Sludge dewatering system

A sludge dewatering and rotor technology, which is used in water/sludge/sewage treatment, sludge treatment, dehydration/drying/concentrated sludge treatment, etc. Continuous dewatering and other problems to achieve the effect of improving sludge dewatering efficiency, avoiding secondary mixing, and realizing continuous dewatering operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

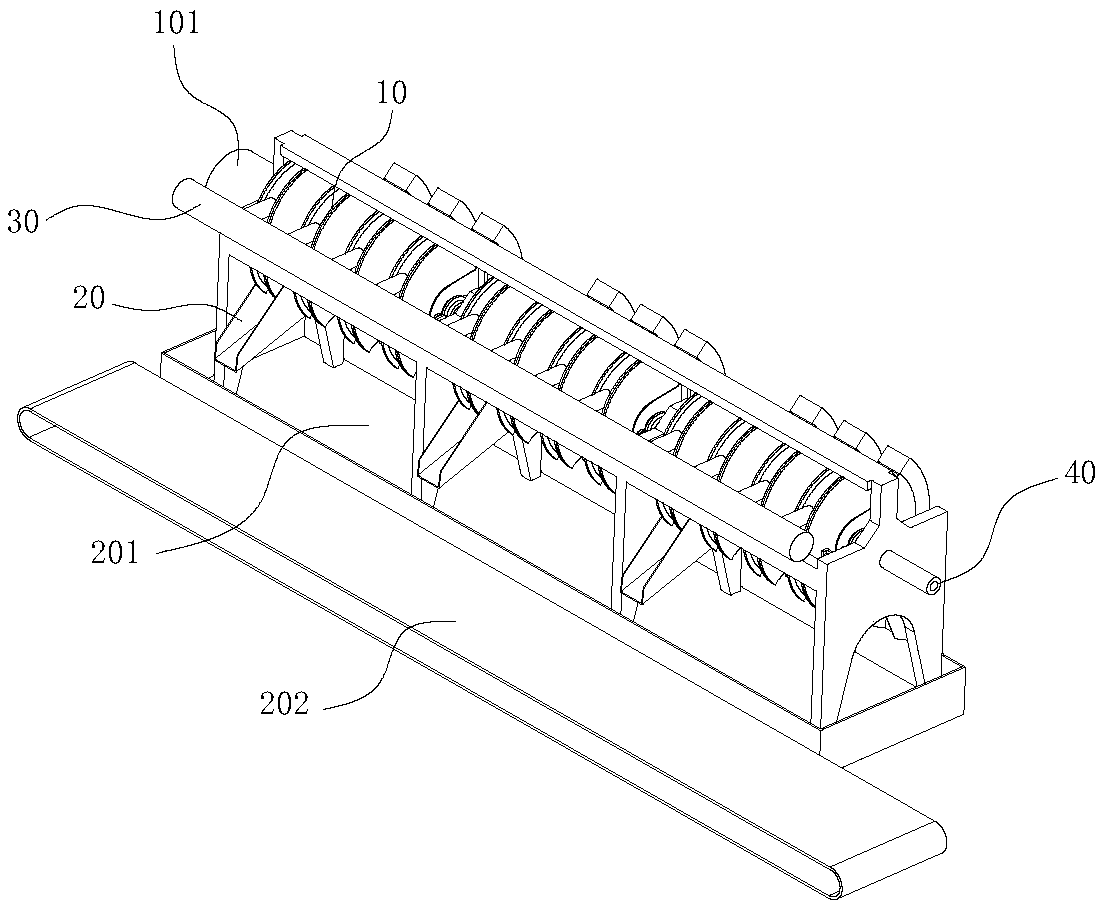

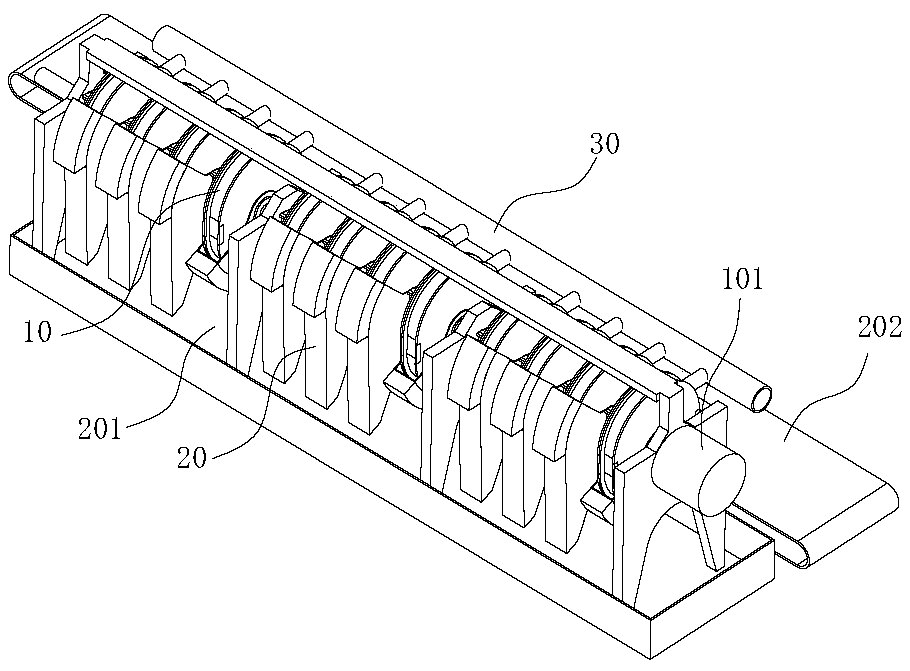

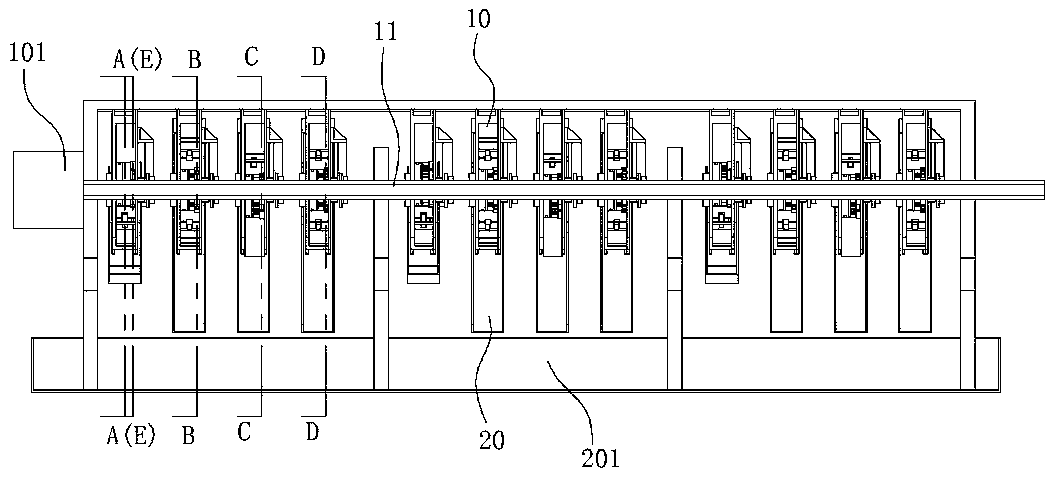

[0035] Such as figure 1 , 2 , 3, a sludge dewatering system includes a feed pipe 30, a dehydration mechanism 10, a liquid discharge pipeline 40 and a slag discharge device 20, the feed pipe 30 communicates with the feed port of the dewatering mechanism 10, and the dehydration mechanism 10 For squeezing sludge, the liquid discharge pipeline 40 communicates with the liquid discharge hole of the dewatering mechanism 10, and the slag discharge device 20 is located at the slag discharge port of the dewatering mechanism 10 and collects the dehydrated sludge; Figure 4 , 5 , 6, 7, 8, and 9, the dehydration mechanism 10 includes a rotor actuator, and the rotor actuator includes a main shaft 11, a rotor 13 and a housing 12, and the housing 12 includes two parallel end plates and connects two The side plate of the end plate, the side plate is a racetrack structure enclosed by two opposite semicircular walls and two opposite straight walls, the main shaft 11 runs through the housing 12 i...

Embodiment 2

[0045]A sludge dewatering method adopting the system described in embodiment 1 to process sludge comprises the steps:

[0046] Step 1: adding flocculant to the sludge to condition the sludge;

[0047] Step 2: Use the sludge pump to send the prepared sludge into the sludge dewatering system for dehydration;

[0048] Step 3: respectively recycle the wastewater discharged from the liquid phase outlet and the sludge discharged from the solid phase outlet of the sludge dewatering system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com