Method and device for detecting and clearing sink roll slagging

A technology of submerged roll and slagging, applied in electric speed/acceleration control, coating, instruments, etc., can solve the problems of scraper moving speed change, roll surface and scraper wear, strip quality defects, etc., and achieve low wear and tear. , Improve the efficiency of use and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

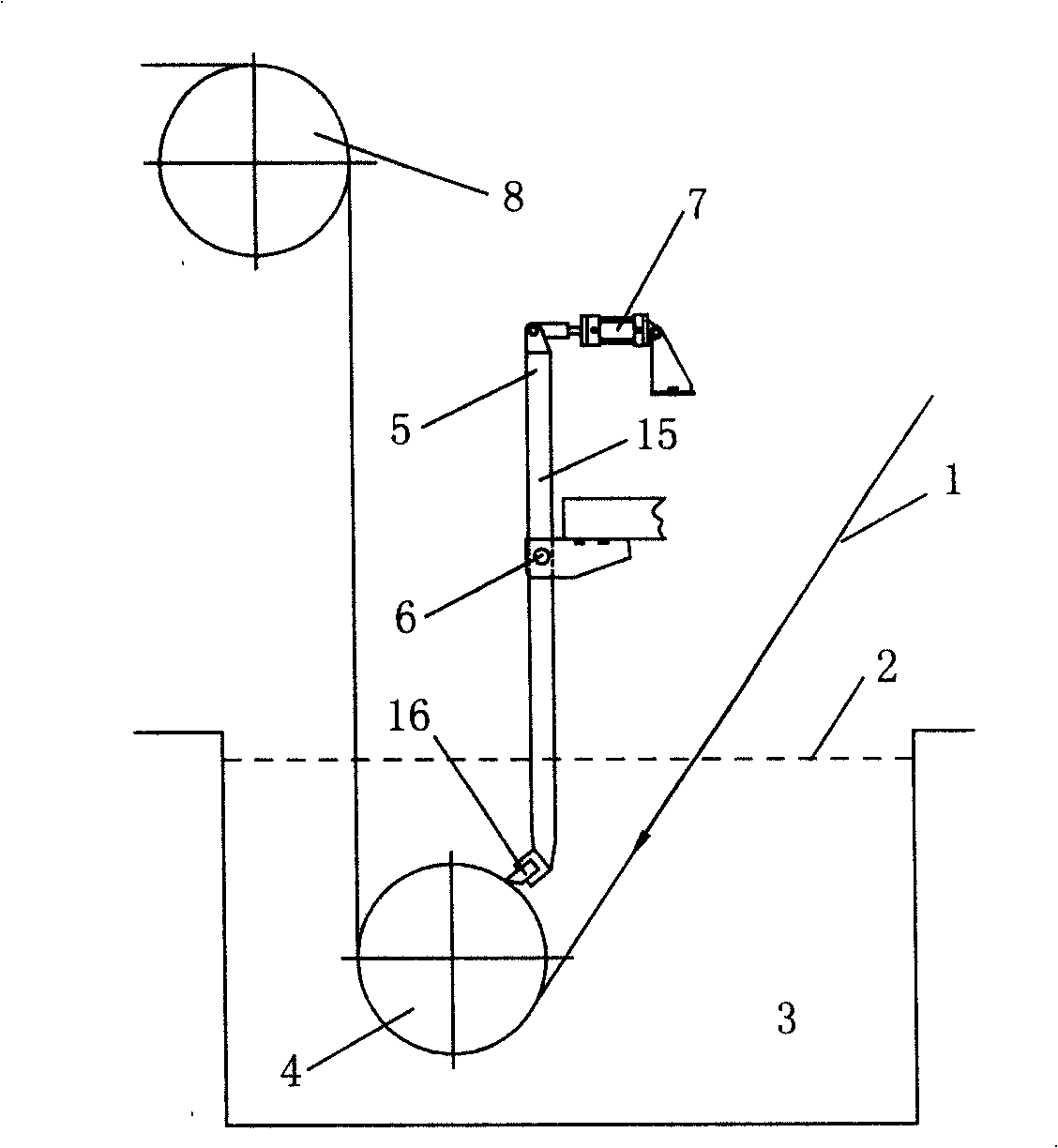

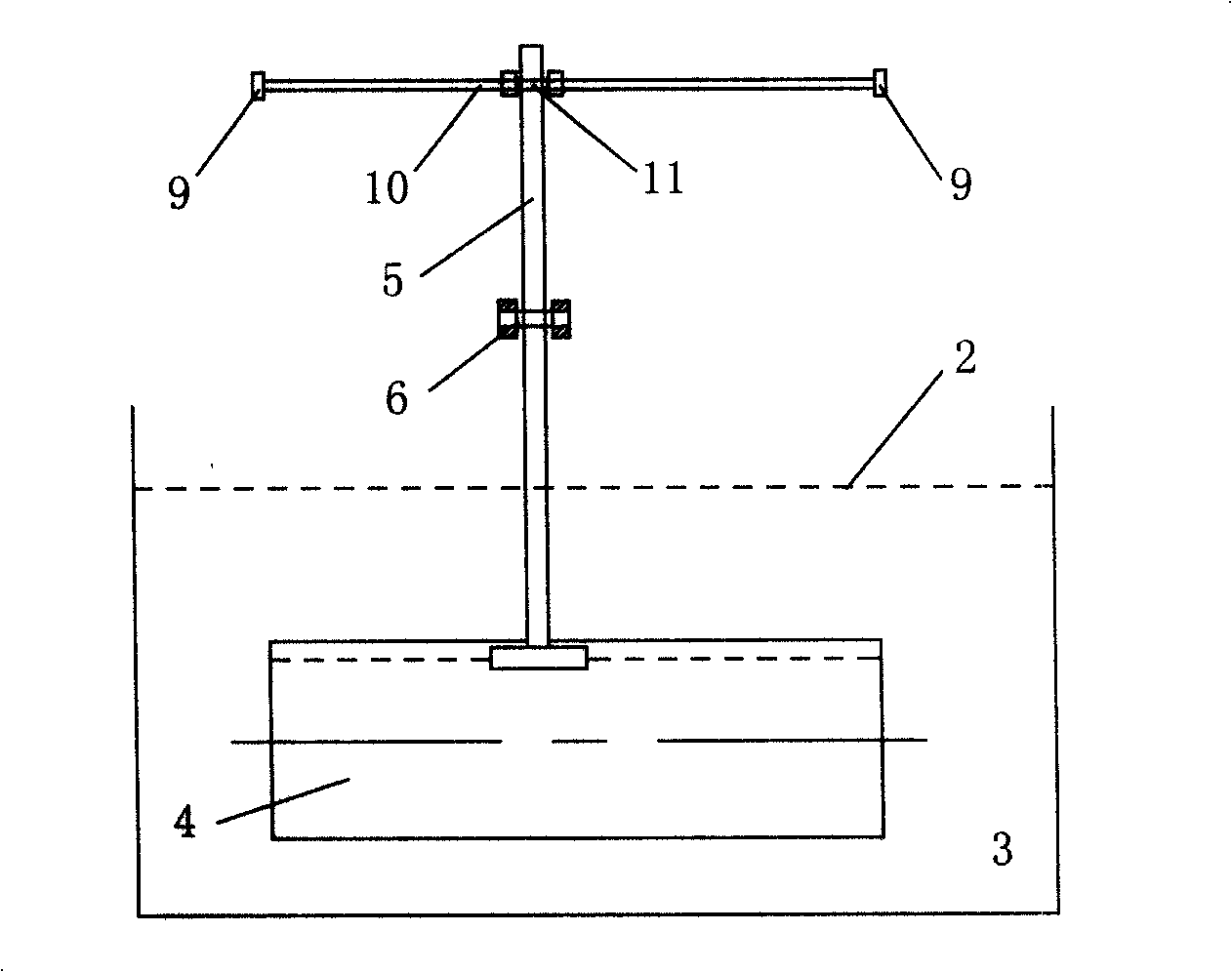

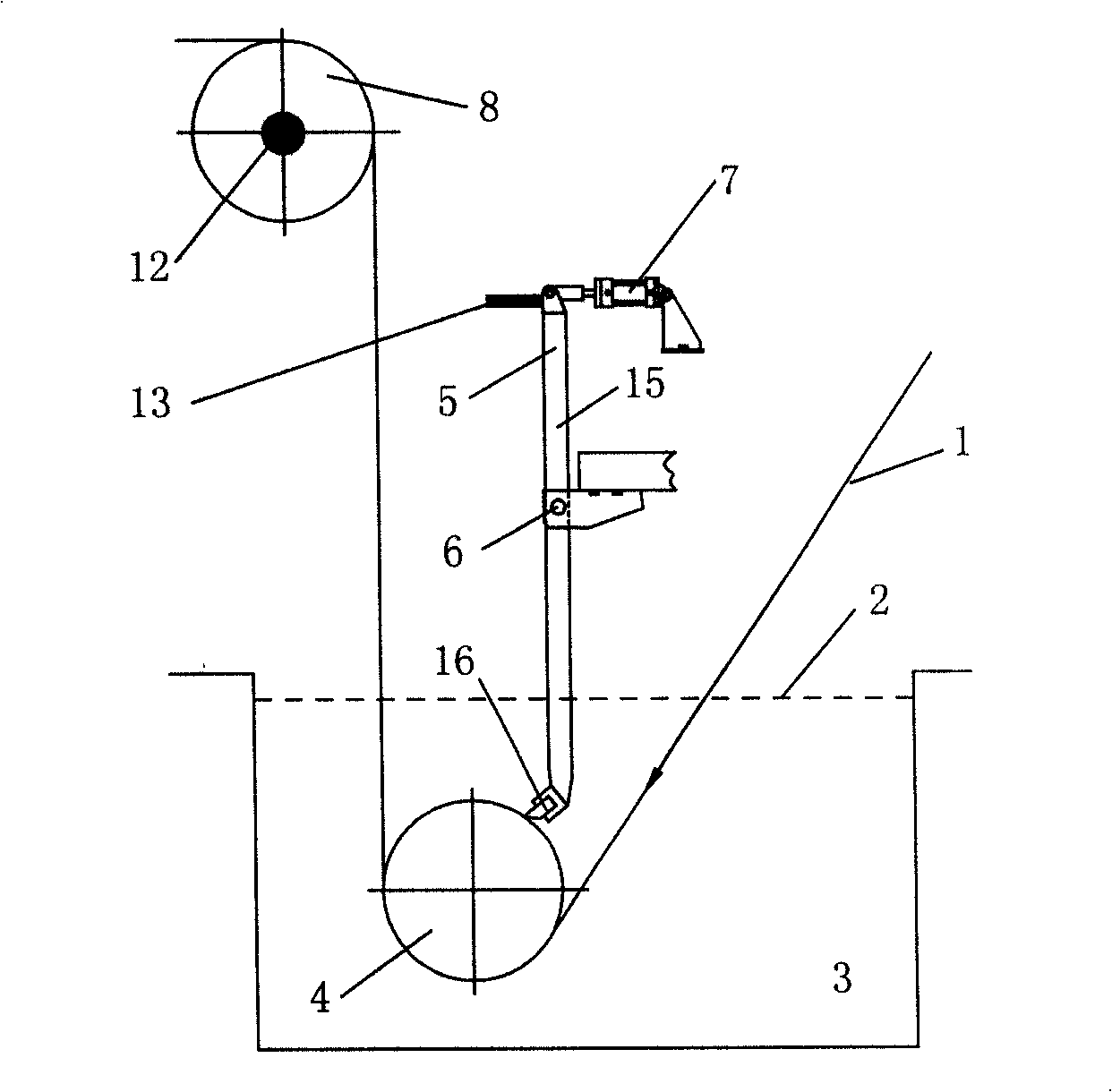

[0043] Install a speed sensor on the top roller, if the top roller speed W=0.5 rev / s is measured, and the top roller diameter Φ=1.5m, then the strip speed V1=πΦW=2.355m / s; then the time for the sinking roller to rotate one circle, That is, the rotation period T=1.067s; if the blade width D is 0.2m, the reasonable speed V2 of the blade moving along the generatrix of the sinking roller is V2=0.1875m / s.

[0044] see Figure 7 , the initial cylinder pressure is set to 0.1bar. By installing a displacement sensor on the extension rod of the sinking roller scraper rod, the slagging thickness is about 0.05-10mm. When the slagging is 0.05mm thick, after the amplification effect of the extension rod, the measured The displacement s1' is 2×0.05mm=0.1mm; when s1'=0.1mm or s1'>0.1mm is detected, it is judged that there is slagging, and the corresponding controller issues instructions. First, stop the moving speed of the scraper along the busbar of the sinking roller for fixed-point scrapi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com