Round Seal Piston Ring Assemblies

A technology for sealing piston and ring components, applied to piston rings, engine components, machines/engines, etc., can solve the problems of emission pollution, increased fuel consumption, hindering the functioning of piston rings, etc., and achieve the effect of simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

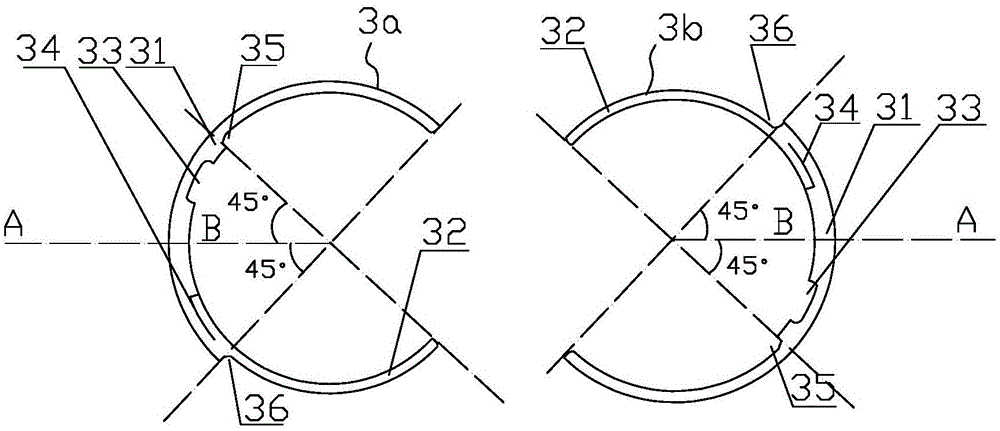

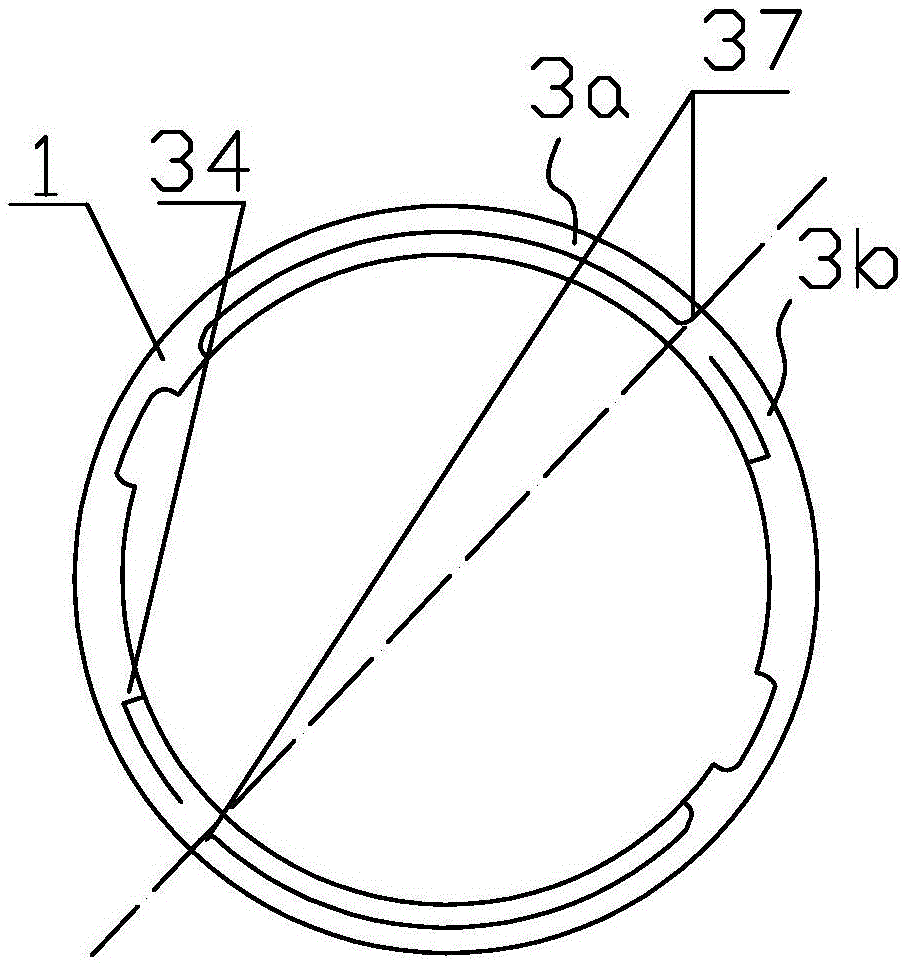

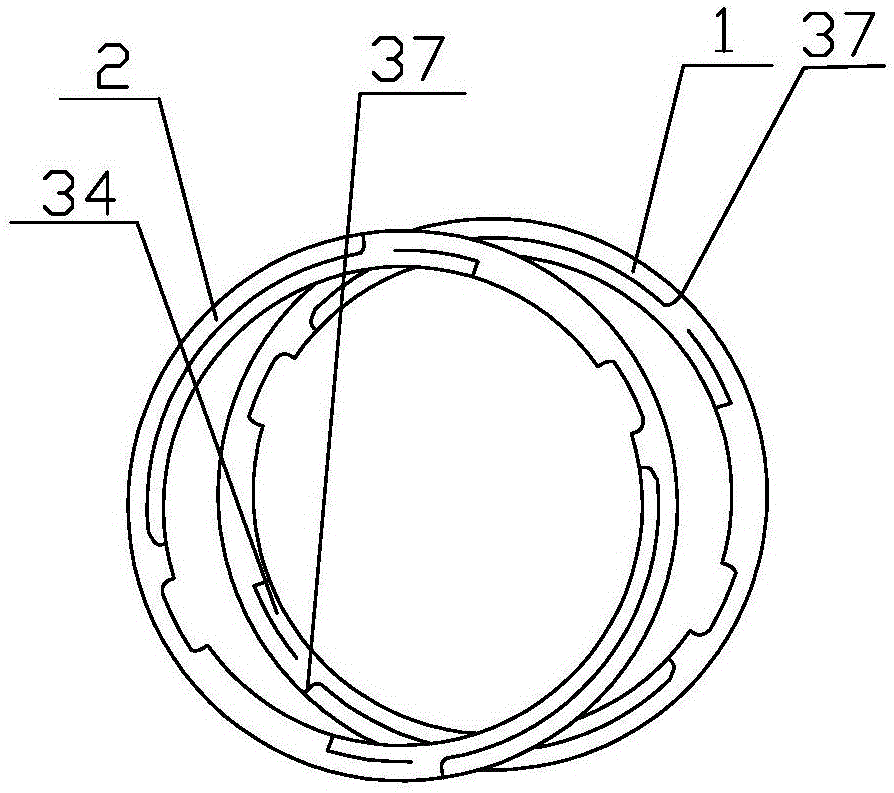

[0014] Please refer to image 3 One embodiment of the sealing assembly of the present invention includes a lower combination ring 1 and an upper combination ring 2, and the lower combination ring 1 and the upper combination ring 2 are installed in the same piston gas ring groove after overlapping. Please continue to refer figure 1 , the upper composite ring 2 and the lower composite ring 1 have the same structure, both including a C-type main ring 3a and a C-type secondary ring 3b, the C-type secondary ring 3b and the C-type main ring 3a have the same structure, figure 1 The C-shaped auxiliary ring 3b shown on the right is obtained by rotating the C-shaped main ring 3a on the left by 180 degrees.

[0015] The C-shaped main ring 3a and the C-shaped auxiliary ring 3b include a semi-circular body 31 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com