A coating production system and coating production method applied to ultra-fine coaxial cables

A production system and coaxial line technology, applied in the direction of using tools for cleaning methods, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of corroding equipment, reducing the utilization rate of tin, and a large amount of tin slag, so as to avoid corrosion. , the effect of improving utilization and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

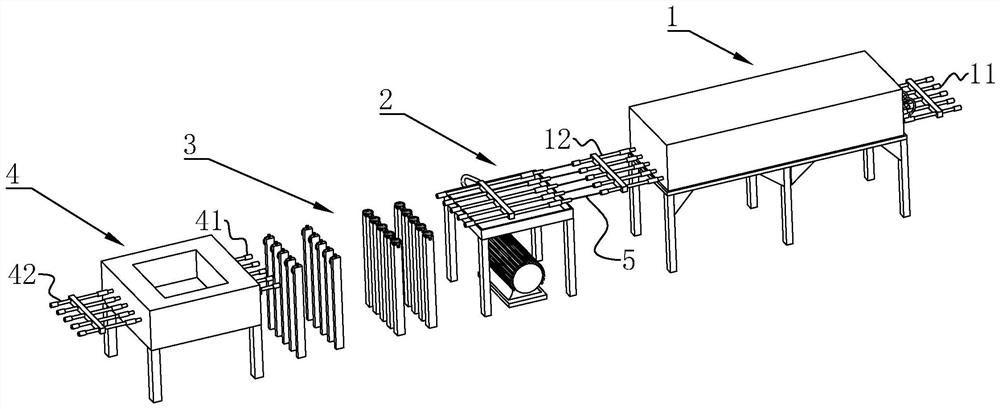

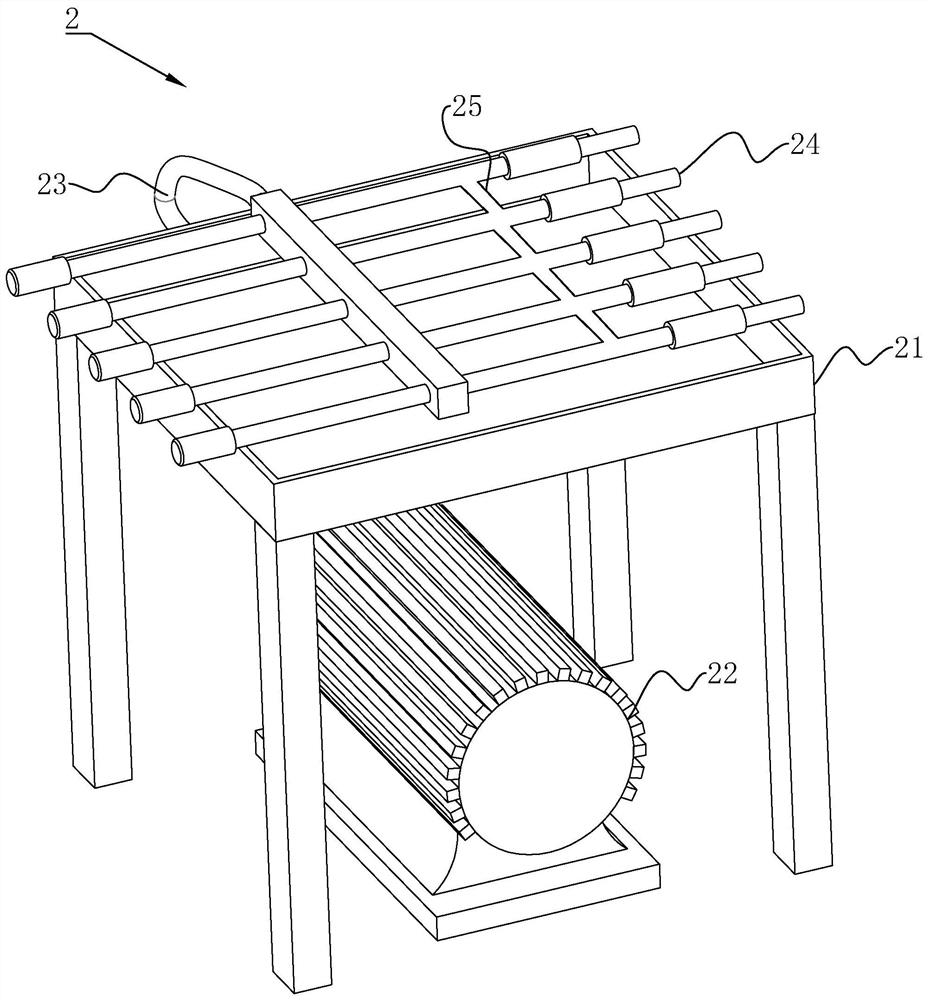

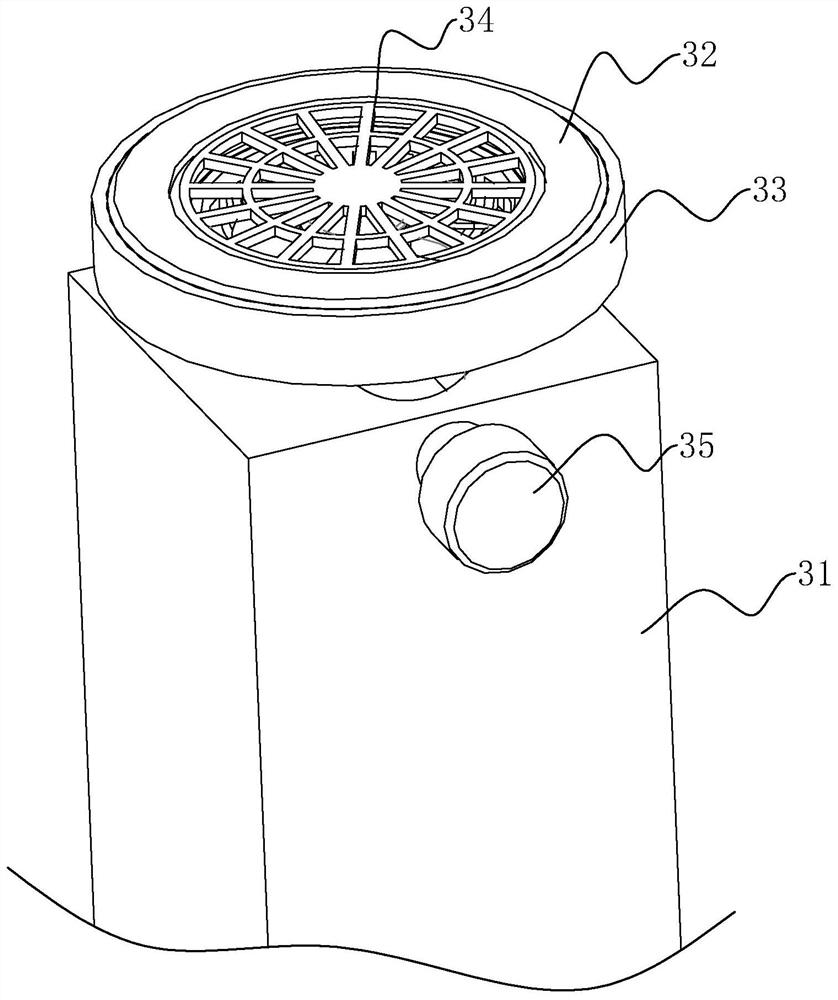

[0046] Such as figure 1 As shown, a coating production system applied to ultra-fine coaxial wires, along the direction of traction and transmission of ultra-thin coaxial wires 5, includes pay-off racks, annealing boxes 1, water vapor cooling devices 2, and surface cleaning devices placed in sequence 3. The tin plating pool 4 and the take-up frame (the pay-off frame and the take-up frame are not shown in the figure). The ultra-thin coaxial line 5 is placed on the pay-off rack, and its end is drawn to the annealing box 1. An inlet pipe 11 and an outlet pipe 12 are respectively arranged on the front and rear sides of the annealing box 1. The above-mentioned ultra-thin coaxial line 5 is The lead-in pipe 11 penetrates into the annealing box 1, and passes through the lead-out pipe 12, and draws the ultra-thin coaxial line 5 passed through the lead-out pipe 12 to the water vapor cooling device 2, passes through the water vapor The treated ultra-fine coaxial line 5 is then drawn into...

Embodiment 2

[0054] A coating production method applied to ultra-fine coaxial cables, including the coating production system in Embodiment 1, specifically further comprising the following steps:

[0055] Step a: place the ultra-thin coaxial cable 5 on the pay-off frame, and pull its end to the annealing box 1;

[0056] Step b: An inlet pipe 11 and an outlet pipe 12 are respectively arranged on the front and back sides of the annealing box 1, and the above-mentioned ultra-thin coaxial line 5 penetrates from the introduction pipe 11 into the annealing box 1, and passes through the outlet pipe 12 out;

[0057] Step c: Draw the ultra-thin coaxial line 5 pierced from the outlet pipe 12 into a steam pipe 24, the steam pipe 24 is connected with the steam engine 22, and the steam generated by the water steam engine 22 passes through the steam pipe continuously 24 is sprayed to the surface of the ultra-fine coaxial line 5, and the water vapor produced by the water steam engine 22 is continuously ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com