Patents

Literature

36results about How to "Reduce pickling process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper bus bar with high strength, high conductivity and high toughness and preparation method thereof

InactiveCN102034563AImprove conductivityImprove equipment technologySingle bars/rods/wires/strips conductorsManufacturing extensible conductors/cablesLiquid cathodeLiquid copper

The invention relates to a copper bus bar with high strength, high conductivity and high toughness and a preparation method thereof. The copper bus bar is characterized in that the material comprises 99.96-99.998% of copper and silver, 0.002-0.02% of yttrium rare earth and 0-0.038% of impurities, wherein silver accounts for 0.0005-0.01% of copper and silver; and the copper master alloy containing the yttrium rare earth is used as a modifier. The preparation method comprises the following steps: (1) melting a copper material: heating the cathode copper in a mains frequency core induction furnace to melt the cathode copper into liquid cathode copper; (2) modifying liquid copper: melting the modifier in the liquid cathode copper and fully mixing the modifier with the liquid cathode copper; (3) drawing a continuously cast copper bar upwards: causing a crystallizer of a continuous casting machine to stretch into the liquid cathode copper, condensing the liquid cathode copper into the copper bar in the crystallizer and drawing the copper bar upwards by means of two pairs of drawing roll mechanisms in the continuous casting machine to lead the copper bar to a take-up machine via a wheel frame; (4) continuously extruding the copper bar at medium temperature and carrying out anti-oxidation cooling; and (5) carrying out draw forming: putting copper bus bar blanks on a drawing machine, carrying out draw forming on the copper bus bar blanks.

Owner:福州市广福有色金属制品有限公司

A copper wire hot-dip tinning process

The invention relates to a copper wire hot tinning process which comprises procedures of wire charging, annealing, drying, tinning and wire discharging. The process uses an existing tinning device, and realizes the tinning effect of the prior art through process optimization of continuously introducing water vapor in the annealing procedure and controlling the drying temperature and without cooling or pickling procedures, and the finished product of tinned copper wire is not oxidized or changes color after long-term exposure in the air. The invention is brief in process flow, low in tin loss, can save investment, is green and pollution-free, and is worthy of popularization and application in wire and cable industry.

Owner:江西正导精密线材有限公司

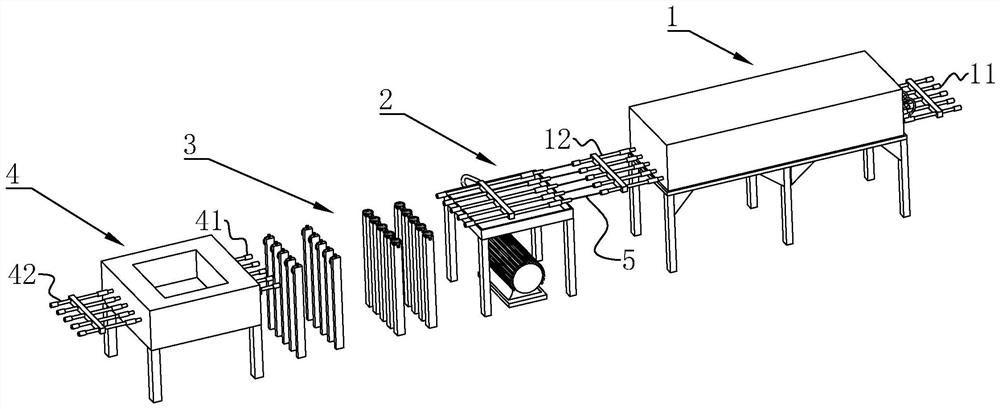

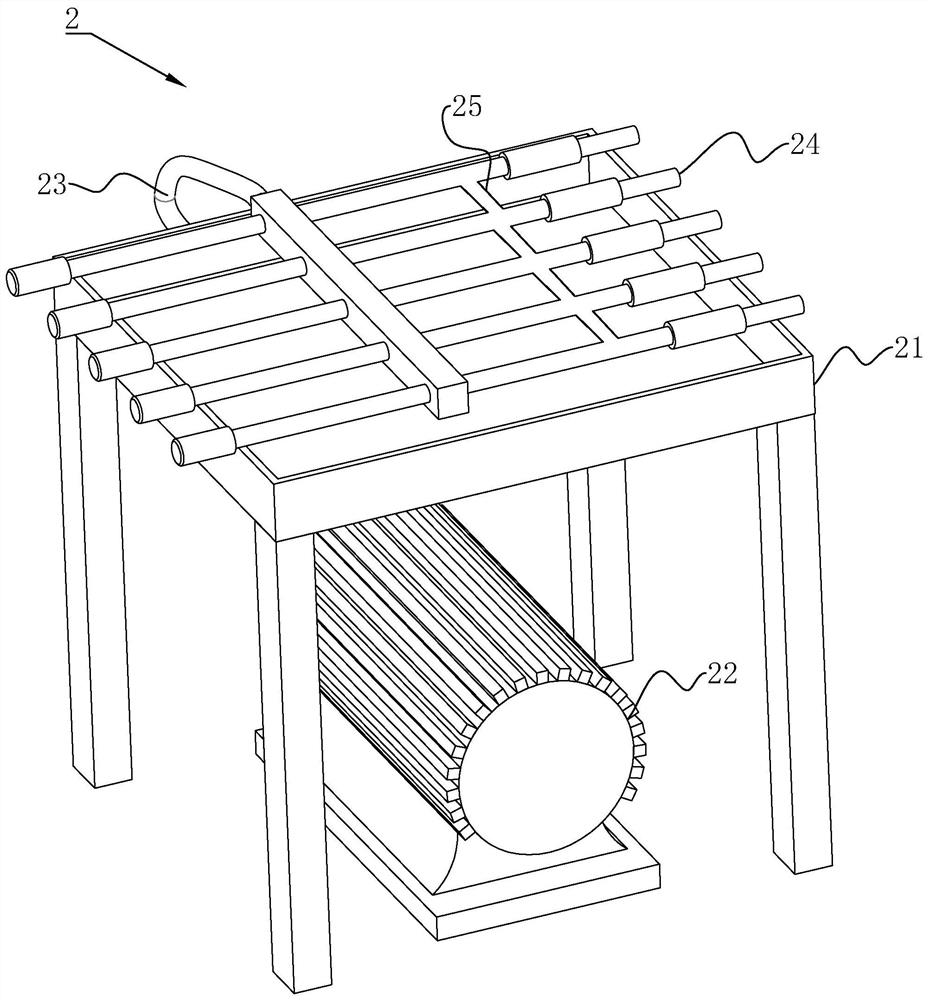

Preparation method of high-performance copper busbar

The invention relates to a preparation method of a high-performance copper busbar. The preparation method comprises the production process steps of A, copper material selection, B, copper material melting, C, copper liquid standing, D, copper liquid heat preservation, E, copper bar continuous casting, F, continuous extrusion, and G, molding by drawing. The purpose of the invention is to provide the preparation method of the high-performance copper busbar having the electric conductivity of greater than 100.3% IACS and the hardness of greater than or equal to 85HB, and bent by greater than or equal to 120 degrees.

Owner:福州聚勤环保科技有限公司

Ramie rapid degumming technique for producing high quality ramie top

InactiveCN101358380AReduced chance of acidic hydrolysisShort processVegetable materialCelluloseSodium acetate

The invention discloses a ramie quick degumming process in the production of high-quality sesame balls. The ramie quick degumming process comprises the following steps: ramie soaking: quick degumming dier boiling agent accounting for 1.0 weight percent to 1.5 weight percent of the ramie is used to soak the ramie for 1.0h to 1.5h at 50 DEG C to 60 DEG C; boiling at normal pressure: under the condition of normal pressure, 6g / l to 10g / l of NaOH aqueous solution is used to cook for 2h to 4h at 95 DEG C to 100 DEG C; the quick degumming dier boiling agent consists of gene improving alkaline pectase, stabilizer sodium acetate and magnesium chloride, penetrative emulsifier peregal O and trimeric sodium phosphate. The process shortens the technological process, and reduces the pickling procedure, so that the cellulose acidic hydrolysis probability is reduced and the degummed ramie forceful injury is small. The obtained degummed ramie has large break length and little hard thread doubling, is tender and applicable in spinning high grade cotton yarn.

