Modified nano MCA composite flame retardant, preparation method thereof and application of modified nano MCA composite flame retardant in preparation of halogen-free flame-retardant nylon composition for spinning

A technology for compounding flame retardants and modifiers, applied in the manufacture of fire-retardant and flame-retardant filaments, single-component polyamide rayon, etc., can solve the problems of nylon spinning performance, wide particle size distribution, etc. Improved spinnability, excellent spinning performance and good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

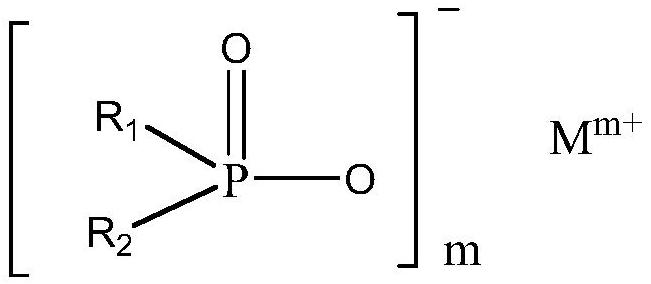

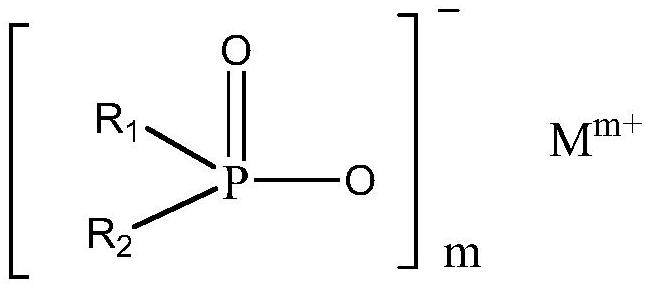

[0046] Add 100g of melamine, 100g of cyanuric acid, 400g of water and 1g of aluminum diethylphosphinate into the reaction device, keep stirring, raise the reaction temperature to 95°C, and react for 2 hours. After the reaction, cool to room temperature, and then centrifuge, filter, dry, and pulverize the product to obtain the modified nano-MCA composite flame retardant.

[0047] After testing, the particle size of the modified nano-MCA composite flame retardant obtained in this example is 40-50 nm.

[0048] With 850g nylon 6, 150g modified nano-MCA composite flame retardant prepared by this implementation, 2g antioxidant 1010 and 168 (mass ratio is 1:1) and 3g lubricant PETS, after blending, prepare through melt extrusion granulation The halogen-free flame-retardant nylon composite material for spinning is obtained; the melt extrusion temperature is 230-240°C.

Embodiment 2

[0057] Add 100g of melamine, 110g of cyanuric acid, 1050g of water and 0.22g of aluminum methylethylphosphinate into the reaction device, stir continuously, raise the reaction temperature to 100°C, and react for 5 hours. After the reaction, cool to room temperature, and then centrifuge, filter, dry, and pulverize the product to obtain the modified nano-MCA composite flame retardant.

[0058] After testing, the particle size of the modified nano-MCA composite flame retardant obtained in this example is 50-60 nm.

[0059] With 900g nylon 6, 100g modified nano-MCA composite flame retardant prepared in this implementation, 1g antioxidant 1010 and 1g lubricant EBS, after blending, prepare the halogen-free flame-retardant nylon composite material through melt extrusion granulation; melt The extrusion temperature is 230-240°C.

Embodiment 3

[0061] Add 100g of melamine, 90g of cyanuric acid, 500g of water and 1.9g of aluminum diisobutylphosphinate into the reaction device, stir continuously, raise the reaction temperature to 90°C, and react for 3 hours. After the reaction, cool to room temperature, and then centrifuge, filter, dry, and pulverize the product to obtain the modified nano-MCA composite flame retardant.

[0062] After testing, the particle size of the modified nano-MCA composite flame retardant obtained in this example is 40-50 nm.

[0063] 950g nylon 6, 50g modified nano-MCA composite flame retardant prepared in this implementation, 2g antioxidant 168 and 2g lubricant EBS were blended to obtain the halogen-free flame-retardant nylon composite for spinning through melt extrusion granulation. Material; melt extrusion temperature is 230~240℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com