Material lifter for building construction

A technology for material hoists and building construction, applied in the direction of emptying containers, loading/unloading, bottle filling, etc., can solve problems such as unloading, unremovable materials, easy to float up and down, etc., to avoid shaking, improve cleaning effect, The effect of increasing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

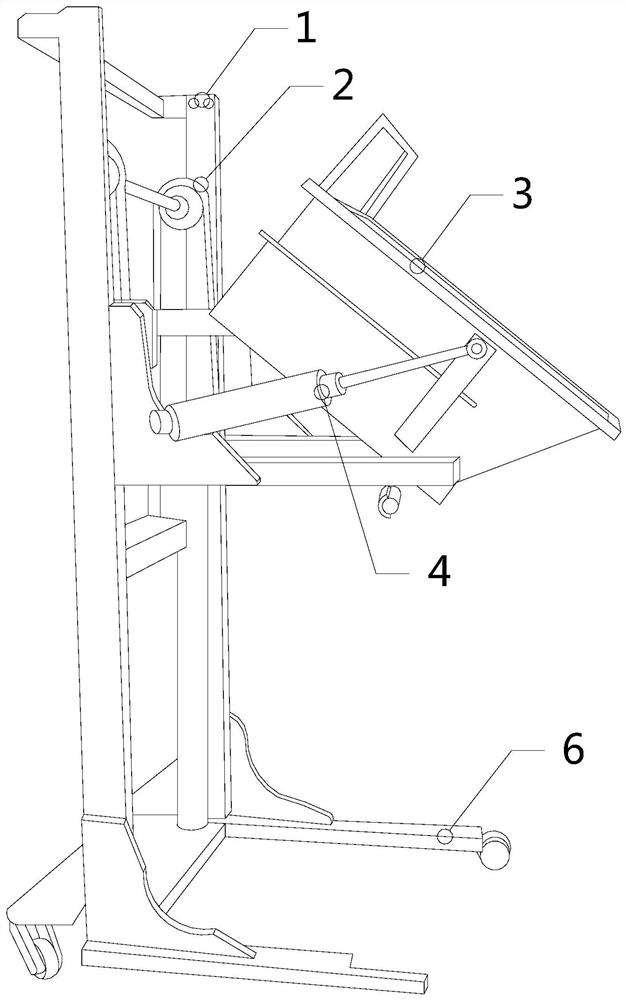

[0023] see Figure 1-Figure 4 , a material hoist for building construction. The invention provides a material hoist for building construction. The structure includes a bracket 1, a conveyor belt 2, a hopper 3, a telescopic rod 4, a bottom frame 6, and a discharge tongue 7. The bottom A support 1 is vertically installed on the frame 6, and the support 1 and the bottom frame 6 are welded vertically. A conveyor belt 2 is installed, the conveyor belt 2 and the hopper 3 are mechanically connected, a discharge tongue 7 is installed at the bottom of the hopper 3, and a motor is provided at the bottom of the hopper 3 .

