3.5-in side tracking horizontal well segmented fracturing method

A sidetracking horizontal well and staged fracturing technology, which is applied in earthwork drilling, wellbore/well components, production fluids, etc., can solve problems such as limited construction displacement, no mechanical hard seal, and small wellbore size , to achieve the effect of reducing construction risk and high sealing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A 3.5-inch sidetracking horizontal well staged fracturing method, comprising the following steps:

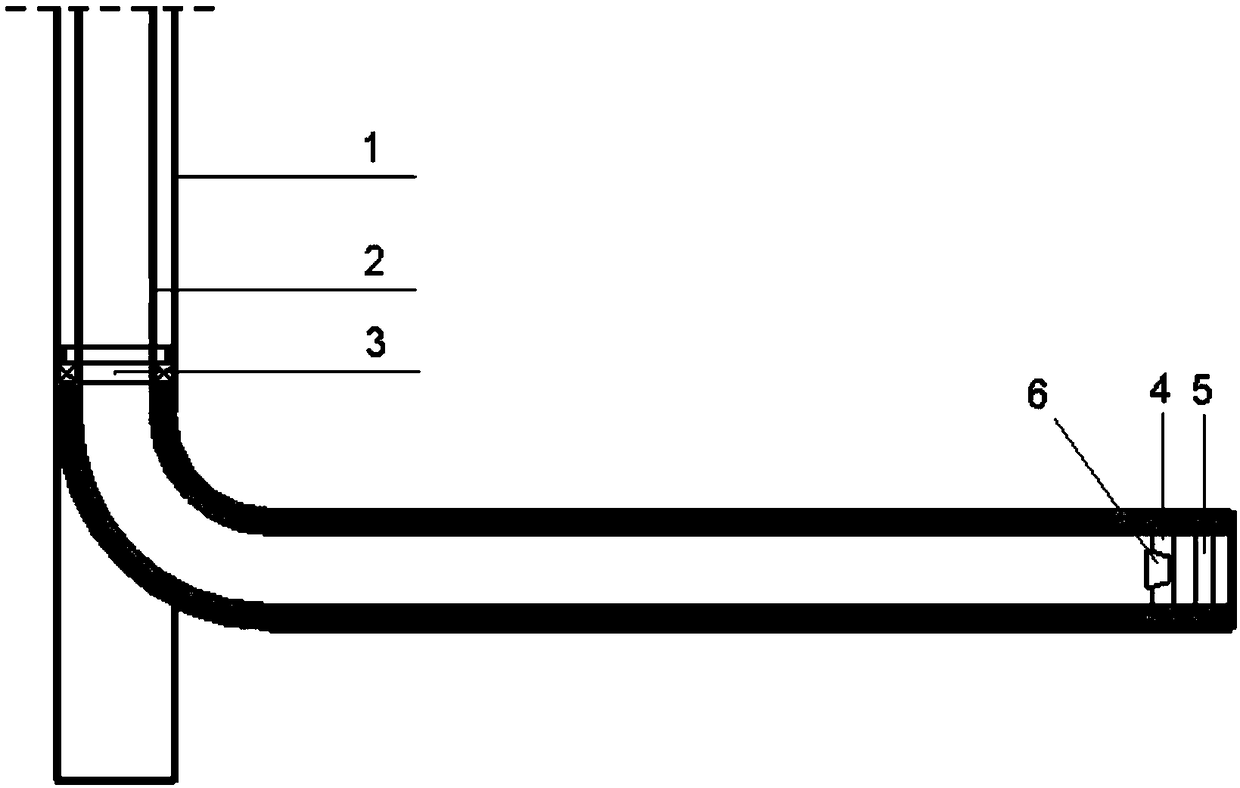

[0038] S1. Sidetrack drilling in the original casing 1, and then place the 3.5in tubing 2 with a suspension packer 3, floating hoop 4, and floating shoes 5 at predetermined positions;

[0039] S2. Set the hanging packer 3, squeeze the cement into the 3.5in tubing 2 to cement the well, throw the cementing plug 6 to touch and press to complete the well cementing, press and test;

