Submerged air jet driven polishing equipment and polishing method

An immersion and equipment technology, applied in the field of precision ultra-precision non-contact sub-aperture polishing, can solve the problems of effective polishing of difficult free-form surfaces, high polishing and maintenance costs, clogging of small-diameter nozzles, etc., to achieve low continuous polishing, low cost, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

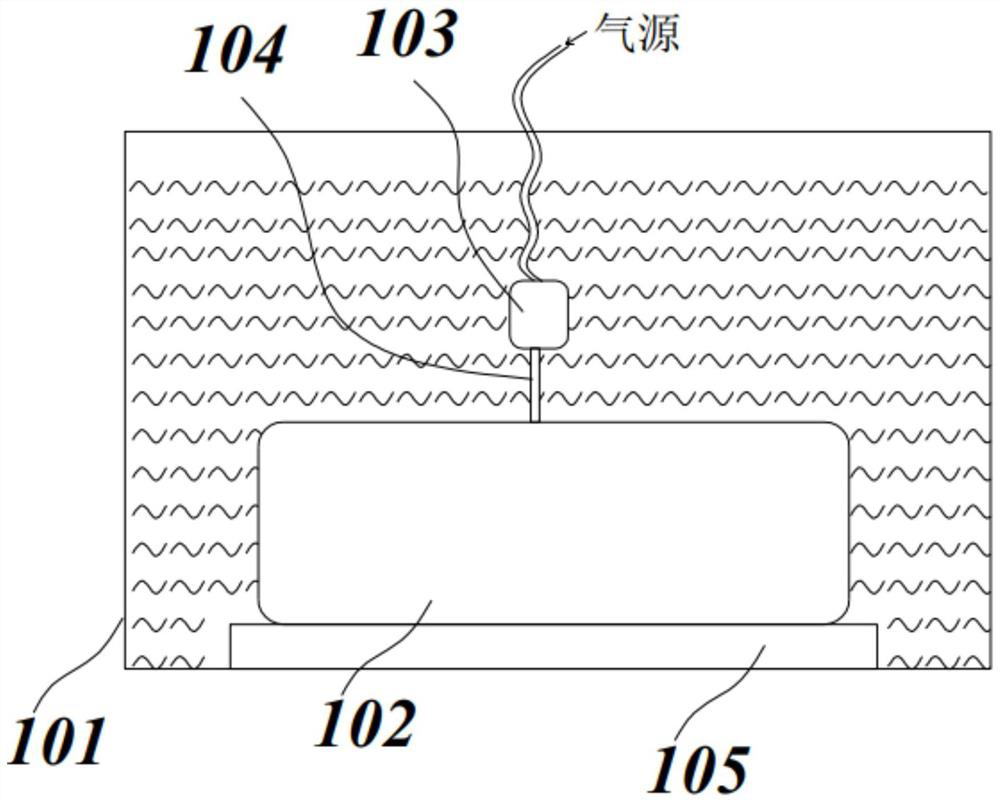

[0052] refer to figure 1 , In this embodiment, the submerged air jet drives ultra-precision polishing, and the workpiece and the nozzle are simultaneously immersed in the polishing solution, and the nozzle and the surface of the workpiece are kept at an appropriate distance (details are shown in the table below, the same below). During the polishing process, the pressurized gas (air jet) overflowing from the nozzle drives the abrasive particles in the polishing liquid near the residence point to undergo shearing motion with the surface of the workpiece, thus forming a flexible polishing head. The nozzle and the workpiece move relatively, which can realize Polishing along the specified path. The pressurized gas here is provided by an external adjustable pressure pump.

[0053] The polishing liquid is a Newtonian polishing liquid composed of cerium oxide and water.

[0054] The pressurized gas is filtered air.

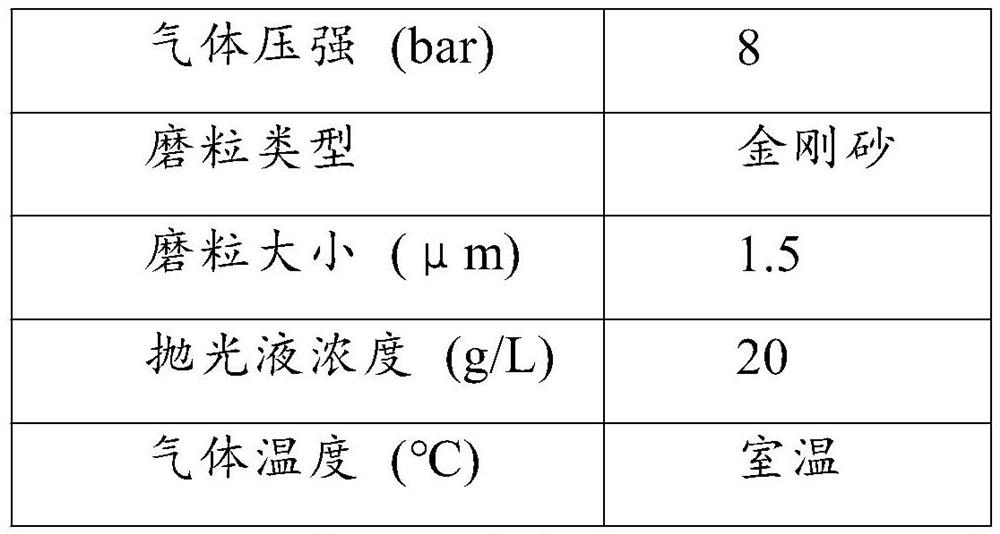

[0055] Table 1 lists the high-efficiency and high-quality polish...

Embodiment 2

[0061] refer to figure 1 , In this embodiment, the immersion air jet drives the ultra-precision polishing, and the workpiece and the nozzle are immersed in the polishing liquid at the same time, and the nozzle and the surface of the workpiece are kept at an appropriate distance. During the polishing process, the pressurized gas (air jet) overflowing from the nozzle drives the abrasive particles in the polishing liquid near the residence point to undergo shearing motion with the surface of the workpiece, thus forming a flexible polishing head. The nozzle and the workpiece move relatively, which can realize Polishing along the specified path. The pressurized gas here is provided by an external adjustable pressure pump.

[0062] The polishing liquid is a Newtonian polishing liquid composed of corundum and water, and contains sulfuric acid with a concentration of 1.5%.

[0063] The pressurized gas is nitrogen.

[0064] Table 2 lists the high-efficiency and high-quality polishin...

Embodiment 3

[0070] refer to figure 1 , In this embodiment, the immersion air jet drives the ultra-precision polishing, and the workpiece and the nozzle are immersed in the polishing liquid at the same time, and the nozzle and the surface of the workpiece are kept at an appropriate distance. During the polishing process, the pressurized gas (air jet) overflowing from the nozzle drives the abrasive particles in the polishing liquid near the residence point to undergo shearing motion with the surface of the workpiece, thus forming a flexible polishing head. The nozzle and the workpiece move relatively, which can realize Polishing along the specified path. The pressurized gas here is provided by an external adjustable pressure pump.

[0071] The polishing liquid is a Newtonian polishing liquid composed of alumina and water.

[0072] The pressurized gas is nitrogen.

[0073] Table 3 lists the high-efficiency and high-quality polishing conditions driven by the submerged air jet in this embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com