Concrete additive and its preparation method and application

An additive and concrete technology, which is applied in the field of building materials, can solve the problems of limited utilization rate, fast formwork turnover, broken boards, etc., and achieve excellent durability and volume stability, improve mechanical properties, and high volume stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

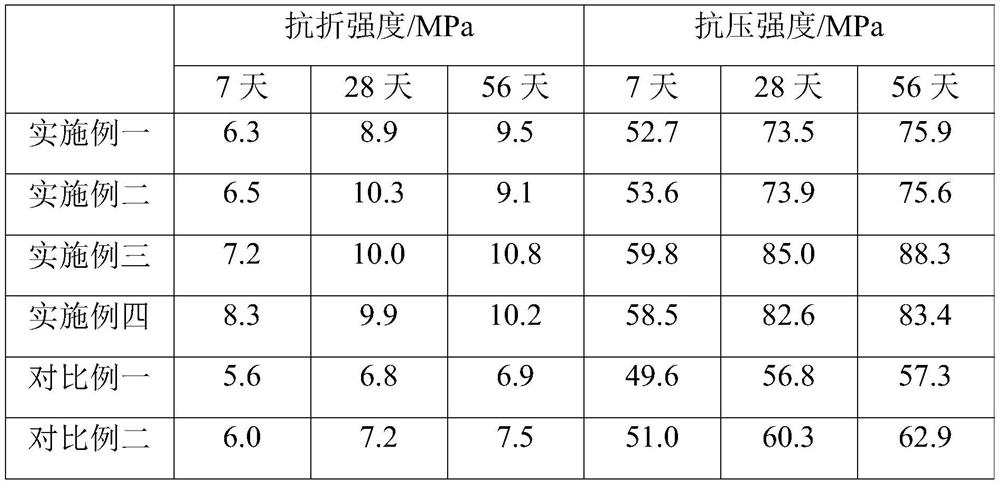

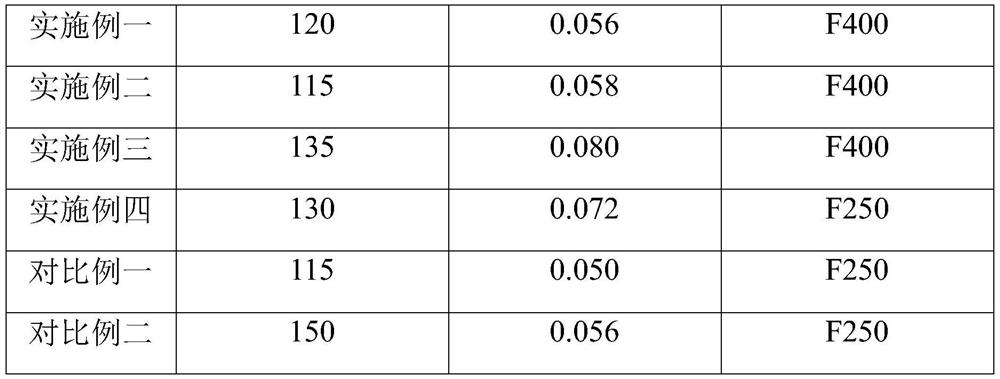

Examples

preparation example Construction

[0031] In addition, for the concrete additive provided by the present invention, the applicant specifically provides a preparation method, comprising the following steps:

[0032] S1: Weigh and mix each raw material component in proportion, adjust the pH value to 5.8-6.2, and then heat. Wherein, the heating temperature is 60-80° C., and the heating time is 30-100 minutes.

[0033] S2: adjusting the pH value of the product obtained in S1 to 7.2-7.6, heating again, and then cooling to room temperature to obtain a concrete additive. Wherein, the heating temperature is 90-100° C., and the heating time is 20-50 minutes.

[0034] In addition, the additive provided by the invention can be further used in the preparation process of concrete, specifically: directly disperse the additive in the concrete evenly to obtain the finished concrete; wherein, the amount of the additive accounts for 0.1-3% of the total mass of the cementitious material.

[0035] Describe below in conjunction w...

Embodiment 1

[0037] This embodiment provides a concrete additive, the raw material components are calculated in parts by weight, including: 20 parts by weight of titanium dioxide, 6 parts by weight of pentaerythritol, 0.2 parts by weight of sodium bisulfite, 5 parts by weight of vinyltrimethoxysilane, and 8 parts by weight of potassium carbonate. Parts by weight, 20 parts by weight of polycarboxylate superplasticizer, 2 parts by weight of sodium lignosulfonate, 1 part by weight of sodium dodecylbenzenesulfonate, 4 parts by weight of polyvinyl alcohol and 300 parts by weight of water.

[0038] According to above-mentioned raw material component, prepare the required concrete additive of the present invention:

[0039] S1: Weigh and mix each raw material component in proportion, adjust the pH value to 5.8, and then heat. Wherein, the heating temperature is 80° C., and the heating time is 30 minutes.

[0040] S2: adjusting the pH value of the product obtained in S1 to 7.6, heating again, and...

Embodiment 2

[0042] This embodiment provides a concrete additive, the raw material components are calculated in parts by weight, including: 5 parts by weight of titanium dioxide, 8 parts by weight of pentaerythritol, 0.1 parts by weight of sodium bisulfite, 20 parts by weight of vinyltrimethoxysilane, 5 parts by weight of potassium carbonate Parts by weight, 60 parts by weight of polycarboxylate water reducer, 1 part by weight of sodium lignosulfonate, 3 parts by weight of sodium dodecylbenzenesulfonate, 2 parts by weight of polyvinyl alcohol and 500 parts by weight of water.

[0043] According to above-mentioned raw material component, prepare the required concrete additive of the present invention:

[0044] S1: Weigh and mix each raw material component in proportion, adjust the pH value to 6.2, and then heat. Wherein, the heating temperature is 60° C., and the heating time is 100 min.

[0045] S2: adjusting the pH value of the product obtained in S1 to 7.2, heating again, and then cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com