Preparation method of titanium and titanium alloy large-specification seamless pipe

A technology for seamless pipes and titanium alloys, which is used in the preparation of large-sized seamless pipes of titanium and titanium alloys, and in the field of titanium and titanium processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

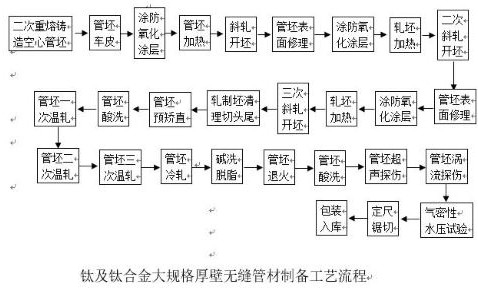

Image

Examples

Embodiment Construction

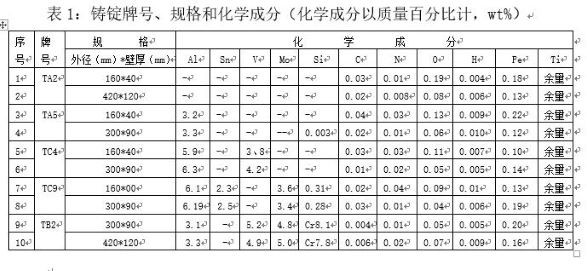

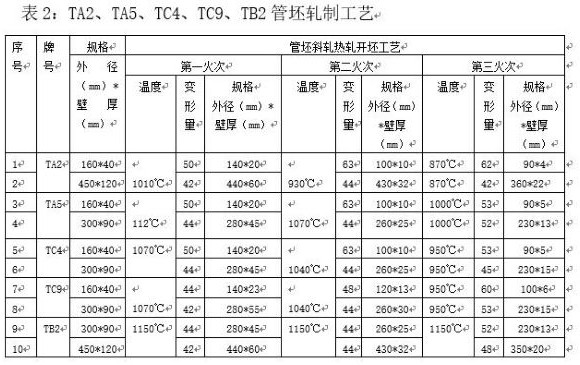

[0047] TA1, TA1ELI, TA1-1, TA2, TA2ELI, TA3, TA3ELI, TA4, TA4ELI, TA5, TA6, TA7, TA7ELI, TA8, TA8 are carried out by vacuum induction melting or vacuum electron beam furnace melting technology or plasma furnace melting technology -1. Primary melting of TA9, TA9-1, TA10, TC1, TC2, TC3, TC4, TC4ELI, TC6, TC7, TC8, TC9, TC10, TC11, TB2, etc., using vacuum electron beam furnace or plasma furnace melting technology Secondary smelting of primary ingots. A hollow ingot crystallizer and an electromagnetic casting device are used to form an ingot for the secondary smelted alloy liquid to obtain a cast hollow tube billet of titanium and titanium alloy. Electromagnetic stirring is performed on the titanium and titanium alloy liquid in the cavity of the crystallizer through the gap opened in the crystallizer to break the dendrites of the ingot, refine the grains of the ingot and improve the plasticity of the ingot. The cast billet has a uniform and fine structure and uniform chemical com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com