Bidirectional energization explosion-propagating device

A technology for pipe blasting and hole blasting, which is used in the production of fluids, wellbore/well components, earth-moving drilling, etc. It can solve the problems of poor detonation sensitivity, no energy boosting, and limited wide use, etc., and achieve high detonation sensitivity and detonation ability. Strong, enhance the effect of magnification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

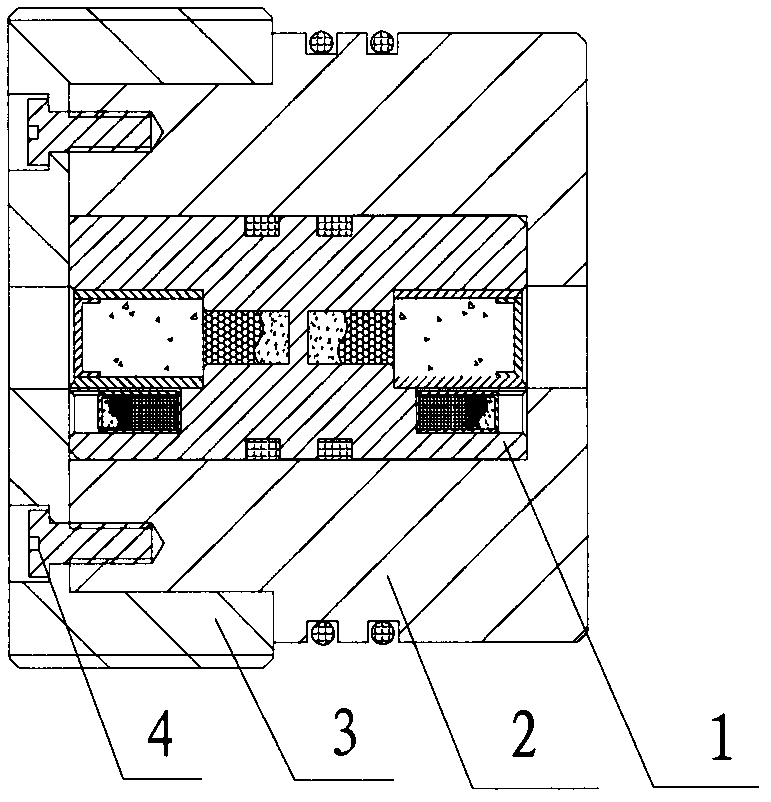

[0021] Such as figure 1 As shown, the two-way energized explosion transmission device provided by the present invention includes a partition 1 , a partition jacket 2 , a partition fastener 3 and a screw 4 . The partition 1 is assembled in the partition jacket 2 and the partition fastener 3, and the above three parts are connected as a whole with screws 4 .

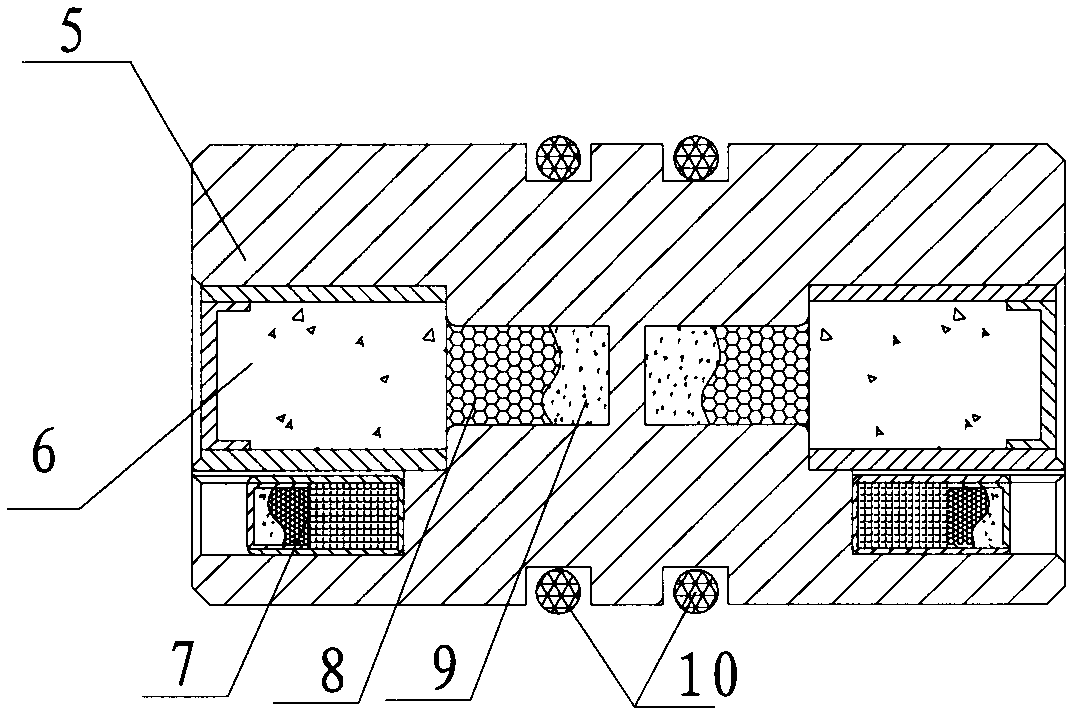

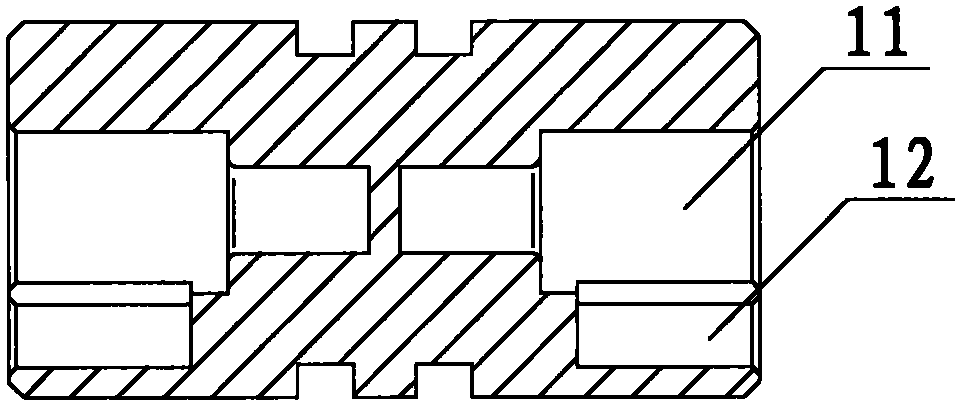

[0022] Such as figure 2 As shown, the partition 1 includes a partition body 5, two expansion tubes 6, and two detonators 7. Partition plate body 5 is a cylinder (see image 3 ) and two sealing ring grooves are provided on the cylindrical surface, stepped blind holes 11 and straight blind holes 12 parallel to each other are opened on both end surfaces of the partition body 5, and the large holes of the straight blind holes 12 and the stepped blind holes 11 Intersect cut. Exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com