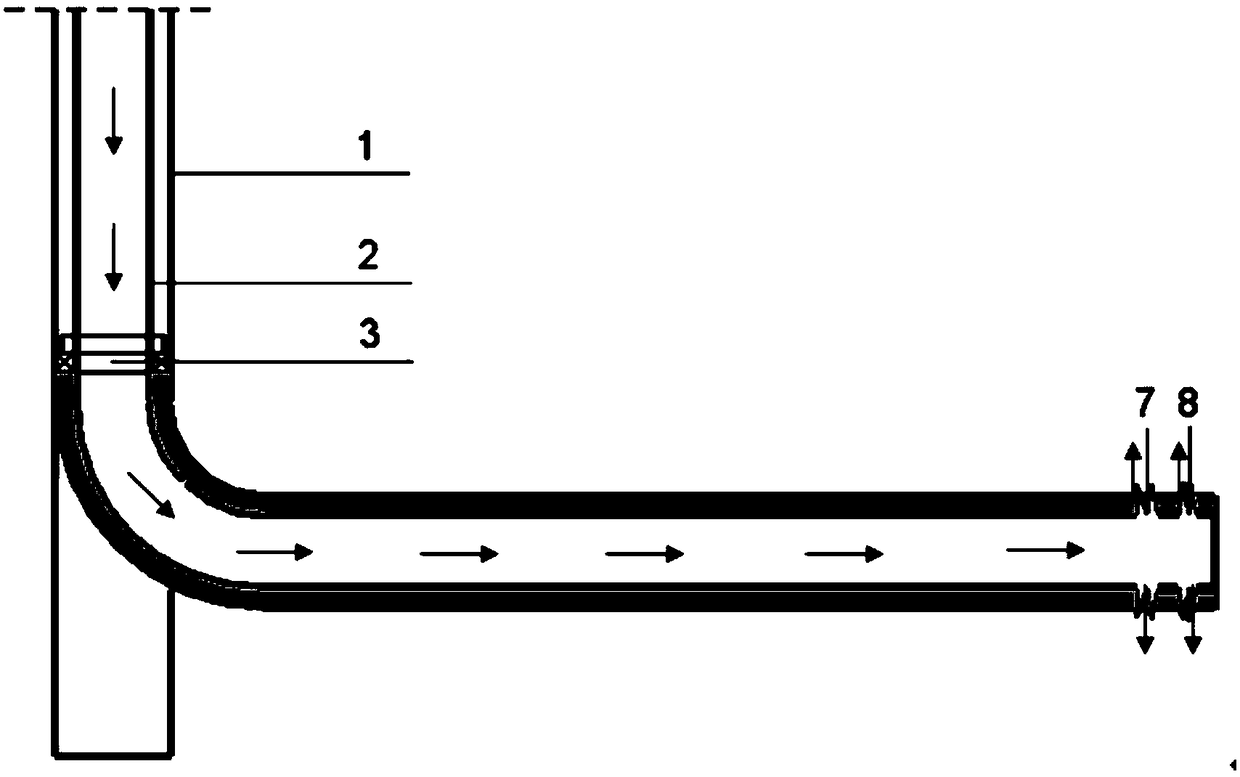

[0040] S3. After the pressure test, the floating hoop 4 dissolution control switch is opened by pressure, the floating hoop 4, the floating shoe 5, and the cementing rubber plug 6 are gradually dissolved. After the dissolution is completed, the first channel 7 is formed, and the 3.5in tubing 2 is injected into the fracturing Liquid, the first stage of fracturing construction;

