Preparation method of small and medium-sized titanium and titanium alloy thin-wall pipes

A thin-walled pipe and titanium alloy technology, applied in the field of non-ferrous metal pressure processing, can solve the problems of low production efficiency, low raw material utilization rate, affecting the application of titanium and titanium pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

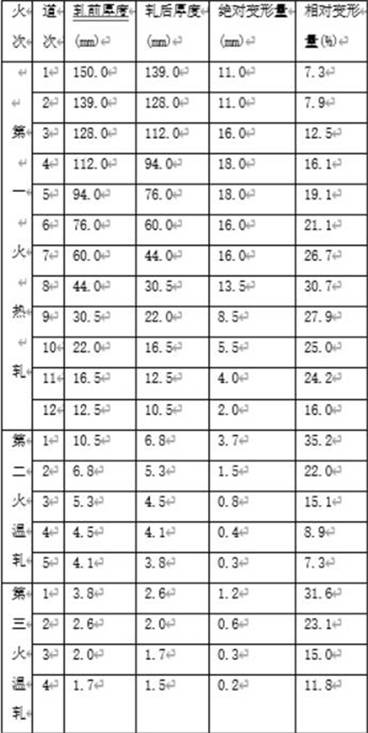

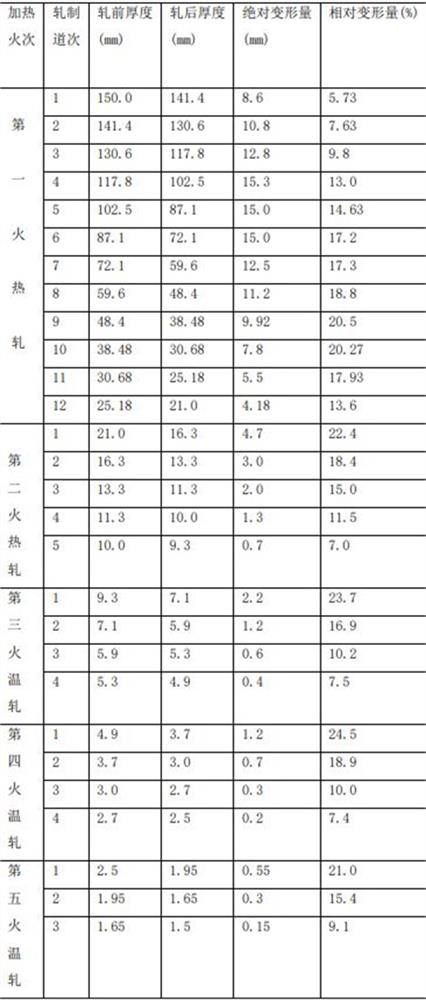

Image

Examples

Embodiment Construction

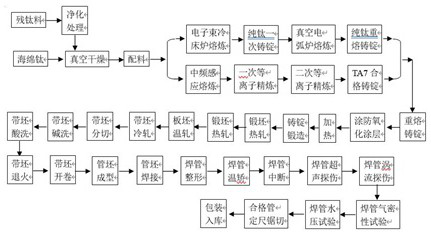

[0038] The present invention adopts electron beam cold bed furnace to carry out industrial pure titanium (TA1, TA1ELI, TA1-1, TA2, TA2ELI, TA3, TA3ELI), TA4, TA4ELI, TA5, TA6, TA7, TA7ELI, TA8, TA8-1, TA9, TA9-1 and TA10 are smelted once, and the industrial pure titanium is smelted for the second time by adopting the vacuum auto-arc melting process to obtain industrial pure titanium ingots. Vacuum induction melting-plasma cooling hearth furnace refining process was used to melt and cast TA7 alloy to obtain TA7 high-quality ingot. Before rolling, the industrial pure titanium (TA0, TA1, TA2, TA3) and TA7 alloy ingots are forged and billeted, and the two-stage ingot heating process of slow heating at low temperature and rapid heating at high temperature is adopted, which can reduce the cost of casting The temperature difference stress of the ingot can shorten the residence time of the ingot at high temperature and reduce the pollution of the gas to the ingot.

[0039] (TA1, TA1E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com