact drilling, rotary drilling and other directions, can solve the problem that the drilling machine relies heavily on labor, the guarantee rate of hole-forming quality is low, and the hole-forming efficiency is reduced. problems, to achieve the effect of improving loading and unloading efficiency and hole forming efficiency, reducing hole forming time, and solving hole forming difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

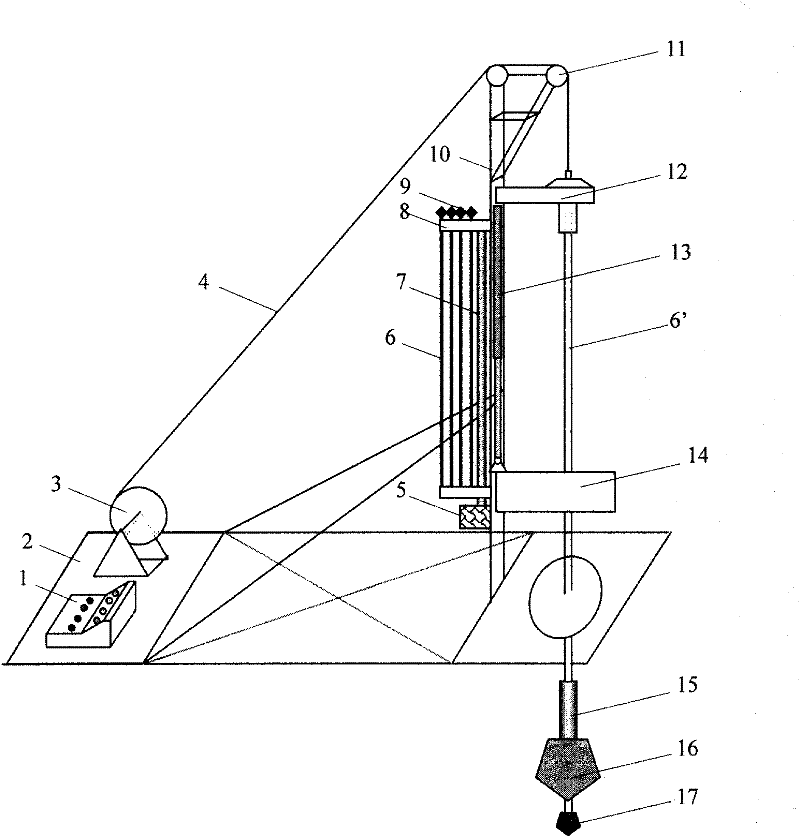

[0012] Below in conjunction with accompanying drawing, the hydraulic type garbage drilling machine of the present invention of the present invention is described in further detail:

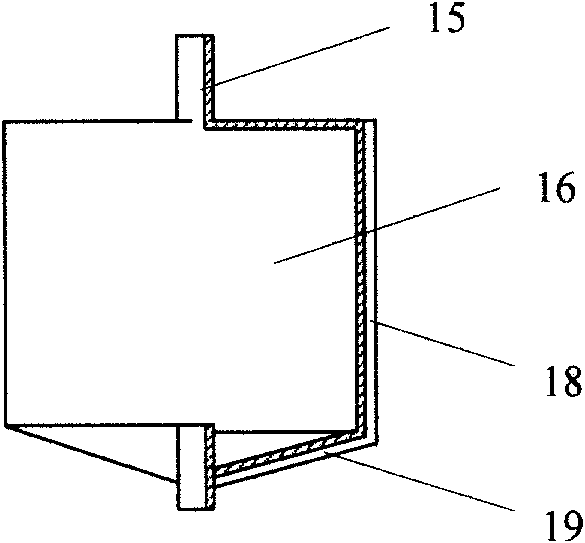

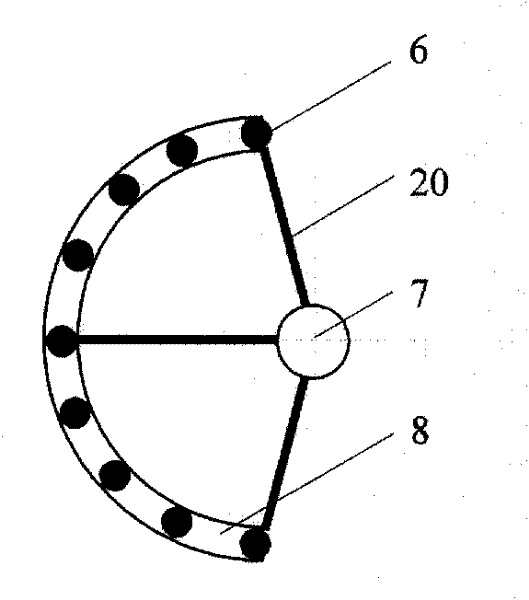

[0013] The hydraulic drilling machine consists of a control cabinet 1, a drill frame 2, a winch 3, a drill pipe slot 8, an overhead wheel 11, a chuck 12, a hydraulic rod 13, a drill pipe 6, a floating rail turntable 14, a drill collar 15, and a combination The drill bit is composed of a control cabinet 1, a hoist 3 and a vertical support 10 fixedly installed on the drill frame 2, and the steel cable 4 on the hoist 3 is connected to the chuck 12 through the sky wheel 11. The control cabinet 1 controls the hydraulic rod 13 of the hydraulic drilling, the winch 3 , the floating rail type turntable 14 and the torsional power device 5 . The hydraulic rod 13 is positioned at one side of the vertical support 10, its lower end is connected to the floating rail type turntable 14 and the upper end is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com