Elasticity enhanced polyester fabric and preparation method thereof

A fabric and polyester technology, applied in the field of stretch polyester fabric and its preparation, can solve the problems of extremely high performance requirements of raw materials, difficult to meet the needs of customers, low elasticity of fabrics, etc. Good electrostatic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

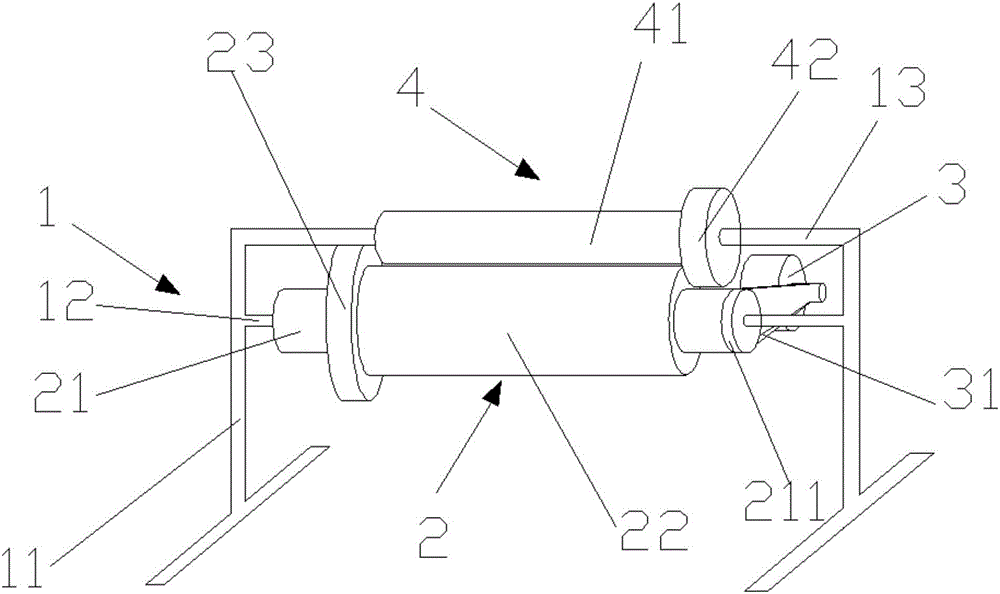

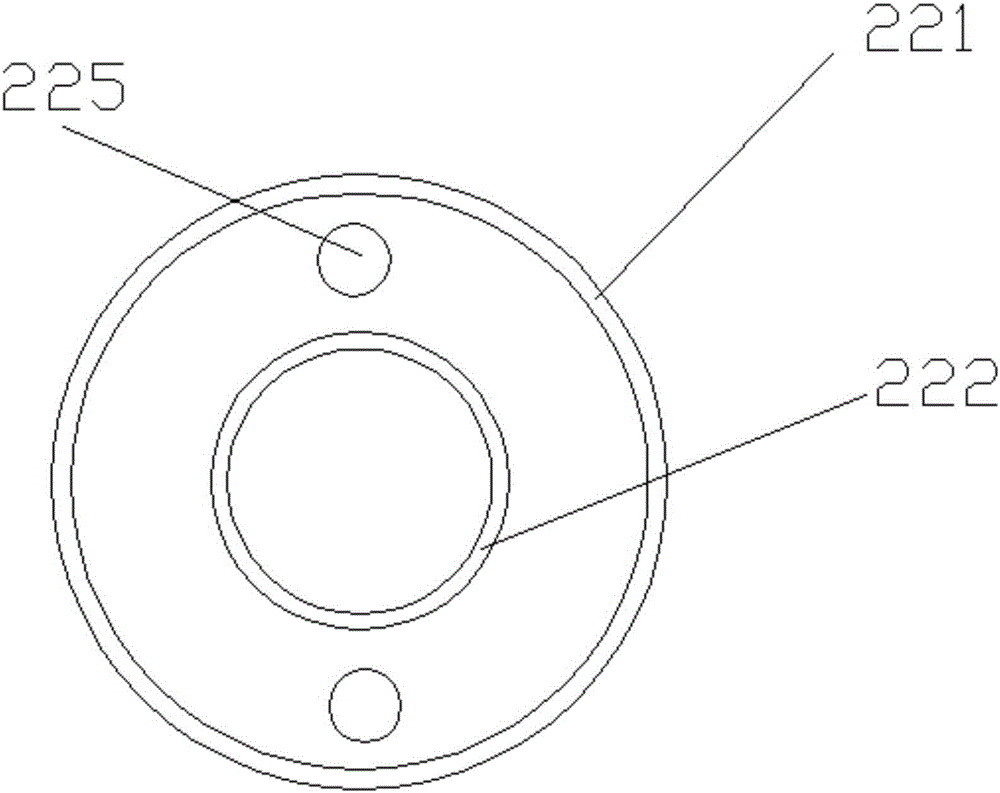

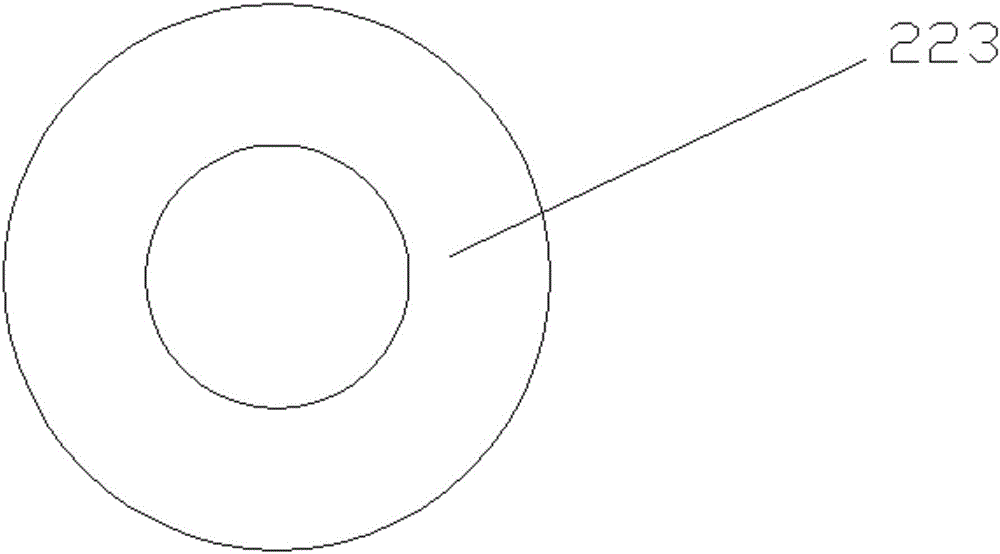

[0049] Such as Figure 1-6 Shown, a kind of preparation method of elastic polyester fabric is characterized in that: described environment-friendly novel fabric is prepared according to the following steps:

[0050] 1), raw materials

[0051] Select the natural color POY of 270Dtex / 384f as the warp and weft;

[0052] 2), spray oil

[0053] Use oil spray device to spray oil, each gram of cloth contains 0.05-0.1g of oil;

[0054] The oil agent is composed of the following components in parts by weight: 40-45 parts of hydrogenated paraffinic base oil, 10-12 parts of hydrogenated naphthenic oil, 2-3 parts of composite antistatic agent, 3-5 parts of sizing agent 1-2 parts of phenolic antioxidant, 1-3 parts of softener, 3-5 parts of nano-silicone oil, some nitrogen;

[0055] The manufacturing process of described oil agent is:

[0056] a. First, add hydrogenated paraffinic base oil and hydrogenated naphthenic oil into the reaction kettle, heat to 120-130°C, add nano-silicone oi...

Embodiment 1

[0087] The oil agent is composed of the following components in parts by weight: 40 parts of hydrogenated paraffinic base oil, 10 parts of hydrogenated naphthenic oil, 2 parts of composite antistatic agent, 3 parts of sizing agent, 1 part of phenolic antioxidant 1 part of softener, 3 parts of nano-silicone oil, some nitrogen;