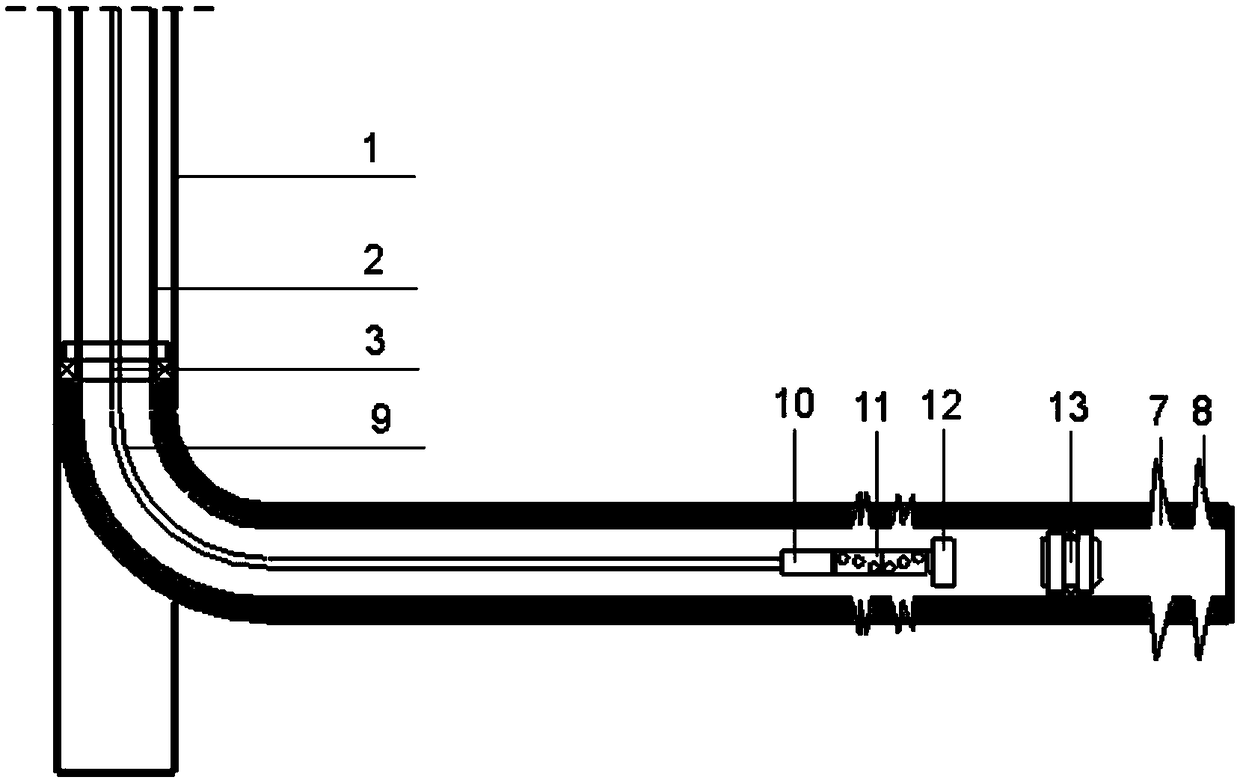

[0041] S4. Enter the bridge injection tool string or hydraulic jet fracturing string through the cable 9, start the sett...

Embodiment 2

[0047] On the basis of Example 1, the dissolution time of the floating hoop, floating shoe, and cementing rubber plug is controllable and adjustable, and does not dissolve during the cementing period, meeting the cementing requirements. After the cementing is completed, the wellbore pressure test is carried out. Soluble tools dissolve quickly after pressure testing.

[0048] The bridge-shooting joint operation tool string is a bridle 10+magnetic positioning+ignition adapter+perforating gun 11+first setting tool 12+soluble bridge plug 13 connected sequentially from top to bottom, wherein the first setting Tool 12 is a fire setting tool or an electric setting tool.

[0049]When in step S4 the cable 9 is lowered into the bridge and used as a tool string, the operation method of the step S5 is as follows: lift the cable 9 so that the perforating gun 11 is located at the designed second-stage fracturing position, start the perforating gun 11, and ignite After perforating, the cabl...

Embodiment 3

[0053] A 3.5-inch sidetracking horizontal well staged fracturing method, comprising the following steps:

[0054] Such as figure 1 As shown, S1. Window sidetracking in 5.5in casing 1, 3.5in tubing 2 with hanging packer 3, floating hoop 4, and floating shoe 5 are placed at predetermined positions;

[0055] S2. Set the hanging packer 3, squeeze the cement into the 3.5in tubing 2 to cement the well, throw the cementing plug 6 to touch and press to complete the well cementing, press and test;

[0056] S3. The cementing is qualified, the pressure opens the dissolution control mechanism of the cementing rubber plug 6, the floating collar 4, and the floating shoe 5, the cementing rubber plug 6, the floating collar 4, and the floating shoe 5 start to dissolve, and the dissolution is completed, and the floating collar dissolution channel 7 is formed , floating shoe dissolving channel 8, such as figure 2 As shown; it is also possible to choose only the cementing rubber plug 6 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com