Owner:湖南华升洞庭麻业有限公司

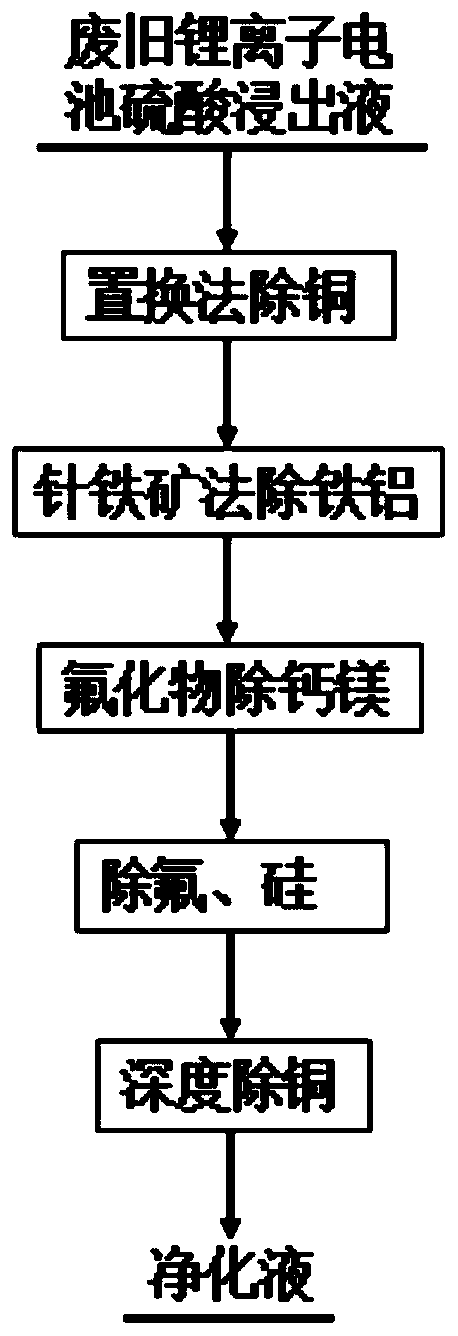

Method for removing impurities from waste battery leachate

The invention relates to a method for removing impurities from waste battery leachate. The method comprises the following steps that iron powder is added, and filtering is carried out after stirring so as to obtain a copper-removed solution; an oxidant is added to obtain a ferrous-removed solution; a small amount of the ferrous-removed solution is taken and diluted to serve as a base solution, theferrous-removed solution and a pH regulator are added, the pH regulator is continuously added after the ferrous-removed solution is completely added, and filtering is carried out after stirring so asto obtain an iron-aluminum-removed solution and iron-aluminum slag; fluoride is added into the iron-aluminum-removed solution, and filtering is carried out after stirring so as to obtain a calcium-magnesium-removed solution; the obtained iron-aluminum slag is added, and filtering is carried out after stirring so as to obtain fluorine-silicon-removed solution and fluorine-silicon-removed iron-aluminum slag; and manganese powder is added into the fluorine-silicon-removed solution, and filtering is carried out after stirring so as to obtain a purified solution. According to the method, the ironpowder is used for replacing and removing copper, and the cost is low; iron and aluminum are removed through a goethite method, and the slag filtering performance is good; fluorine and silicon are removed from the iron-aluminum slag, so that the waste slag is effectively utilized, and the iron-aluminum slag pickling process is reduced; and the copper is deeply removed through the manganese powder,the environment is protected, and the operation is easy.

Owner:HUNAN BRUNP RECYCLING TECH +2

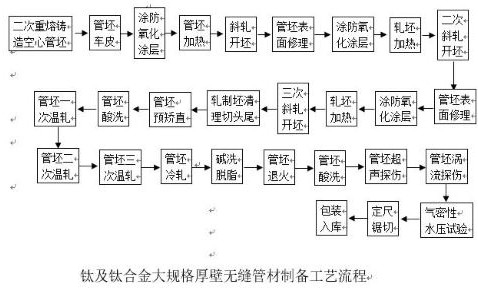

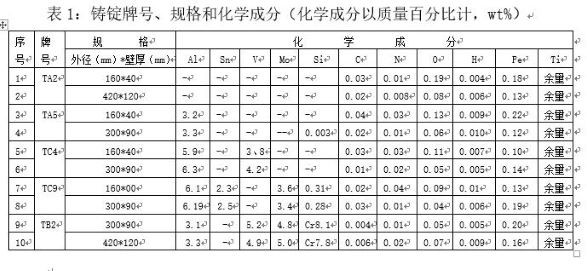

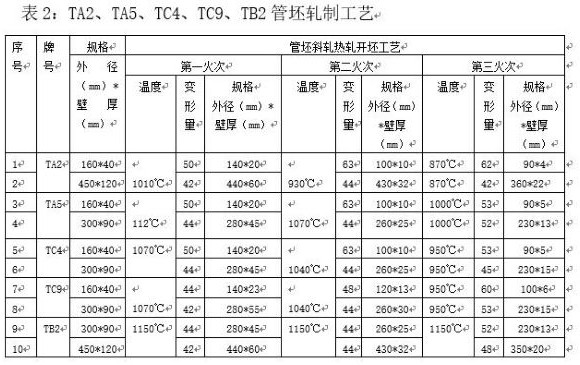

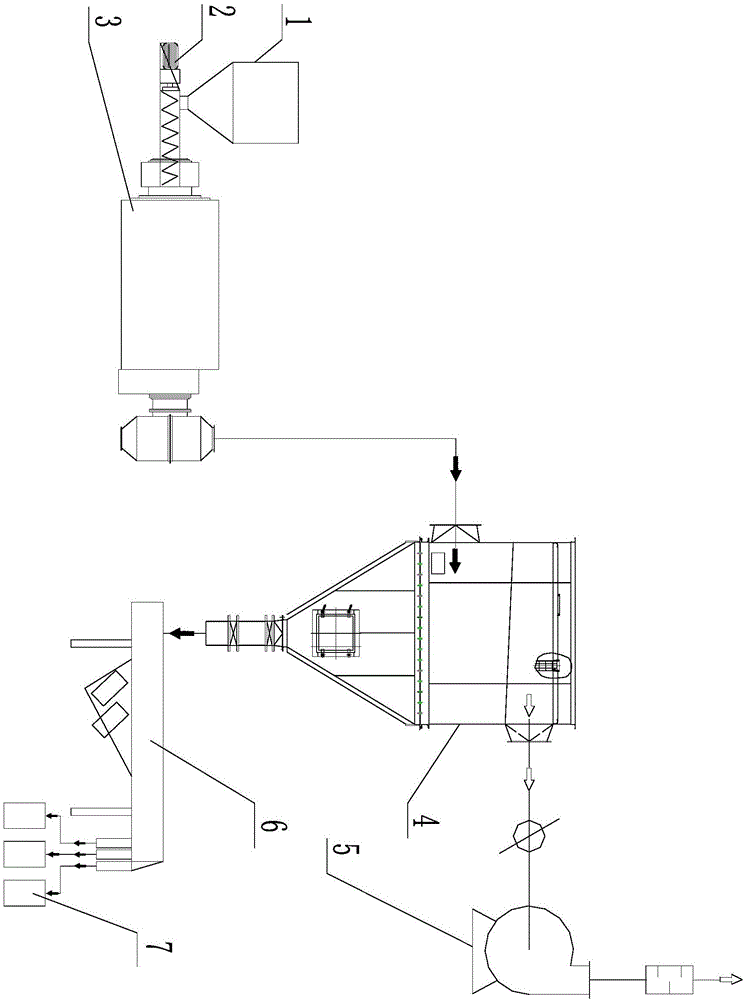

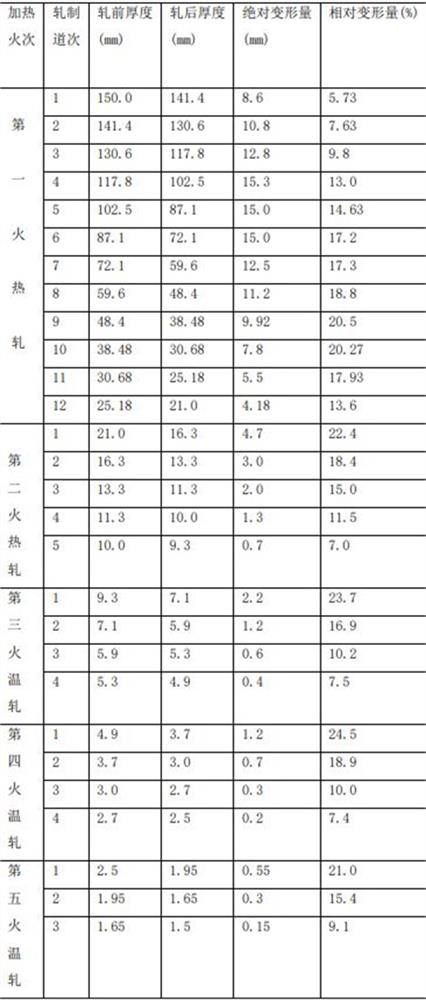

Preparation method of titanium and titanium alloy large-specification seamless pipe

ActiveCN112845654AImprove plasticityReduce lossTemperature control deviceFurnace typesElectromagnetic castingSurface cleaning

The invention provides a preparation method of a titanium and titanium alloy large-specification seamless pipe. According to the preparation method, an electromagnetic casting hollow pipe blank is adopted, a two-roller or three-roller skew rolling process is adopted to conduct cogging on the pipe blank for 2-3 passes, then warm rolling-cold rolling-cold stretching or warm rolling-cold stretching or warm rolling-expanding stretching is conducted, and the stretched pipe is subjected to inspection, fixed-length sawing, surface cleaning and finished product annealing and then is packaged and put in storage. By means of the preparation method, the problems of uneven wall thickness, unstable quality, unsuccessful perforation and the like of a pierced billet in the traditional skew rolling-perforation process are avoided; the process link of repeatedly heating and repeatedly rolling a cast ingot in the traditional process is omitted, so that the heating time is shortened, and oxidation of the pipe blank which sucks air after heating is relieved; annealing and pickling procedures and pickling metal loss are reduced; and large-specification seamless pipes with the diameter ranging from 80mm to 424mm and the wall thickness ranging from 2mm to 30mm can be produced to meet market requirements.

