Cable production cutting equipment with automatic feeding and discharging function

A technology of automatic loading and unloading, cutting equipment, applied in the field of cable production, can solve problems such as inability to cut cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

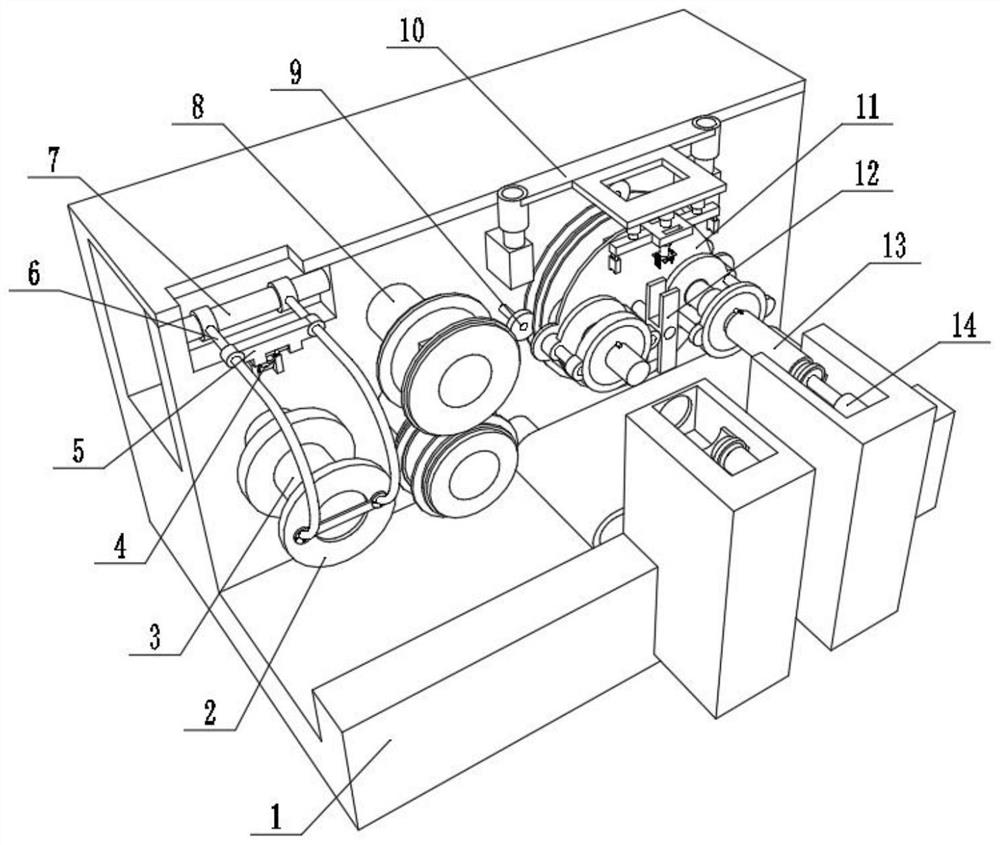

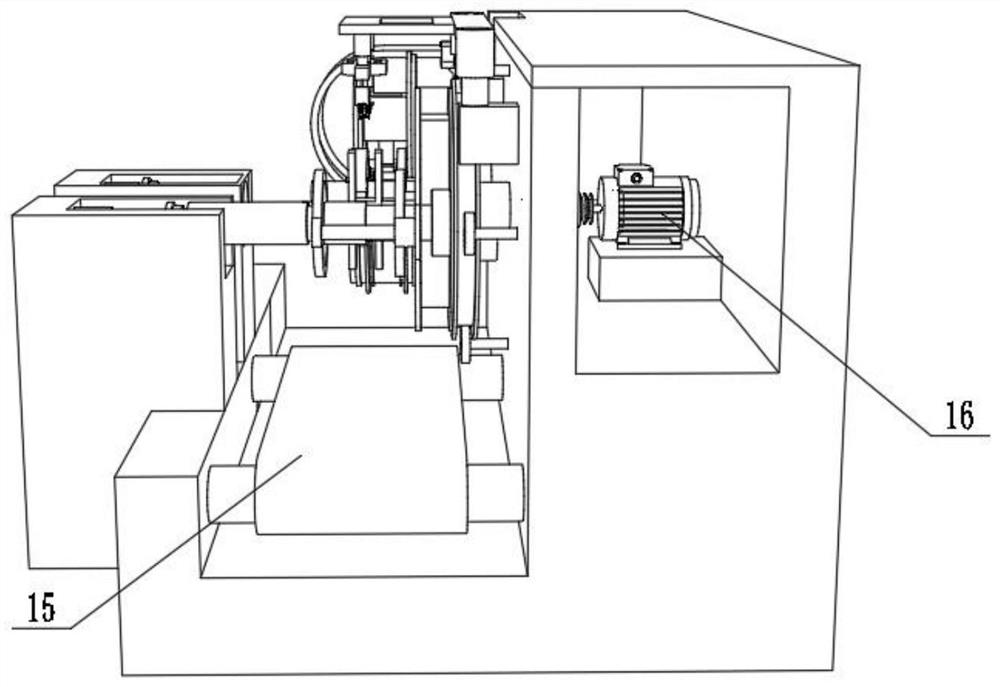

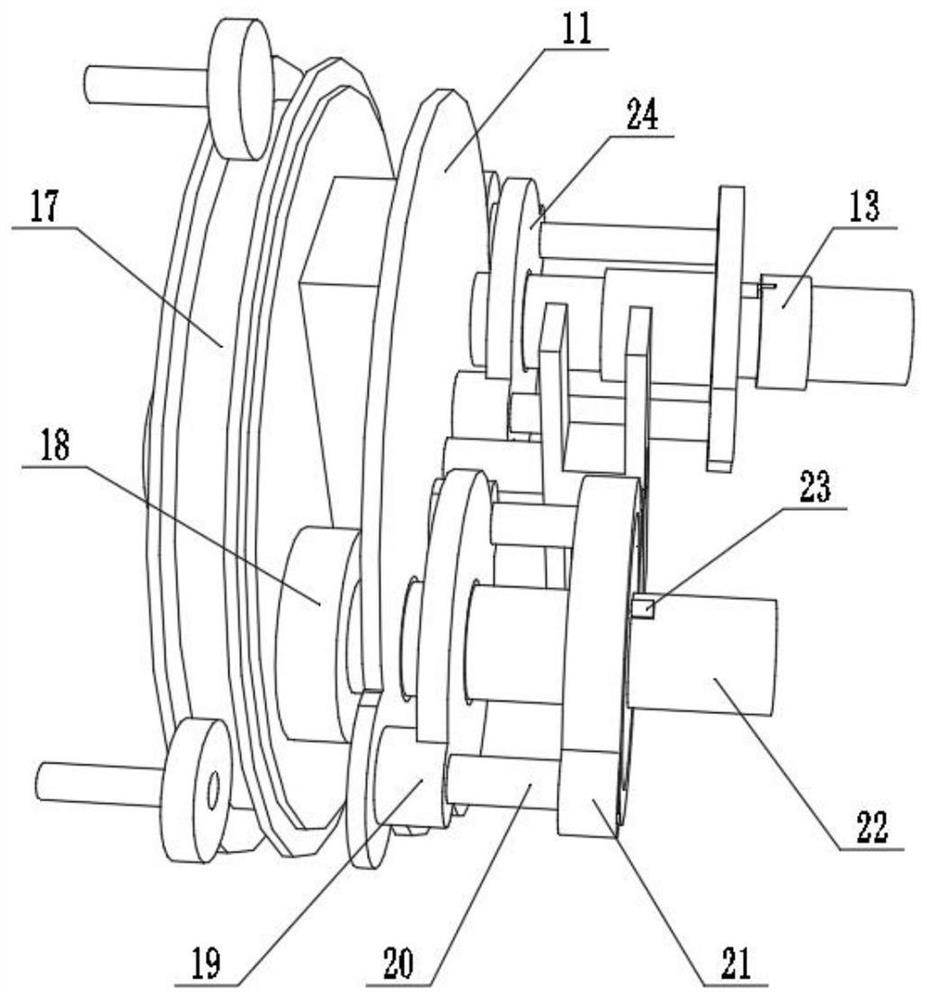

[0036]A cable production and cutting equipment with automatic loading and unloading functions, such asfigure 1 ,2, 3, 4, and 8, including a housing 1 and a reel 13. The inner wall of the housing 1 is rotatably connected with a conversion disk 11, and the inner wall of the housing 1 is fixed with a motor 16 by screws. The output shaft of the motor 16 It is connected to the conversion disk 11 through a coupling. Two connecting posts 19 are welded on both ends of the outer wall of the conversion disk 11. The outer walls of the two connecting posts 19 are fixed with the same connecting disk 24 by screws, and the inner wall of the connecting disk 24 is rotatably connected. The rod 22, the inner wall of the connecting plate 24 is fixed with a motor two 18 by screws, the output shaft of the motor two 18 is connected to the rotating rod 22 through a coupling, and the two ends of the outer wall of the connecting plate 24 are welded with two electric telescopic rods 20, two The outer walls of...

Embodiment 2

[0041]A cable production and cutting equipment with automatic loading and unloading function, in order to facilitate the feeding of cables; such asfigure 1 As shown, the outer wall of the housing 1 is welded with a feeding rod 3, and the outer wall of the housing 1 is welded with a connecting rod 7 that is rotatably connected to the outer wall of the connecting rod 7 with a support frame 6, and the outer wall of the support frame 6 is fixed by screws. The limit baffle 2, the outer wall of the support frame 6 is clamped with a connecting frame 5, the outer wall of the connecting frame 5 is fixed with a hydraulic rod 4 through a hinge, and the other side of the hydraulic rod 4 is connected to one side of the housing 1 through a hinge The outer wall is connected; by setting the feeding rod 3 and the limit baffle 2, the coiled cable is placed on the feeding rod 3, and then the hydraulic rod 4 is controlled to lift the support frame 6, and the limit baffle 2 is stuck in One end of the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com