[0088] The manufacturing process of described oil agent is:

[0089] a. First, add hydrogenated paraffinic base oil and hydrogenated naphthenic oil into the reaction kettle, heat to 120-130°C, add nano-silicone oil, and stir for 30-40 minutes;

[0090] b. Cool to 35°C, put in compound antistatic agent and sizing agent, and heat in two temperature zones. The temperature in the first temperature zone is heated from 35°C to 45°C and maintained for at least 30 minutes. The second temperature The temperature of the zone is heated from 45°C to 60°C, and the time is controlled at 20-25min;

[0091] c. Fill the reaction kettle with nitrogen protection, then a...

Embodiment 2

[0093] The oil agent is composed of the following components in parts by weight: 42 parts of hydrogenated paraffinic base oil, 11 parts of hydrogenated naphthenic oil, 2 parts of composite antistatic agent, 4 parts of sizing agent, 1.5 parts of phenolic antioxidant part, 2 parts of softener, 4 parts of nano-silicone oil, some nitrogen;

[0094] The manufacturing process of described oil agent is:

[0095] a. First, add hydrogenated paraffinic base oil and hydrogenated naphthenic oil into the reaction kettle, heat to 120-130°C, add nano-silicone oil, and stir for 30-40 minutes;

[0096] b. Cool to 35°C, put in compound antistatic agent and sizing agent, and heat in two temperature zones. The temperature in the first temperature zone is heated from 35°C to 45°C and maintained for at least 30 minutes. The second temperature The temperature of the zone is heated from 45°C to 60°C, and the time is controlled at 20-25min;

[0097] c. Fill the reaction kettle with nitrogen protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com