Intelligent brick stacking machine

A technology of intelligent brick yard machine and driving motor, which is applied to conveyor objects, stacking, transportation and packaging of objects, etc. The effect of stacking, avoiding collapse, and preventing dumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

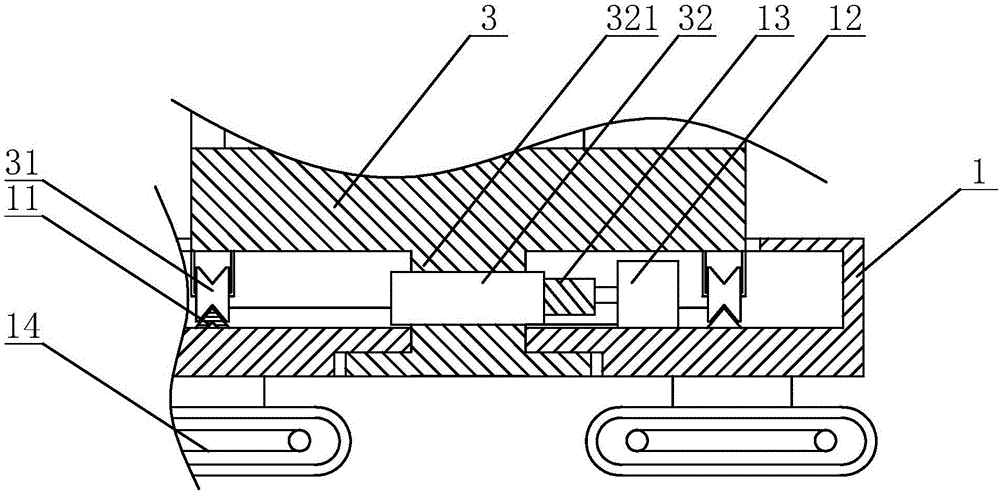

[0031]Embodiment 1: The present invention is an intelligent code brick machine, including a support 1 and a PLC controller 2, a concave space is provided on the support 1, and a rotating platform 3 is arranged in the concave space, and the bottom of the rotating platform 3 is There is a moving wheel 31, the support 1 is provided with a guide rail 11 compatible with the moving wheel 31, the rotating platform 3 is circular, the moving wheel 31 is 4 grooved wheels evenly distributed, and the guide rail 11 has an inverted V-shaped cross section type circular track. The support 1 is provided with a first motor 12 , and the first motor 12 is located in the concave space and below the rotating platform 3 . The output shaft of the first motor 12 is connected with a worm screw 13, a support shaft 321 is provided below the rotating platform 3, and a worm wheel 32 is fixedly arranged on the support shaft 321. 1 is provided with a concave cavity compatible with the fixed plate, and the s...