Owner:XINJIANG UNIVERSITY

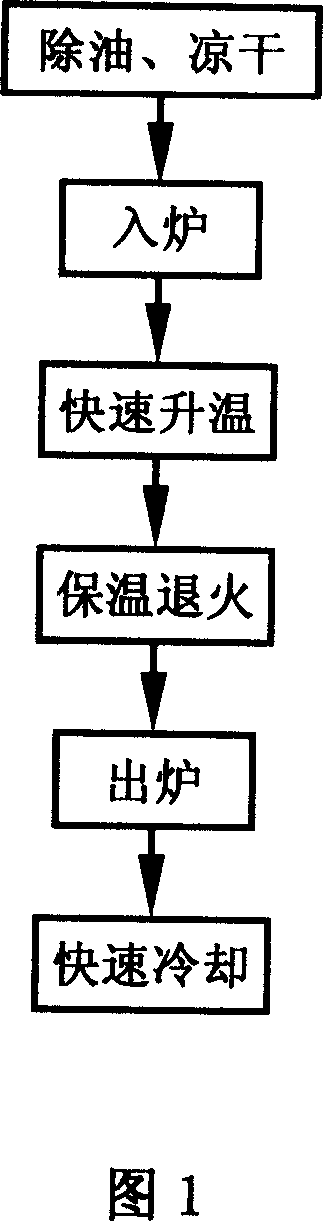

Quick annealing method for titanium seamless pipe

InactiveCN101086056AIncrease productivityReduce energy consumptionIncreasing energy efficiencyFurnace typesAutomatic controlIntermediate frequency

This invention discloses a method for annealing ti-seamless tubes. It comprises following steps: putting titanium tube into intermediate frequency induction annealing furnace orderly, heating to crystallization temperature rapidly when crossing intermediate frequency induction annealing furnace, restraining 'recovery' process, finishing recrystallization rapidly, cooling to room temperature fast, restraining ' grain growth' and high temperature oxidation. It only need several minutes for heating, thermal insulating and cooling for one titanium tube. It solves the technical problems of low production efficiency and high cost in background technology. The invention is characterized by automatic control, suitability for different length tubes annealing, mass or small production and excellent performance.

Owner:WESTERN TITANIUM TECH

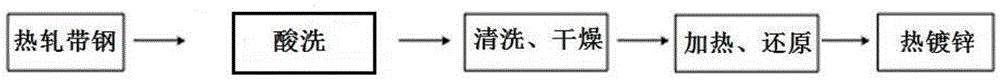

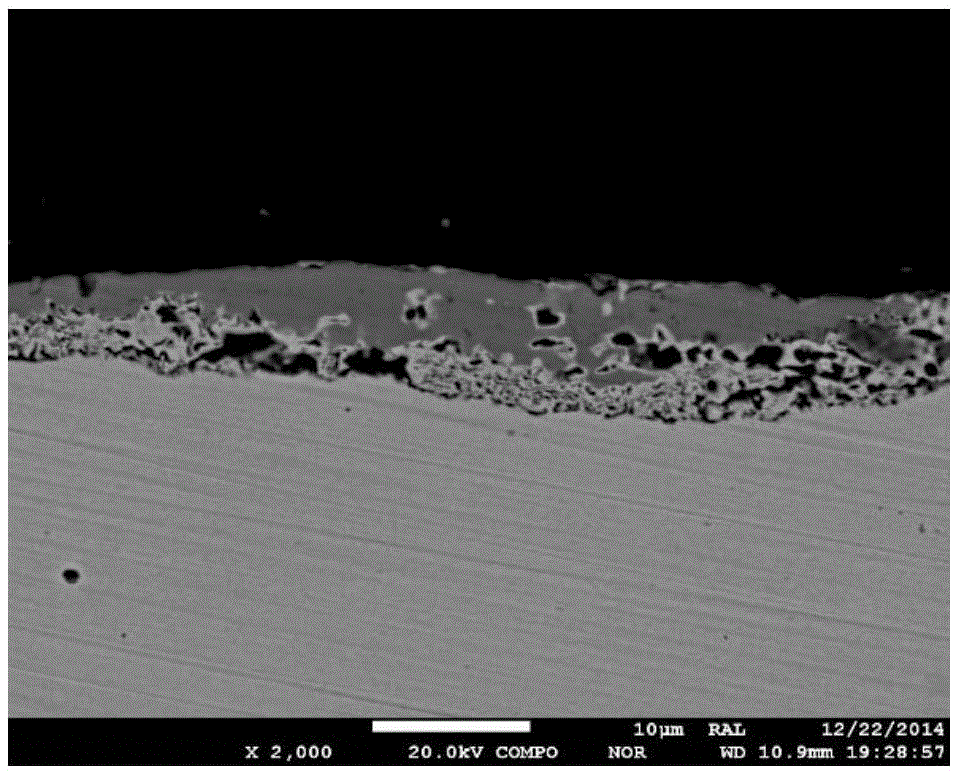

Acid washing-free direct hot galvanizing method of hot-rolled strip steel

InactiveCN105543750AIncrease the reduction ratioImprove reduction efficiencyHot-dipping/immersion processesTemperature control deviceBreaking strengthHydrogen atmosphere

The invention relates to an acid washing-free direct hot galvanizing method of hot-rolled strip steel, and belongs to the technical field of metallurgy; mainly aiming at the problems of weak hot galvanizing effect and low oxide scale reduction efficiency in a traditional galvanizing technology, the invention provides a method for improving a hot-rolled strip steel oxide scale reduction ratio; the oxide scale thickness and structure of the hot-rolled strip steel are adjusted in the hot rolling process: the hot-rolled strip steel is straightened in a straightener after being wound; after the surface of the strip is suffered from the bending stress, the strip is repeatedly bent and stretched; the huge difference of iron basal body and oxide scale covering layer material performances is used; the iron basal body is stressed to generate a certain plastic deformation; because of weaker plasticity and low breaking strength, a surface oxide scale layer cannot adapt to the deformation of the iron basal body to cause the internal stress to be higher than the breaking strength so as to finally generate different forms of scale cracks or stripping; the heating reduction is performed in a hydrogen atmosphere to improve the reduction efficiency; and then, the hot galvanizing is performed to obtain a more excellent acid washing-free reduction hot galvanizing effect.

Owner:武汉钢铁有限公司

Copper bus bar with high strength, high conductivity and high toughness and preparation method thereof

InactiveCN102034563BReduce energy consumptionReduce pickling processSingle bars/rods/wires/strips conductorsManufacturing extensible conductors/cablesLiquid cathodeLiquid copper

The invention relates to a copper bus bar with high strength, high conductivity and high toughness and a preparation method thereof. The copper bus bar is characterized in that the material comprises 99.96-99.998% of copper and silver, 0.002-0.02% of yttrium rare earth and 0-0.038% of impurities, wherein silver accounts for 0.0005-0.01% of copper and silver; and the copper master alloy containingthe yttrium rare earth is used as a modifier. The preparation method comprises the following steps: (1) melting a copper material: heating the cathode copper in a mains frequency core induction furnace to melt the cathode copper into liquid cathode copper; (2) modifying liquid copper: melting the modifier in the liquid cathode copper and fully mixing the modifier with the liquid cathode copper; (3) drawing a continuously cast copper bar upwards: causing a crystallizer of a continuous casting machine to stretch into the liquid cathode copper, condensing the liquid cathode copper into the copper bar in the crystallizer and drawing the copper bar upwards by means of two pairs of drawing roll mechanisms in the continuous casting machine to lead the copper bar to a take-up machine via a wheel frame; (4) continuously extruding the copper bar at medium temperature and carrying out anti-oxidation cooling; and (5) carrying out draw forming: putting copper bus bar blanks on a drawing machine, carrying out draw forming on the copper bus bar blanks.

Owner:福州市广福有色金属制品有限公司

Method of improving yield of titanium alloy wire rods

The invention relates to the technical field of titanium alloy wire rod preparation and discloses a method of improving yield of titanium alloy wire rods. The method comprises the following steps of A, aligning the wire rods with diameters phi of 7.8-8.2 mm and clamping the wire rods at an inlet of a rotary swaging machine; B, reducing the wire rods with diameters phi of 7.8-8.2 mm to phi of 1.8-2.2 mm by using the rotary swaging machine; C, in the reducing process, when the diameters phi of the wire rods are 5.8-6.2 mm, 4.3-4.7 mm,3.2-3.6 mm and 2.4-2.8 mm separately, annealing the wire rodsby using a vacuum annealing furnace; and D, in the reducing process, lubricating and cooling the wire rods by using anti-wear hydraulic oil. The method which does not use wire drawing powder as a lubricant cancels a pickling step and reduces the diameters by using a roller die, so that scratches of the surfaces of the wire rods are eliminated and the surface smoothness is guaranteed. Meanwhile, inthe reducing process, problems of severe oxidization of the surface of a material and the like are avoided through cold working, so that the yield of the material is improved greatly.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

