Single cone heat pipe spiral dryer

A spiral dryer and heat pipe technology, applied in non-progressive dryers, drying solid materials, drying and other directions, can solve the problems of small contact hot surface of materials, low heat energy use efficiency, large radiator volume, etc. The effect of low conversion efficiency, low loss, increased total heat energy transmission, and uniform drying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

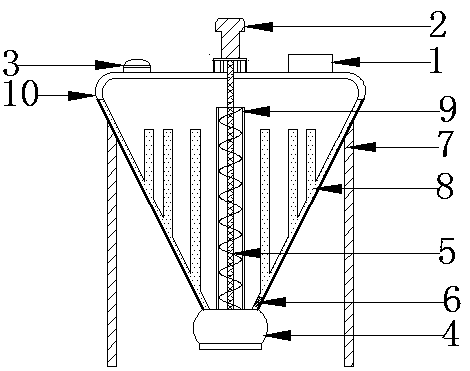

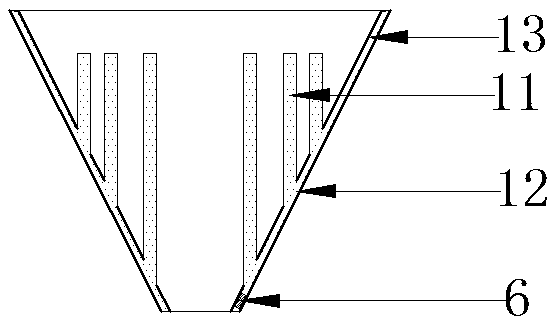

[0020] like figure 1 Shown: a single-cone heat pipe type spiral dryer, which consists of a vacuum unit (1), a driving device (2), an inlet valve (3), an outlet valve (4), a screw shaft (5), and a bracket (7 ), a heat pipe radiator (8), a conduit (9), and a hemispherical top cover (10).

[0021] The heat pipe radiator (8) is supported and fixed by a bracket (7), the upper end of the heat pipe radiator (8) is covered and closed by a hemispherical top cover (10), and a discharge valve is installed at the lower end of the heat pipe radiator (8) (4), the heat pipe radiator (8) is closed by the hemispherical top cover (10) and the discharge valve (4), and its space just constitutes a drying chamber.

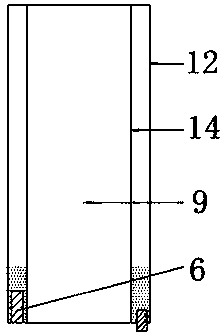

[0022] A conduit (9) is installed at the center of the heat pipe radiator (8), and a helical shaft (5) is arranged in the conduit (9).

[0023] The hemispherical top cover (10) has a vacuum unit (1), a driving device (2), and a feed valve (3), or a vacuum gauge, temperature instrumen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com