Textile machine for cutting gauze

A technology of textile machinery and gauze, which is applied in the field of textile machinery for cutting gauze, and can solve the problems of non-absorbing fluff fluff, easy flying into the air, and inability to assist cooling with rollers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

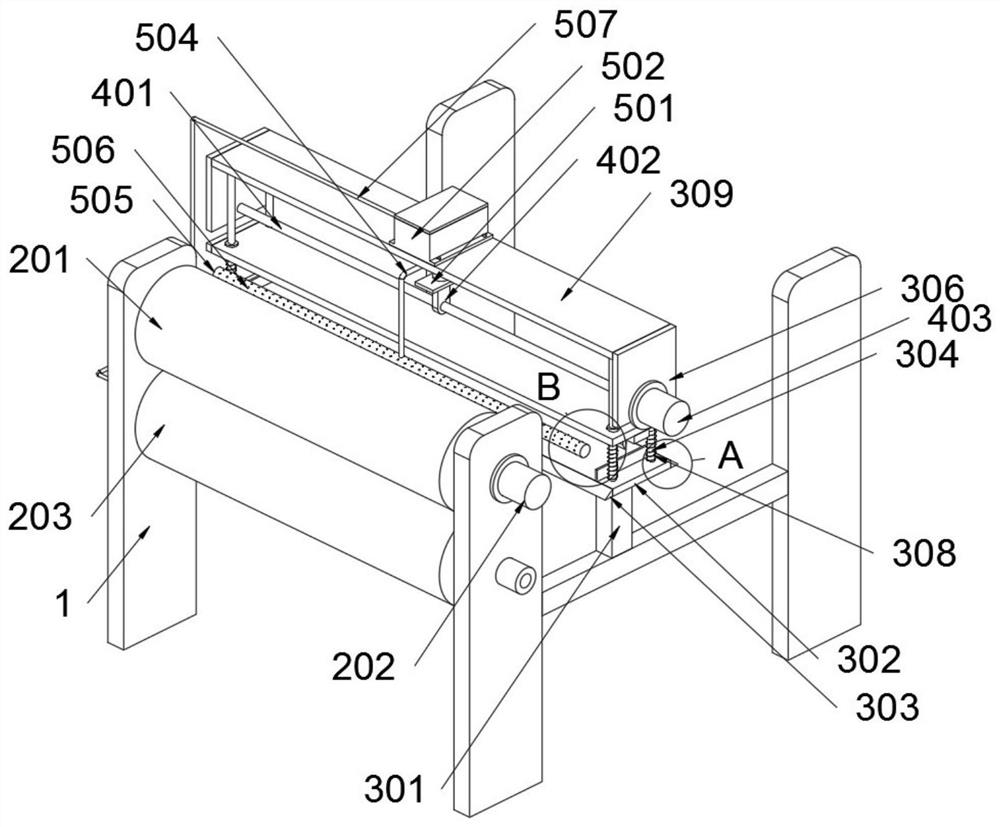

[0030] as attached figure 1 to attach Figure 6 Shown:

