A device for continuous grouping of bamboo beam curtains for bamboo reconstituted timber

A technology for reconstituting bamboo materials and bamboo beam curtains, which is applied in the directions of wood compression, wood processing appliances, manufacturing tools, etc., can solve the problems of low efficiency, slow artificially assembling bamboo beam curtains, and inability to accurately assemble billets in a predetermined arrangement. problems to reduce the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

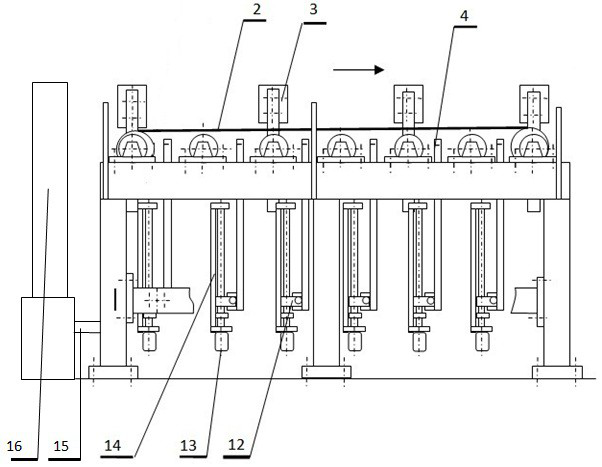

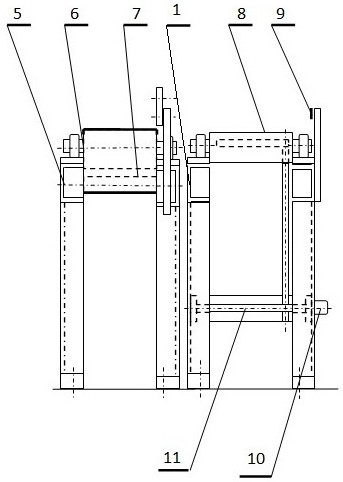

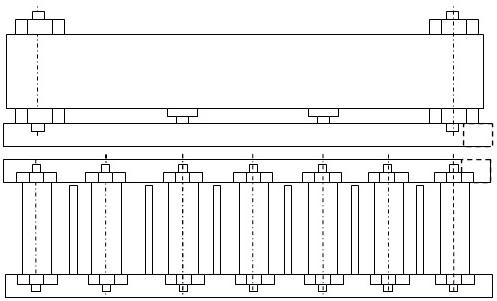

[0019] First, soak the bamboo curtain with a length of 1980mm, a width of 650mm, and a thickness of 6mm, dry it at low temperature, and cut off the joint to make the joint straight; place a piece of bamboo curtain on the forming drum 8 and transport it forward, and at the same time displace The sensor 9 works; when it reaches the predetermined position, the displacement sensor 9 sends a signal, and the inverted L-shaped curtain rod 4 rises under the drive of the vertical screw rod 14, and the bamboo bundle curtain is lifted from the drum; when it rises to a position higher than the unloading rod, The horizontal screw 11 works to move the bamboo curtain horizontally above the conveyor belt; the vertical screw 14 works to make the bamboo curtain drop to close to the conveyor belt 2; the horizontal screw reverses to send the curtain rod back to the forming drum position; the vertical screw rod rotates in reverse, and the curtain delivery rod is lowered to the initial position belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com