Aluminium section heat exchanger

An aluminum profile, heat exchanger technology, applied in the direction of heat exchanger type, indirect heat exchanger, heat exchange equipment, etc., can solve the problems of low heat energy use efficiency, small heat dissipation area, low thermal conductivity of carbon steel, etc. The effect of increasing the total amount of transmission, expanding the heat dissipation speed, and increasing the thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

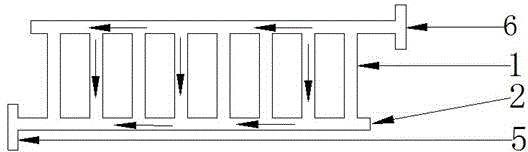

[0023] Such as figure 1 Shown: an aluminum profile heat exchanger is composed of two heat-conducting tubes (2) and multiple aluminum profile heat-exchanging tubes (1).

[0024] The heat conduction pipe (2) is made of carbon steel pipe, one end of the heat conduction pipe (2) is sealed, and the other end is the heat conduction inlet (6), or the heat conduction outlet (5), and the heat conduction pipe (2) is opened There is a port for the aluminum profile heat exchange tube (1) to pass through and be fixedly connected.

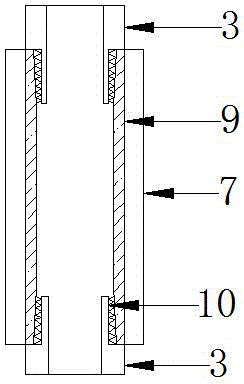

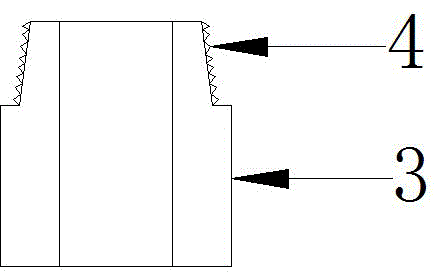

[0025] Such as figure 2 As shown: the aluminum profile heat exchange tube (1) is composed of an aluminum profile tube (9) and a pipe joint (3). The two ends of the processed and extruded aluminum profile pipe (9) are tightly closed and fixed by the screws of the pipe joint (3).

[0026] The aluminum profile pipe (9) is made of aluminum, according to the thickness of the pipe wall of the aluminum profile pipe (9), the diameter of the pipe, the height of the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com