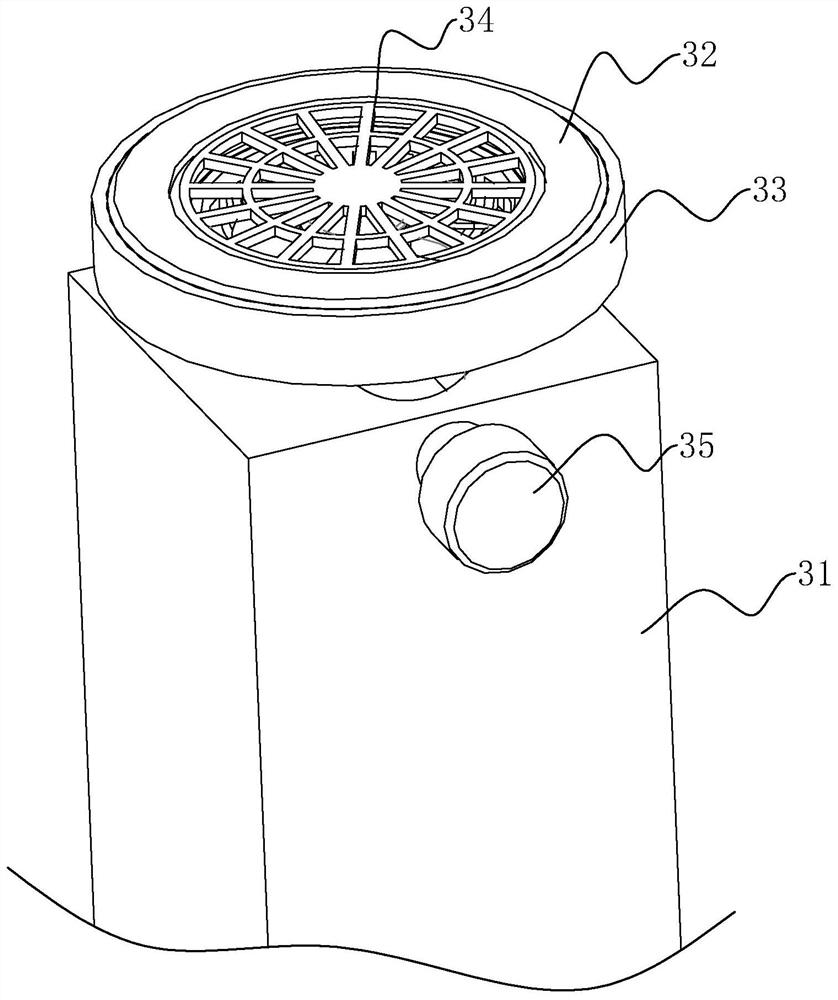

Production method for ground glass fibers and grinding device

The invention provides a production method for ground glass fibers and a grinding device. The production method comprises the steps of raw material storage, grinding, raw material particle collection, screening and packaging. The grinding device comprises a feeder. An inlet of the feeder is connected with an outlet of a feeding hopper. An outlet of the feeder is connected with an inlet of a ball mill. An outlet of the ball mill is connected with an inlet of a bag collector. An outlet of the bag collector is connected with a screening machine. All outlets of the screening machine are each provided with a split-charging bag. According to the production method and the grinding device, by the adoption of the continuous type ceramic ball mill, continuous operation in the grinding process is achieved, so that continuous production is achieved, the process is simple and practical, and the quality is easy to control; rust is avoided due to the ceramic characteristic of the continuous type ceramic ball mill, secondary pollution to glass fiber raw materials is avoided, meanwhile the acid pickling process is reduced, the working efficiency is high, and the higher economy is achieved.

Owner:JUSHI GRP CO

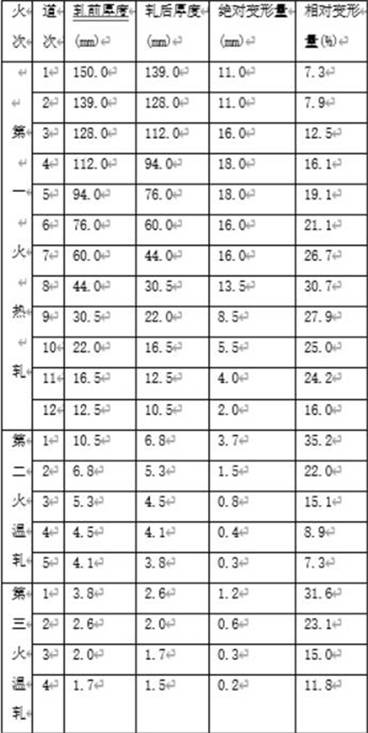

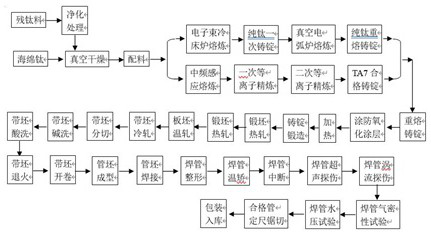

Preparation method of small and medium-sized titanium and titanium alloy thin-wall pipes

ActiveCN113881859AIncrease profitIncrease productivityGeneral water supply conservationIncreasing energy efficiencyIngotTitanium

The invention discloses a preparation method of small and medium-sized titanium and titanium alloy thin-wall pipes. According to the preparation method, industrial pure titanium is cast by adopting an electron beam cold bed melting-vacuum consumable arc melting process, a TA7 alloy is refined by adopting vacuum induction melting-plasma, impurities in the alloy are removed through melting, dissolving, flotation and sedimentation for removing inclusions in the alloy, the burning loss of low-melting-point alloy elements such as aluminum and tin is reduced, and harmful gas impurities in the alloy are removed. Segmented heating and forging cogging are adopted, and air suction pollution of cast ingots is reduced. The hot rolling-warm rolling-cold rolling process is adopted, so that the plasticity of the alloy can be utilized to the maximum extent, annealing and pickling procedures are reduced, and metal oxidation and pickling metal loss are reduced. The thin-wall pipes with the diameter ranging from phi 6.3 mm to phi 7.26 mm and the wall thickness ranging from 0.10 mm to 0.8 mm are welded through rolled strips to replace seamless pipes, and the method has the advantages of high raw material utilization rate, high production efficiency and good economic benefit.

Owner:XINJIANG UNIVERSITY

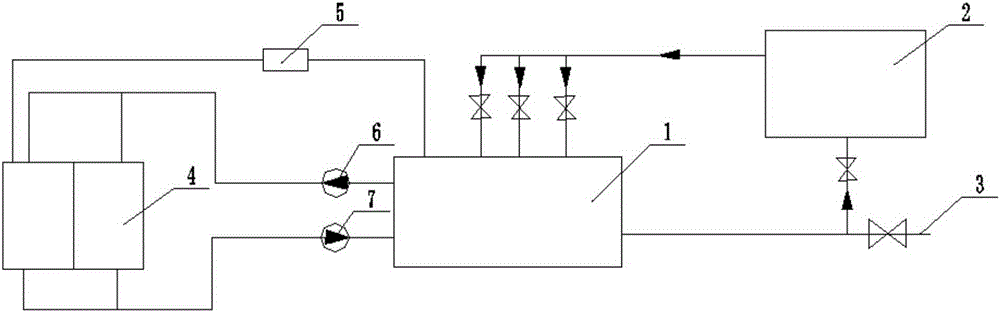

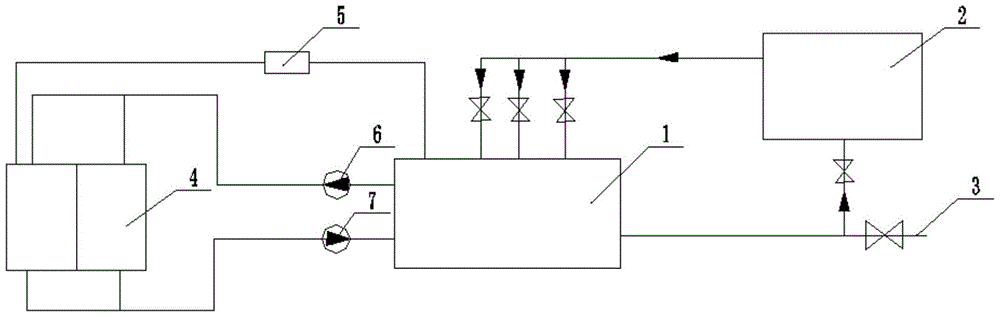

Flushing system and method for lubricating oil system of steam turbine generator unit

ActiveCN105179026AReduce interim measuresAvoid secondary pollutionMachines/enginesEngine componentsOil qualityPollution

The invention discloses a flushing system and method for a lubricating oil system of a steam turbine generator unit. The method includes the first step of connecting a bearing pedestal with an oil inlet and return pipe according to the design state, the second step of removing a bearing oil inlet pipe inside the bearing pedestal, the third step of starting a first oil filtering machine and cleaning a main oil tank and the bearing pedestal, the fourth step of shutting down the first oil filtering machine, pouring all lubricating oil of the main oil tank into an oil storage tank through a second oil filtering machine, and cleaning the main oil tank and the bearing pedestal, and the fifth step of pouring the lubricating oil in the oil storage tank into the main oil tank through the second oil filtering machine, starting the first oil filtering machine, sampling the lubricating oil of the main oil tank for testing, recovering an oil pipe inside the bearing pedestal and finishing the flush if the oil meets NAS7, and carrying out the steps 3-5 repeatedly if the oil does not meet NAS7. The lubricating oil can return to the main oil tank after directly entering the bearing pedestal and being flushed, so that provisional measures taken for oil inlet and return pipes of bearing pedestals are reduced, the cost is reduced, the installation period is shortened, and oil is prevented from secondary pollution.

