Motor frame and disc type motor adopting same

A motor skeleton, skeleton technology, applied in the shape/style/structure of winding insulation, magnetic circuit shape/style/structure, magnetic circuit static parts, etc. Complex operation process and other problems, to achieve the effect of saving materials, saving maintenance, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

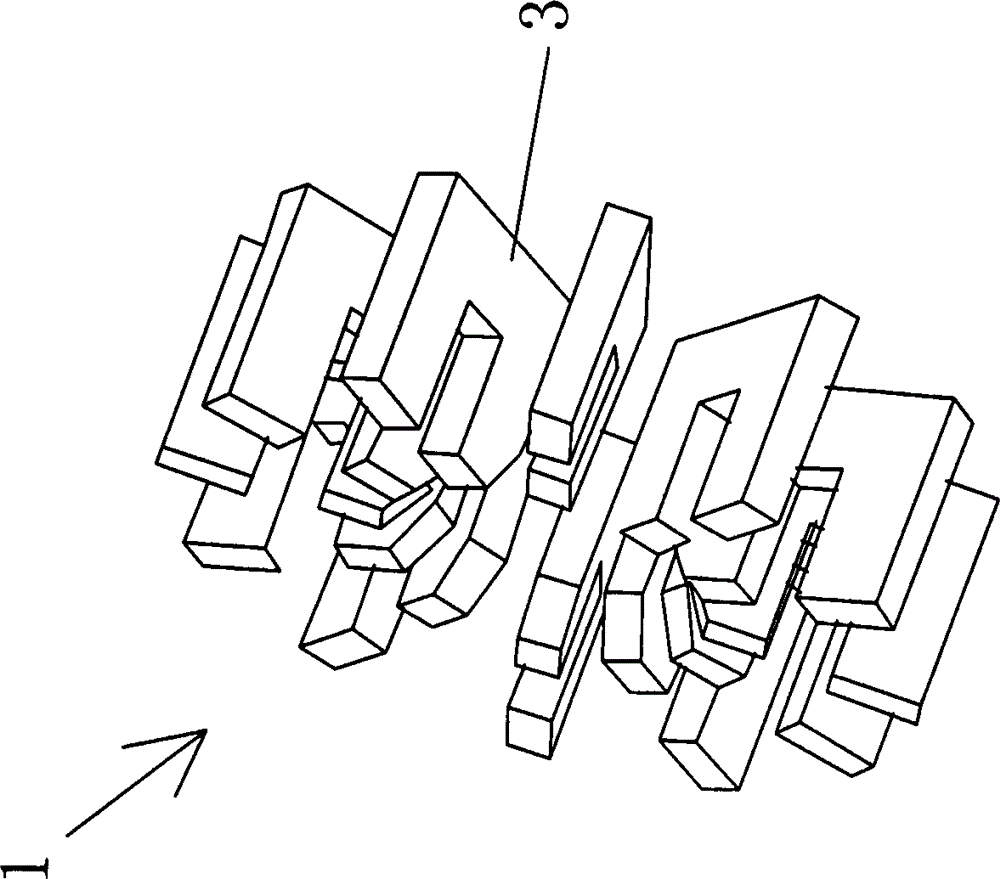

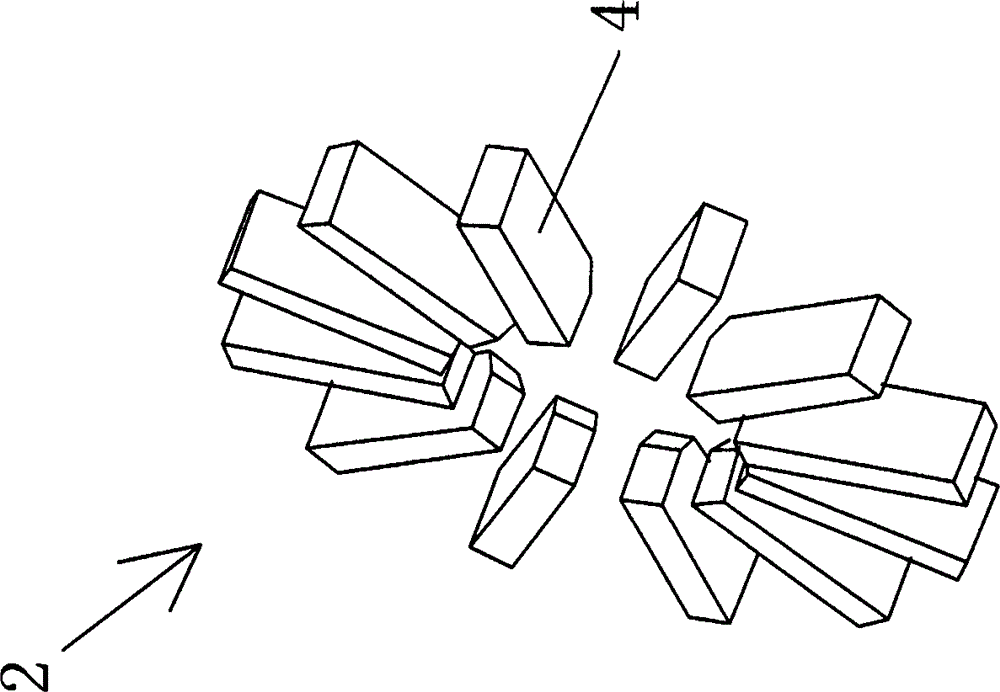

[0040] Such as figure 1 and figure 2 , the disc motor core assembly includes: a stator core assembly 1 and an end cover core assembly 2, the stator core assembly 1 is formed by a plurality of U-shaped stator cores 3 arranged in the circumferential direction, adjacent The included angle between the stator cores 3 is set to a constant value according to the type of the motor, and the end cover core assembly 2 is formed by a plurality of block-shaped end cover cores 4 arranged along the circumferential direction.

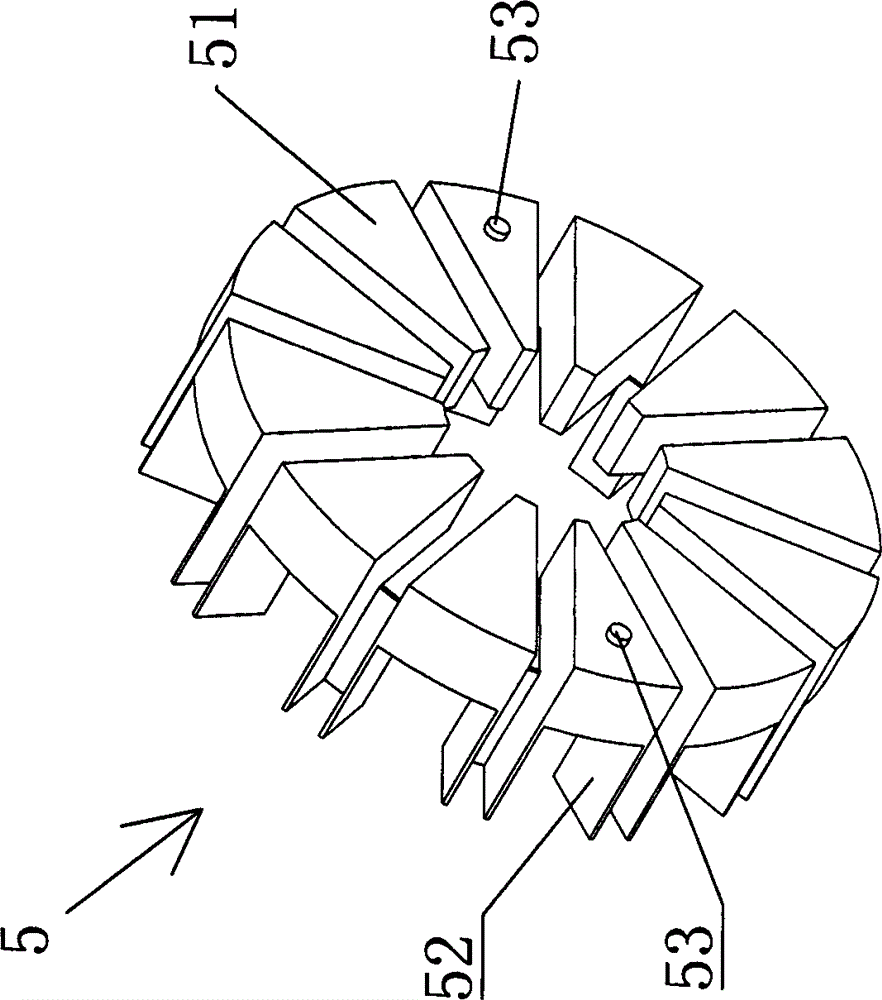

[0041] Such as image 3 and Figure 4, the stator core frame 5 includes a plurality of sector blocks 51 arranged along the circumferential direction, the angle between the sector blocks 51 is a constant value, and the outer edge of the adjacent sector blocks 51 is provided for connecting the adjacent sector blocks The groove piece 52, the section of this groove piece 52 is U-shaped, and the shape of the groove in the groove piece 52 matches the gap between the adja...

Embodiment 2

[0045] The above-mentioned stator core skeleton and end cover iron core skeleton are adopted in the disc motor in this embodiment, which includes: end cover 8 and casing 9, such as Figure 9-11 , the end cap 8 includes a ring body 81, one side of the ring body 81 is provided with a circular cover plate 82, the center of the cover plate 82 is provided with a circular step 83, and the center of the step 83 is provided with a circular through hole 84 , A pair of end cover positioning blind holes 85 are symmetrically arranged on the inner surface of the cover plate 82 .

[0046] Such as Figure 12-14 , the casing 9 includes a cylindrical body 91 with an annular cross section, a circular partition 92 is provided at the middle section of the cylindrical body 91, and the partition plate 92 divides the inner cavity of the cylindrical body 91 into two, and the partition plate The center of 92 is provided with the cylindrical bearing 93 that extends to both sides, and the center of thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com