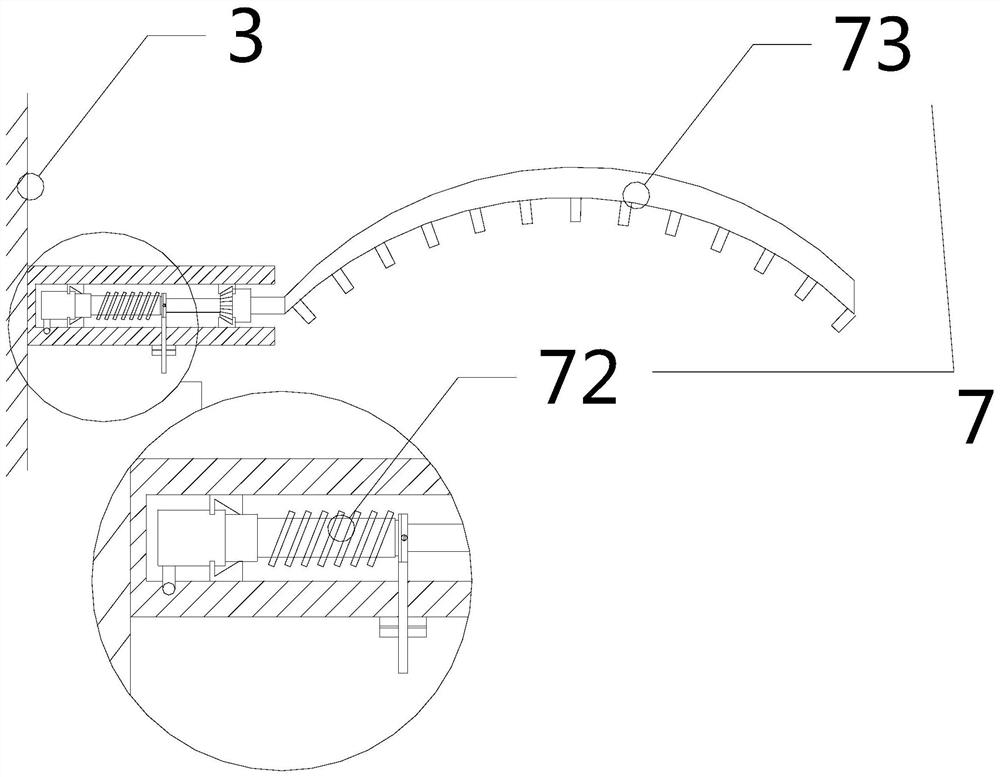

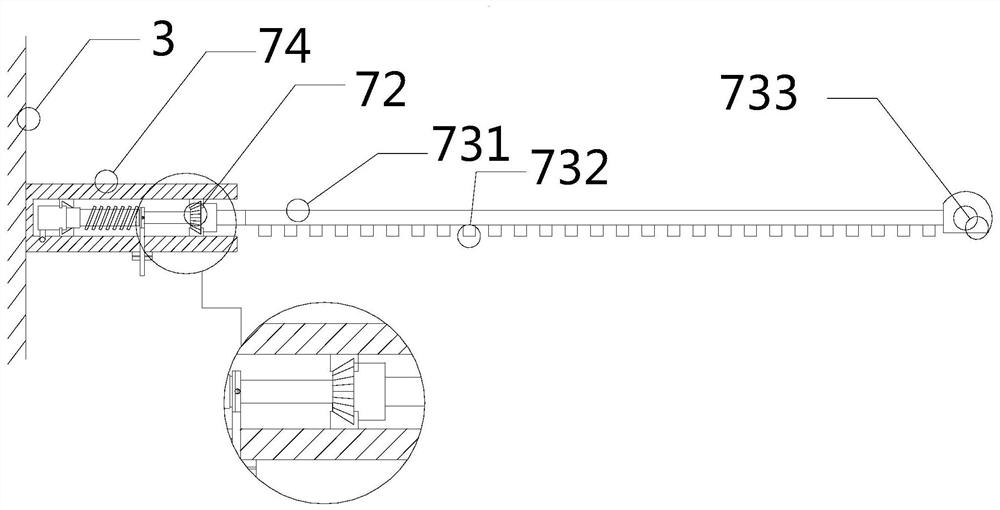

[0024] The discharge tongue 7 is provided with a balance and stability structure 72, a tongue 73, and a fixed shell 74. The fixed shell 74 is installed on the inner bottom of the hopper 3 close to the inner wall of the bracket 1, and the other end of the balance and stability structure 72 is A tongue plate 73 is installed, and the tongue plate 73 and the inner bottom...

Embodiment 2

[0030] see Figure 1-Figure 4 A material hoist for building construction. The invention provides a material hoist for building construction. The structure includes a bracket 1, a conveyor belt 2, a hopper 3, a telescopic rod 4, an underframe 6, and a discharge tongue 7. The underframe 6 is vertically installed with a support 1, and the support 1 and the bottom frame 6 are vertically welded. There is a conveyor belt 2, the conveyor belt 2 and the hopper 3 are mechanically connected, the bottom of the hopper 3 is equipped with a discharge tongue 7, and the bottom of the hopper 3 is provided with a motor.

[0031]The discharge tongue 7 is provided with a balance and stability structure 72, a tongue 73, and a fixed shell 74. The fixed shell 74 is installed on the inner bottom of the hopper 3 close to the inner wall of the bracket 1, and the other end of the balance and stability structure 72 is A tongue plate 73 is installed, and the tongue plate 73 and the inner bottom end surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com