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

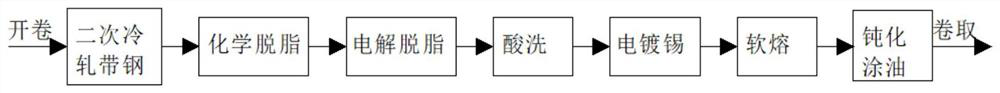

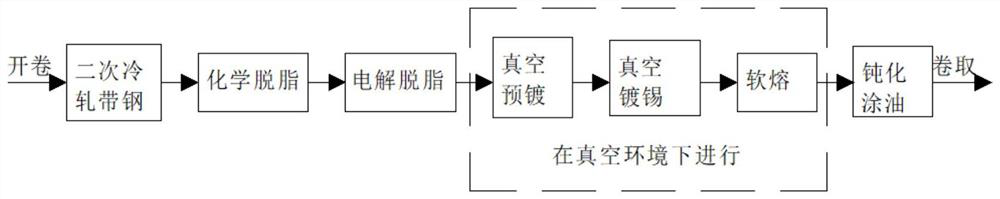

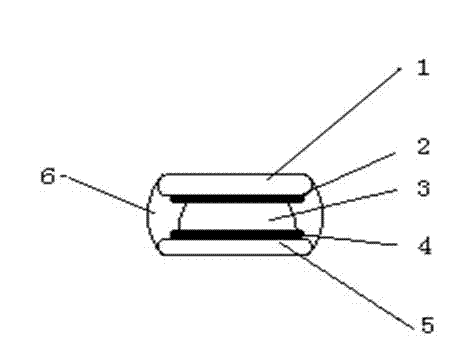

Manufacturing method of vacuum tinned plate

InactiveCN111945112AAvoid pollutionAvoid problems such as too many restrictive linksVacuum evaporation coatingSputtering coatingTin platingStrip steel

The invention discloses a manufacturing method of a vacuum tinned plate. The manufacturing method comprises the following steps that S1, secondary cold-rolled strip steel is cleaned; S2, the cleaned secondary cold-rolled strip steel is subjected to pre-plating; S3, after tinning or tin alloy plating is conducted on the surface of the pre-plated secondary cold-rolled strip steel, soft melting treatment is conducted, and the tinned plate is obtained; and S4, passivation and oil removal are conducted on the tinned plate. The manufacturing method has the following beneficial effects that the acidpickling procedure is omitted; the problems of high pollution, many limiting links and the like in the electroplating process are avoided; and oxidation of a tin layer in the soft melting process is avoided. The technology is an environment-friendly, high-adaptability, high-production-efficiency and excellent-plating-layer-performance manufacturing method for the tinned plate.

Owner:BAOSHAN IRON & STEEL CO LTD

Table-board manufacture technology for lead-free diode

InactiveCN102543721AReduce pickling stepsReduce pickling processSemiconductor/solid-state device manufacturingManufacturing technologyAcid washing

The invention discloses a table-board manufacture technology for a lead-free diode. The table-board manufacture technology is characterized by corroding the table-board of the lead-free diode directly corroded twice by strong alkali; corroding for the first time by using strong alkali with mass concentration of 8-15% at 70-95 DEG C. for 5-15 minutes; and corroding second time using strong alkali with mass concentration of 2-6% at 70-95 DEG C. for 5-15 minutes. The table-board manufacture technology disclosed by the invention has the advantages that after the subsequent acid washing steps in patent 2009101346788 with a patent name of table-board manufacture technology for lead-free diode is reduced, the problem that products are broken by reaction of acid and lead-free welding sheets is solved, the high-temperature welding of the product is ensured at the speed of 265+ / -5 DEG C / 10s, and various performances can be equivalent to those of the table-board manufactured by the mentioned patent.

Owner:如皋市日鑫电子有限公司

Fur chromium-free and aldehyde-free tanning process

InactiveCN106222324AReduce usageEmission reductionTanning treatmentPre-tanning chemical treatmentChromium freePollutant emissions

The invention discloses a fur chromium-free and aldehyde-free tanning process. The process includes the steps of pre-soaking, primary soaking, fleshing, degreasing, washing, enzyme bating and tanning. The degreasing process includes the steps that 0.8-1.2 g / L of a penetrating agent, 0.5-1 g / L of sodium carbonate, 1.5-2.5 g / L of an anion degreasing agent, 0.2-0.7 g / L of an enzymatic soaking agent 100-c, 0.2-0.7 g / L of lipase and 0.5-1 g / L of neutral enzyme FN are added; Ph is 6.5-7.5, the water temperature is 38-40 DEG C, and reaction time is 2-4 h; and after degreasing is completed, dehydration and cleaning are performed, and the tanning process is executed. The tanning process includes the steps that 1.5-2.5 g / L of Bascal S, 1.5-2.5 g / L of fatty aldehyde and 8-12 g / L of an aluminum tanning agent are added, and the water temperature is 38-40 DEG C; and after reaction is carried out for 1.5-2.5 hours, the PH value is 3-3.5, and 10-15 g / L of chromium powder is added at twice. The adjustment solution pH does not need to be adjusted by adding acid as for the Ph in the degreasing procedure, neutral salt and acid are avoided, tanned fur and fleece are loose and flexible, and a fur plate is plump, flexible and elastic. All the indexes can meet the industrial standard requirement. In addition, the pickling procedure is omitted, namely the neutral salt and acid are avoided, and pollutant emission is reduced.

Owner:桐乡市鑫诺皮草有限公司

High-temperature-resistant titanium alloy plate and annealing method thereof

InactiveCN107586998AImprove thermal stabilityImprove high temperature creep resistanceTitanium alloyHeating temperature

The invention discloses a high-temperature-resistant titanium alloy plate. A titanium alloy plate material is prepared from the following components in percentage by weight: 0.5 to 1.2 percent of aluminum, 3 to 5 percent of silicon, 0.2 to 0.5 percent of iron, 1.2 to 1.8 percent of nickel, 0.1 to 0.2 percent of carbon and the balance of titanium. A preparation process of the titanium alloy plate comprises the following steps: 1, mixing all the raw materials according to the formula amounts, feeding the mixture into a vertical type induction heating furnace, controlling heating temperature at 1,400 to 1,450 DEG C for smelting, and performing ingoting to form a titanium alloy ingot; 2, performing hot rolling on the titanium alloy ingot prepared in the step 1 to prepare a titanium alloy plateblank; 3, performing thermal treatment on the titanium alloy plate blank prepared in the step 2; 4, performing alkaline pickling on the titanium alloy plate subjected to the thermal treatment in thestep 3 to remove a surface oxide film, and mechanically grinding the titanium alloy plate till the surface coarseness is 0.5 to 1 [mu]m, thereby obtaining the titanium alloy plate. The high-temperature-resistant titanium alloy plate is good in thermal stability and high-temperature creep resistance. The invention further discloses a method of annealing the titanium alloy plate.

