Controllable dissolvable well cementation rubber plug

A technology of cementing rubber plugs and rubber bowls, which is applied in wellbore/well parts, earthwork drilling, sealing/isolation, etc., which can solve problems such as cumbersome construction procedures, complex tool structures, and difficult construction, and achieve the goal of avoiding jetting. Hole operation, easy to use and operate, and efficient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

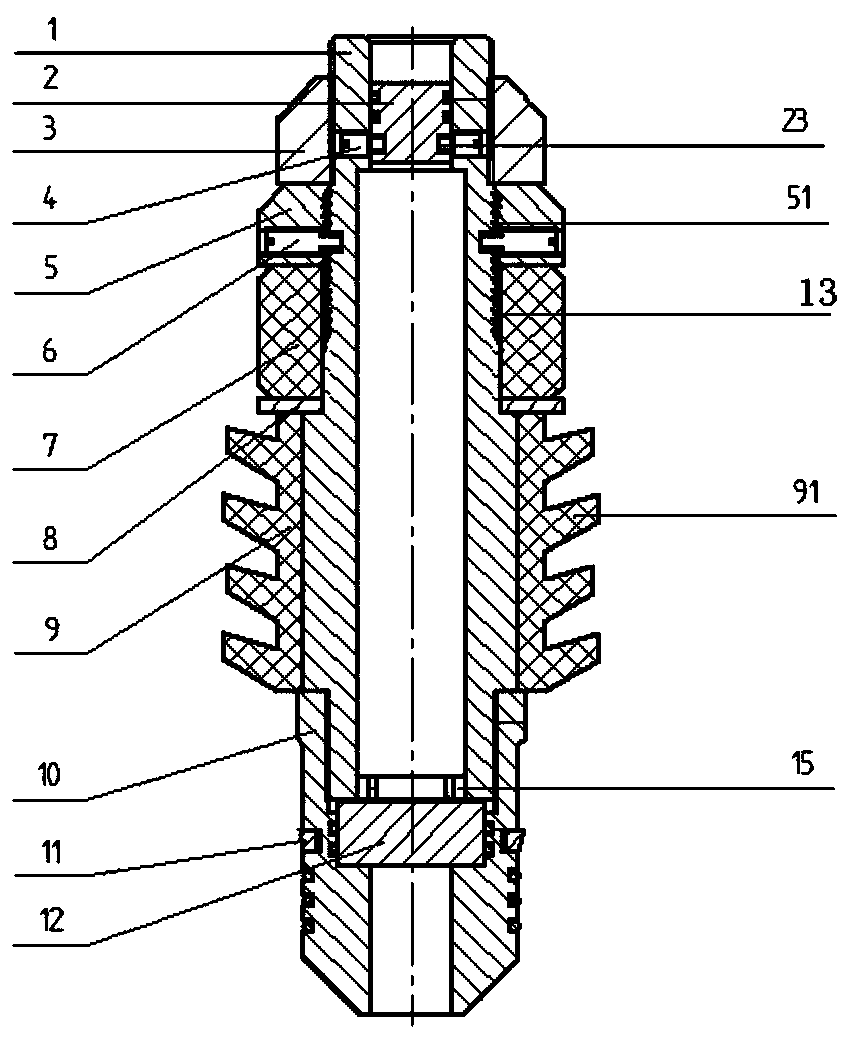

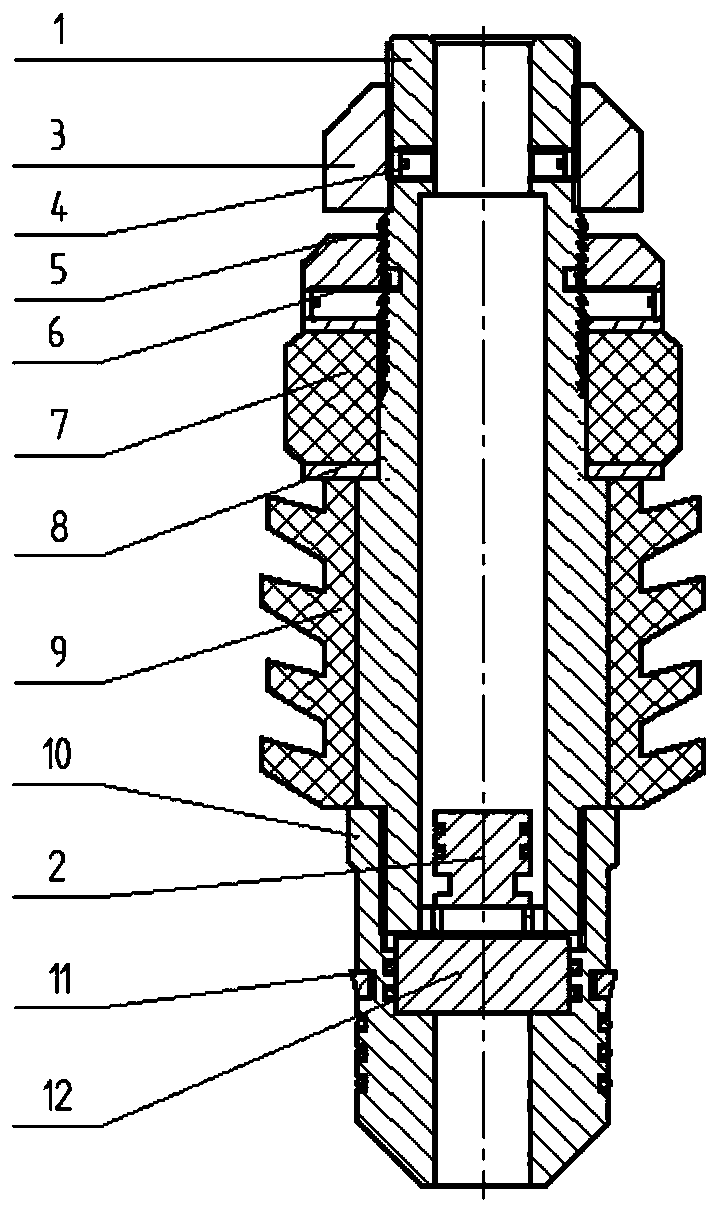

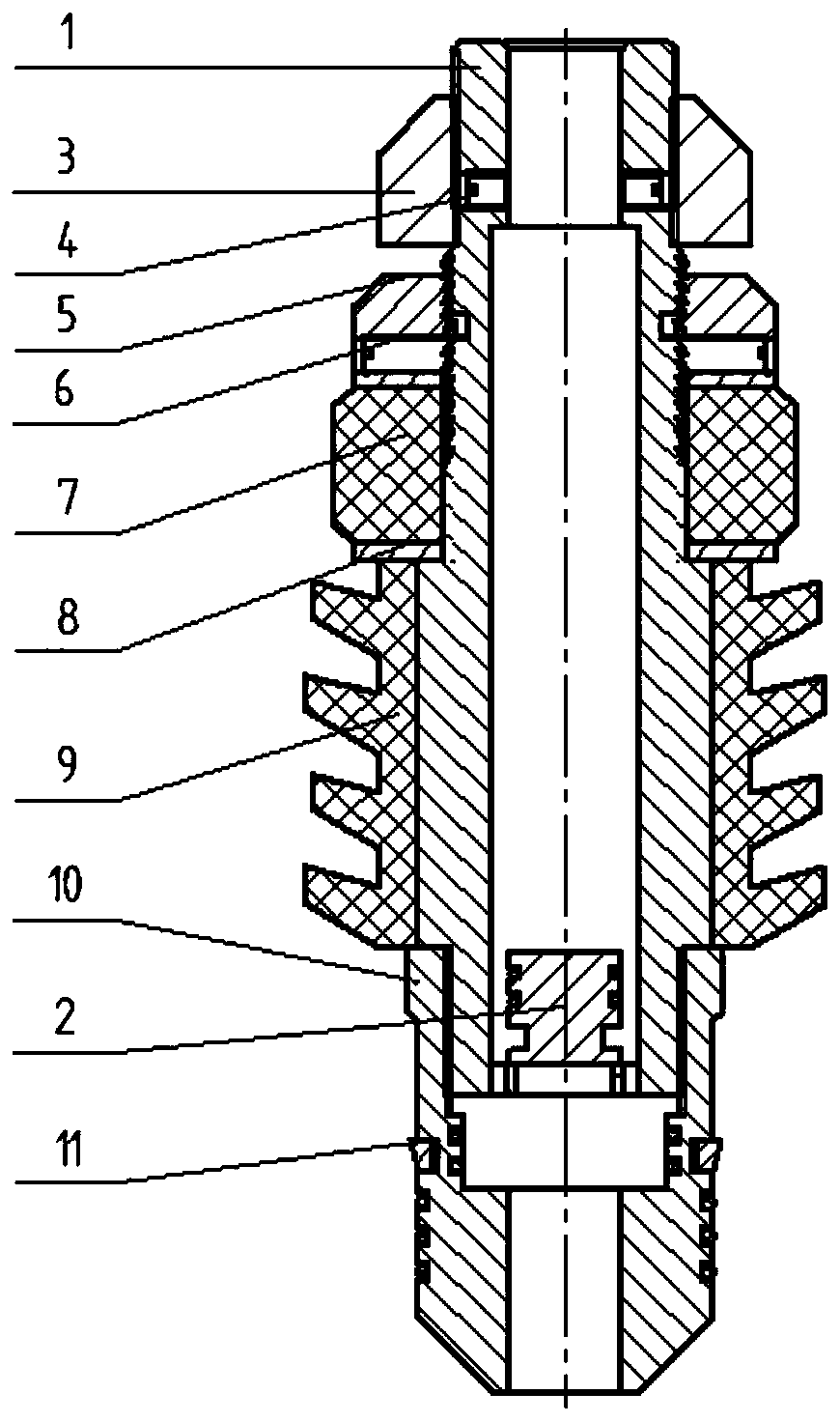

[0022] The present invention is further described below in conjunction with accompanying drawing:

[0023] see Figure 1 to Figure 3 , a controllable dissolving cementing plug, comprising a mandrel 1, a sealing core 2, a lock cap 3, a liquid cylinder 5, a rubber barrel 7, a rubber bowl 9, a sealing body 10 and a dissolvable core 12; the mandrel 1 It is a hollow cylindrical structure, the sealing core 2 is arranged inside one end of the mandrel 1, the other end of the mandrel 1 is covered with a sealing body 10, and a cavity is formed between the inside of the sealing body 10 and the end of the mandrel 1, The dissolvable core body 12 is arranged in the cavity; the outer side of the mandrel 1 at one end of the sealing body 10 and the outer side of the other end of the mandrel 1 are sequentially provided with a rubber bowl 9 , a rubber tube 7 , a liquid cylinder 5 and a lock cap 3 .

[0024] The diameters of both ends of the mandrel 1 are smaller than the diameter of the middle,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com