Construction machine with material conveying system

A technology of construction machinery and transmission system, applied in the field of construction machinery, to achieve the effects of optimized preparation, precise adjustment, and increased transmission volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

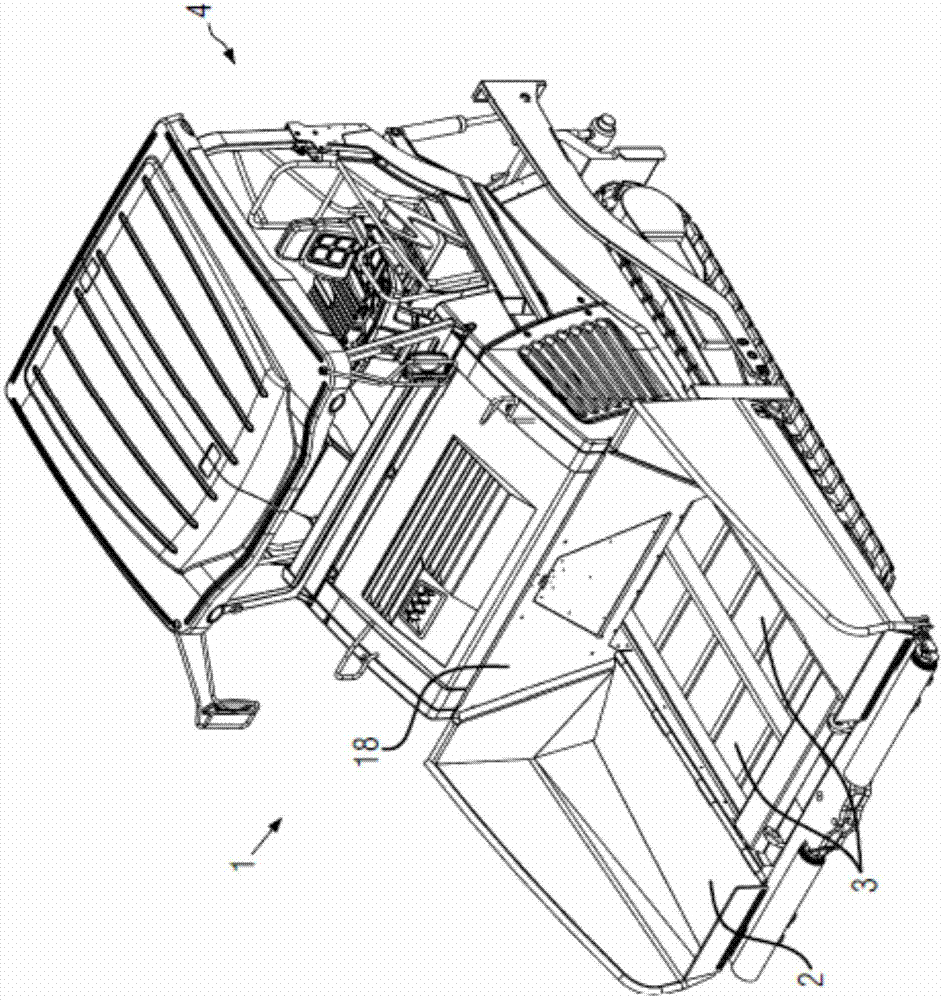

[0034] figure 1 A construction machine 1 is shown with a material hopper 2 for mixtures or generally for bulk materials. A downstream conveying system 3 (in this case two scraper belts) extends in the central part of the hopper 2 . The downstream transport system 3 is used to transport the mixture under the cab 4 to the paving site.