Owner:BAOJI YONGSHENGTAI TITANIUM IND

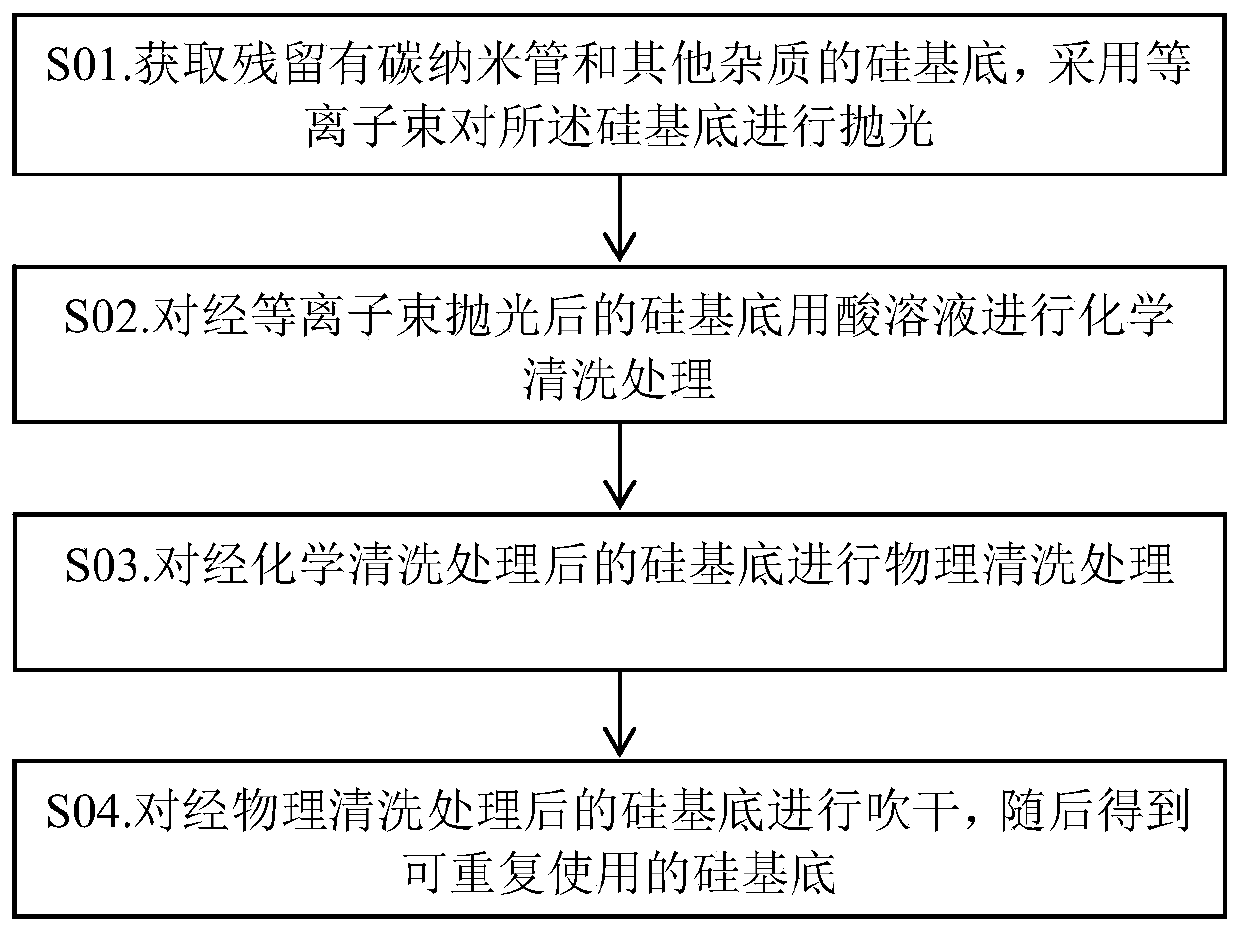

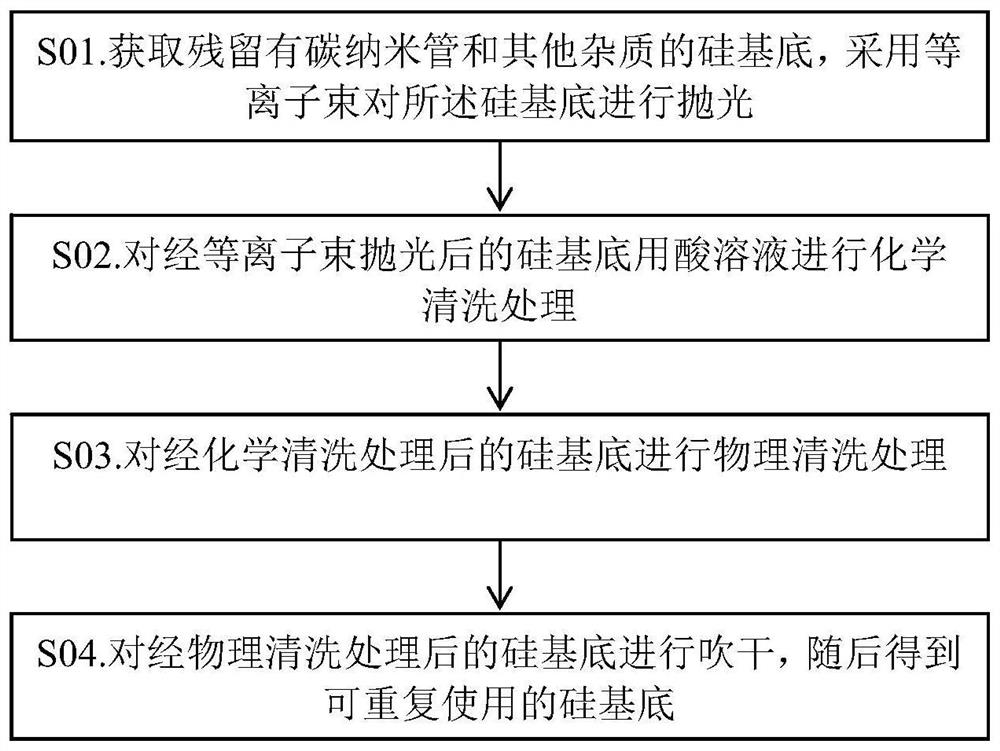

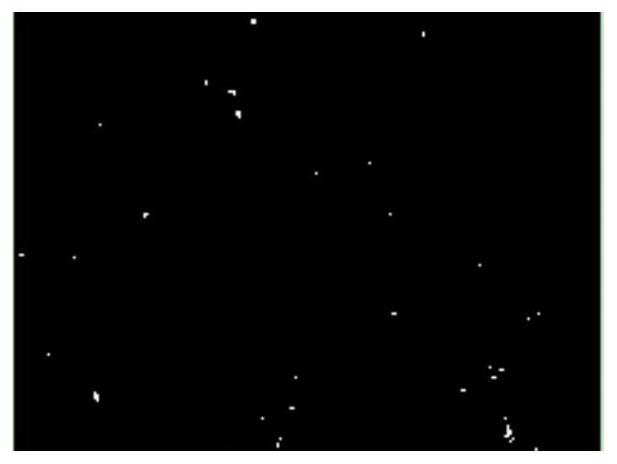

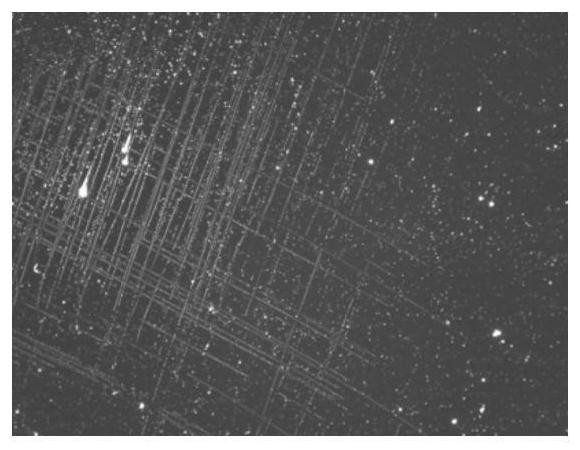

Silicon substrate cleaning method

ActiveCN110459461AArray Height UniformGood spinning performanceSemiconductor/solid-state device manufacturingCarbon nanotubesCarbon nanotubePlasma beam

The invention provides a silicon substrate cleaning method. The silicon substrate cleaning method comprises steps that the silicon substrate with carbon nanotubes and other impurities remaining is obtained, and the silicon substrate is polished through plasma beams; the silicon substrate after plasma beam polishing is chemically cleaned with acid solution; and silicon substrate after chemical cleaning is subjected to physical cleaning; the silicon substrate physical cleaning is blown dry, and then a reusable silicon substrate is obtained. The method is advantaged in that the silicon surface color is uniform and consistent after cleaning, a spot and ash stamp problem is eliminated, and the secondary carbon nanotube growth test shows that the carbon nanotube output reaches 92-98% of new silicon wafers, which basically met target requirements.

Owner:CONE SCI CITY GUANGZHOU ADVANCED MATERIALS CO LTD

Cold working pipe-making technique for aero alloy tube

InactiveCN101284352AGuaranteed physical and chemical propertiesQuality assuranceBoring/drilling machinesAviationAlloy

The invention discloses a cold-working tube manufacture process of an aerometal tube, which includes a blank tube manufacture process, a heat treatment process and a straightening procedure, wherein the blank tube manufacture process includes piercing, end flattening, oiling and multi-time cold rolling processes. The piercing process adopts a processing manner of machine tool drilling. The manufacture process has no need for heating the tube blank before drilling, thereby guaranteeing the physical and the chemical properties of the tube blank, avoiding the processing defect, increasing the qualification rate of the blank tube to 100%, ensuring the quality of the blank tube, simplifying the technological process and saving the production cost. The manufacture process has no need for heating the tube blank, therefore, the acid cleaning procedure is eliminated so that no waste generates except the solid one, and the generated solid waste can be recovered, thereby saving resource and cost and causing no environment pollution.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

A method for cleaning a silicon substrate

ActiveCN110491772BReduce outputReduce manufacturing costSemiconductor/solid-state device manufacturingCleaning processes and apparatusCarbon nanotubeSilicon chip

Owner:CONE SCI CITY GUANGZHOU ADVANCED MATERIALS CO LTD

A method for improving the yield of titanium alloy wire

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

High-quality flax staple fiber processing method

InactiveCN103114451BGood color fixation rateNo pollutionSucessive textile treatmentsVegetal fibresFiberYarn

Owner:QIQIHAR UNIVERSITY

Flushing system and flushing method of lubricating oil system of turbogenerator set

ActiveCN105179026BReduce interim measuresAvoid secondary pollutionMachines/enginesEngine componentsOil canOil quality

The invention discloses a flushing system and a flushing method for the lubricating oil system of a turbine generator set. The first step is to connect the bearing seat and the oil inlet and return pipe according to the design state; the second step is to remove the bearing oil inlet pipe inside the bearing seat; the third step is to open the third Use the first oil filter to clean the main oil tank and bearing seat; step four, stop the first oil filter and pass the lubricating oil in the main oil tank through the second filter. Pour all the oil into the oil storage tank, clean the main oil tank and bearing seat; step 5, pour the lubricating oil from the oil storage tank into the main oil tank through the second oil filter, turn on the first oil filter, and lubricate the lubricating oil entering the main oil tank. The oil is sampled and tested. When the result reaches NAS7, restore the oil pipeline inside the bearing seat and complete the flushing. When the test result does not reach NAS7, repeat steps three to five. The lubricating oil can directly enter the bearing seat for flushing and then return to the main oil tank. Reduce temporary measures at the oil return pipe of each bearing seat, save costs, shorten the installation period, and avoid secondary pollution of oil.

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

A fine-drawing process for small-diameter thin-walled nickel-based tubes

ActiveCN111804747BEasy to operateHigh strengthSolution treatmentElectrical resistance and conductance

The present invention provides a small-diameter thin-walled nickel-based pipe fine drawing process, comprising the following steps: 1) Heading the nickel-based pipe; 2) Cold drawing the pipe; 3) Heating and annealing the pipe; 4) Repeating step 2 ) and step 3) multiple times of cold drawing and multiple heating and annealing of the tube; 5) solid solution treatment of the finished tube obtained in step 4) under a protective gas atmosphere, and then cooling; 6) the tube obtained in step 5) Straightening, head and tail cutting, inspection and testing, cutting to length, packaging and storage. The precision drawing process of the small-diameter thin-walled nickel-based tube of the present invention has high process operability, adopts resistance heating annealing, and reasonably controls the holding position, and the position close to the head can reduce cold deformation stress due to heat conduction of the tube and prevent thin-walled nickel-based tubes The cold drawing process breaks the head.

