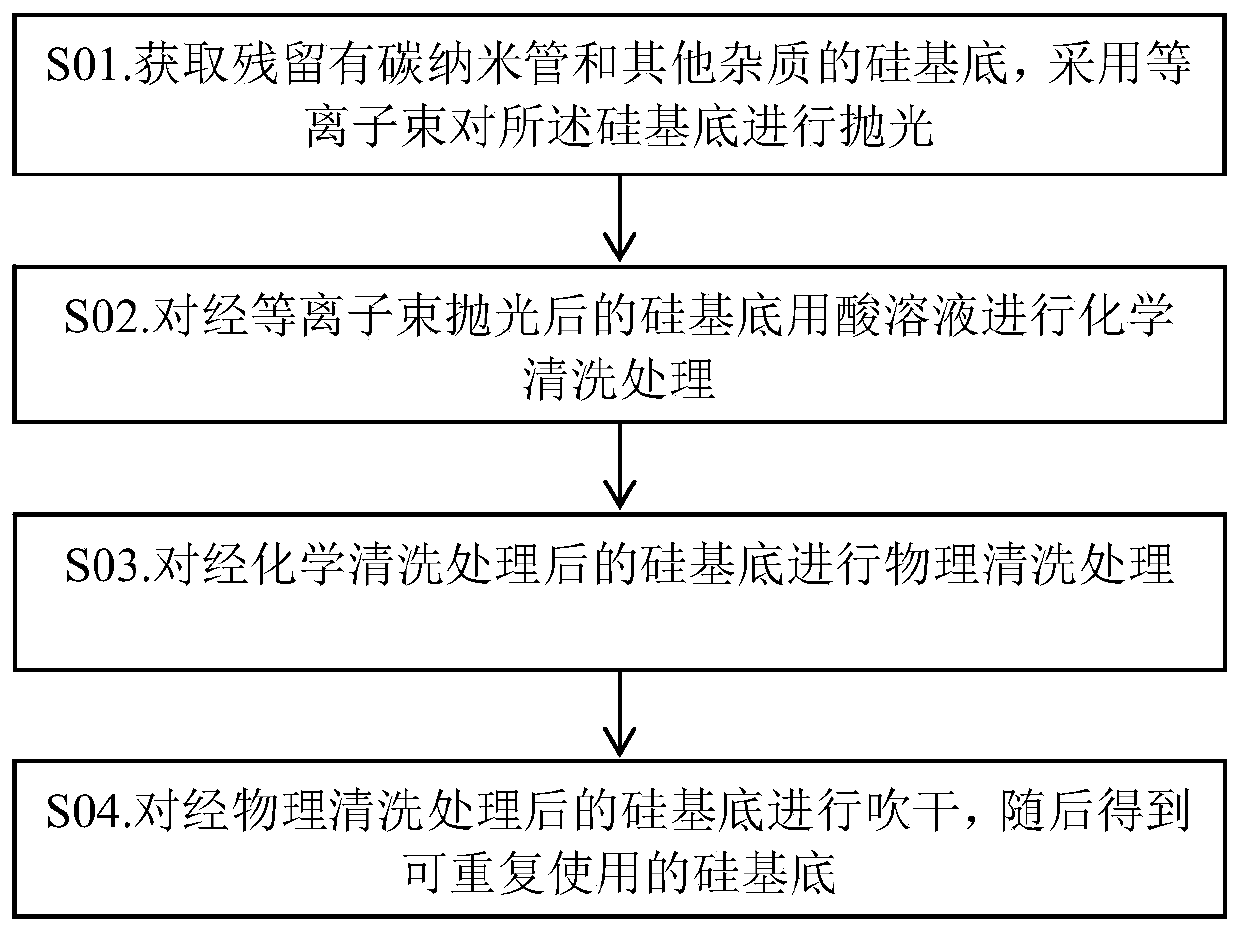

Silicon substrate cleaning method

A silicon substrate, physical cleaning technology, used in electrical components, carbon nanotubes, semiconductor/solid-state device manufacturing, etc., can solve the problems of poor cleaning effect of carbon nanotube root residues, easy to corrode oxide layers, etc., and achieve large-scale promotion. Value, uniform array height, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

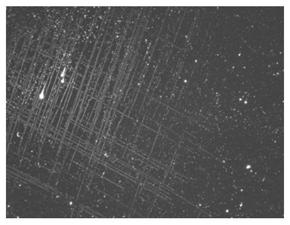

[0063] 200 8-inch silicon substrates with residual carbon nanotubes and other impurities were obtained, and the silicon substrates were polished with a plasma beam. Specifically, the silicon substrate is horizontally placed on the conveyor belt of the plasma cleaning machine, so that the side on which the carbon nanotubes grow is in contact with the conveyor belt, so that the conveyor belt is polished by the ion beam ejected from the plasma emission head along with the conveyor belt, The ion beam loosens the carbon nanotubes and amorphous carbon attached to the surface of the silicon substrate. The speed of the conveyor belt of the plasma cleaning machine is 33 mm / s; the speed of the plasma axis is 500 mm / s. The plasma beam polished silicon substrate is chemically cleaned with an acid solution, the acid solution is an SPM acid solution, and the cleaning treatment is performed at a temperature of 110° C. for 15 minutes. Wherein, the SPM acid solution is a mixed solution of conc...

Embodiment 2

[0065]200 8-inch silicon substrates with residual carbon nanotubes and other impurities were obtained, and the silicon substrates were polished with a plasma beam. Specifically, the silicon substrate is horizontally placed on the conveyor belt of the plasma cleaning machine, so that the side on which the carbon nanotubes grow is in contact with the conveyor belt, so that the conveyor belt is polished by the ion beam ejected from the plasma emission head along with the conveyor belt, The ion beam loosens the carbon nanotubes and amorphous carbon attached to the surface of the silicon substrate. The speed of the conveyor belt of the plasma cleaning machine is 32 mm / s; the speed of the plasma axis is 498 mm / s. The plasma beam polished silicon substrate is chemically cleaned with an acid solution, the acid solution is an HPM acid solution, and the cleaning treatment is carried out at a temperature of 70° C. for 15 minutes. Wherein, the HPM acid solution is a mixed solution of deio...

Embodiment 3

[0067] 200 8-inch silicon substrates with residual carbon nanotubes and other impurities were obtained, and the silicon substrates were polished with a plasma beam. Specifically, the silicon substrate is horizontally placed on the conveyor belt of the plasma cleaning machine, so that the side on which the carbon nanotubes grow is in contact with the conveyor belt, so that the conveyor belt is polished by the ion beam ejected from the plasma emission head along with the conveyor belt, The ion beam loosens the carbon nanotubes and amorphous carbon attached to the surface of the silicon substrate. The speed of the conveyor belt of the plasma cleaning machine is 34 mm / s; the speed of the plasma axis is 504 mm / s. The plasma beam polished silicon substrate is chemically cleaned with an acid solution, the acid solution is a hydrochloric acid solution, and the cleaning treatment is carried out at a temperature of 70° C. for 15 minutes. Wherein, the hydrochloric acid solution is a hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com