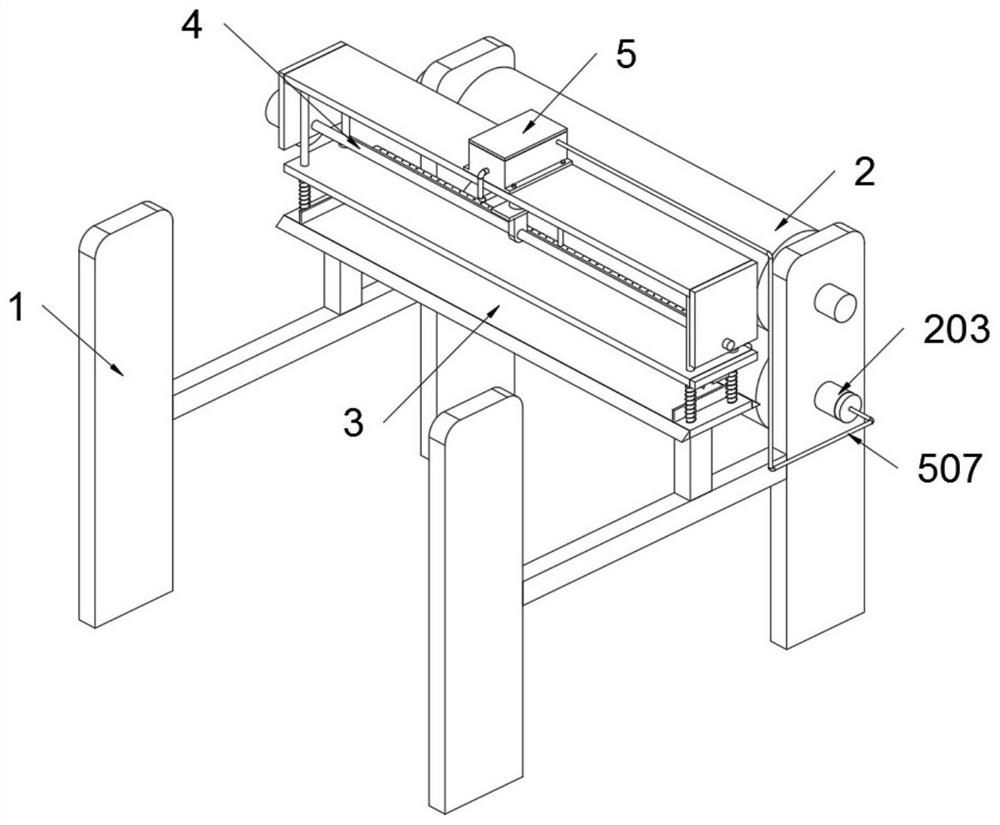

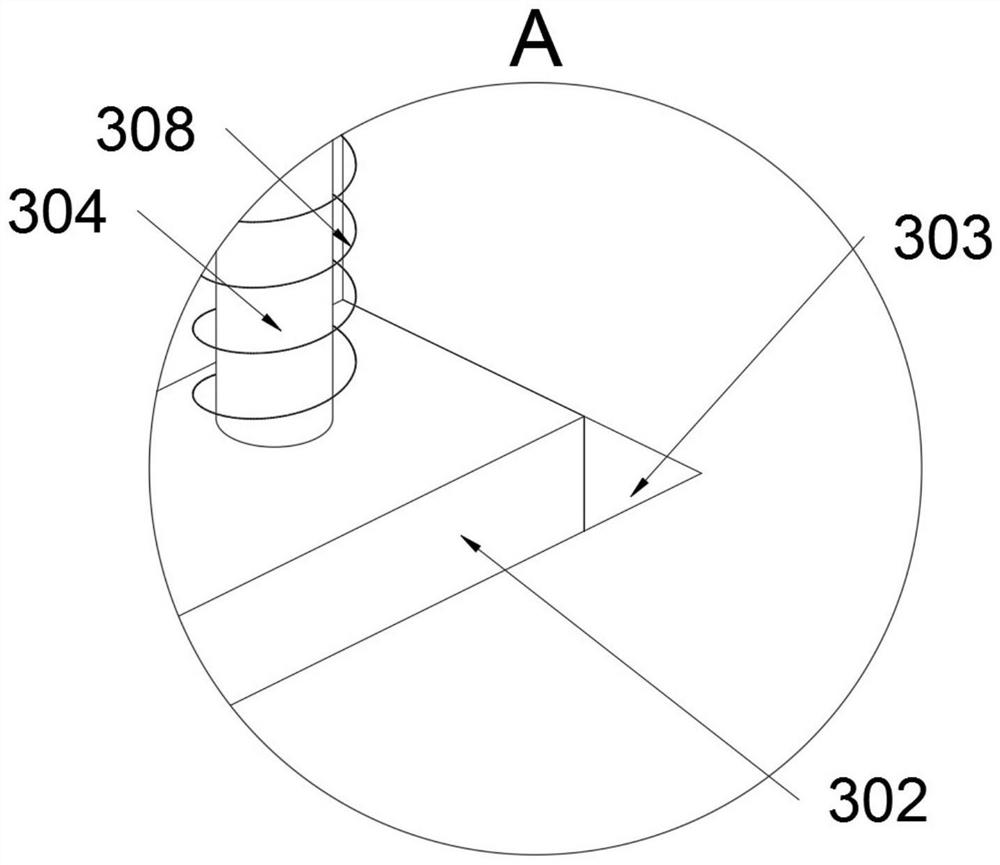

[0031] The invention provides a textile machine for cutting gauze, which comprises an assembly line frame body 1; a cloth driving structure 2 is installed on the assembly line frame body 1, and a cutting structure 3 is welded on the assembly line frame body 1; Moving structure 4, and auxiliary structure 5 is also installed on the cutting structure 3; Refer to as figure 2 and image 3, the cutting structure 3 includes a cylindrical rod 301, a cutting seat 302 and an auxiliary block 303, the cylindrical rod 301 is welded on the assembly line frame body 1, and the cylindrical rod 301 is welded with a cutting seat 302, and the cloth passes through the cutting seat 302; An auxiliary block 303 is welded on the left end face and the right end face of the seat 302, and the two auxiliary blocks 303 are triangular columnar rod-shaped structures, and the two auxiliary blocks 303 are arranged in a mirror image, thereby improving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com