Owner:江苏隆达超合金股份有限公司

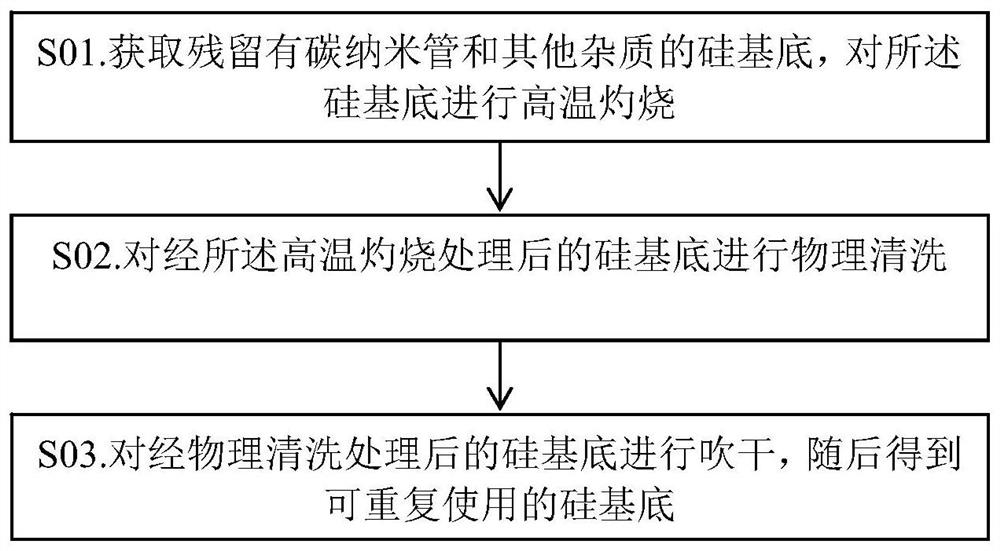

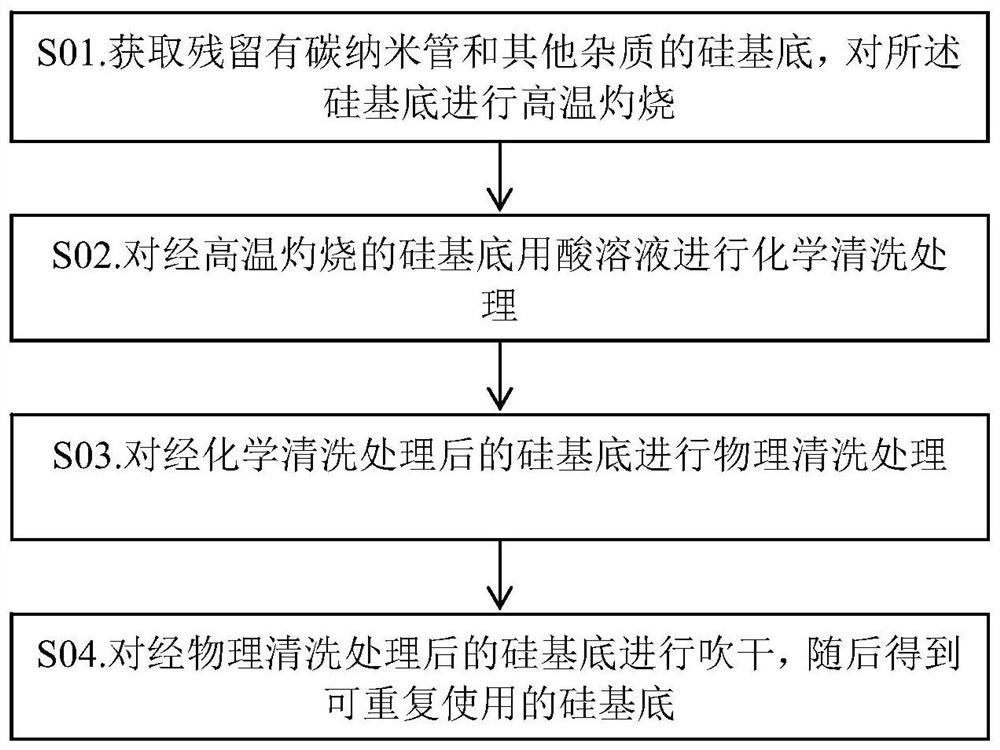

A method for cleaning a silicon substrate

ActiveCN110491773BReduce outputUniform arraySemiconductor/solid-state device manufacturingCarbon nanotubeSilicon chip

The invention provides a method for cleaning a silicon substrate, comprising the following steps: obtaining a silicon substrate with residual carbon nanotubes and other impurities, burning the silicon substrate at a high temperature; cleaning the silicon substrate burned at a high temperature with an acid solution Chemical cleaning treatment; performing physical cleaning treatment on the silicon substrate after chemical cleaning treatment; drying the silicon substrate after physical cleaning treatment, and then obtaining a reusable silicon substrate. After cleaning, the surface color of the silicon wafer is uniform, without spots and gray marks; the secondary carbon nanotube growth test shows that the output of carbon nanotubes reaches 90%-97.8% of the new silicon wafer, which basically meets the target requirements.

Owner:CONE SCI CITY GUANGZHOU ADVANCED MATERIALS CO LTD

A coating production system and coating production method applied to ultra-fine coaxial cables

