Paper cutting device used for color printing and packaging

A paper cutting device and packaging technology, applied in the direction of transportation and packaging, metal processing, conveyor objects, etc., can solve the problems of paper moving direction deviation, affect paper cutting, and cannot achieve fast cutting, etc., to achieve continuous cutting, improve Paper cutting efficiency and equipment space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

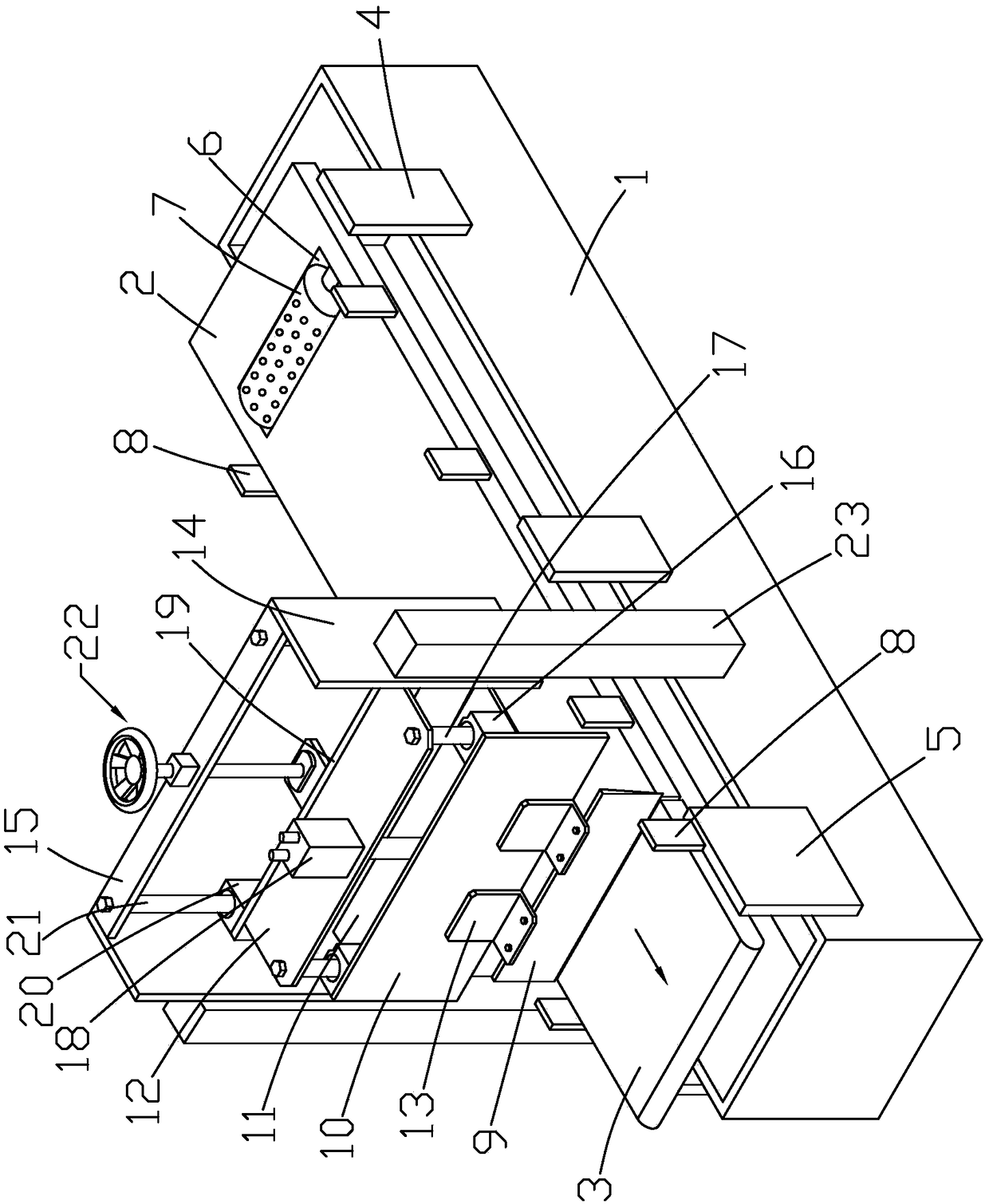

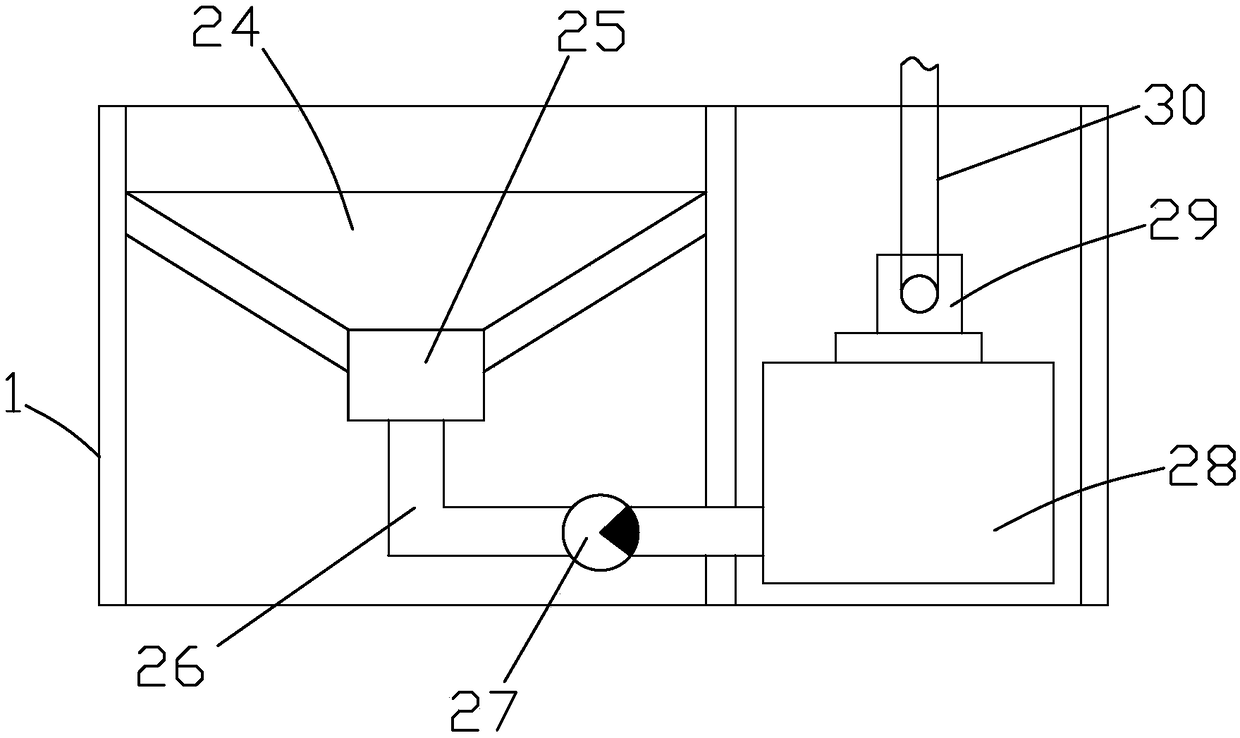