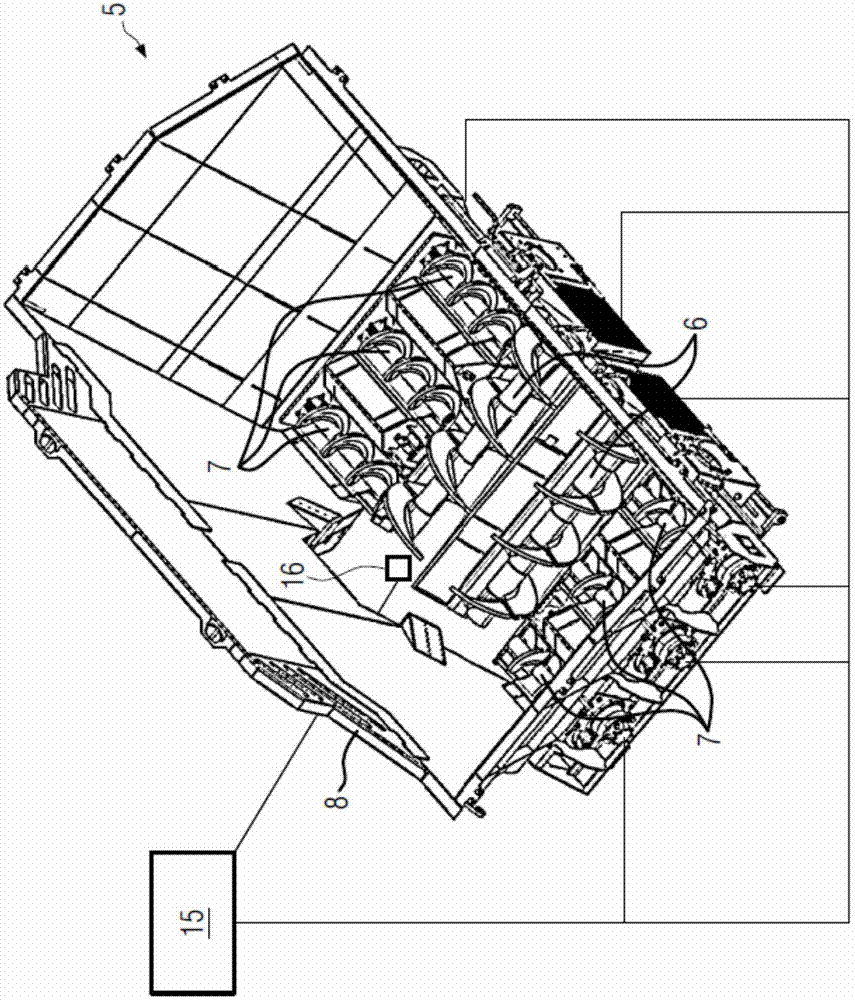

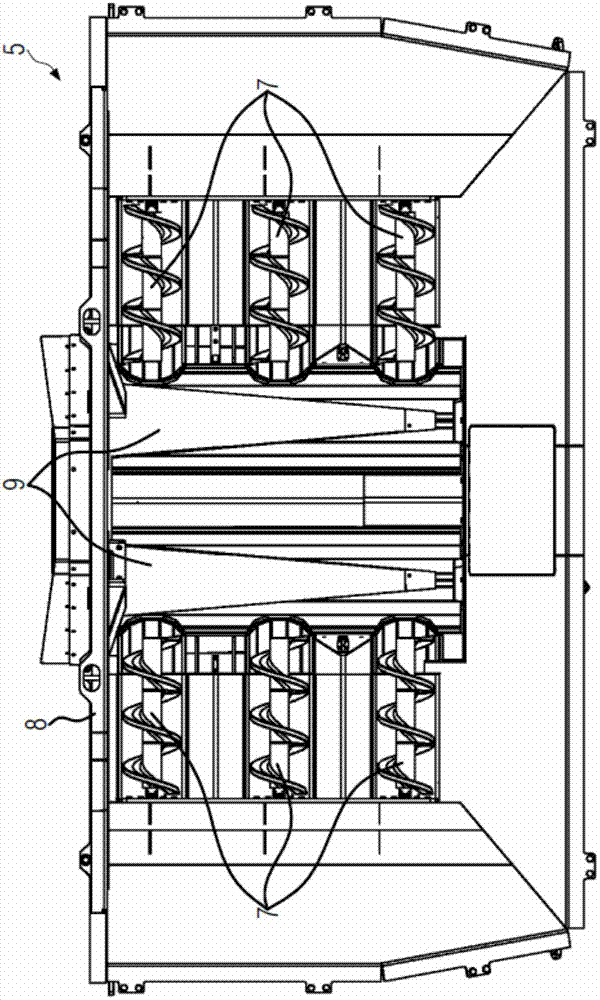

[0035] figure 2 A material transfer system 5 possibly arranged in the hopper 2 is shown. The material conveying system comprises two longitudinal conveying screws 6 , six transverse conveying screws 7 and a rear wall 8 . In the installed state, said rear wall 8 is oriented towards the rear wall 18 of the hopper. Such as figure 2 As can be seen in , the transfer screws 6, 7 cover the entire bottom area of the material transfer system. Since the conveying screws 6, 7 can be operated independently of each other, the individual material flows from the various parts of the material conveying system 5 can be controlled in a desired manner. For...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com