Embodiment 2

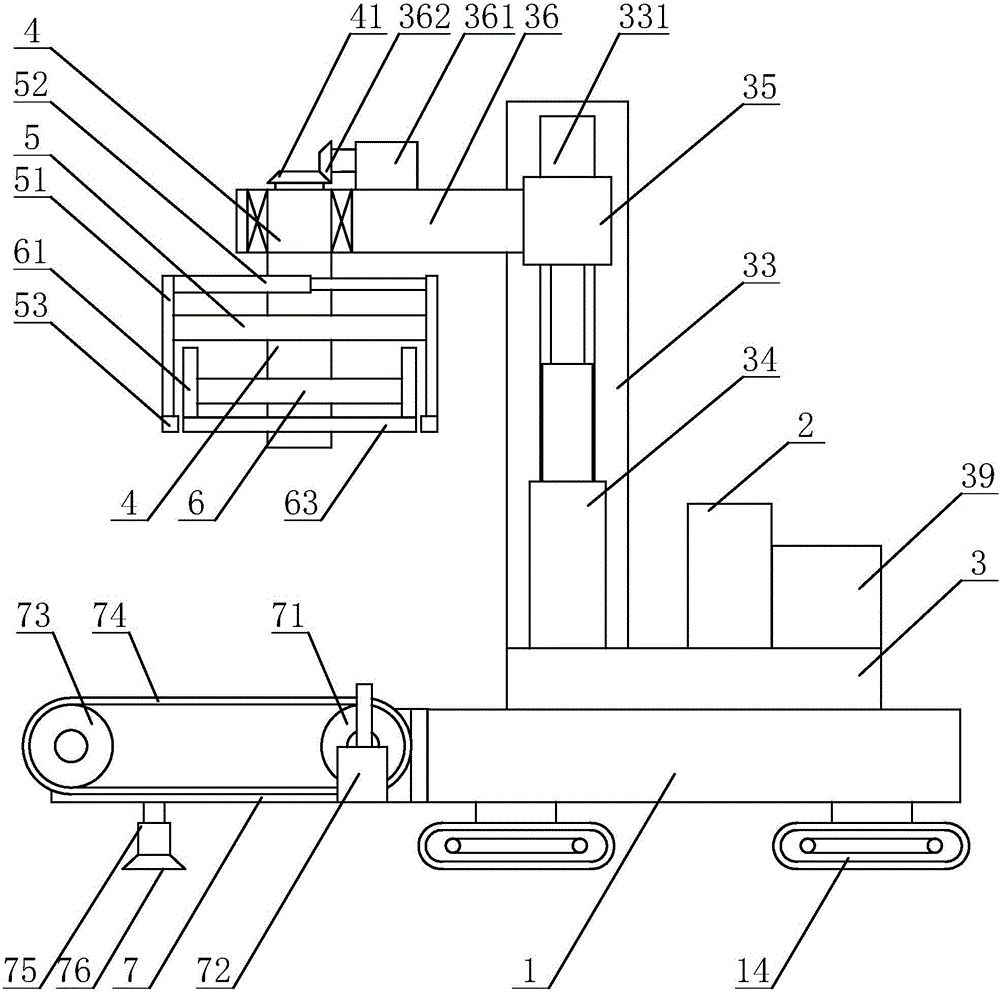

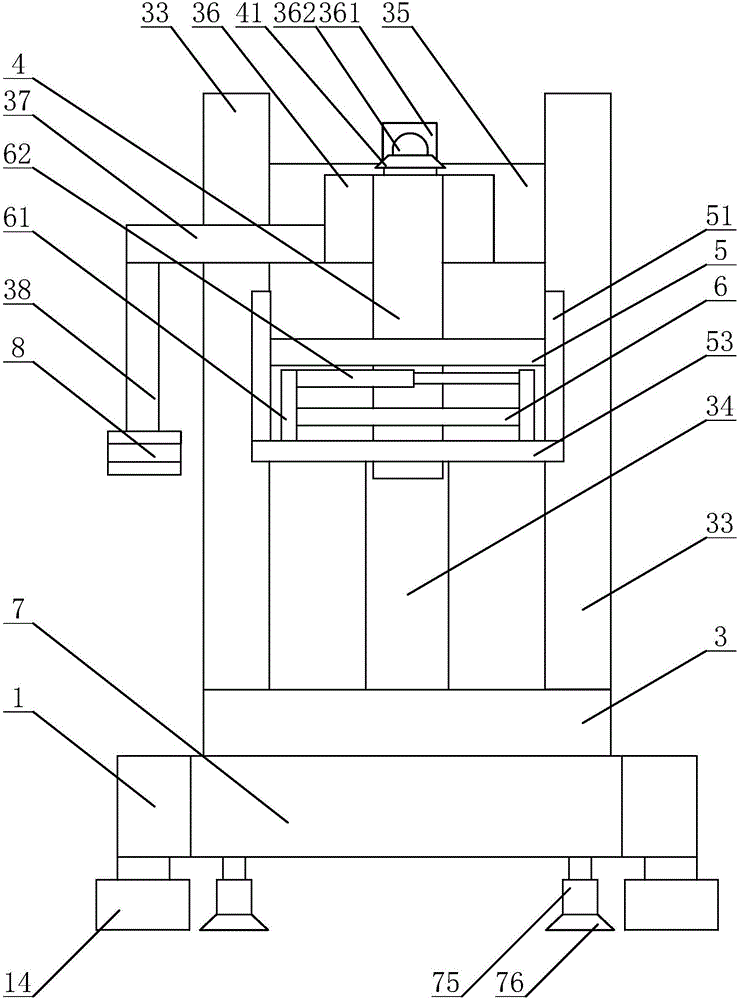

[0032] Embodiment 2: The present invention is an intelligent code brick machine, including a support 1 and a PLC controller 2, the support 1 is provided with a concave space, and a rotating platform 3 is arranged in the concave space, and the bottom of the rotating platform 3 is A moving wheel 31 is provided, a guide rail 11 adapted to the moving wheel 31 is provided on the support 1 , a first motor 12 is provided on the support 1 , and the first motor 12 is located in the concave space and below the rotating platform 3 . The output shaft of the first motor 12 is connected with a worm screw 13, a support shaft 321 is provided below the rotating platform 3, and a worm wheel 32 is fixedly arranged on the support shaft 321. 1 is provided with a concave cavity compatible with the fixed plate, and the support shaft 321 is rotatably connected with the support 1 to ensure that the first motor 12 drives the rotating platform 3 to rotate, and at the same time, the cooperation between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com