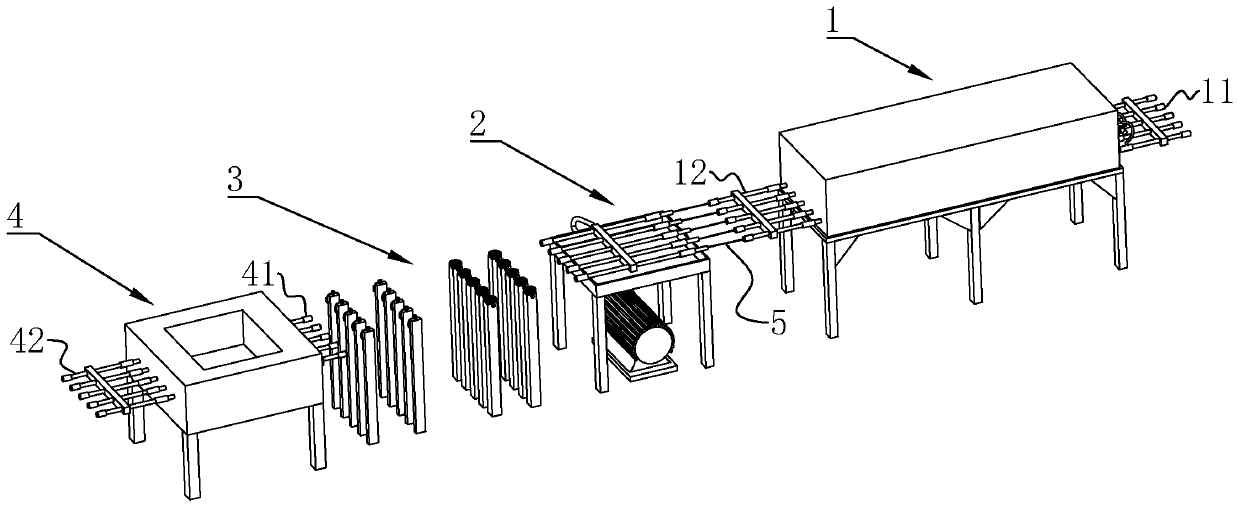

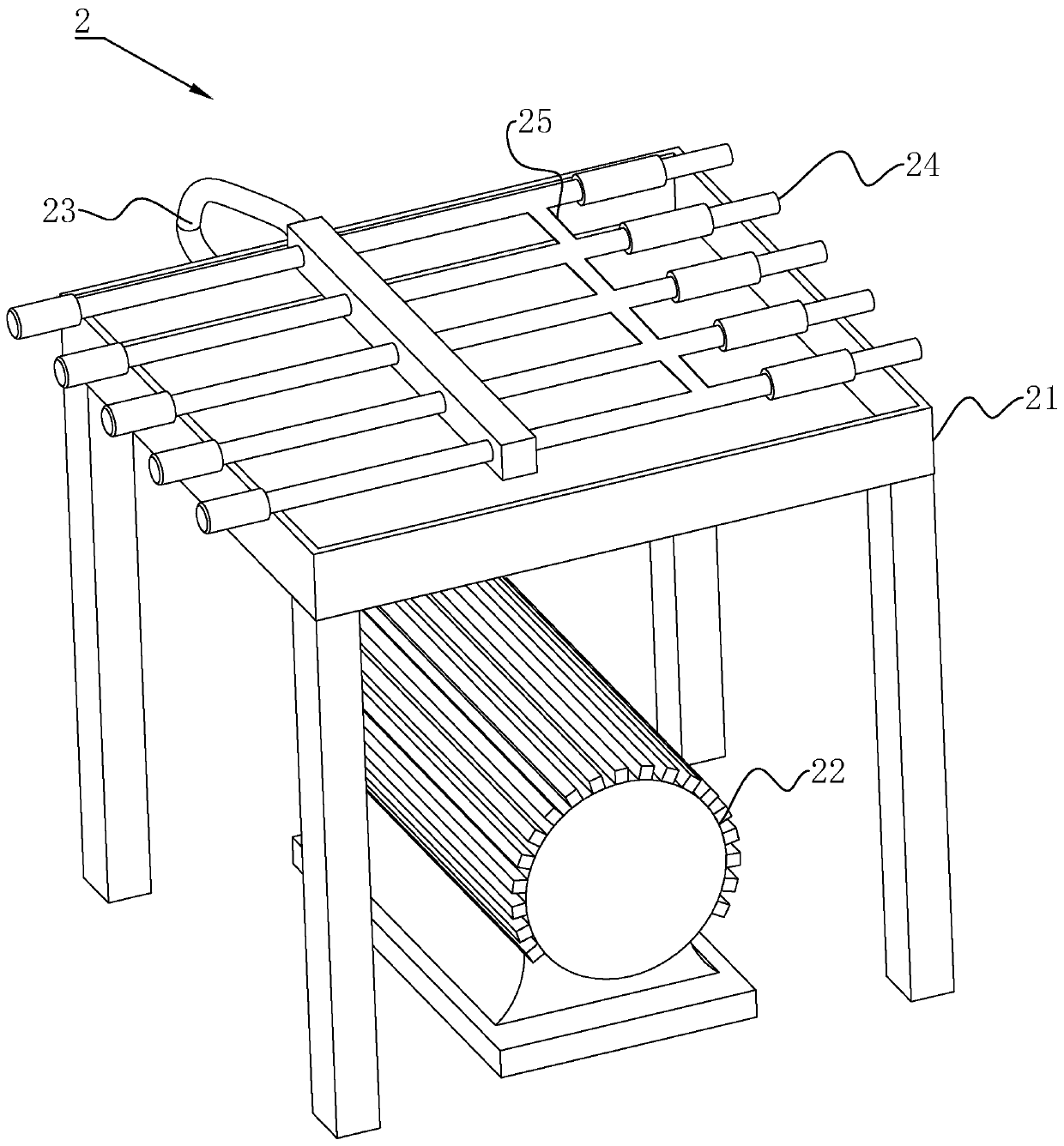

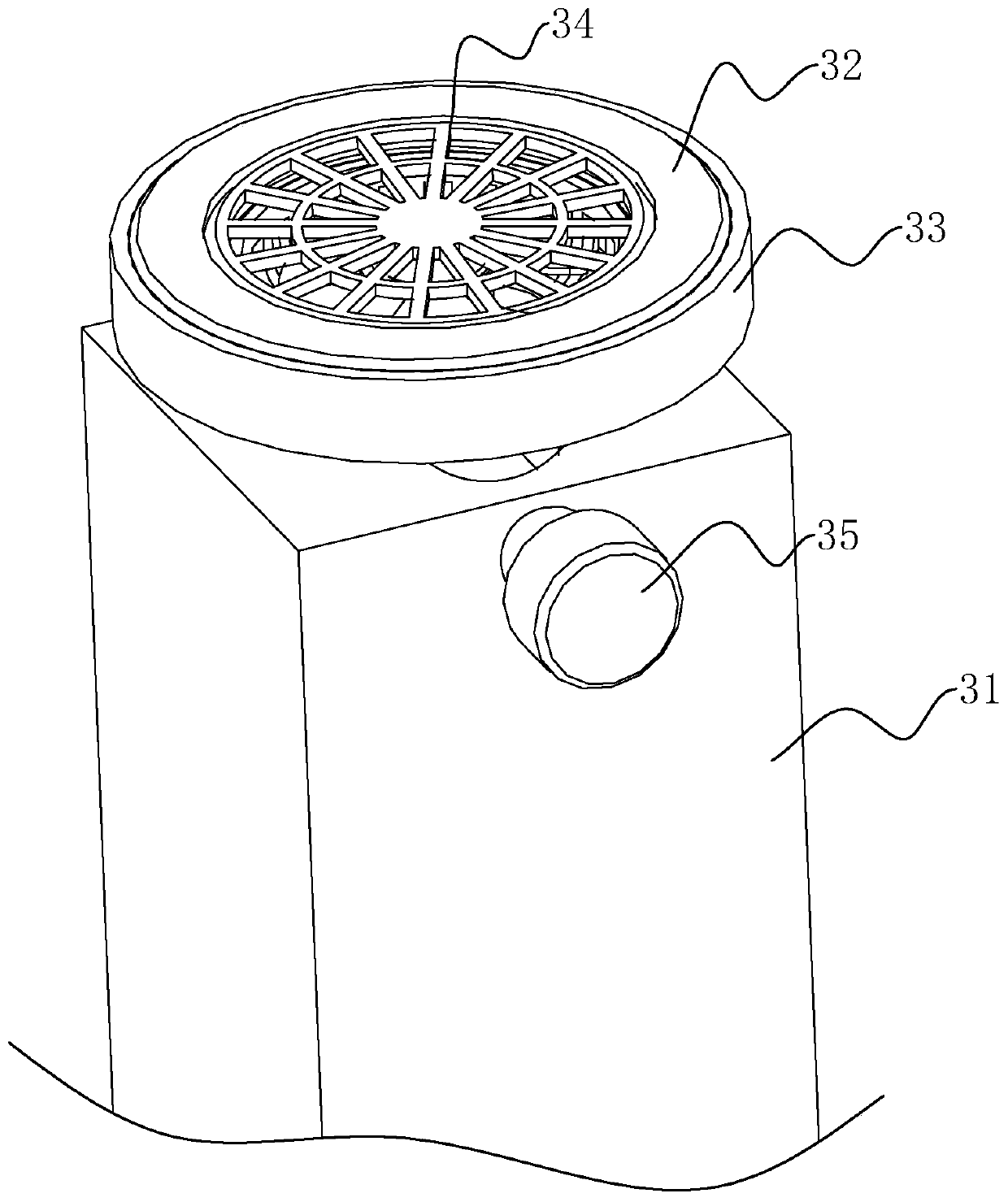

ActiveCN110129544BAvoid pollutionReduce pickling processHot-dipping/immersion processesFurnace typesTinningCoaxial cable

The invention discloses a coating production system and a coating production method applied to ultra-fine coaxial lines. The coating production system includes a pay-off frame, an annealing box, a tin plating pool and a take-up frame. A water vapor cooling device and a surface cleaning device are provided at the same time. The ultra-fine coaxial line passes through the water vapor cooling device. The surface cleaning device includes a fixed block. A flexible layer is provided on the surface of the fixed block. The ultra-fine coaxial line and the flexible The surfaces of the layers are in contact to form line contact; by adopting the above-mentioned production system and production method, the pickling process is omitted, which on the one hand has the effect of being environmentally friendly and pollution-free, and on the other hand can effectively improve the utilization rate of tin.

Owner:信电电线(深圳)有限公司

A method for cleaning a silicon substrate

ActiveCN110459461BReduce outputImprove spinnabilitySemiconductor/solid-state device manufacturingCarbon nanotubesCarbon nanotubeIon beam

The invention provides a method for cleaning a silicon substrate, comprising the following steps: obtaining a silicon substrate with residual carbon nanotubes and other impurities, using a plasma beam to polish the silicon substrate; The solution is chemically cleaned; the chemically cleaned silicon substrate is physically cleaned; the physically cleaned silicon substrate is dried to obtain a reusable silicon substrate. After cleaning, the surface color of the silicon wafer is uniform, without spots and gray marks; the secondary carbon nanotube growth test shows that the output of carbon nanotubes reaches 92%-98% of the new silicon wafer, which basically meets the target requirements.

Owner:CONE SCI CITY GUANGZHOU ADVANCED MATERIALS CO LTD

Copper wire hot tinning process

ActiveCN102277546BWill not polluteWill not corrodeHot-dipping/immersion processesProcess optimizationTinning

The invention relates to a copper wire hot tinning process which comprises procedures of wire charging, annealing, drying, tinning and wire discharging. The process uses an existing tinning device, and realizes the tinning effect of the prior art through process optimization of continuously introducing water vapor in the annealing procedure and controlling the drying temperature and without cooling or pickling procedures, and the finished product of tinned copper wire is not oxidized or changes color after long-term exposure in the air. The invention is brief in process flow, low in tin loss, can save investment, is green and pollution-free, and is worthy of popularization and application in wire and cable industry.

Owner:江西正导精密线材有限公司

Cladding layer production system and cladding layer production method applied to micro coaxial cable

ActiveCN110129544AAvoid pollutionReduce pickling processHot-dipping/immersion processesFurnace typesCoaxial cableSurface cleaning

The invention discloses a cladding layer production system and cladding layer production method applied to a micro coaxial cable. The cladding layer production system comprises a paying off frame, anannealing box, a tinning pool and a take-up frame and further comprises a water steam cooling device and a surface cleaning device which are arranged behind the annealing box and are connected in sequence, the micro coaxial cable penetrates through the water steam cooling device, the surface cleaning device comprises a fixed block, the surface of the fixed block is provided with a flexible layer,and the micro coaxial cable is in abut joint with the surface of the flexible layer to form linear contact, through the above production system and production method, the acid pickling procedure is omitted, the environment-friendly pollution-free effect is achieved, and the use rate of tin can be effectively improved.

Owner:信电电线(深圳)有限公司

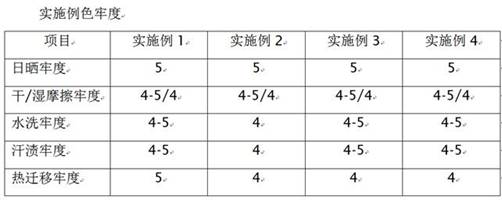

Dyeing method of bio-based nylon 56 fabric disperse dye

PendingCN114369962AHigh authenticity rate of printingGood coloring rateDyeing processDisperse dyeTextile printer

The invention relates to the technical field of textile, and discloses an anhydrous printing method for bio-based nylon 56 fabric, which comprises the following steps: 1) treating the bio-based nylon 56 fabric by using a stabilizer to obtain gray fabric in a pre-treatment scouring process; or the fabric made of the high-stability bio-based nylon fiber is directly used as the gray fabric; and 2) thermal transfer printing or hot melting direct printing. The printing process is simple to operate, basically free of wastewater discharge, energy-saving and emission-reducing, and meets the environmental protection requirement; according to the method, the nylon 56 grey cloth of the common biotechnology is subjected to stabilizer treatment before printing, so that the nylon fabric is protected to a certain extent, and the nylon fabric is prevented from being damaged due to overhigh temperature in the heat transfer printing process or the high-temperature ageing and color fixing process of direct printing. The method disclosed by the invention is particularly suitable for fabrics made of high-stability bio-based nylon fibers, and the nylon fabrics prepared by the method do not need to be treated by adopting a stabilizer, and have the advantages of high printed certified product rate, good dyeing degree, high color fastness and good quality.

Owner:上海普弗门化工新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com