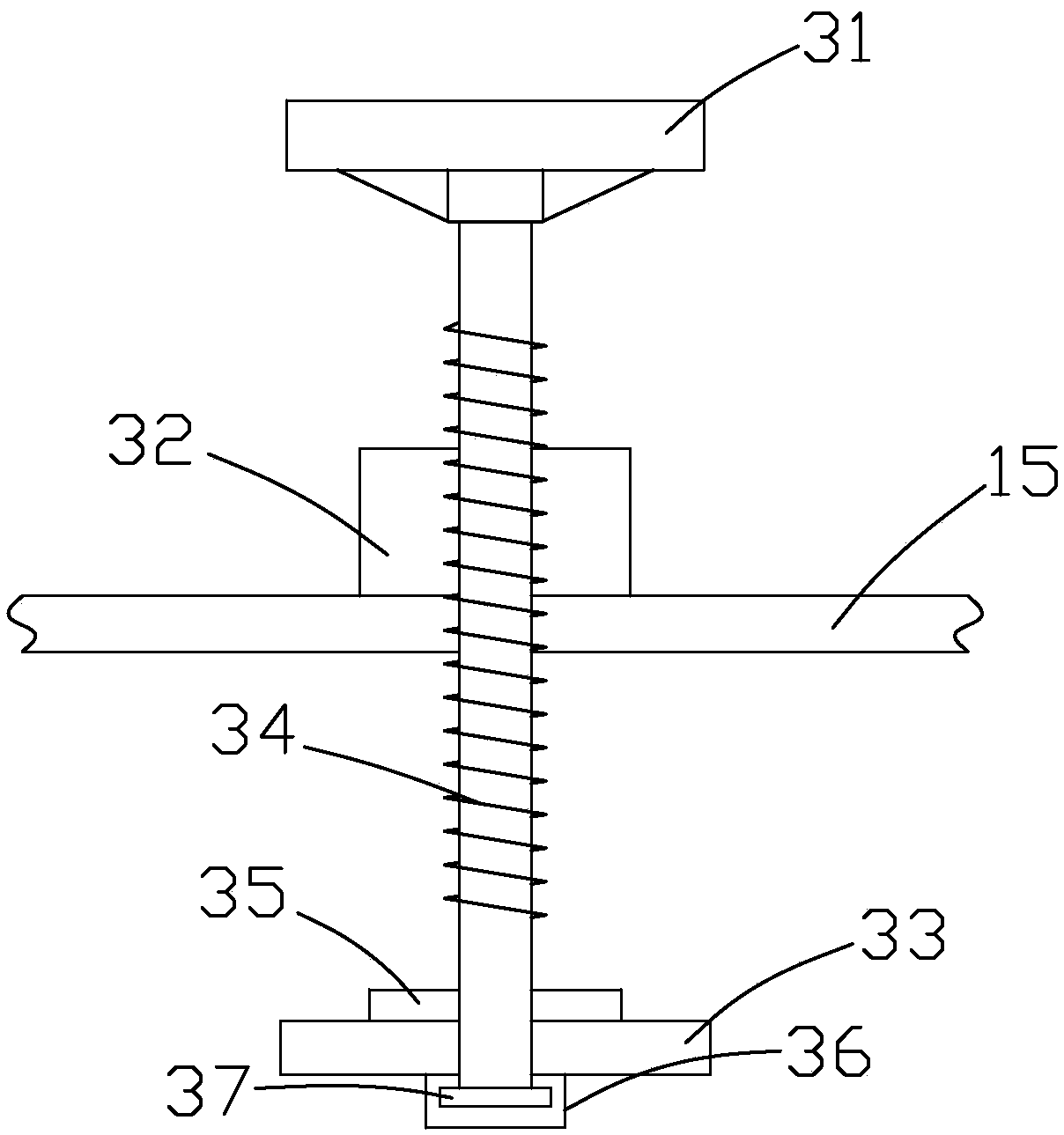

[0024] Such as Figure 1 to Figure 3 As shown, it is a paper cutting device for color printing packaging according to the present invention, which includes a box body 1, a first conveying plate 2, a second conveying plate 3 and a paper cutting mechanism, and the first conveying plate 2 and the second conveying plate 3 respectively pass through the first conveying plate A supporting plate 4 and a second supporting plate 5 are fixedly connected above the box body 1, the first conveying plate 2 and the second conveying plate 3 are located on the same horizontal plane, and a The cutting groove (not shown in the figure), the horizontal design is conducive to the movement of the paper in the same direction after cutting, and at the same time it will not cause overlap. The cutting groove can ensure that the paper cutter 9 can cut the paper once every time it is cut. The two sides of the conveying plate 2 and the second conveying plate 3 are symmetrically provided with baffles 8. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com