Efficient plastic pipe cutting equipment

A technology for plastic pipes and cutting equipment, applied in metal processing, etc., can solve the problems of low work efficiency, inconvenient adjustment of cutters and clamping parts, etc., and achieve the effects of high work efficiency, increased practicability, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

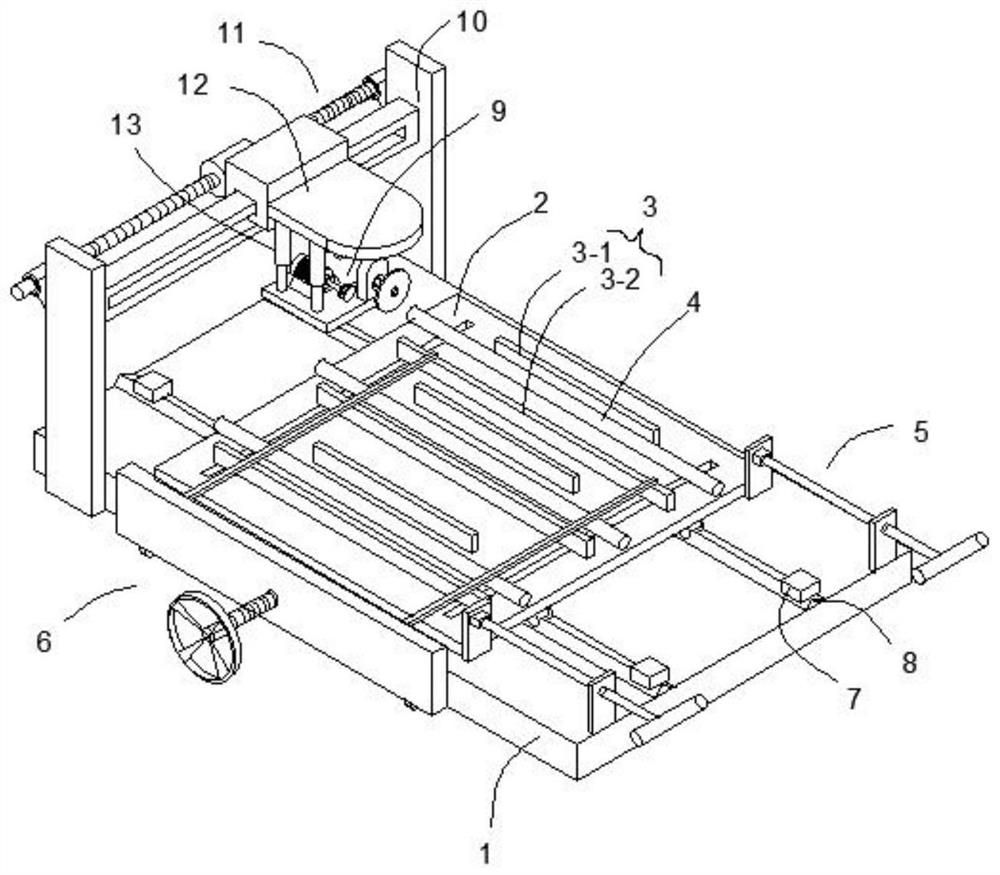

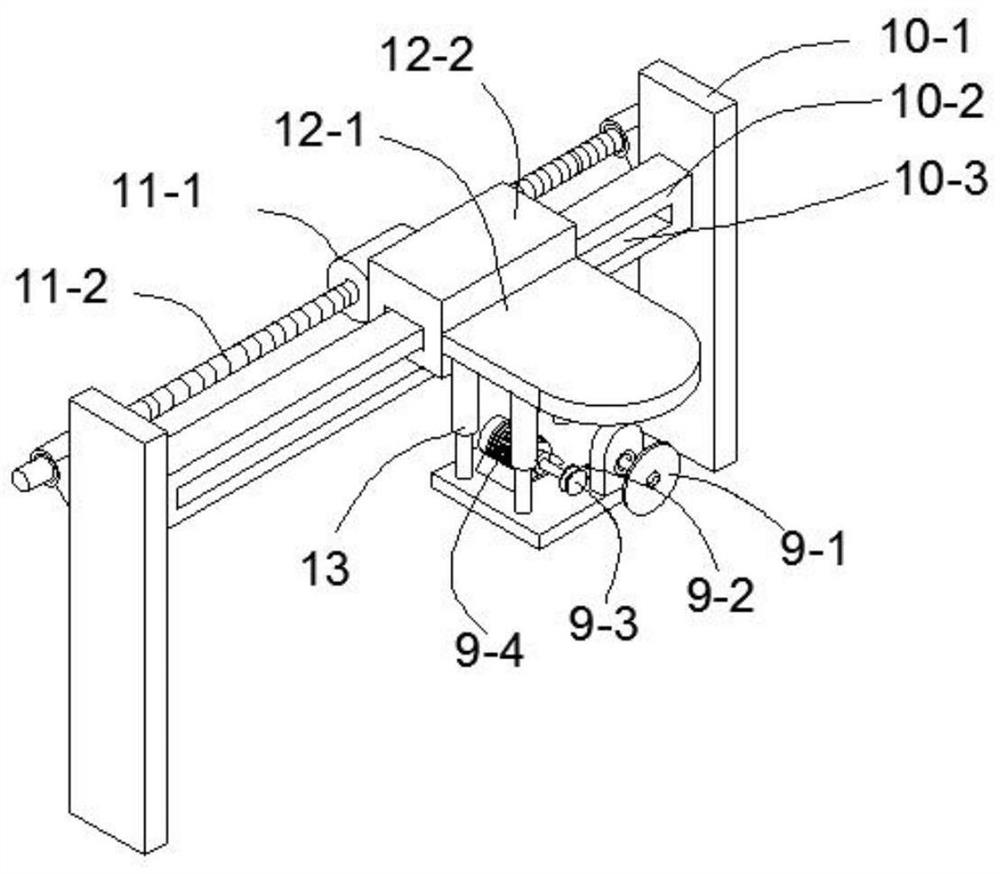

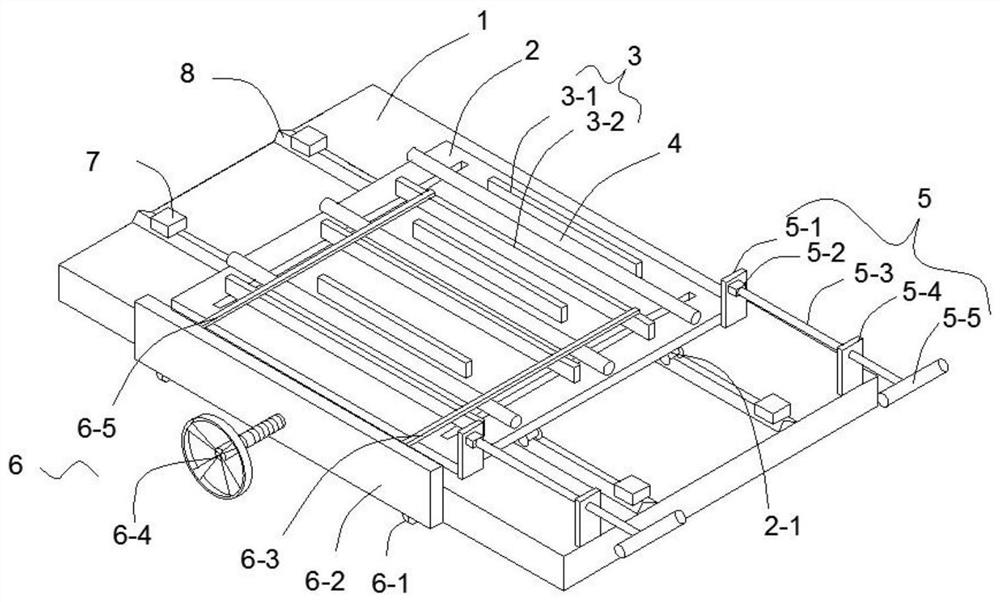

[0031] Such as Figures 1 to 3 As shown, the present embodiment provides a high-efficiency plastic pipe cutting equipment, including a square base 1 and a door-shaped knife mounting frame 10 arranged above one end of the square base 1. The door-shaped knife mounting frame 10 is provided with a The tool mounting seat 12 that moves at the top of the tool mounting frame 10, the door-shaped tool mounting frame 10 is provided with a linear drive mechanism 11 that drives the tool mounting seat 12 to move, and a horizontal plate is connected below the tool mounting seat 12 through a telescopic mechanism 13. The horizontal plate is provided with a compound cutter mechanism 9, and the square base 1 is provided with a mobile platform 2, and multiple groups of adjustable clamps for clamping the plastic pipe 4 to be cut are arranged side by side on the mobile platform 2. Component 3, the square base 1 is provided with a distance adjustment mechanism 6 capable of synchronously adjusting th...

Embodiment 2

[0037] This embodiment is further optimized on the basis of embodiment 1, specifically:

[0038] The square base 1 is provided with two guide rails 8 in parallel according to the length direction, the mobile platform 2 can reciprocate along the two guide rails 8, and the square base 1 is provided with a driving assembly for driving the square base 1 to reciprocate Each set of adjustable clamping components 3 includes a fixed clamping block 3-1 and a movable clamping block 3-2 arranged along the length direction of the square base 1 and parallel to each other, and the corresponding fixed clamping block 3-1 and movable clamping block 3-1 The distance between the clamping blocks 3-2 can be adjusted, and both ends of the mobile platform 2 are provided with limiting grooves 2-2 which are orthogonal to the movable clamping block 3-2 and limit the reciprocating movement direction of the movable clamping block 3-2, The distance adjusting mechanism 6 is fixedly connected to the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com