A kind of polyurethane resin for filling bridge height-adjusting bearings and its preparation method and construction method

A polyurethane resin and height adjustment technology, which is applied in the field of polyurethane resin, can solve the problems of easy mixing unevenness, pump body damage, easy blockage of grouting pumps, etc., and achieve the effect of improving the final strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

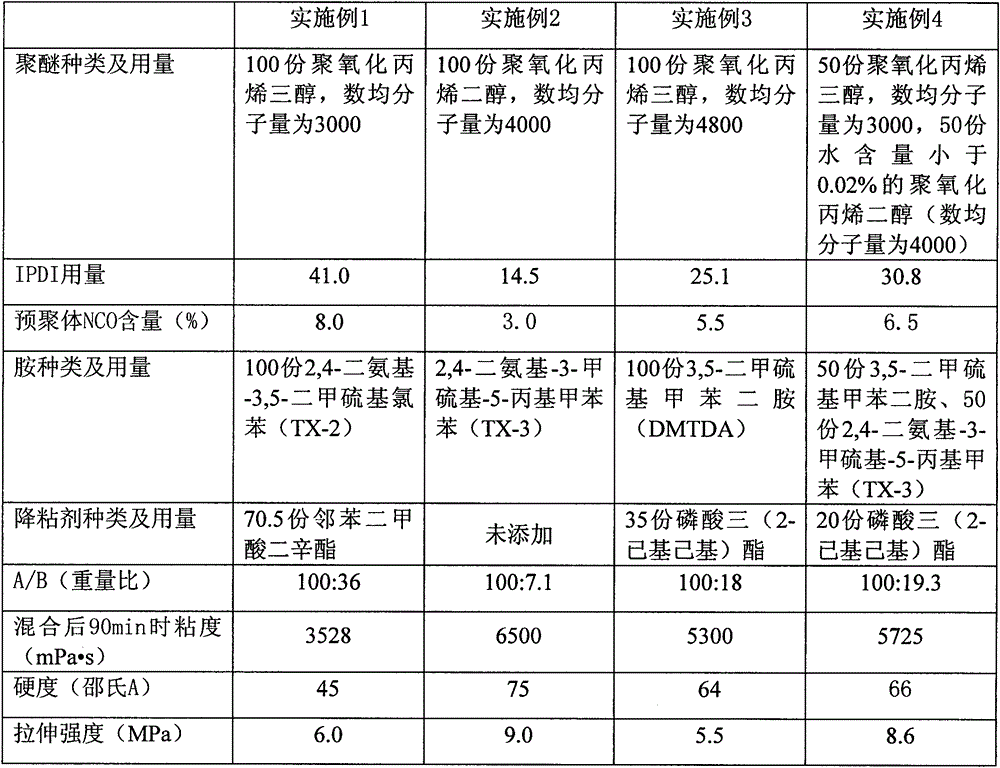

[0020] The present invention will be further described below in conjunction with embodiment. The parts mentioned below are all parts by weight.

[0021] Polyurethane resin preparation method:

[0022] Component A: Slowly add polyether with a water content of less than 0.02% and a polyether with a terminal primary hydroxyl group content greater than 70% to isophorone diisocyanate, and react at 85°C for 4 hours to obtain an isocyanate-terminated prepolymer.

[0023] Component B: After fully mixing the aromatic diamine and the viscosity reducer with a water content of less than 0.02%, the component B is obtained.

[0024] Polyurethane resin construction method:

[0025] Mix the A / B components at room temperature for 60 minutes to ensure that they are evenly mixed. When placed for 90 minutes, test its viscosity according to the rotational viscosity test method in GB / T2794-1995. The mixed material was poured into a mold of 100mm×100mm×2mm by a high-pressure pump, and after stan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com